Numerical Calculation Method of the Wellbore Temperature Field for Electric Heating Heavy Oil Thermal Recovery

-

摘要:

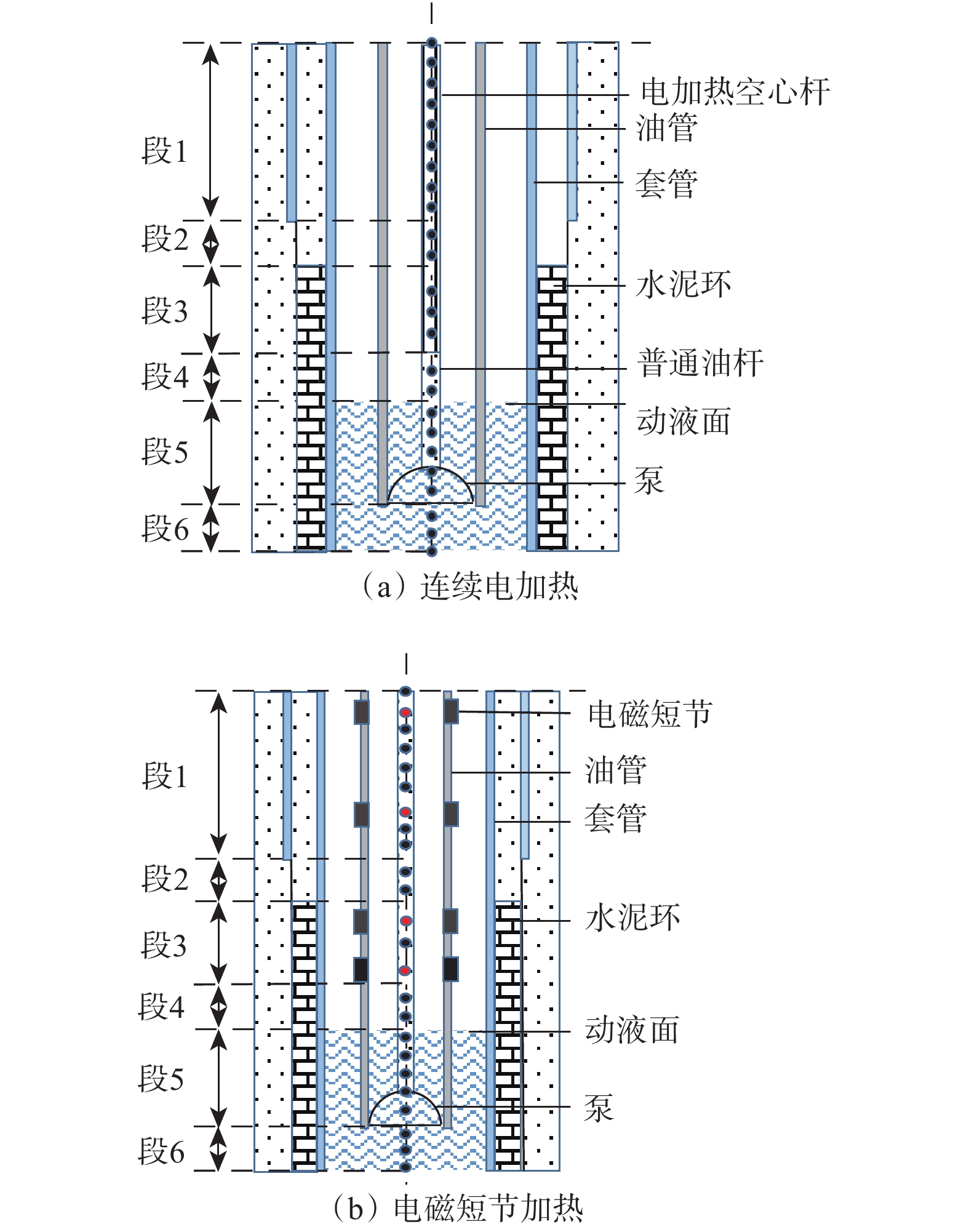

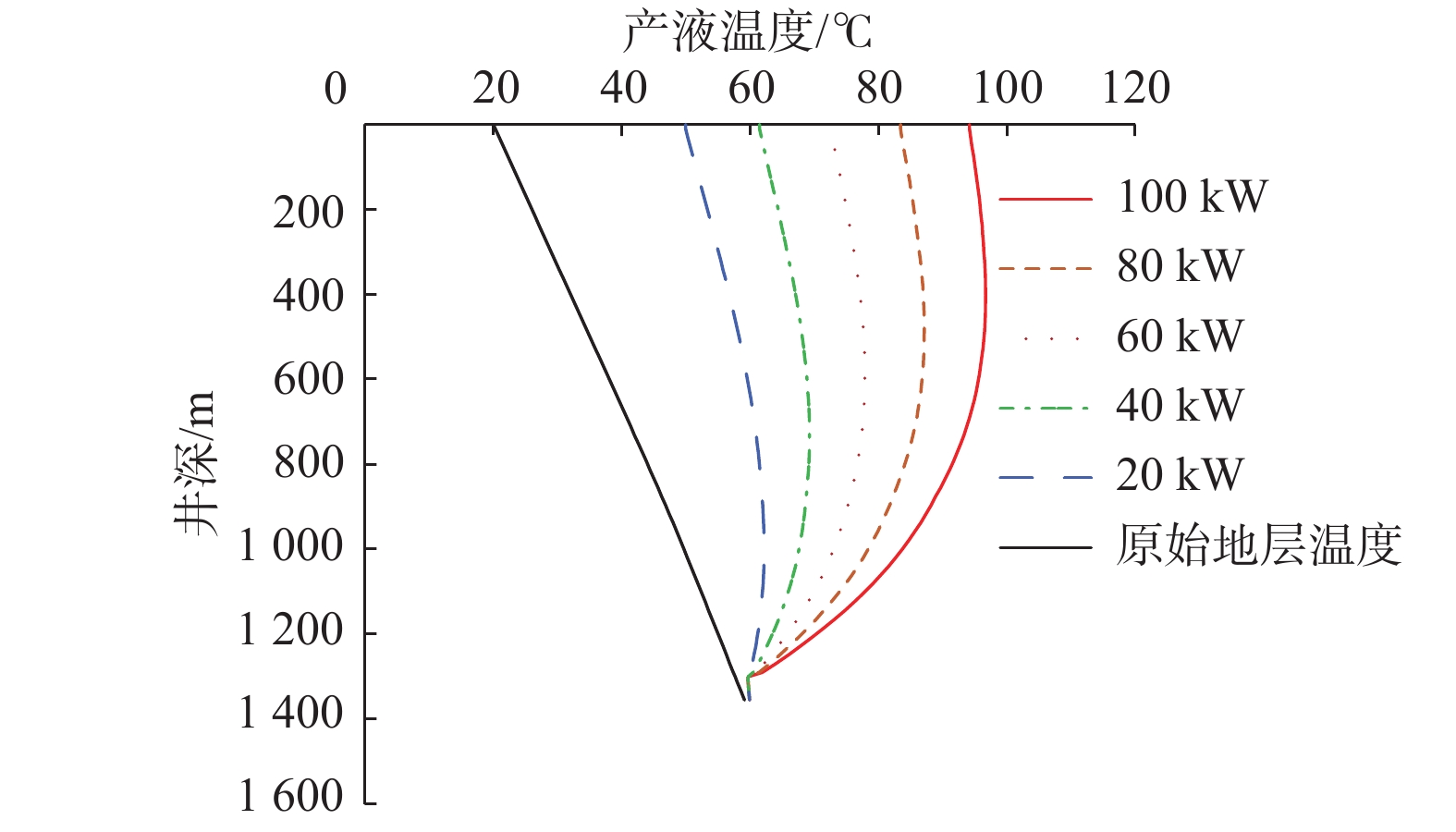

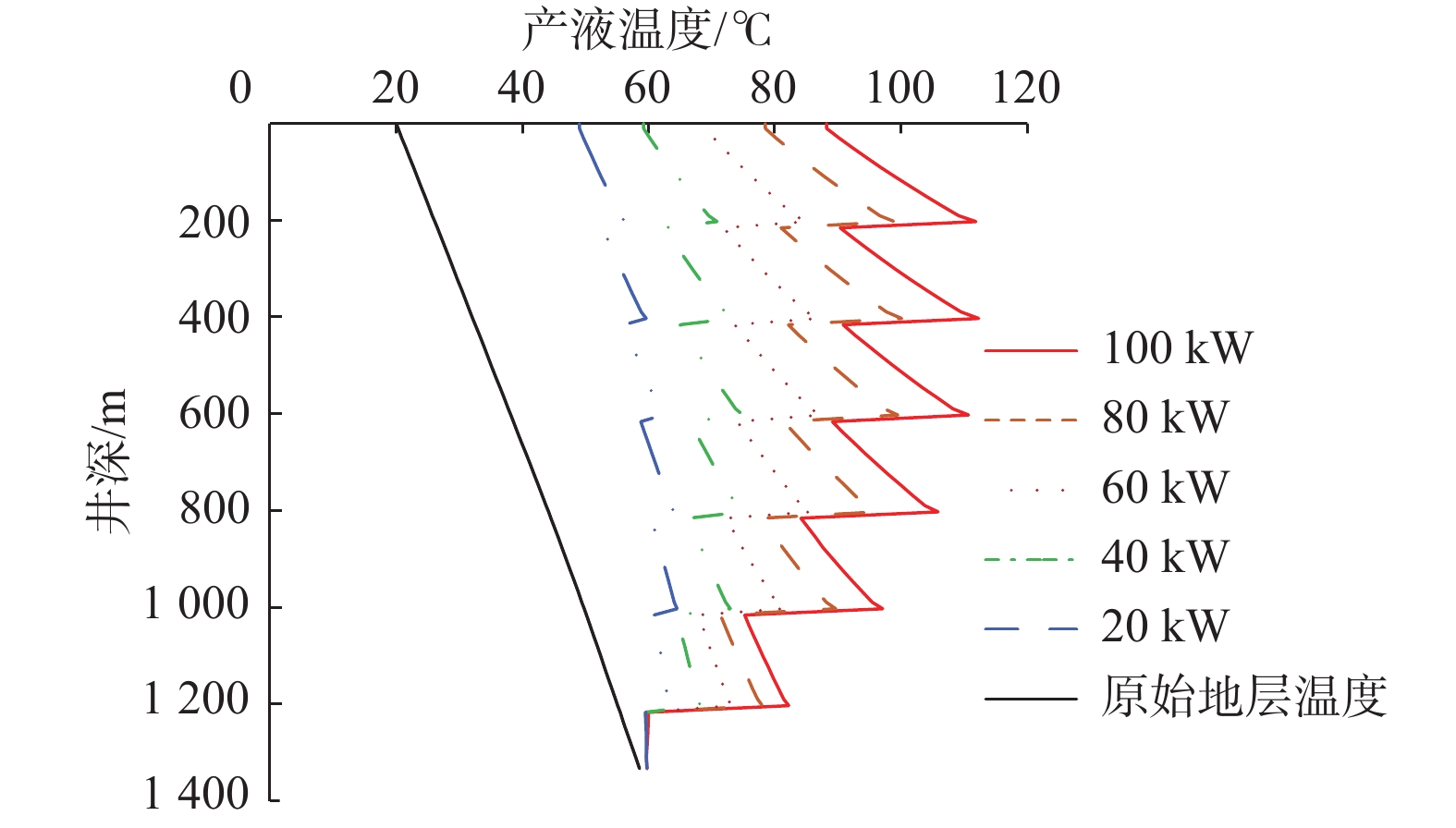

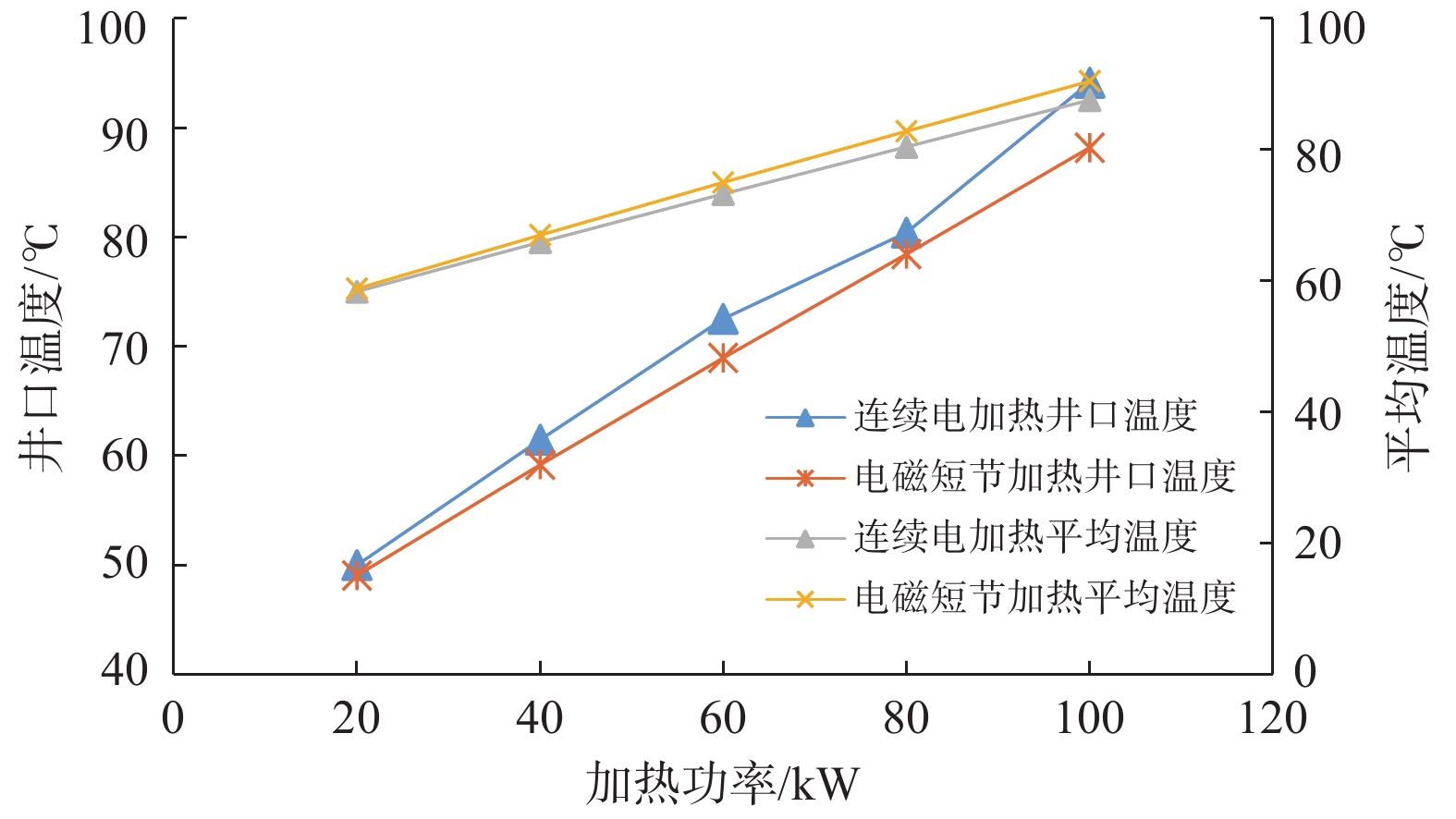

电加热稠油热采井筒温度场是热采作业参数设计的核心依据,基于传热学理论和气液两相流井筒温压场计算方法,考虑温度对稠油热物性影响,建立了连续电加热和电磁短节加热工艺井筒温度场的数值计算方法,并以大港油田X井为例,计算了不同加热功率下连续电加热和电磁短节加热工艺的井筒温度场。计算结果表明:井口温度的模型计算结果与实测值相对误差仅为3.10%,满足工程设计精度要求,也验证了计算方法的有效性和准确性;连续电加热工艺的井筒温度剖面平滑连续,而电磁短节加热工艺的井筒温度剖面呈锯齿形,且温度波动更大;连续电加热工艺的井口温度高于电磁短节加热,而连续电加热工艺的平均温度则低于电磁短节加热工艺。该研究结果可为电加热稠油热采工艺选择、作业参数设计提供指导和借鉴。

Abstract:The wellbore temperature field of electric heating-based heavy oil thermal recovery forms the basis of the thermal recovery operation parameters design. Based on the heat transfer theory and the calculation method of wellbore temperature/pressure fields for gas-liquid two-phase flow, the wellbore temperature field numerical calculation method for continuous electric heating and electromagnetic nipple heating processes that considers the influence of temperature on the thermal properties of heavy oil was established. By taking the Well X in Dagang Oilfield as an example, the wellbore temperature fields of continuous electric heating and electromagnetic nipple heating processes under different heating powers were calculated. The calculation results showed that the relative error between the wellhead temperature calculated with this model and the measured one was only 3.10%. This met the requirements of engineering design accuracy, and verified the validity and accuracy of this calculation method. The wellbore temperature profile formed by continuous electric heating was smooth and continuous, whereas the profile formed by electromagnetic nipple heating process was zigzag and had dramatic fluctuations. The wellhead temperature formed by the continuous electric heating process was higher than that of the electromagnetic nipple heating, and the average temperature of the continuous electric heating process was lower than that of the electromagnetic nipple heating process. The research results could provide guidance and reference for the selection of electric heating heavy oil thermal recovery processes and operation parameters design.

-

-

表 1 大港油田X井实钻井身结构

Table 1 Actual casing program of Well X in Dagang Oilfield

套管 外径/mm 井眼直径/mm 套管下深/m 水泥返高/m 表层套管 244.50 311.1 290.00 地面 生产套管 139.70 215.9 1 388.00 865.00 表 2 连续电加热和电磁短节加热工艺的井筒温度场剖面均方差比较

Table 2 Comparison of the mean square errors of wellbore temperature field profiles formed by continuous electric heating and electromagnetic nipple heating processes

加热方法 不同加热功率的井筒温度场剖面均方差 20 kW 40 kW 60 kW 80 kW 100 kW 连续电加热 11.63 8.40 5.31 2.97 3.82 电磁短节加热 14.40 10.96 7.40 4.40 4.01 -

[1] 刘文章. 普通稠油油藏二次热采开发模式综述[J]. 特种油气藏, 1998, 5(2): 1–7. LIU Wenzhang. Summary of secondary thermal recovery for conventional heavy oil reservoir[J]. Special Oil & Gas Reservoirs, 1998, 5(2): 1–7.

[2] 梁丹,冯国智,曾祥林,等. 海上稠油两种热采方式开发效果评价[J]. 石油钻探技术, 2014, 42(1): 95–99. doi: 10.3969/j.issn.1001-0890.2014.01.019 LIANG Dan, FENG Guozhi, ZENG Xianglin, et al. Evaluation of two thermal methods in offshore heavy oilfields development[J]. Petroleum Drilling Techniques, 2014, 42(1): 95–99. doi: 10.3969/j.issn.1001-0890.2014.01.019

[3] 唐述凯,李明忠,刘陈伟,等. 闭式热流体循环井筒温度分布规律研究[J]. 石油钻探技术, 2014, 42(5): 104–108. TANG Shukai, LI Mingzhong, LIU Chenwei, et al. Temperature distribution in closed wellbore with hot fluid circulation[J]. Petroleum Drilling Techniques, 2014, 42(5): 104–108.

[4] 任瑛. 加热开采稠油工艺的探讨:井筒中的热流体循环[J]. 华东石油学院学报(自然科学版), 1982, 6(4): 53–66. REN Ying. Thermal production of viscous oil with recycling of hot fluid in well bore[J]. Journal of East China Petroleum Institute (Edition of Natural Science), 1982, 6(4): 53–66.

[5] 阚庆山,江永全,徐凌云,等. 大港油田火成岩油藏稠油热采工艺[J]. 石油钻采工艺, 2009, 31(2): 115–117. KAN Qingshan, JIANG Yongquan, XU Lingyun, et al. Technology of thermal recovery of volcanic high-viscosity reservoirs in Dagang Oilfield[J]. Oil Drilling & Production Technology, 2009, 31(2): 115–117.

[6] 李伟超,刘平,于继飞,等. 渤海稠油油田井筒电加热技术可行性分析[J]. 断块油气田, 2012, 19(4): 513–516. LI Weichao, LIU Ping, YU Jifei, et al. Feasibility analysis on electric heating of wellbore in heavy oilfield of Bohai[J]. Fault-Block Oil & Gas Field, 2012, 19(4): 513–516.

[7] 余五星, 潘建华, 林军, 等. 超稠油中频电加热采油技术[J]. 特种油气藏, 2000, 7(增刊1): 31–33. YU Wuxing, PAN Jianhua, LIN Jun, et al. Thermal producing of super heavy oil with frequency current[J]. Special Oil & Gas Reservoirs, 2000, 7(Supplement1): 31–33.

[8] 宋时权,张公社,李晶晶,等. 电加热杆抽油井温度分布计算[J]. 断块油气田, 2008, 15(3): 121–123. SONG Shiquan, ZHANG Gongshe, LI Jingjing, et al. Calculation of temperature distribution of electrical heating rod in pumping well[J]. Fault-Block Oil & Gas Field, 2008, 15(3): 121–123.

[9] 姚传进,雷光伦,吴川,等. 高凝原油井筒温度场影响因素研究[J]. 石油钻探技术, 2011, 39(5): 74–78. doi: 10.3969/j.issn.1001-0890.2011.05.016 YAO Chuanjin, LEI Guanglun, WU Chuan, et al. Study of the factors impacting on wellbore temperature in high pour point oil production[J]. Petroleum Drilling Techniques, 2011, 39(5): 74–78. doi: 10.3969/j.issn.1001-0890.2011.05.016

[10] 卢智慧,何雪芹,刘志恒,等. 考虑环境因素的井筒流动温度场计算[J]. 断块油气田, 2016, 23(5): 652–654. LU Zhihui, HE Xueqin, LIU Zhiheng, et al. Calculation of wellbore flowing temperature distribution considering environmental factors[J]. Fault-Block Oil & Gas Field, 2016, 23(5): 652–654.

[11] 李梦博,柳贡慧,李军,等. 考虑非牛顿流体螺旋流动的钻井井筒温度场研究[J]. 石油钻探技术, 2014, 42(5): 74–79. LI Mengbo, LIU Gonghui, LI Jun, et al. Research on wellbore temperature field with helical flow of non-Newtonian fluids in drilling operation[J]. Petroleum Drilling Techniques, 2014, 42(5): 74–79.

[12] 王江帅,李军,柳贡慧,等. 循环钻进过程中井筒温度场新模型[J]. 断块油气田, 2018, 25(2): 240–243. WANG Jiangshuai, LI Jun, LIU Gonghui, et al. New model of wellbore temperature field during drilling process[J]. Fault-Block Oil and Gas Field, 2018, 25(2): 240–243.

[13] RAMEY H J Jr. Wellbore heat transmission[J]. Journal of Petroleum Technology, 2013, 14(4): 427–435.

[14] 宋洵成,韦龙贵,何连,等. 气液两相流循环温度和压力预测耦合模型[J]. 石油钻采工艺, 2012, 34(6): 5–9. doi: 10.3969/j.issn.1000-7393.2012.06.004 SONG Xuncheng, WEI Longgui, HE Lian, et al. Acoupled model for wellbore temperature and pressure prediction of gas-liquid drilling fluid[J]. Oil Drilling & Production Technology, 2012, 34(6): 5–9. doi: 10.3969/j.issn.1000-7393.2012.06.004

[15] HASAN A R, KABIR C S, SAYARPOUR M. Simplified two-phase flow modeling in wellbores[J]. Journal of Petroleum Science and Engineering, 2010, 72(1/2): 42–49.

[16] BEGGS H D, BRILL J P. A study of two-phase flow in inclined pipes[J]. Journal of Petroleum Technology, 1973, 25(5): 607–617. doi: 10.2118/4007-PA

[17] ANSARI A M, SYLVESTER N D, SHOHAM O, et al. A comprehensive mechanistic model for upward two-phase flow in wellbores[R]. SPE 20630, 1990.

-

期刊类型引用(12)

1. 曾文广,王熙,李芳,张江江,曾德智. 稠油井内衬保温油管热损失分析及开采参数优化. 特种油气藏. 2024(01): 144-151 .  百度学术

百度学术

2. 许富强,薛亚斐,宋先知,熊波,莫邵元. 废弃油井转地热井取热性能评价及井型对比. 石油钻探技术. 2024(06): 156-166 .  本站查看

本站查看

3. 唐洋,谢娜,熊浩宇,何胤,黄顺潇. 煤炭地下气化高温喷淋井筒温度应力场研究. 煤田地质与勘探. 2023(11): 13-23 .  百度学术

百度学术

4. 郑晨阳,韩超,周祥. 电加热管柱技术在渤海油田高含蜡油井中的应用. 石油和化工设备. 2023(11): 123-126 .  百度学术

百度学术

5. 刘奕杉,黄顺潇,袁光杰,唐洋. 煤炭地下气化高温井筒温度场研究. 煤炭转化. 2022(01): 58-64 .  百度学术

百度学术

6. 卢迎波,胡鹏程,申婷婷,洪锋,董森淼,马鹏,陈超. 电加热辅助蒸汽吞吐提高水平井水平段动用程度的技术. 大庆石油地质与开发. 2022(02): 167-174 .  百度学术

百度学术

7. 薛继军,杨文波,白哲,上官丰收. 空心杆电加热系统加热效果影响因素分析. 石油机械. 2022(04): 118-123 .  百度学术

百度学术

8. 周晓晖,苏义脑,牛成成,程远方,魏佳. 保护冻土层的真空隔热套管性能试验与数值模拟研究. 石油钻探技术. 2021(03): 21-26 .  本站查看

本站查看

9. 杨立龙. 中深层超稠油油藏SAGD开发热效率分析及提升对策. 特种油气藏. 2021(03): 151-156 .  百度学术

百度学术

10. 李荆江,楼一珊,朱亮. 稠油热采蒸汽驱分层配汽器的结构优化设计. 应用化工. 2021(S1): 420-424+430 .  百度学术

百度学术

11. 王正旭,高德利. 高频电磁加热稠油储层温度分布及其影响因素分析. 石油钻探技术. 2020(01): 90-97 .  本站查看

本站查看

12. 宋志军,汪泓,张铭,张晨剑,张明波. 高温井下温压数据声传直读监测技术. 特种油气藏. 2020(04): 163-167 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: