The Research and Application of a Key Tool for Coiled Tubing Fishing with Coiled Tubing

-

摘要:

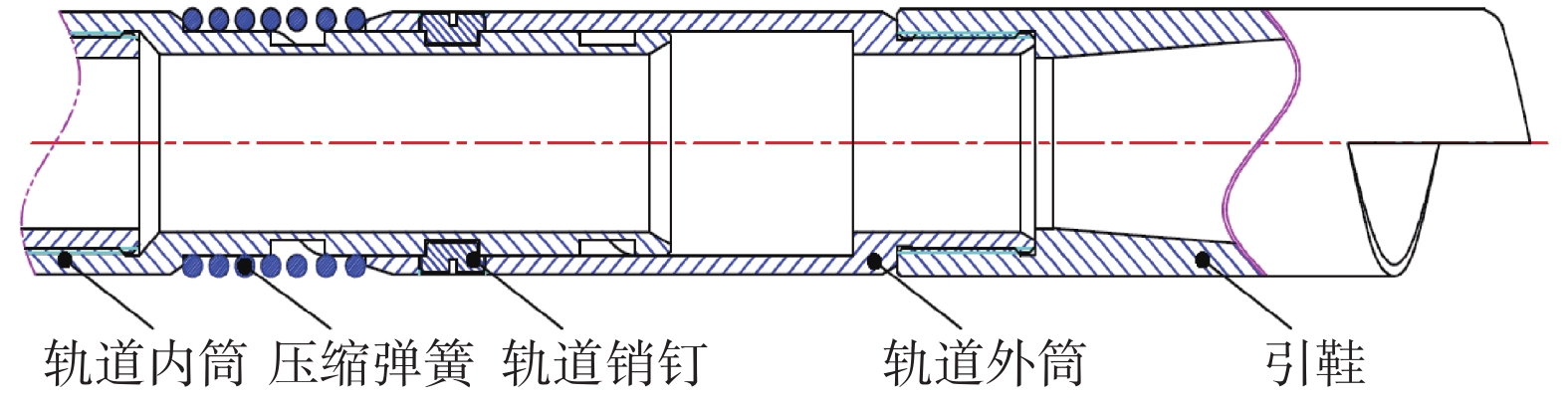

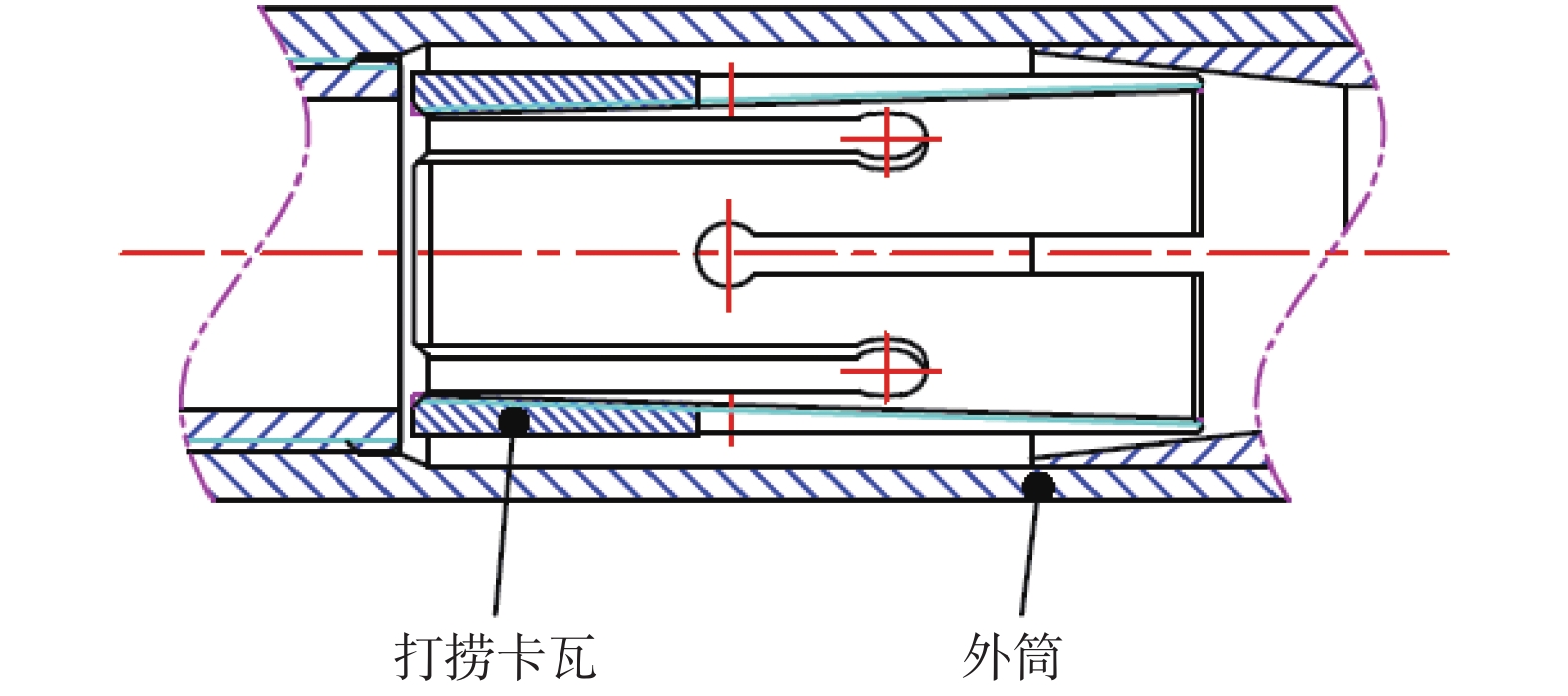

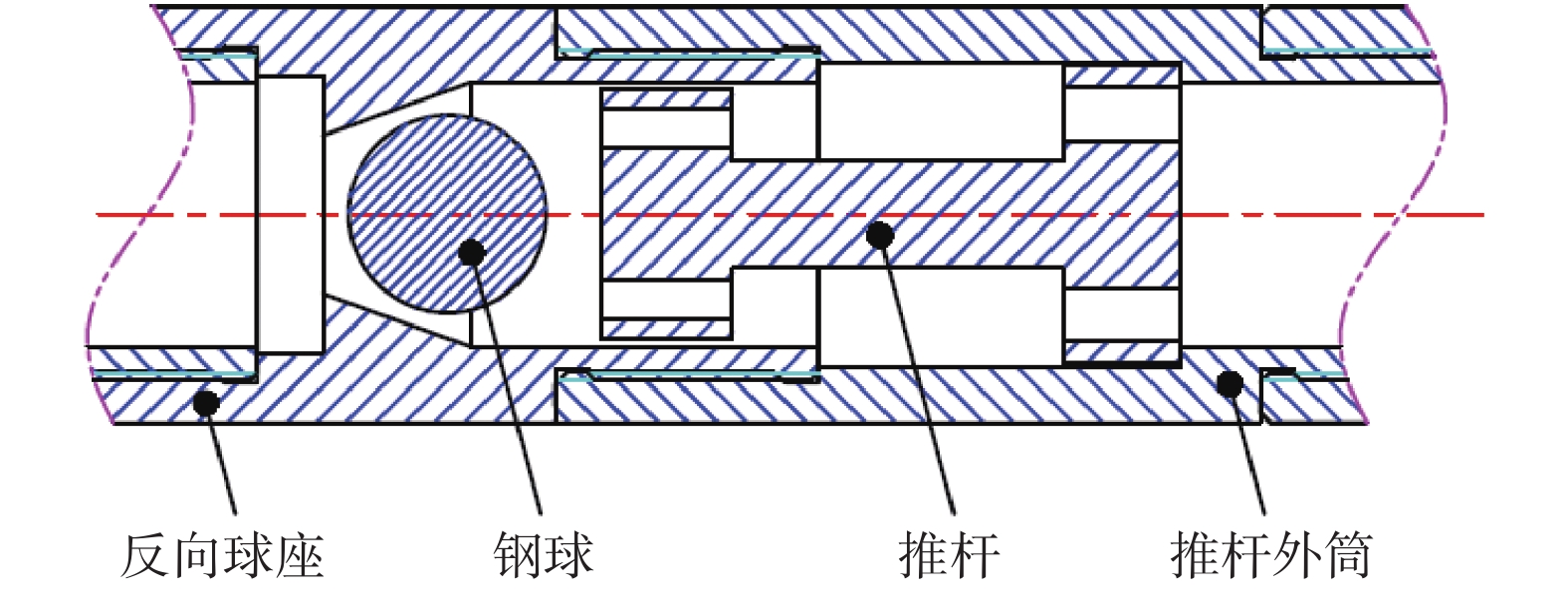

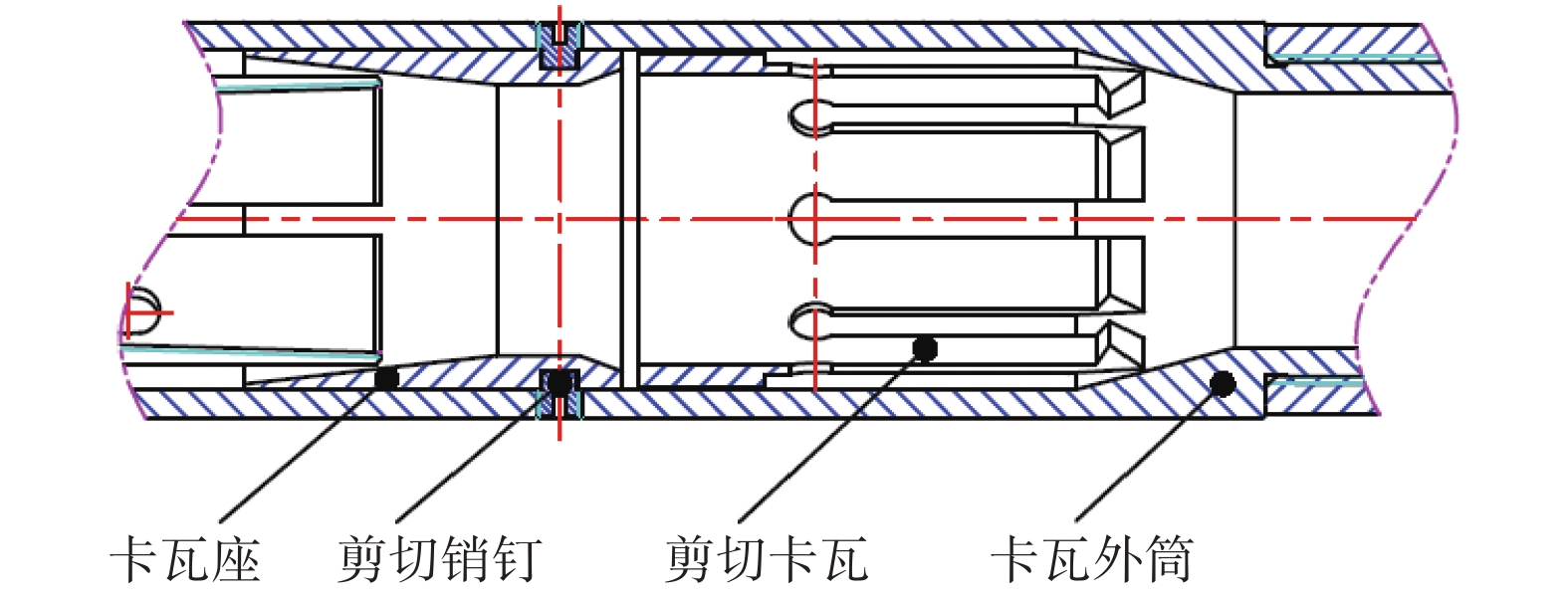

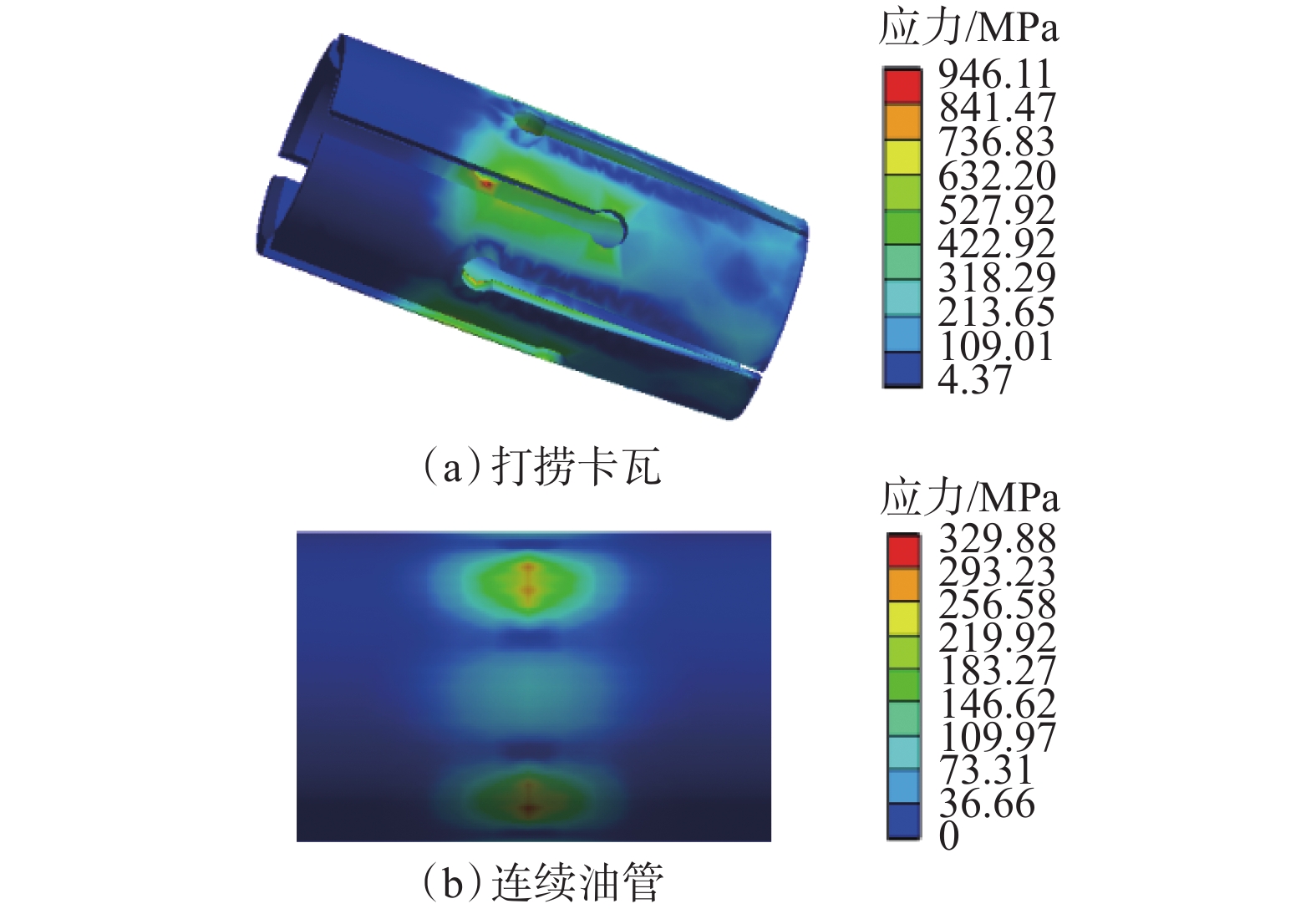

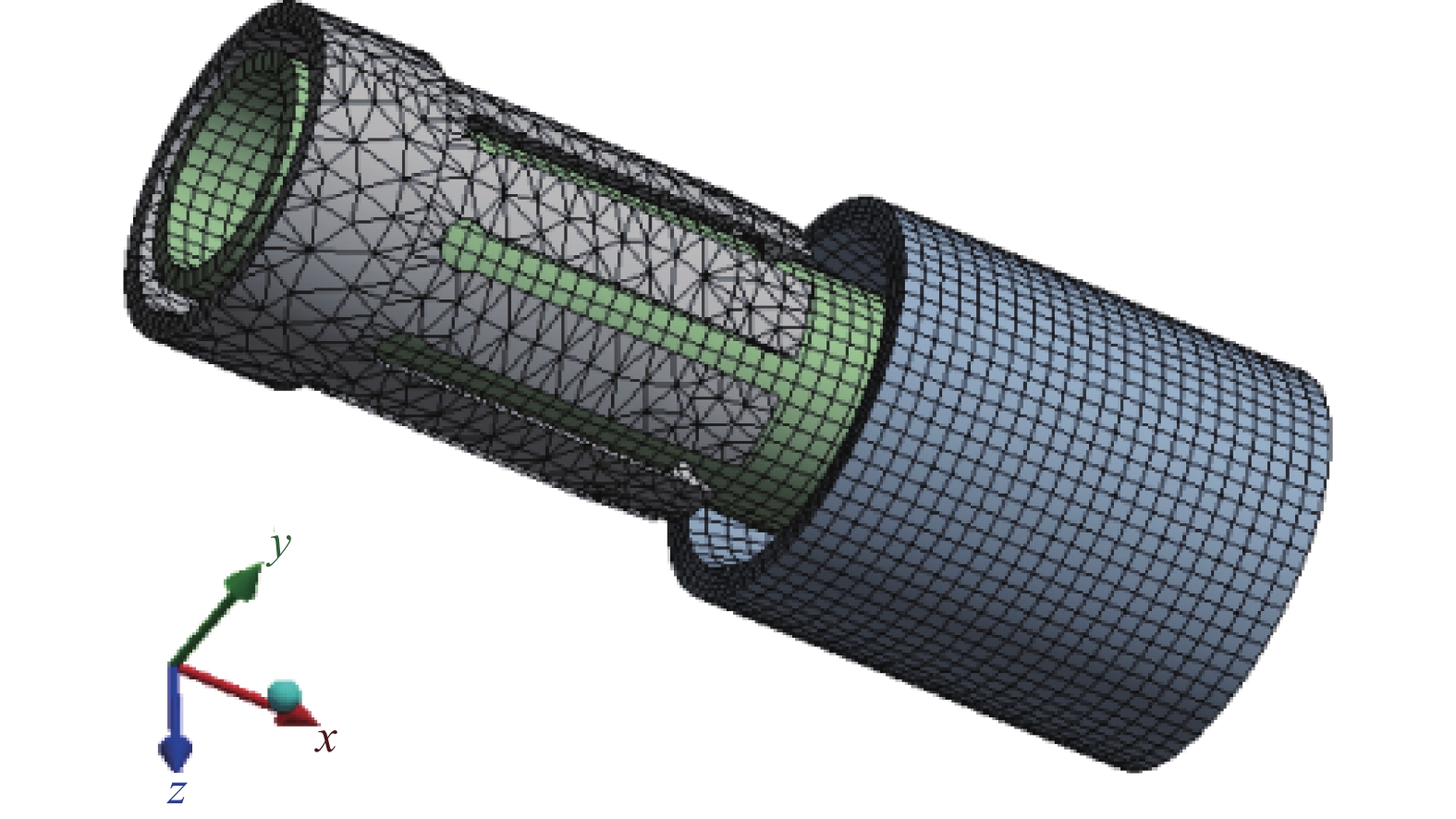

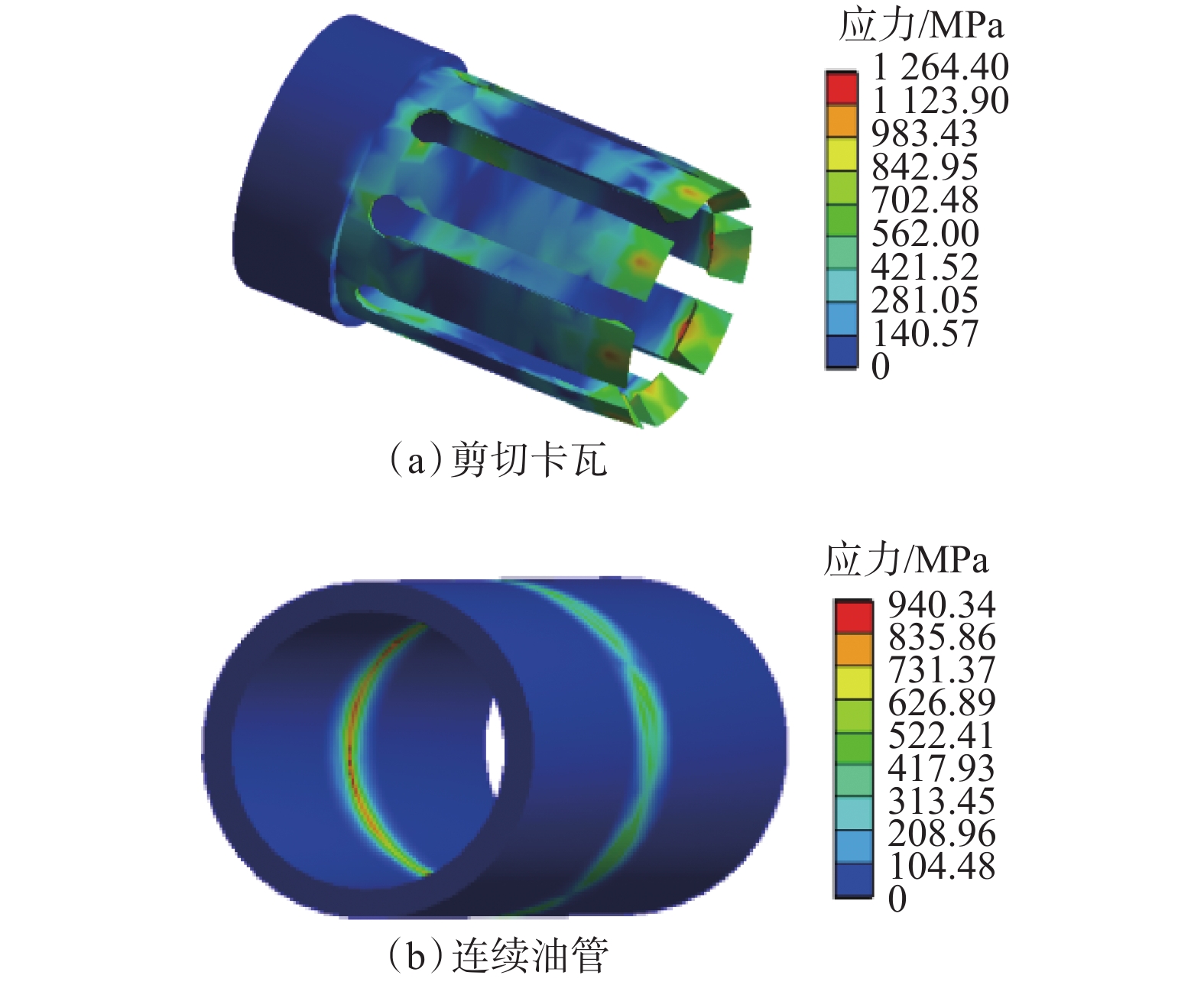

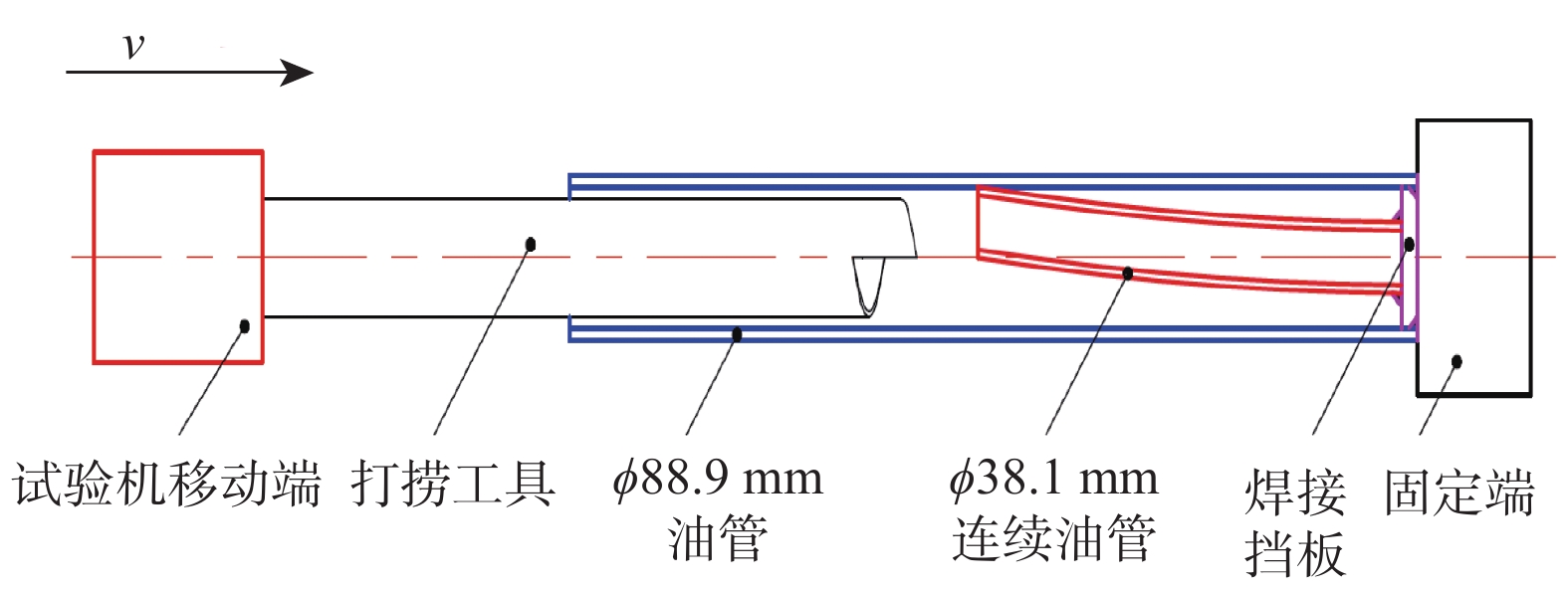

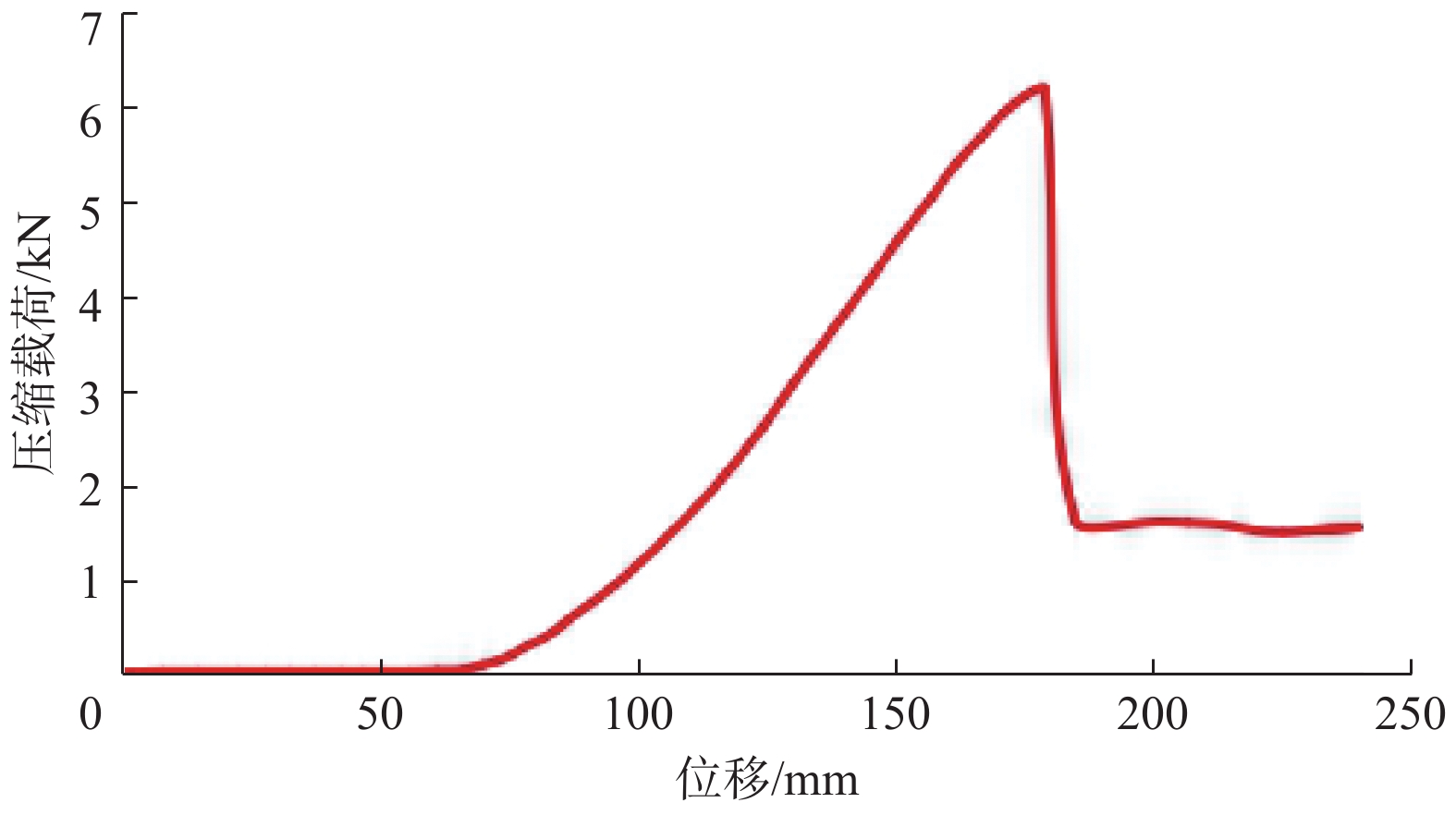

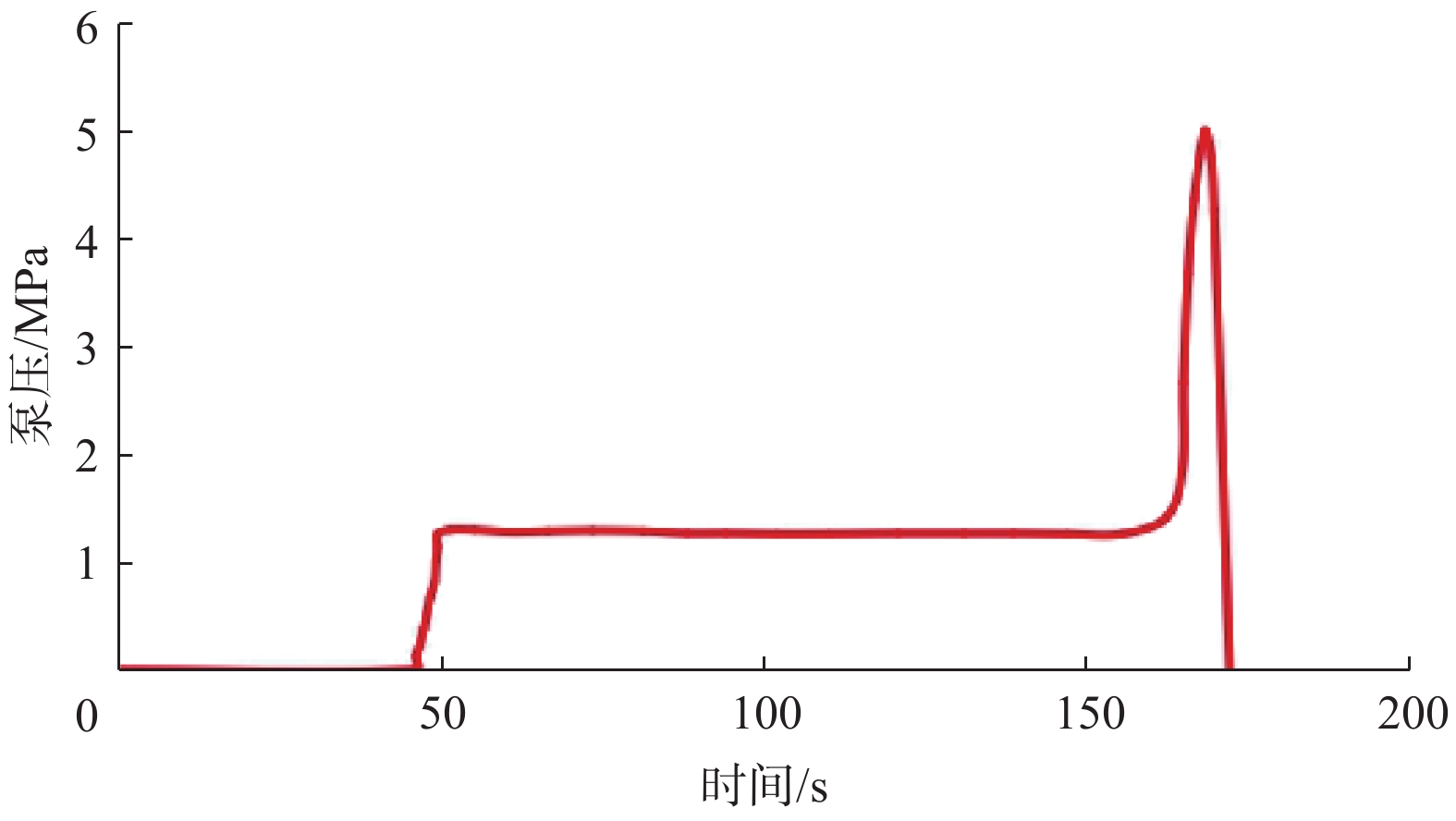

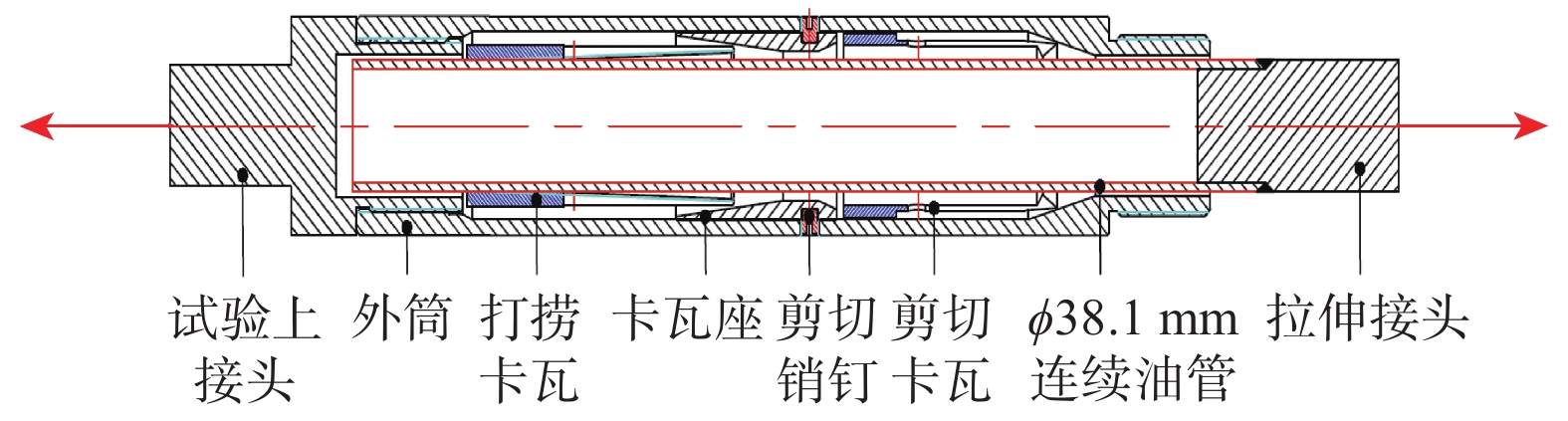

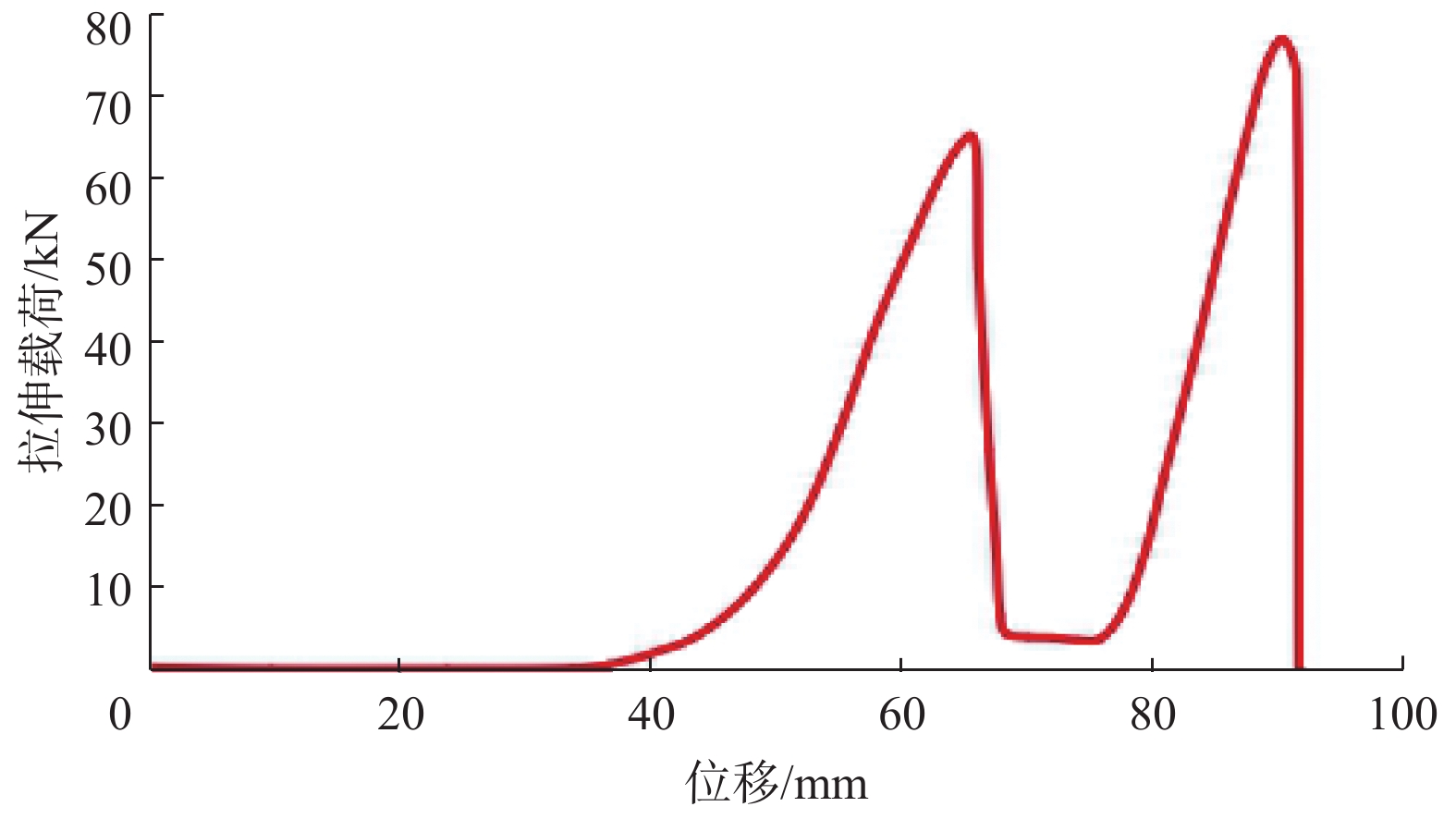

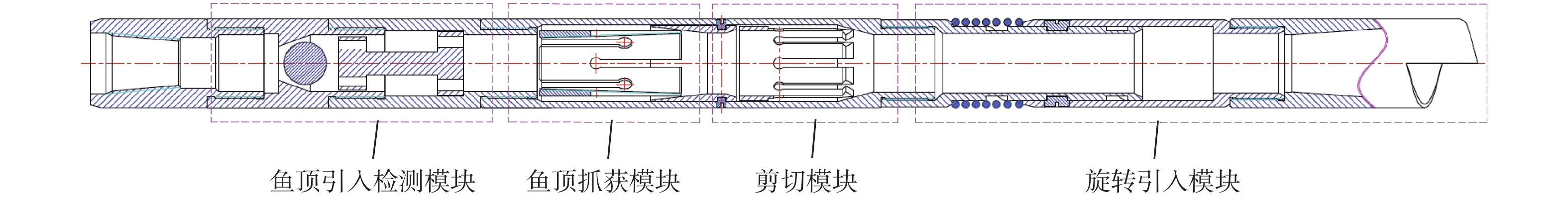

针对用常规管柱打捞连续油管作业效率低、风险和施工强度高等问题,在调研连续油管作业技术现状的基础上,提出了连续油管打捞连续油管的思路,针对现场技术需求研发了专用打捞工具。通过模块化结构设计,在专用打捞工具中集成了鱼顶旋转引入、鱼顶检测、鱼顶抓获及剪切等功能机构,使其能够适应连续油管打捞连续油管的工况。模拟计算和室内试验证明,专用打捞工具的性能达到了设计要求。该专用打捞工具在塔里木油田X–1井ϕ88.9 mm生产管柱内进行了13次打捞连续油管的作业,累计捞获井内严重遇卡的ϕ38.1 mm连续油管2 851.87 m,捞获率100%,作业效率是常规管柱打捞作业的4倍,验证了专用打捞工具性能的稳定性。研究结果表明,连续油管专用打捞工具能够满足打捞连续油管的要求,可提高打捞连续油管的成功率和作业效率。

Abstract:In view of the low efficiency, high risk and high labor intensity of coiled tubing fishing with a conventional tubing string, research was conducted to investigate the current status of coiled tubing operation technologies. The process of coiled tubing fishing with coiled tubing was proposed, and a specific tool was developed. By virtue of its modular design, the tool was able to integrate the functions of fish top rotation entrance, fish top detection, fish top capture and shearing into the tool, so that the tool could adapt to the operation conditions of coiled tubing fishing. The results of simulation calculation and laboratory test verified that the performance of this tool met the desired design requirements. This fishing tool was used in Well X–1 of Tarim Oilfield on coiled tubing, and it finished 13 fishing jobs in ϕ88.9 mm production string. In total 2 851.87 m of ϕ38.1 mm coiled tubing that had been seriously stuck in the hole was retrieved, and the retrieval rate was up to 100%, while the fishing efficiency was four times higher than that of the conventional fishing string. The field application also verified the stability of tool’s performance. Studies suggested that this coiled tubing fishing tool could also be effectively applied in coiled tubing fishing, and it could provide technical references in the future for fishing in coiled tubing.

-

Keywords:

- coiled tubing /

- objects lost-in-hole /

- fishing tools /

- TarimOilfield

-

-

[1] 肖磊,杨博仲,李永杰. HT区块超深含硫井压回法压井技术应用研究[J]. 钻采工艺, 2018, 41(6): 16–18. doi: 10.3969/J.ISSN.1006-768X.2018.06.05 XIAO Lei, YANG Bozhong, LI Yongjie. Application of bullheading killing technology at HT Area[J]. Drilling & Production Technology, 2018, 41(6): 16–18. doi: 10.3969/J.ISSN.1006-768X.2018.06.05

[2] 牛新明,张进双,周号博. " 三超”油气井井控技术难点及对策[J]. 石油钻探技术, 2017, 45(4): 1–7. NIU Xinming, ZHANG Jinshuang, ZHOU Haobo. Technological challenges and countermeasures in well control of ultra-deep, ultra-high temperature and ultra-high pressure oil and gas wells[J]. Petroleum Drilling Techniques, 2017, 45(4): 1–7.

[3] 邹先雄,石孝至,董守涛. 打捞连续油管落鱼工艺技术研究与应用[J]. 钻采工艺, 2018, 41(5): 16–18, 22. doi: 10.3969/J.ISSN.1006-768X.2018.05.05 ZOU Xianxiong, SHI Xiaozhi, DONG shoutao. Study on how to fish coiled tubing and application[J]. Drilling & Production Technology, 2018, 41(5): 16–18, 22. doi: 10.3969/J.ISSN.1006-768X.2018.05.05

[4] 曹学军,周赟,傅伟,等. 连续油管带压作业技术在特殊复杂井况中的应用[J]. 天然气勘探与开发, 2012, 35(2): 50–52, 56. doi: 10.3969/j.issn.1673-3177.2012.02.014 CAO Xuejun, ZHOU Yun, FU Wei, et al. Application of pressure operation technology of coiled tubing in special complex well condition[J]. Natural Gas Exploration and Development, 2012, 35(2): 50–52, 56. doi: 10.3969/j.issn.1673-3177.2012.02.014

[5] 王伟佳,熊江勇,张国锋,等. 页岩气井连续油管辅助压裂试气技术[J]. 石油钻探技术, 2015, 43(5): 88–93. WANG Weijia, XIONG Jiangyong, ZHANG Guofeng, et al. Auxiliary fracturing and testing of gas in shale gas well with coiled tubing[J]. Petroleum Drilling Techniques, 2015, 43(5): 88–93.

[6] 窦益华,刘曼,郑杰,等. 新型双卡瓦可退式连续油管打捞工具的设计与有限元分析[J]. 机械制造, 2019, 54(1): 74–76, 80. doi: 10.3969/j.issn.1000-4998.2019.01.023 DOU Yihua, LIU Man, ZHENG Jie, et al. Design and finite element analysis of new double-kava retractable fishing tool for continuous reeled tubing[J]. Machinery, 2019, 54(1): 74–76, 80. doi: 10.3969/j.issn.1000-4998.2019.01.023

[7] 于东兵,包文德,马卫国,等. 连续油管打捞技术专用工具研究现状及展望[J]. 石油机械, 2007, 35(1): 45–47. doi: 10.3969/j.issn.1001-4578.2007.01.015 YU Dongbing, BAO Wende, MA Weiguo, et al. Research status and expectation of special tools for coiled tubing fishing technology[J]. China Petroleum Machinery, 2007, 35(1): 45–47. doi: 10.3969/j.issn.1001-4578.2007.01.015

[8] 石孝志,苏贵杰,王忠胜,等. 连续油管打捞技术在川渝地区的应用[J]. 天然气工业, 2008, 28(8): 58–60. doi: 10.3787/j.issn.1000-0976.2008.08.016 SHI Xiaozhi, SU Guijie, WANG Zhongsheng, et al. Application of coiled tubing fishing technology in Sichuan and Chongqing Area[J]. Natural Gas Industry, 2008, 28(8): 58–60. doi: 10.3787/j.issn.1000-0976.2008.08.016

[9] 吴永兴,朱培珂,熊伟. 连续油管打捞工艺在水平井的应用问题及措施[J]. 石油矿场机械, 2016, 45(7): 80–83. doi: 10.3969/j.issn.1001-3482.2016.07.018 WU Yongxing, ZHU Peike, XIONG Wei. Coiled tubing fishing process application problems and measures in horizontal well[J]. Oil Field Equipment, 2016, 45(7): 80–83. doi: 10.3969/j.issn.1001-3482.2016.07.018

[10] 王伟佳. 页岩气水平井连续油管带压打捞长电缆技术[J]. 石油钻探技术, 2018, 46(3): 109–113. WANG Weijia. The technology of long cable snubbing fishing through coiled tubing in horizontal shale gas wells[J]. Petroleum Drilling Techniques, 2018, 46(3): 109–113.

[11] 赵广慧,梁政. 连续油管力学性能研究进展[J]. 钻采工艺, 2008, 31(4): 97–101. doi: 10.3969/j.issn.1006-768X.2008.04.032 ZHAO Guanghui, LIANG Zheng. Research on mechanical property of coiled tubing[J]. Drilling & Production Technology, 2008, 31(4): 97–101. doi: 10.3969/j.issn.1006-768X.2008.04.032

[12] 刘健,林铁军,练章华,等. 考虑残余应变的连续油管螺旋屈曲载荷新公式[J]. 石油机械, 2008, 36(1): 25–28. LIU Jian, LIN Tiejun, LIAN Zhanghua, et al. A new calculating formula for helical buckling load of coiled tubing with residual strain[J]. China Petroleum Machinery, 2008, 36(1): 25–28.

[13] 陈迎春,张仕民,王文明,等. 连续油管屈曲力学特性研究进展[J]. 石油矿场机械, 2013, 42(12): 15–20. doi: 10.3969/j.issn.1001-3482.2013.12.004 CHEN Yingchun, ZHANG Shimin, WANG Wenming, et al. Study progress in buckling behavior of coiled tubing[J]. Oil Field Equipment, 2013, 42(12): 15–20. doi: 10.3969/j.issn.1001-3482.2013.12.004

下载:

下载: