Heat Extraction Evaluation and Well Pattern Comparison of Abandoned OilWells Converted into Geothermal Wells

-

摘要:

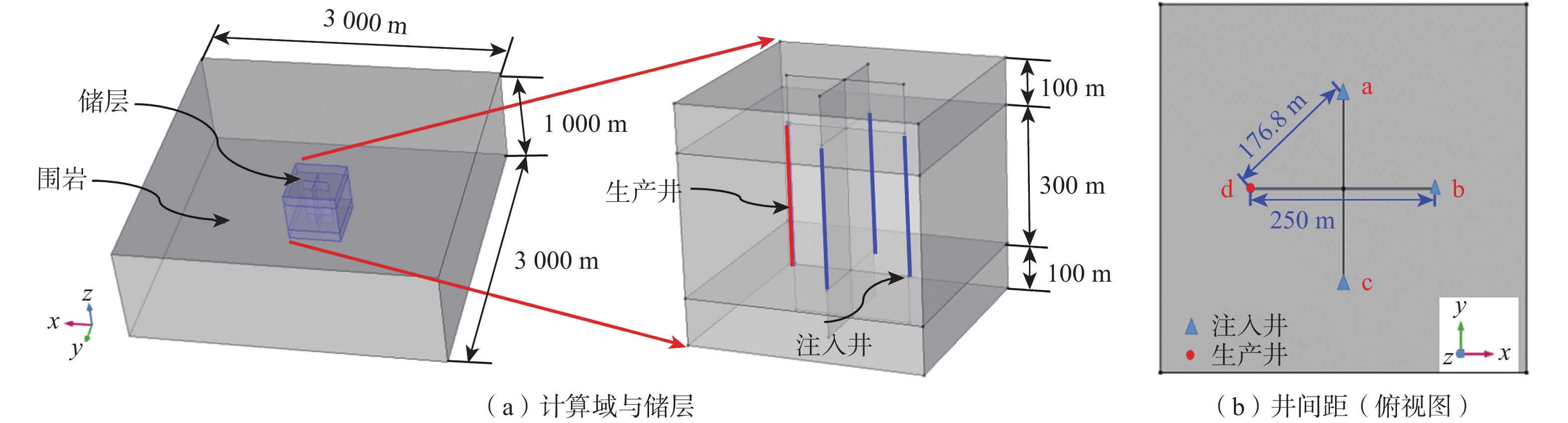

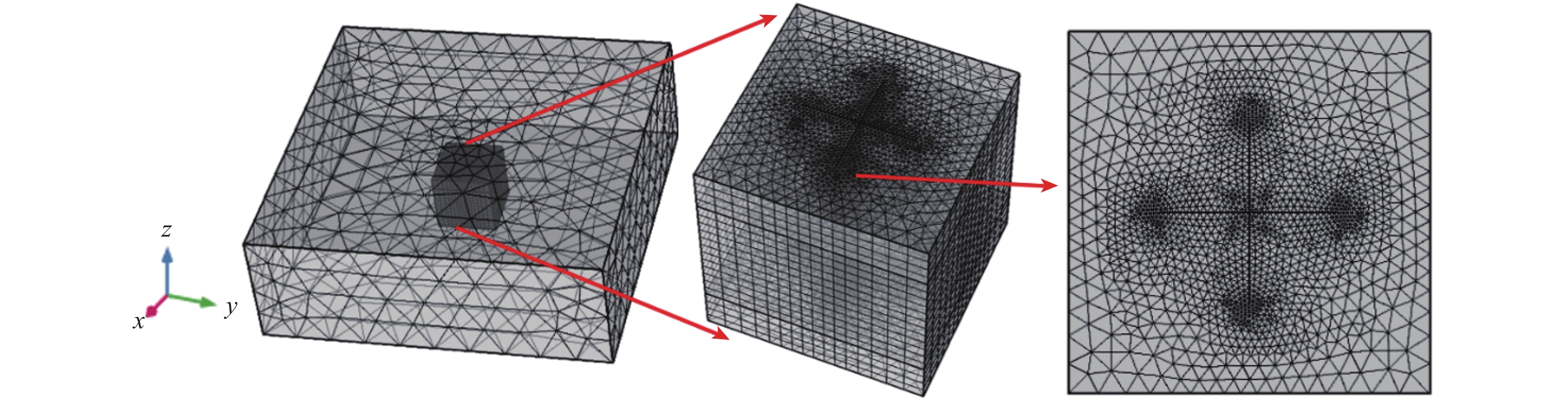

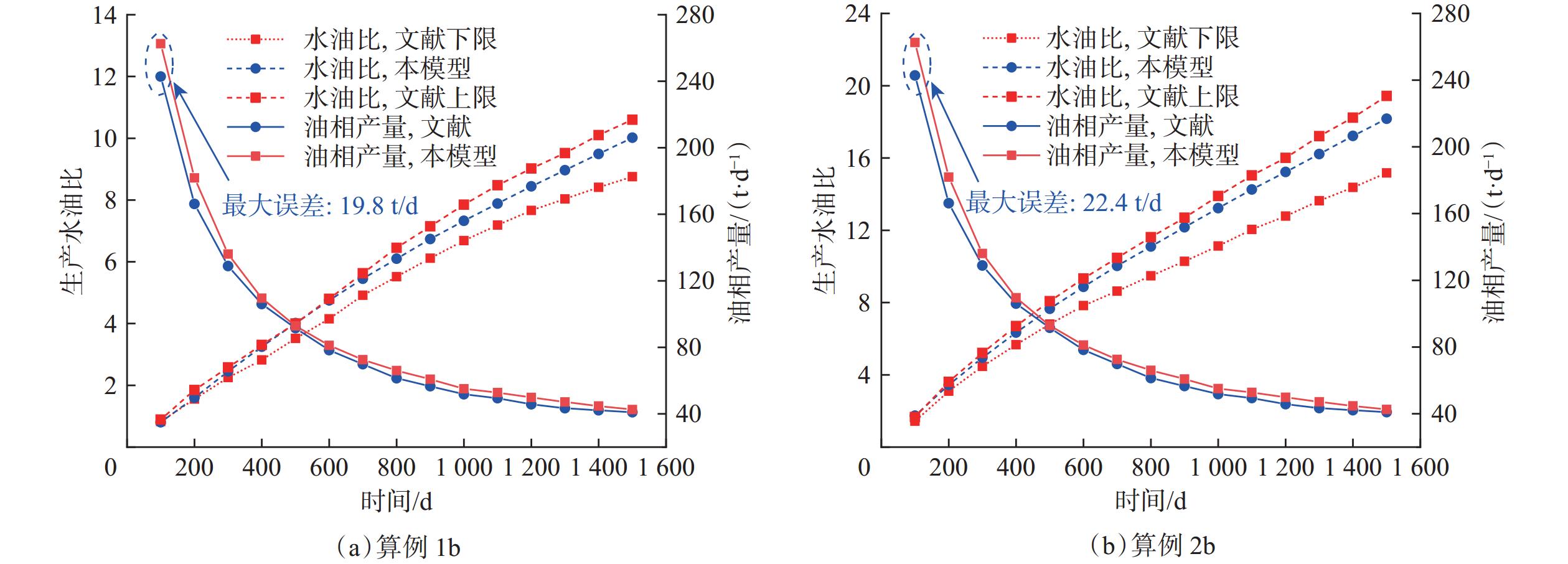

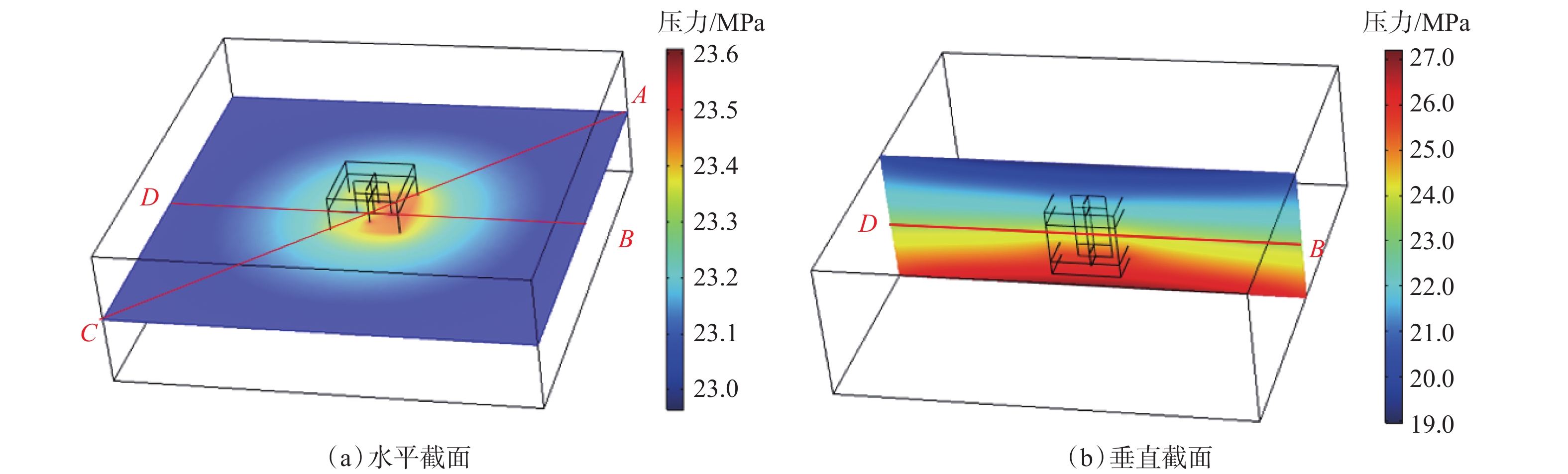

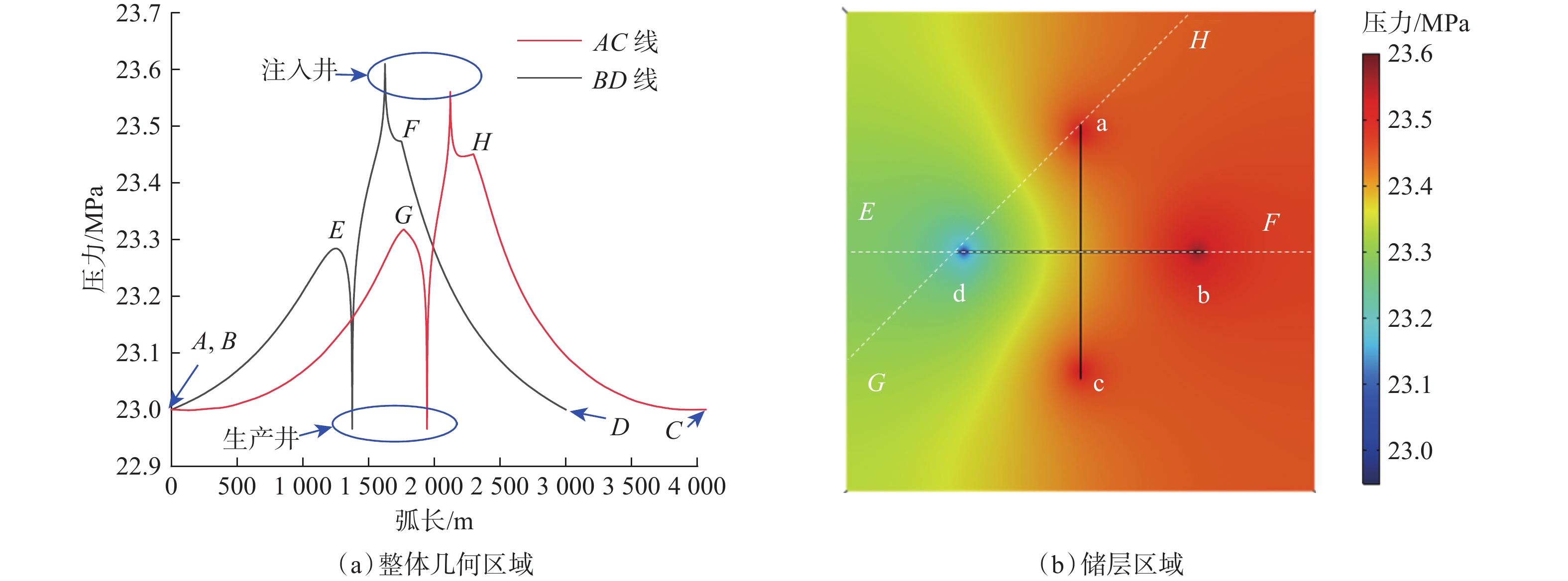

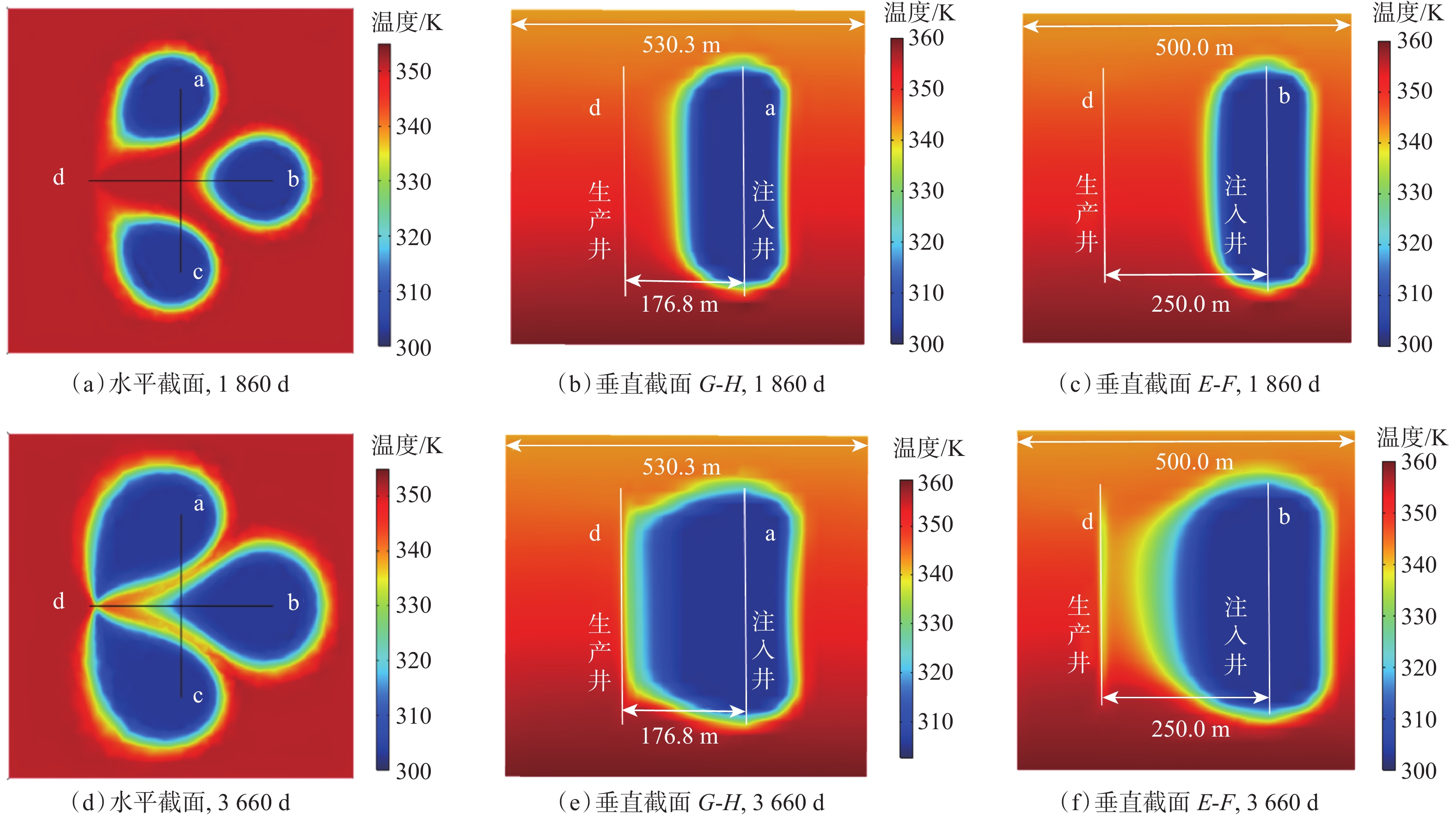

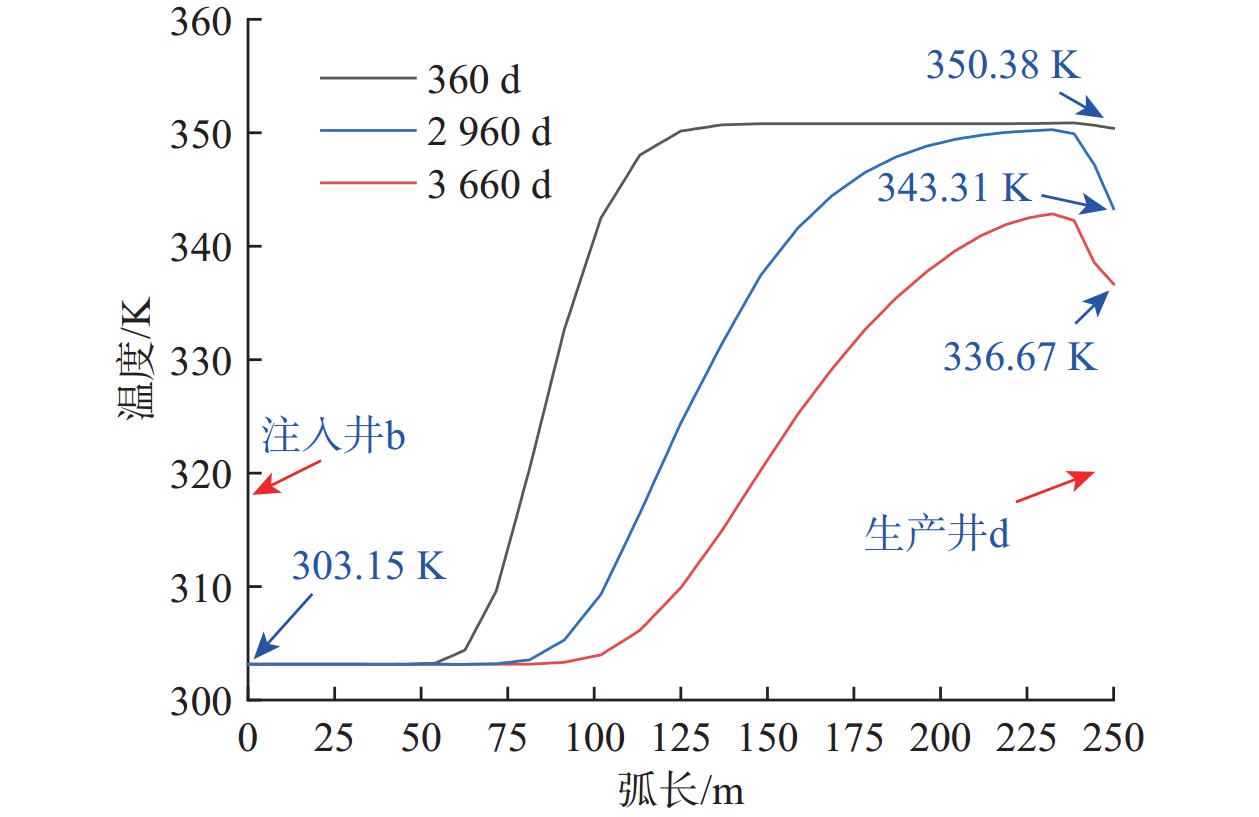

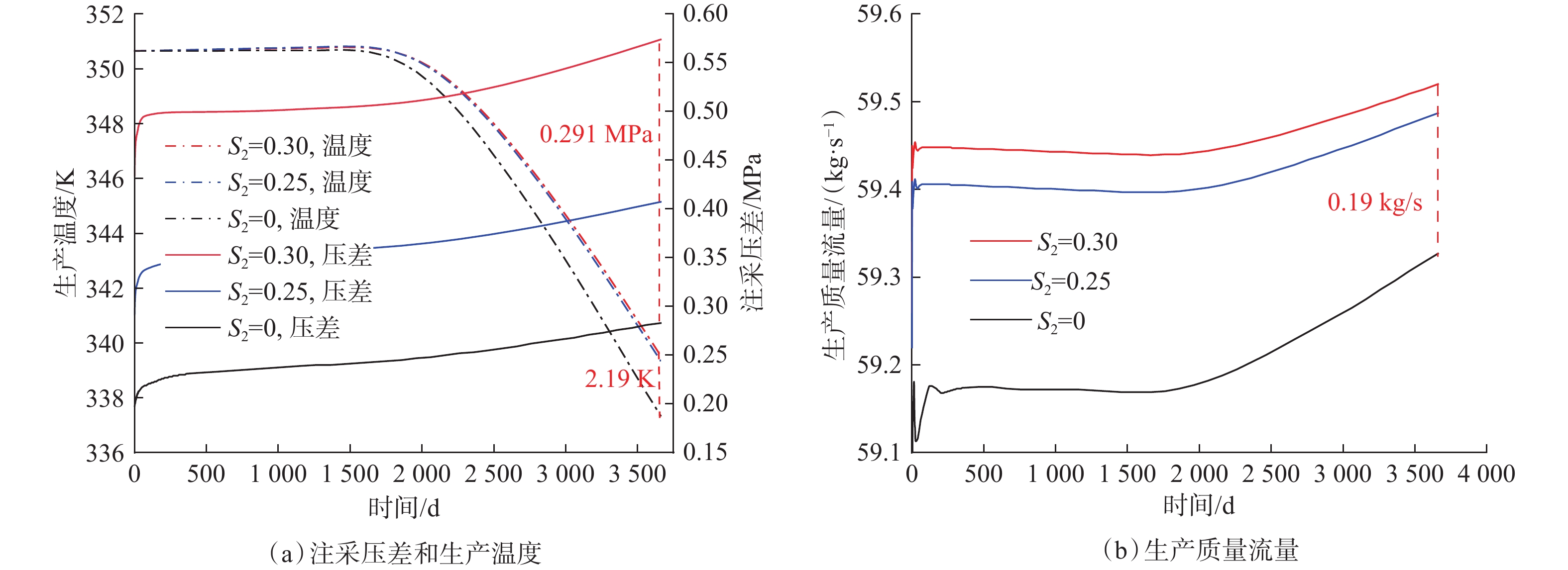

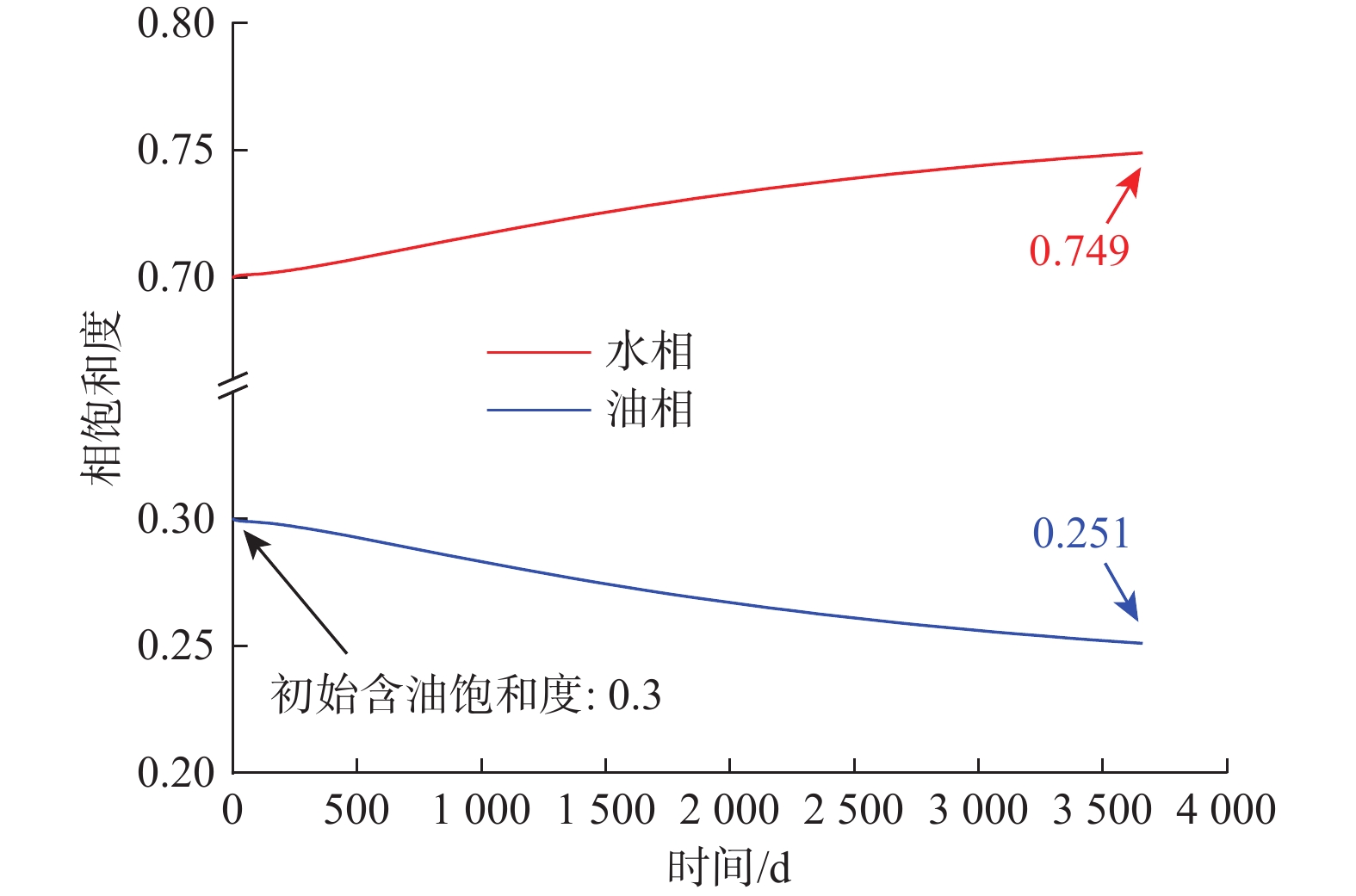

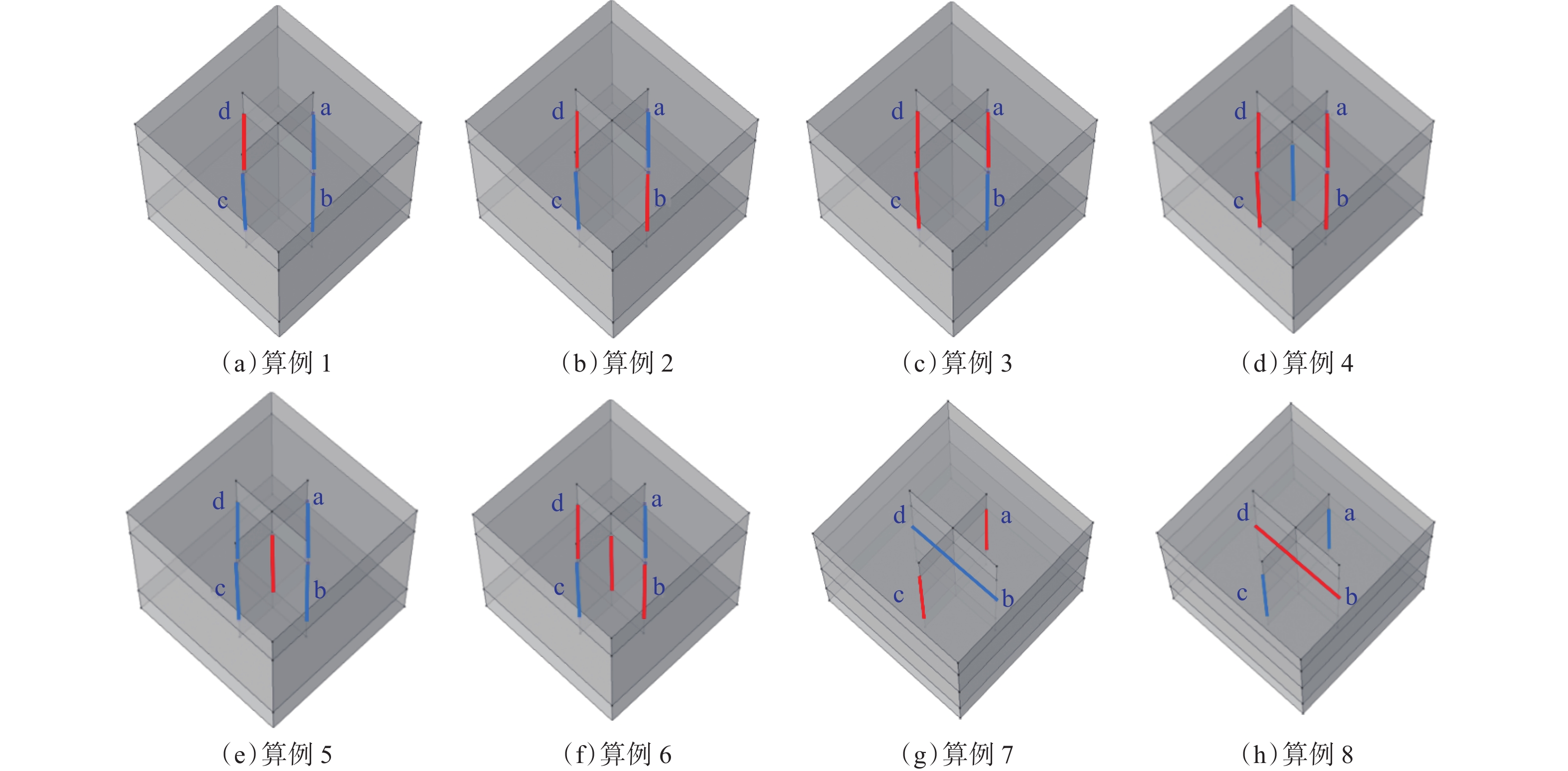

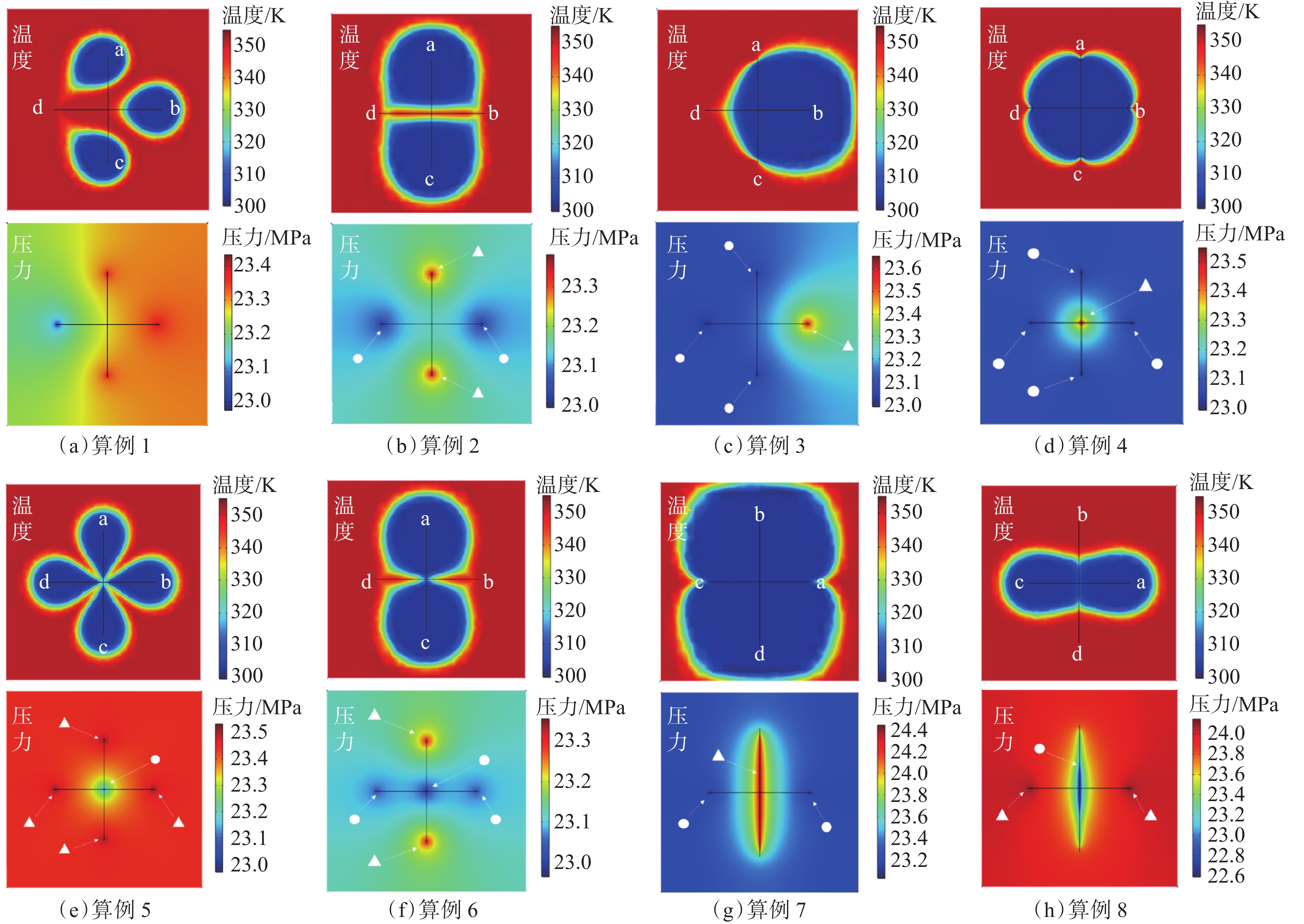

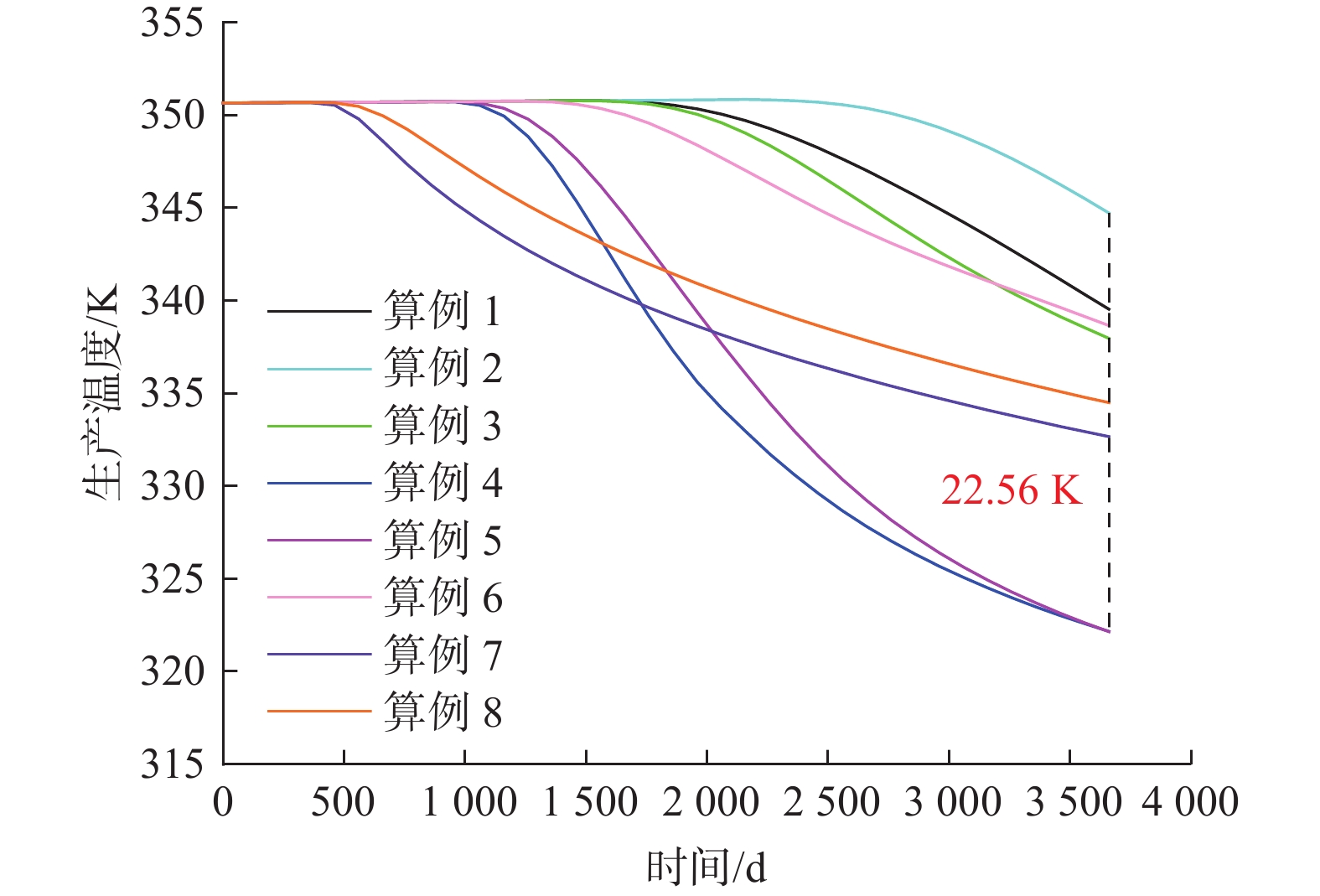

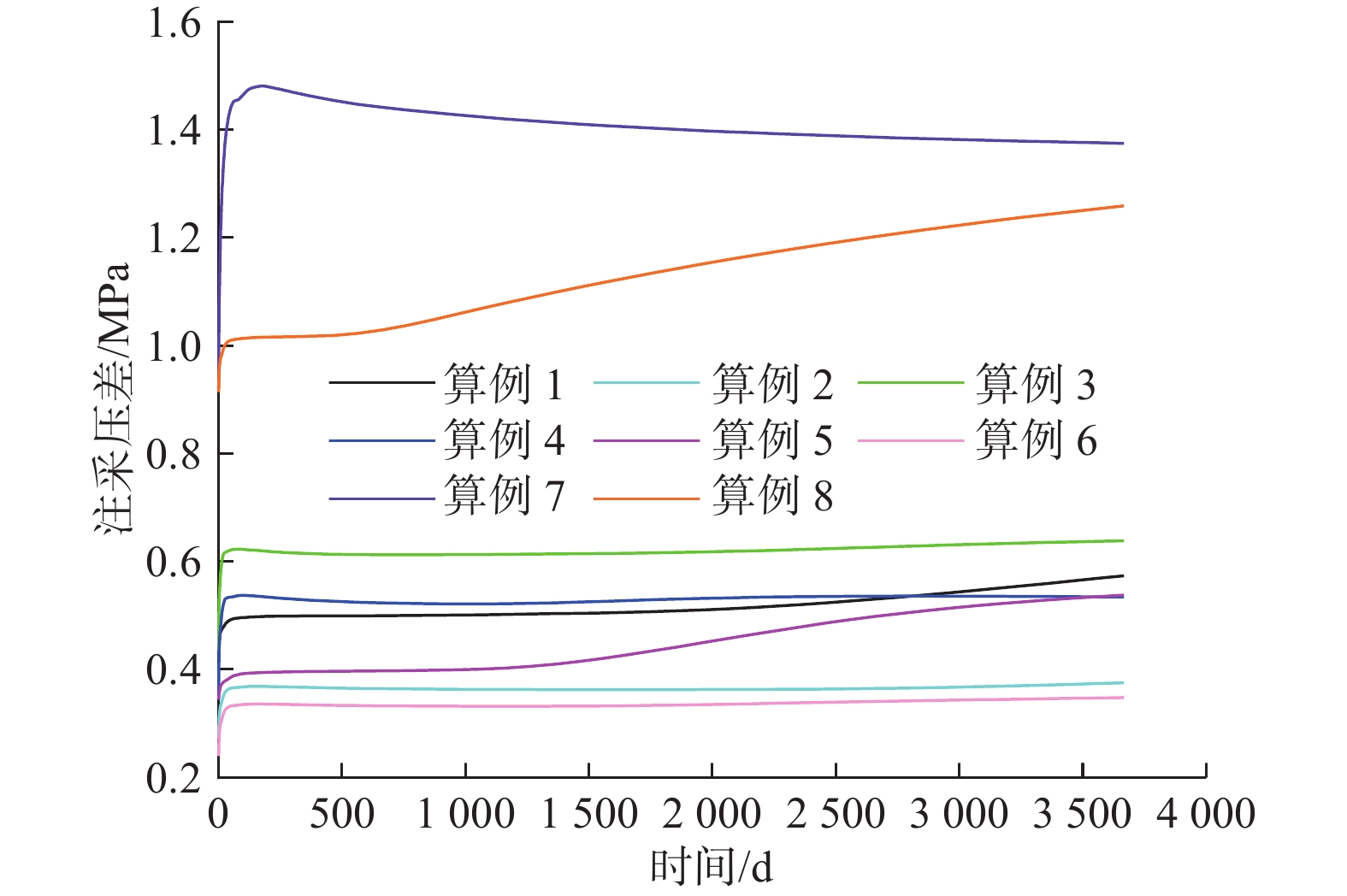

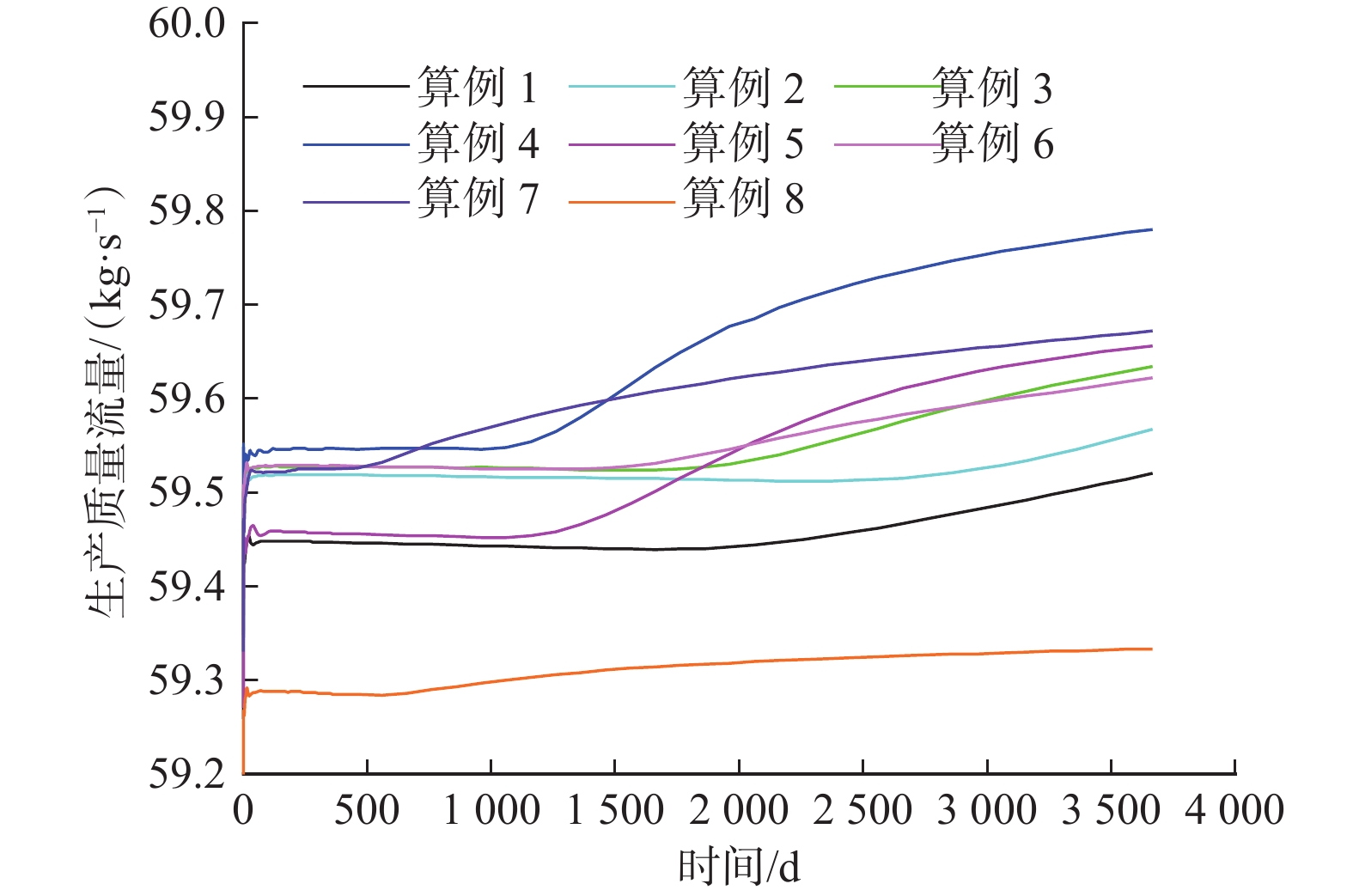

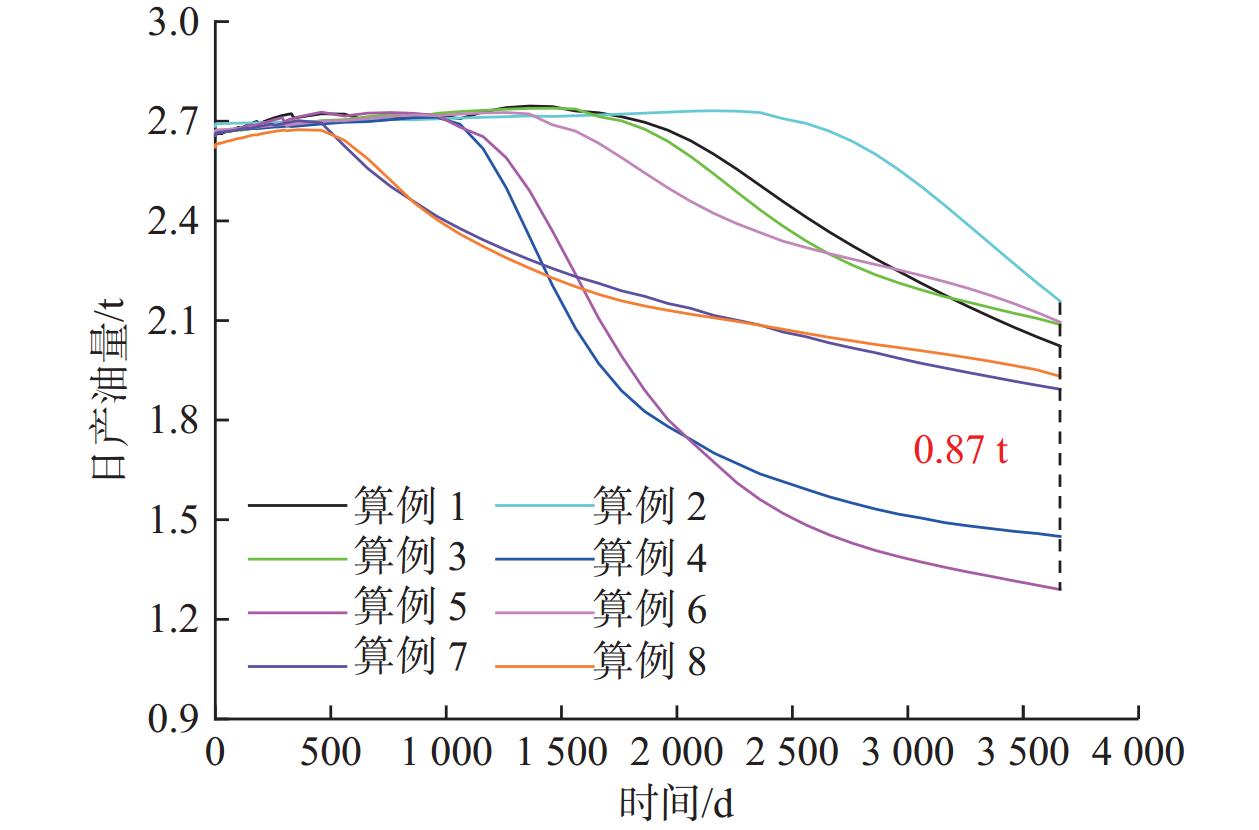

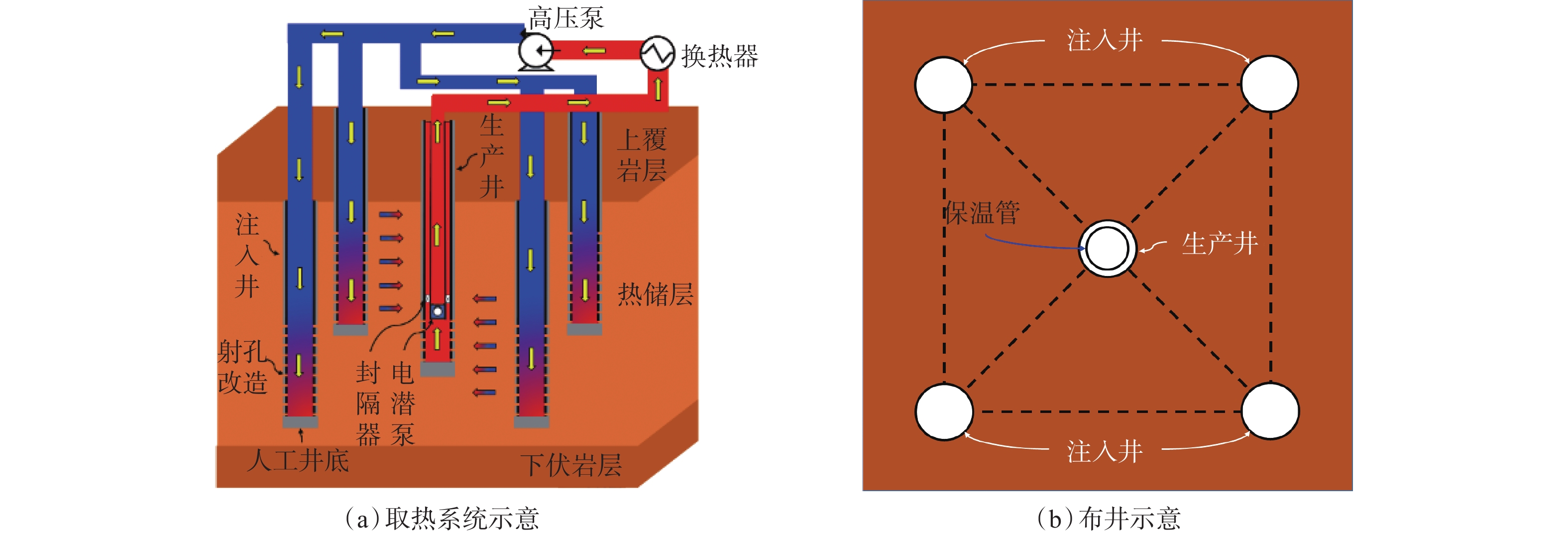

地热能开发具有很多优势,但建井成本占总成本一半以上,限制了其推广利用。部分油田废弃井蕴含丰富的地热资源,将废弃油井改造为地热井进行取热,可大幅降低成本,提升经济效益。达到含水经济极限的油藏也可用于热量提取,实现热−油联产。目前,大多数地热井网取热研究为定井型或/和不考虑油水两相流动。然而,不同井型下油水流动和传热特性对油田地热开发方案的设计与调整具有重要影响。为此,建立了考虑油水两相流的热流耦合模型,对比了各种井型下的生产特性,如生产温度、注采压差、产液量和产油量。研究表明:不同井型的生产温度和压差的最大差值分别可达22.56 K和1.03 MPa,注入井和生产井交叉对称分布时,取热系统具有最高的生产温度和产油量,同时具有较低的注采压差。研究揭示了不同井型在热提取过程中温压场的演变特征,可为设计和调整井型提供依据,为油田热−油联产评价提供一定指导。

Abstract:Geothermal energy development has many advantages, but well construction accounts for half of the total costs, which restricts the promotion and utilization of geothermal energy. Some abandoned oil wells have abundant geothermal resources and converting them into geothermal wells for heat extraction can significantly reduce costs and improve economic efficiency. Moreover, the reservoirs that reach the economic limit of water cut can also be used for heat extraction to achieve co-production of heat and oil. Currently, most research on heat extraction from geothermal well patterns focuses on fixed well patterns or/and does not consider oil-water two-phase flows. However, the oil-water flow and heat transfer characteristics of different well patterns are of great significance for the design and adjustment of geothermal development schemes of oilfields. Therefore, a heat-flow coupling model considering oil-water two-phase flows was established. The production characteristics of diverse well patterns were compared, such as production temperature, pressure difference between injection and production, liquid production, and oil production. Research shows that the maximum difference of the production temperatures and pressure differences between diverse well patterns can reach 22.56 K and 1.03 MPa, respectively. When the injection wells and production wells are cross-symmetrically distributed, the heat extraction system has the highest production temperature and oil production, as well as a lower pressure difference between injection and production. The research reveals the evolution characteristics of temperature and pressure fields during heat extraction from different well patterns, providing a basis for designing and adjusting the well patterns and some guidance for the evaluation of the co-production of heat and oil in oilfields.

-

-

表 1 储层和盖层物性参数

Table 1 Physical properties of reservoir and cap rocks

类型 密度/

(kg·m−3)比热容/

(J·(kg·K)−1)热导率/

(W·(m·K)−1)水平渗透率/

mD孔隙度,

%储层 2 700 800 2.0 500.0 30.0 围岩 2 800 850 2.2 0.1 5.0 -

[1] 谢文苹,路睿,张盛生,等. 青海共和盆地干热岩勘查进展及开发技术探讨[J]. 石油钻探技术,2020,48(3):77–84. doi: 10.11911/syztjs.2020042 XIE Wenping, LU Rui, ZHANG Shengsheng, et al. Progress in hot dry rock exploration and a discussion on development technology in the Gonghe Basin of Qinghai[J]. Petroleum Drilling Techniques, 2020, 48(3): 77–84. doi: 10.11911/syztjs.2020042

[2] BP. Statistical review of world energy 2020[R]. London: BP, 2020.

[3] BU Xianbiao, MA Weibin, LI Huashan. Geothermal energy production utilizing abandoned oil and gas wells[J]. Renewable Energy, 2012, 41: 80–85. doi: 10.1016/j.renene.2011.10.009

[4] 姜光政,高堋,饶松,等. 中国大陆地区大地热流数据汇编(第四版)[J]. 地球物理学报,2016,59(8):2892–2910. doi: 10.6038/cjg20160815 JIANG Guangzheng, GAO Peng, RAO Song, et al. Compilation of heat flow data in the continental area of China (4th ed)[J]. Chinese Journal of Geophysics, 2016, 59(8): 2892–2910. doi: 10.6038/cjg20160815

[5] LI Kewen, BIAN Huiyuan, LIU Changwei, et al. Comparison of geothermal with solar and wind power generation systems[J]. Renewable and Sustainable Energy Reviews, 2015, 42: 1464–1474. doi: 10.1016/j.rser.2014.10.049

[6] KUJAWA T, NOWAK W, STACHEL A A. Analysis of the exploitation of existing deep production wells for acquiring geothermal energy[J]. Journal of Engineering Physics and Thermophysics, 2005, 78(1): 127–135. doi: 10.1007/s10891-005-0038-1

[7] CAULK R A, TOMAC I. Reuse of abandoned oil and gas wells for geothermal energy production[J]. Renewable Energy, 2017, 112: 388–397. doi: 10.1016/j.renene.2017.05.042

[8] 宋先知,张逸群,李根生,等. 雄安新区地热井同轴套管闭式循环取热技术研究[J]. 天津大学学报(自然科学与工程技术版),2021,54(9):971–981. SONG Xianzhi, ZHANG Yiqun, LI Gensheng, et al. Performance study of the downhole coaxial closed-loop heat exchange technology in Xiong'an New Area[J]. Journal of Tianjin University(Science and Technology), 2021, 54(9): 971–981.

[9] 于超,张逸群,宋先知,等. 井下同轴闭式地热系统循环工质综合评价优选[J]. 石油钻探技术,2021,49(5):101–107. doi: 10.11911/syztjs.2021066 YU Chao, ZHANG Yiqun, SONG Xianzhi, et al. Comprehensive evaluation and optimization of circulating working fluids in the coaxial borehole heat exchanger closed-loop geothermal system[J]. Petroleum Drilling Techniques, 2021, 49(5): 101–107. doi: 10.11911/syztjs.2021066

[10] 宋先知,许富强,宋国锋. 废弃井地热能开发技术现状与发展建议[J]. 石油钻探技术,2020,48(6):1–7. doi: 10.11911/syztjs.2020120 SONG Xianzhi, XU Fuqiang, SONG Guofeng. Technical status and development suggestions in exploiting geothermal energy from abandoned wells[J]. Petroleum Drilling Techniques, 2020, 48(6): 1–7. doi: 10.11911/syztjs.2020120

[11] GONG Bin, LIANG Hongbin, XIN Shouliang, et al. Numerical studies on power generation from co-produced geothermal resources in oil fields and change in reservoir temperature[J]. Renewable Energy, 2013, 50: 722–731. doi: 10.1016/j.renene.2012.07.026

[12] WESTPHAL D, WEIJERMARS R. Economic appraisal and scoping of geothermal energy extraction projects using depleted hydrocarbon wells[J]. Energy Strategy Reviews, 2018, 22: 348–364. doi: 10.1016/j.esr.2018.10.008

[13] NGHIEM L, COLLINS D A, SHARMA R. Seventh SPE comparative solution project: modelling of horizontal wells in reservoir simulation[R]. SPE 21221, 1991.

[14] 朱广海,刘章聪,熊旭东,等. 电加热稠油热采井筒温度场数值计算方法[J]. 石油钻探技术,2019,47(5):110–115. doi: 10.11911/syztjs.2019109 ZHU Guanghai, LIU Zhangcong, XIONG Xudong, et al. Numerical calculation method of the wellbore temperature field for electric heating heavy oil thermal recovery[J]. Petroleum Drilling Techniques, 2019, 47(5): 110–115. doi: 10.11911/syztjs.2019109

[15] 蔡少斌,杨永飞,刘杰. 考虑热流固耦合作用的多孔介质孔隙尺度两相流动模拟[J]. 力学学报,2021,53(8):2225–2234. doi: 10.6052/0459-1879-21-294 CAI Shaobin, YANG Yongfei, LIU Jie. Pore-scale simulation of multiphase flow considering thermo-hydro-mechanical coupling effect in porous media[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(8): 2225–2234. doi: 10.6052/0459-1879-21-294

[16] HOLZBECHER E O. Modeling density-driven flow in porous media: Principles, numerics, software[M]. Berlin: Springer, 1998.

[17] HEMMATI-SARAPARDEH A, SHOKROLLAHI A, TATAR A, et al. Reservoir oil viscosity determination using a rigorous app-roach[J]. Fuel, 2014, 116: 39–48. doi: 10.1016/j.fuel.2013.07.072

[18] WANG Jing, LIU Jungang, LI Zhaoguo, et al. Synchronous injection-production energy replenishment for a horizontal well in an ultra-low permeability sandstone reservoir: a case study of Changqing Oilfield in Ordos Basin, NW China[J]. Petroleum Exploration and Development, 2020, 47(4): 827–835. doi: 10.1016/S1876-3804(20)60098-2

[19] XU Fuqiang, SONG Xianzhi, SONG Guofeng, et al. Numerical studies on heat extraction evaluation and multi-objective optimization of abandoned oil well patterns in intermittent operation mode[J]. Energy, 2023, 269: 126777. doi: 10.1016/j.energy.2023.126777

[20] GeoMark Research. RFD base (reservoir fluid database)[Z]. 2003.

[21] 宋先知,许富强,姬佳炎,等. 多层合采油藏废弃井网取热性能评价[J]. 天然气工业,2022,42(4):54–62. doi: 10.3787/j.issn.1000-0976.2022.04.005 SONG Xianzhi, XU Fuqiang, JI Jiayan, et al. Evaluation on the heat extraction performance of abandoned well pattern in multi-layer commingled production oil reservoirs[J]. Natural Gas Industry, 2022, 42(4): 54–62. doi: 10.3787/j.issn.1000-0976.2022.04.005

[22] BROOKS R H, COREY A T. Properties of porous media affecting fluid flow[J]. Journal of the Irrigation and Drainage Division, 1966, 92(2): 61–88. doi: 10.1061/JRCEA4.0000425

[23] 石宇. 多分支井循环二氧化碳开采地热机理与参数研究[D]. 北京:中国石油大学(北京),2020. SHI Yu. Study on mechanism and parameters of geothermal exploitation using multilateral wells with CO2 as working fluid[D]. Beijing: China University of Petroleum(Beijing), 2020.

[24] EPPELBAUM L, KUTASOV I, PILCHIN A. Thermal properties of rocks and density of fluids[M]//EPPELBAUM L, KUTASOV I, PILCHIN A. Applied geothermics. Berlin: Springer, 2014: 99-149.

[25] 宋子豪. 油田废弃井网循环取热规律与方案优化研究 [D]. 北京:中国石油大学(北京), 2023. SONG Zihao. Study on circulation heat extraction rule and scheme optimization of abandoned oilfield well pattern[D]. Beijing: China University of Petroleum (Beijing), 2023.

[26] XU Fuqiang, SONG Xianzhi, SONG Zihao, et al. Heat extraction and interlayer interference in heterogeneous multi-layer commingled production oil reservoir[R]. ARMA-2022-0504, 2022.

[27] ABDELGAWAD A, MALEKZADEH D. Determination of the drainage area of horizontal wells in the presence of vertical wells: effect of reservoir and well parameters[J]. Journal of Canadian Petroleum Technology, 2001, 40(10): 45–54.

-

期刊类型引用(14)

1. 陈雅辉,匡立新,龙志平,陈士奎,王恒. NC页岩气田东胜构造带浅表层防漏治漏工艺. 石油地质与工程. 2023(03): 102-105 .  百度学术

百度学术

2. 陆长青,高元,杨广国,彭金龙. 基于温敏形状记忆聚合物的堵漏水泥浆体系研究. 钻采工艺. 2023(03): 141-146 .  百度学术

百度学术

3. 曾义金. 中国石化深层超深层油气井固井技术新进展与发展建议. 石油钻探技术. 2023(04): 66-73 .  本站查看

本站查看

4. 吴天乾,宋文宇,谭凌方,张军义,杨春文,郭胜来. 超低密度水泥固井质量评价方法. 石油钻探技术. 2022(01): 65-70 .  本站查看

本站查看

5. 谢关宝. 轻质水泥浆固井质量测井评价标准构建. 石油钻探技术. 2022(01): 119-126 .  本站查看

本站查看

6. 袁光杰,付利,王元,郭凯杰,陈刚. 我国非常规油气经济有效开发钻井完井技术现状与发展建议. 石油钻探技术. 2022(01): 1-12 .  本站查看

本站查看

7. 匡立新,刘奎,丁士东,初永涛,周仕明,姜政华,肖京男. 机械充氮泡沫水泥浆固井技术在页岩气井的应用. 石油机械. 2022(07): 26-33 .  百度学术

百度学术

8. 王建云,张红卫,邹书强,李明军,王鹏. 顺北油气田低压易漏层泡沫水泥浆固井技术. 石油钻探技术. 2022(04): 25-30 .  本站查看

本站查看

9. 路飞飞,于洋,王伟志,李明军. 顺北油气田防漏固井用封隔式分级箍研制与应用. 石油钻探技术. 2022(04): 31-36 .  本站查看

本站查看

10. 陈晓华,狄伟. 针对裂缝性地层的低密度高强度韧性水泥浆体系研究. 钻井液与完井液. 2021(01): 109-115 .  百度学术

百度学术

11. 吴天乾,李明忠,李建新,李德红,张军义,何斌斌. 杭锦旗地区正注反挤固井技术研究. 钻采工艺. 2021(03): 104-107 .  百度学术

百度学术

12. 张辉. 超低密度水泥浆的复合减轻剂研究及应用. 重庆科技学院学报(自然科学版). 2020(03): 7-10+43 .  百度学术

百度学术

13. 陈铧. 封固气层的泡沫水泥浆固井技术研究. 中国石油和化工标准与质量. 2019(10): 213-214 .  百度学术

百度学术

14. 林四元,张杰,韩成,胡杰,田宗强,郑浩鹏. 东方气田浅部储层大位移水平井钻井关键技术. 石油钻探技术. 2019(05): 17-21 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: