Development and Application of Visual Cable Sticking Warning System

-

摘要:

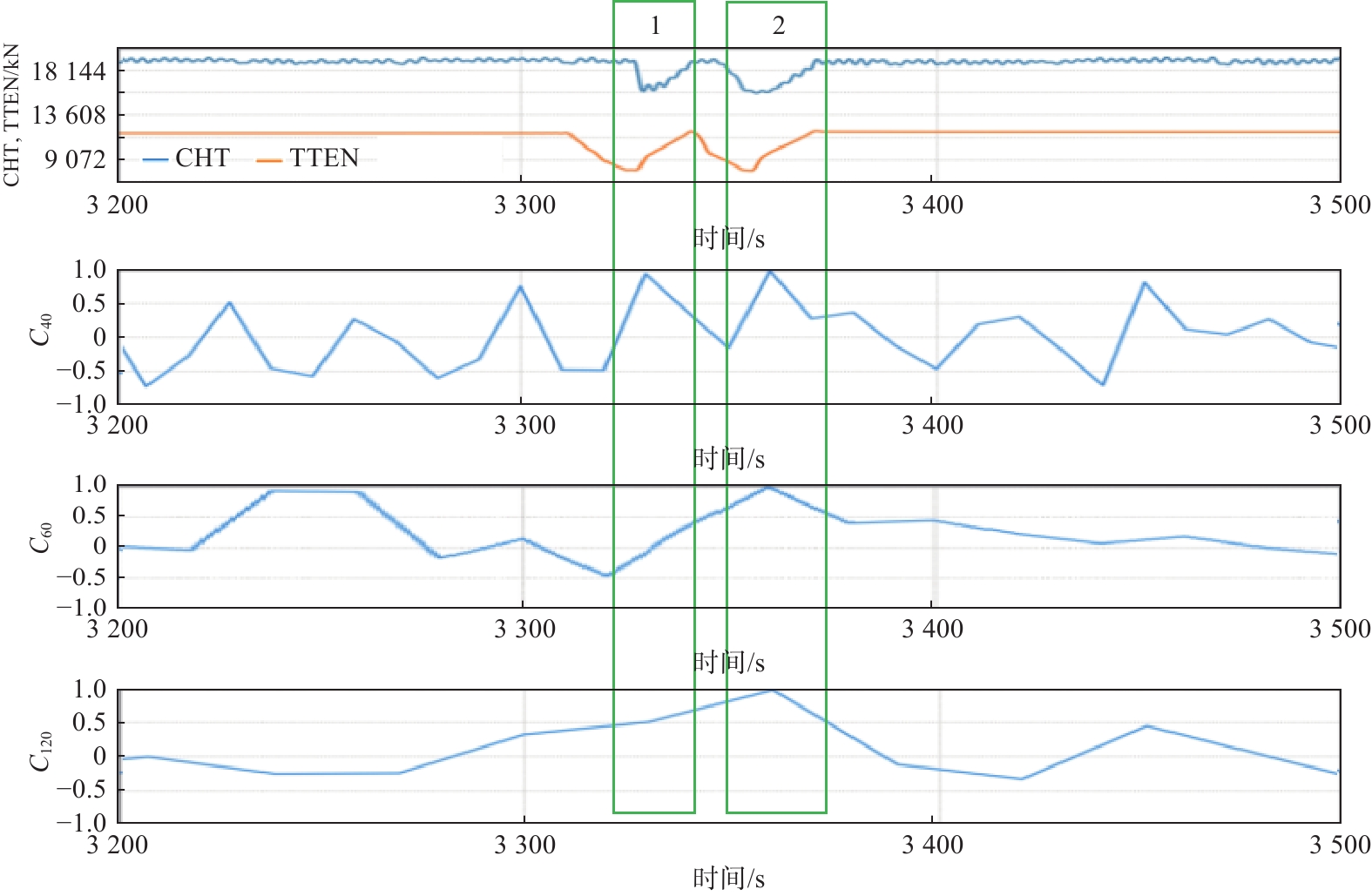

裸眼电缆测井经常发生电缆粘卡故障,且常规电缆防粘卡技术因井下粘卡识别准确率低,易发生电缆卡死的问题,严重影响测井时效及作业成本。对近几年海上油田发生电缆粘卡油气井的马龙头张力(CHT)和电缆总张力(TTEN)进行研究分析,发现通过CHT曲线和TTEN曲线的相关性可以直观判断井下电缆的状态。为此,将CHT和TTEN的相关系数作为电缆粘卡预警参数,根据发生电缆粘卡油气井的数据统计分析,确定了预警阀值,将电缆粘卡状态按低风险、中风险、高风险3个等级进行预警,并研制了WinchMonitor电缆粘卡可视化预警系统。在南海东部油田27井次的现场应用结果表明,该系统能够基于实时采集的电缆张力数据,实现电缆粘卡的颜色、声音实时预警,确保在“黄金3分钟”内采取有效防卡、解卡措施,大幅提高了复杂情况下裸眼电缆测井作业的一次成功率。研究与应用结果表明,WinchMonitor电缆粘卡可视化预警系统避免了因电缆粘卡识别不及时、不准确导致电缆卡死的作业风险,实现电缆粘卡“零打捞”,大大降低了电缆测井成本。

Abstract:With the increase of drilling speed and deep exploration in offshore oil fields, there are more and more directional Wells and complex Wells, and cable sticking accidents occur frequently in open hole wireline logging, which seriously affect the logging time and operating cost. In this paper, by studying the performance characteristics of CHT and TTEN curves of total cable tension of cable sticking in offshore oil fields in recent years, the correlation coefficient C between the two is calculated as the cable sticking warning parameter, the warning threshold C1 and C2 are studied, and the cable sticking status is divided into three levels: low risk, medium risk and high risk. And developed a visual cable sticking early warning system, in the open hole logging, in the cable sticking in the "golden 3 minutes" to realize intelligent identification and early warning, timely remind the field engineers quickly unstuck, to avoid cable stuck accident. Up to now, the early warning system has been applied 27 times in domestic offshore oil fields, realizing the "zero fishing" accident of cable sticking and greatly saving the operating cost.

-

Keywords:

- Open hole logging /

- Cable sticking /

- Cable tension /

- Intelligent early warning /

- Total tension /

- Halter tension /

- XXX /

- XXX

-

-

表 1 19口井发生电缆粘卡时的相关系数C统计情况

Table 1 Analysis and statistics of correlation coefficient C when cables are stuck

相关系数C 累计次数/次 电缆状态 风险级别 措施 电缆最终状态 0~0.1 56 卡死状态 高风险 解卡 卡死状态 0.1~0.2 34 卡死状态 高风险 解卡 卡死状态 0.2~0.3 12 卡死状态 高风险 解卡 卡死状态 0.3~0.4 3 卡死状态 高风险 解卡 卡死状态 0.4~0.5 3 卡死状态 高风险 解卡 卡死状态 0.5~0.6 2 卡死状态 高风险 防卡 卡死状态 0.6~0.7 3 异常状态 中风险 防卡 正常状态 0.7~0.8 9 异常状态 中风险 防卡 正常状态 0.8~0.9 4 异常状态 中风险 防卡 正常状态 0.9~1.0 44 正常状态 低风险 无 正常状态 -

[1] 薄和秋. 电缆测井事故的预防及处理[J]. 石油钻探技术,2002,30(2):10–12. doi: 10.3969/j.issn.1001-0890.2002.02.004 BO Heqiu. Precaution and treatment of wireline logging accidents[J]. Petroleum Drilling Techniques, 2002, 30(2): 10–12. doi: 10.3969/j.issn.1001-0890.2002.02.004

[2] 张文昌. MDT测井施工的几点体会[J]. 测井技术,2002,26(3):261–263. doi: 10.3969/j.issn.1004-1338.2002.03.020 ZHANG Wenchang. Experience in MDT log operations[J]. Well Logging Technology, 2002, 26(3): 261–263. doi: 10.3969/j.issn.1004-1338.2002.03.020

[3] 张羽臣. QK17−2S−1D井测井事故案例分析[J]. 化学工程与装备,2015(10):223–225. ZHANG Yuchen. Case analysis of well logging accident in QK17−2S−1D[J]. Chemical Engineering and Equipment, 2015(10): 223–225.

[4] 郭素俊,高娉,陈仁东,等. 测井电缆故障分析及调理使用[J]. 石油管材与仪器,2003,17(4):50–51. doi: 10.3969/j.issn.1004-9134.2003.04.018 GUO Sujun, GAO Pin, CHEN Rendong, et al. Failure analysis and conditioning of well logging cable[J]. Petroleum Tubular Goods & Instruments, 2003, 17(4): 50–51. doi: 10.3969/j.issn.1004-9134.2003.04.018

[5] 陈永才,朱佩清. 裸眼测井遇卡处理方法剖析[J]. 测井技术,2000,24(4):314–318. doi: 10.3969/j.issn.1004-1338.2000.04.014 CHEN Yongcai, ZHU Peiqing. A method for rapid recovery of stuck cable or Tool using the rheological behavior of rocks in openhole[J]. Well Logging Technology, 2000, 24(4): 314–318. doi: 10.3969/j.issn.1004-1338.2000.04.014

[6] 李志新. 测井工程遇卡原因分析与处理[J]. 测井技术,1989,13(5):60–61. LI Zhixin. Analysis and solution of stucking logging tools during logging operation[J]. Well Logging Technology, 1989, 13(5): 60–61.

[7] 白玉印,李群德. 井壁坍塌测井遇卡穿心解卡打捞技术[J]. 内蒙古石油化工,2016,42(4):87–88. doi: 10.3969/j.issn.1006-7981.2016.04.035 BAI Yuyin, LI Qunde. Inner Mongolia petrochemical industry[J]. Inner Mongolia Petrochemical Industry, 2016, 42(4): 87–88. doi: 10.3969/j.issn.1006-7981.2016.04.035

[8] 张峰. 浅谈测井施工遇卡事故预防及处理技术[J]. 内蒙古石油化工,2018,44(8):86–90. doi: 10.3969/j.issn.1006-7981.2018.08.030 ZHANG Feng. Discussion on prevention and treatment technology of log construction incident[J]. Inner Mongolia Petrochemical Industry, 2018, 44(8): 86–90. doi: 10.3969/j.issn.1006-7981.2018.08.030

[9] 文虎成,王秀明,庞日轩. 浅谈长庆油田裸眼井测井仪器遇卡及处理方法[J]. 陕西地质,2010,28(2):99–103. doi: 10.3969/j.issn.1001-6996.2010.02.018 WEN Hucheng, WANG Xiuming, PANG Rixuan. Treatment methods for open hole logging instrument sticking in Changqing oil field[J]. Geology of Shaanxi, 2010, 28(2): 99–103. doi: 10.3969/j.issn.1001-6996.2010.02.018

[10] 罗荣,蒋建平,崔光. 塔河油田测井工程事故处理及预防探讨[J]. 测井技术,2013,37(5):552–556. doi: 10.3969/j.issn.1004-1338.2013.05.019 LUO Rong, JIANG Jianping, CUI Guang. On logging engineering accident treatment and prevention in Tahe Oilfield[J]. Well Logging Technology, 2013, 37(5): 552–556. doi: 10.3969/j.issn.1004-1338.2013.05.019

[11] 韩春田,张希瑜. 测井仪器遇阻遇卡报警装置[J]. 石油管材与仪器,2006,20(5):17–19. doi: 10.3969/j.issn.1004-9134.2006.05.006 HAN Chuntian, ZHANG Xiyu. An automatic alarm device for logging tools get blocked or stuck[J]. Petroleum Tubular Goods & Instruments, 2006, 20(5): 17–19. doi: 10.3969/j.issn.1004-9134.2006.05.006

[12] 穆贵鹏,张国强,李欣,等. 渤海油田电缆测井遇卡原因分析及预防措施[J]. 化工管理,2020(33):194–196. doi: 10.3969/j.issn.1008-4800.2020.33.095 MU Guipeng, ZHANG Guoqiang, LI Xin, et al. Cause analysis and preventive measures of wire logging stucked in Bohai Oilfield[J]. Chemical Enterprise Management, 2020(33): 194–196. doi: 10.3969/j.issn.1008-4800.2020.33.095

[13] 魏冉. 电缆测井遇卡原因分析及预防措施[J]. 化学工程与装备,2022(2):140–141. WEI Ran. Reason analysis and preventive measures of stuck cable logging[J]. Chemical Engineering & Equipment, 2022(2): 140–141.

[14] 蒋恒丰. 测井施工作业中常见故障的分析与处理[J]. 内蒙古石油化工,2020,46(10):61–63. doi: 10.3969/j.issn.1006-7981.2020.10.022 JIANG Hengfeng. Analysis and processing of the common faults in logging operation[J]. Inner Mongolia Petrochemical Industry, 2020, 46(10): 61–63. doi: 10.3969/j.issn.1006-7981.2020.10.022

[15] 曹宝军,李相方,刘书民,等. 地层测试器测试期间仪器的安全问题[J]. 石油钻采工艺,2006,28(6):78–79. CAO Baojun, LI Xiangfang, LIU Shumin, et al. Safety study of formation tester while testing[J]. Oil Drilling & Production Technology, 2006, 28(6): 78–79.

[16] 汪源,孙建军,彭秀兰. 复杂井眼环境下测井遇阻、遇卡情况分析与对策[J]. 测井技术,2010,34(5):501–504. WANG Yuan, SUN Jianjun, PENG Xiulan. Analysis and countermeasures for blocking and locking in complex borehole logging[J]. Well Logging Technology, 2010, 34(5): 501–504.

-

期刊类型引用(11)

1. 史配铭,李刚,刘振. SN0144i-XX小井眼测井仪器套捞一体打捞技术研究及应用. 石油工业技术监督. 2025(02): 1-6 .  百度学术

百度学术

2. 杨明,刘巨保,王田玉,丁宇奇,岳欠杯,杨宝. 井口无支撑段连续油管极限拉压载荷分析. 东北石油大学学报. 2023(01): 116-126+12 .  百度学术

百度学术

3. 邸德家,毛军,庞伟,张同义. 涪陵页岩水平井生产测井仪器遇卡处理及分析. 油气井测试. 2022(05): 54-57 .  百度学术

百度学术

4. 陆应辉,唐凯,张柟乔,任国辉,张清彬,李奔驰,李妍僖. 水平井桥塞射孔联作管串解卡力计算模型及应用. 长江大学学报(自然科学版). 2021(01): 79-86 .  百度学术

百度学术

5. 焦金龙. XS14-P2水平井落井电缆打捞技术. 油气井测试. 2021(02): 34-38 .  百度学术

百度学术

6. 张德龙,吴洪涛,贺宇迪,赵伟峰,刘佳欣. 连续油管内穿电缆测井工艺在水平井中的应用. 化学工程与装备. 2021(05): 110-111 .  百度学术

百度学术

7. 王栋,赖学明,唐庆,周俊杰. 沧东凹陷页岩油水平井不压井作业技术. 石油钻探技术. 2021(04): 150-154 .  本站查看

本站查看

8. 唐凯,陈锋,陆应辉,任国辉,李奔驰,杨登波. 水平井桥射联作电缆及其弱点的受力分析. 测井技术. 2021(04): 445-450 .  百度学术

百度学术

9. 陆应辉,唐凯,任国辉,聂华富,杨登波. 水平井泵送分簇射孔落鱼打捞工艺及应用. 长江大学学报(自然科学版). 2019(05): 23-28+6 .  百度学术

百度学术

10. 徐学利,王涛,张世虎,李希,张广利,董会,李霄,康国强,白自龙. 接触载荷对CT80连续油管摩擦磨损性能的影响. 材料保护. 2019(11): 8-12 .  百度学术

百度学术

11. 艾白布·阿不力米提,庞德新,王一全,郭新维,杨文新,焦文夫. 连续油管打捞连续油管关键工具研究与应用. 石油钻探技术. 2019(06): 89-95 .  本站查看

本站查看

其他类型引用(2)

下载:

下载: