Drilling Fluid Technology for Ultra-Deep Displacement Wells in Enping 21-4 Oilfield in the eastern South China Sea

-

摘要:

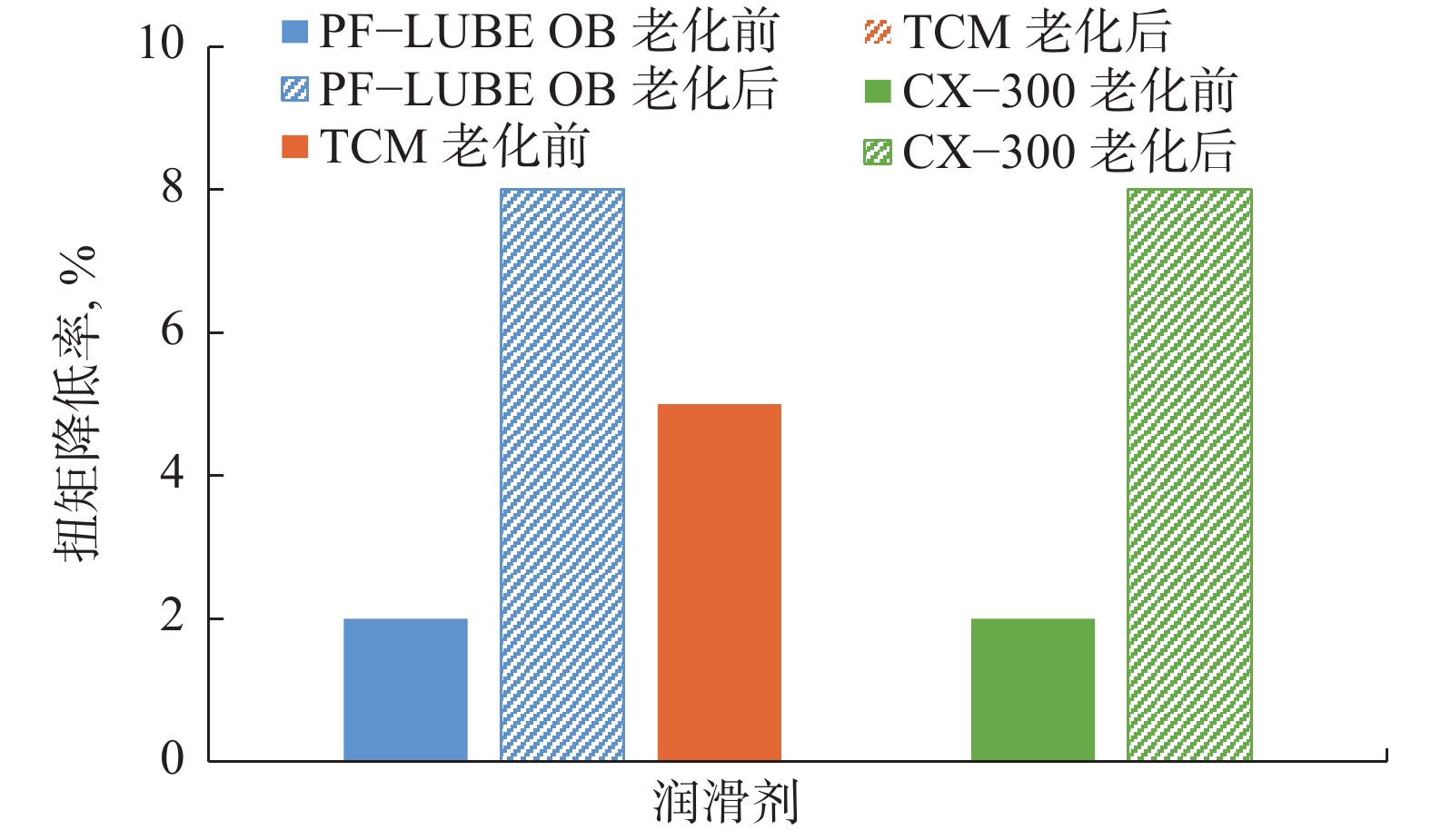

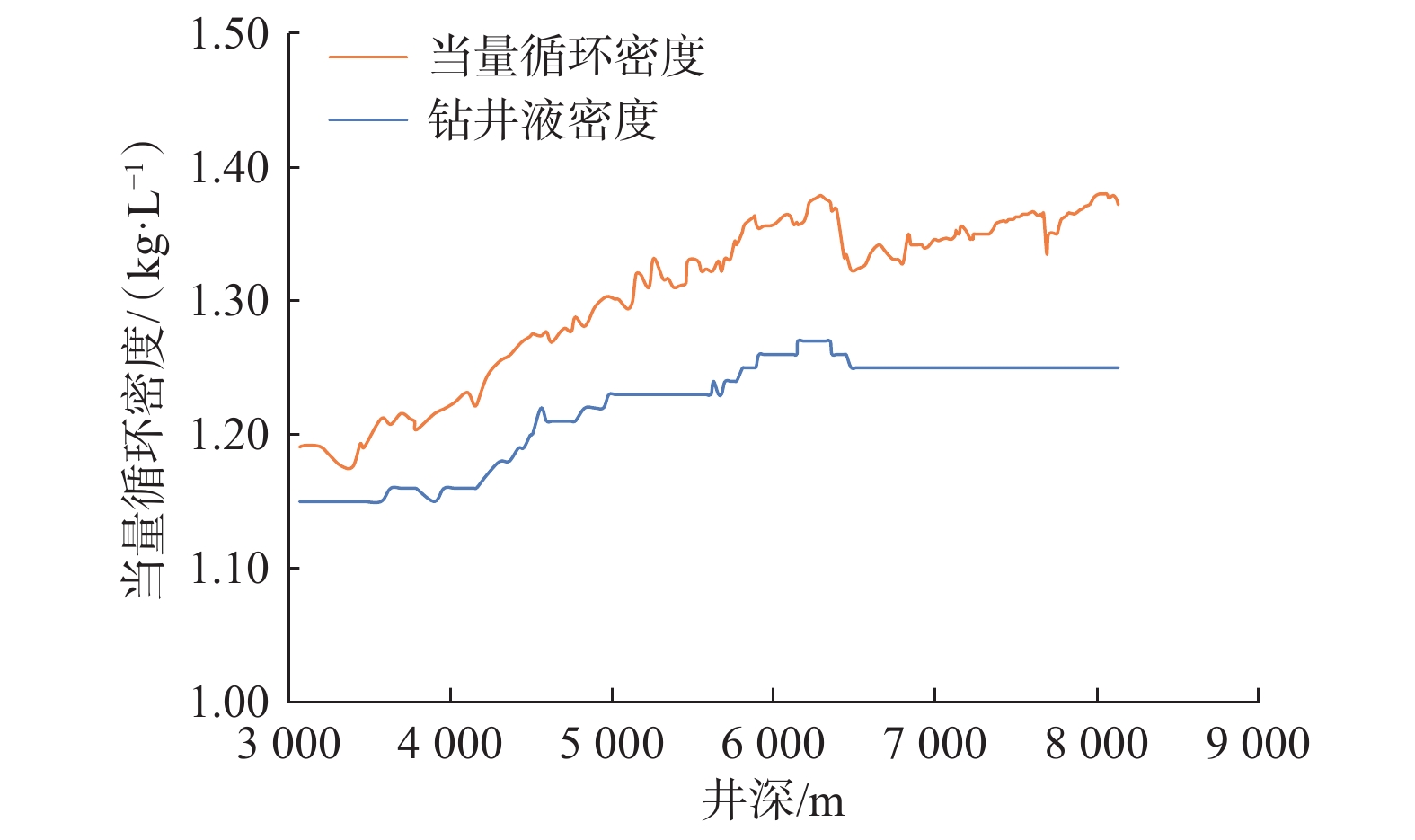

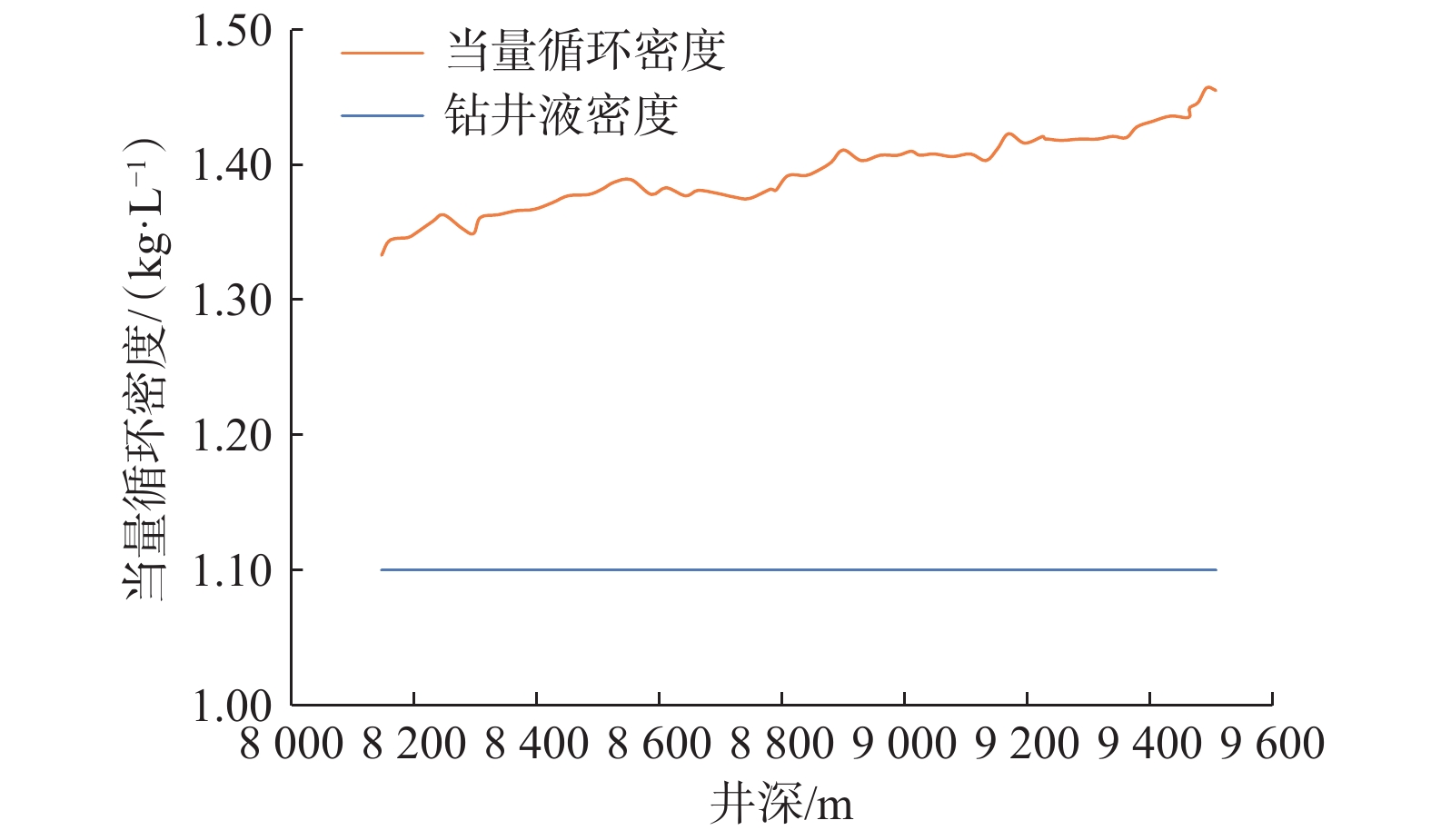

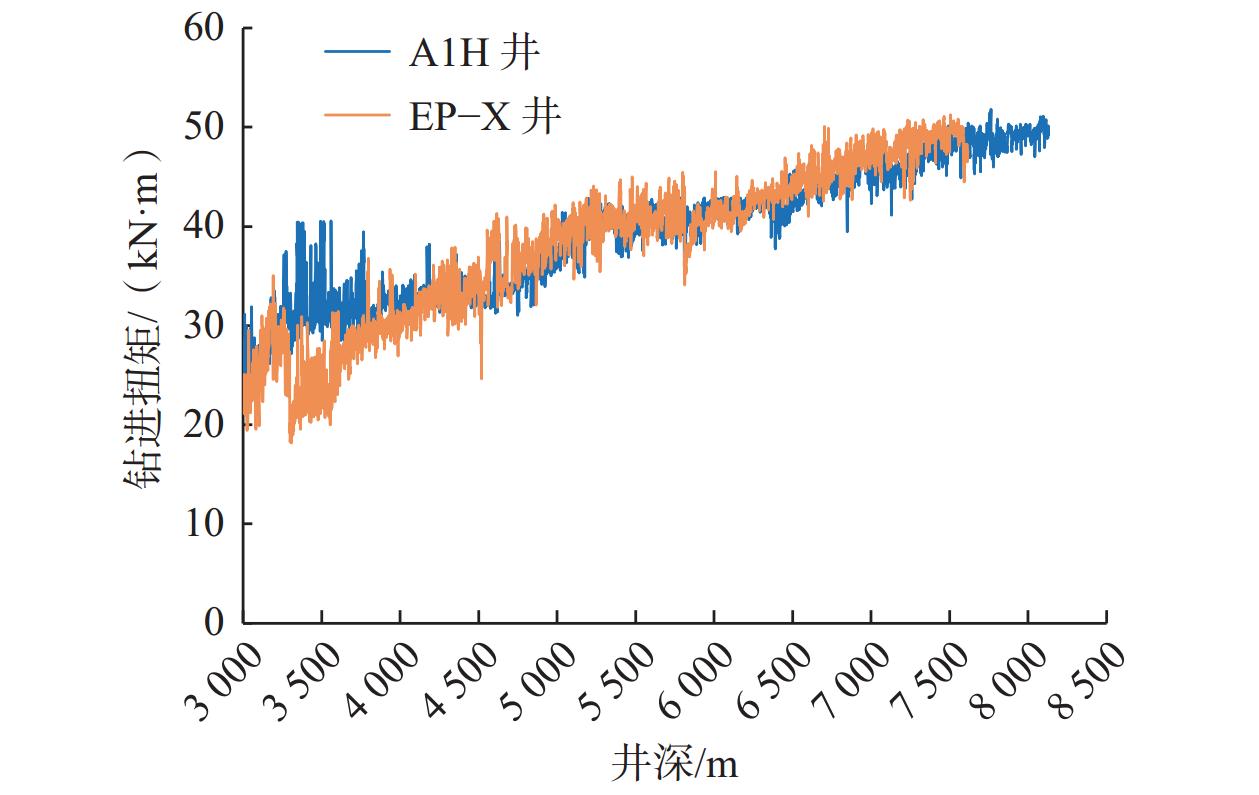

南海东部恩平21−4油田是典型的边际油田,在该油田超深大位移井钻井中存在井眼难以清洁、疏松砂岩承压能力低、钻遇多条断层、摩阻扭矩高、下套管易遇阻等风险挑战。为解决该油田钻井中存在的问题,选择BIODRILL S合成基钻井液并优选了合成基液、降滤失剂、流性调节剂、润滑剂,优化了乳化剂加量,调整了BIODRILL S合成基钻井液配方。室内性能评价结果表明,该配方的钻井液能够保持良好、稳定的流变性能,具有较高的低剪切速率,抑制性强,封堵性、抗污染性、润滑性能优异,高温高压滤失量2.4 mL,极压润滑系数0.03~0.06,满足了恩平21−4油田超深大位移井钻井要求。按该配方配制的BIODRILL S合成基钻井液及研究的关键配套技术在南海东部超深大位移井A1H井、EP−X井进行了现场试验,试验表明:BIODRILL S合成基钻井液性能稳定,具有较好的携岩能力,润滑性能优异,ϕ311.1 mm井眼钻进期间摩阻系数为0.17~0.21,下入ϕ244.5 mm套管时裸眼摩阻系数为0.40~0.45,钻井过程顺利。该钻井液技术不但有效解决了南海东部超深大位移井的钻井难点,还为该海域万米级大位移井的安全钻井提供了技术手段。

Abstract:Enping 21-4 oilfield in the eastern part of the South China Sea is a typical marginal oilfield. The reservoir is shallow in depth, with large unconsolidated sandstone formations and wide distribution of sandstone particle size. During drilling, there are risks and challenges such as clean hole, low pressure bearing capacity of unconsolidated sandstone and easy leakage, drilling multiple faults, large friction and torque, and casing resistance. According to the formation characteristics and technical challenges of this oilfield, the BIODRILL S synthetic base drilling fluid system was optimized. The system has good rheology, high low shear rate, excellent inhibition, sealing property, anti-pollution and excellent lubricity. The high temperature and high pressure filtration loss is 2.4 mL, and the extreme pressure lubrication coefficient is 0.03~0.06. Well A1H in Enping 21-4 Oilfield is the first self-designed and implemented ultra-deep extended reach well in China. BIODRILL S system was applied for the first time in ultra-deep extended reach well in eastern South China Sea. The results show that: The system has stable performance and the reading of low shear rate ϕ6 stays above 12, so it has good rock carrying capability. Excellent lubrication performance, the friction coefficient of ϕ311.1 mm hole drilling is 0.17~0.21, the friction coefficient of ϕ244.5 mm casing open hole is 0.40~0.45, the drilling process is smooth. The successful application of this system has a guiding significance for the popularization and application of drilling fluid technology in shallow ultra-deep extended reach wells.

-

-

表 1 几种不同基液的性能指标

Table 1 Performance comparison of different base fluids

基液 运动黏度

(40 ℃)/(mPa·s)密度(20 ℃)/

(kg·L−1)闪点

(开口)/℃芳烃含量,% BIO−OIL 2.40 0.780 93 0.050 5#白油 3.94 0.819 130 0.170 3#白油 3.38 0.810 124 0.152 表 2 主、副乳化剂和润湿剂的基本性能

Table 2 Basic properties of emulsifiers and wetting agents

名称 密度(常温)/(kg·L−1) 乳化率,% HLB值 PF−FSEMUL 0.91 95 1~4 PF−FSCOAT 0.95 7~9 PF−FSWET 1.05 90 5~7 表 3 不同乳化剂和润滑剂配比下的破乳电压

Table 3 Emulsifier ratio experiment

加量,% 破乳电压/V 主乳化剂 辅乳化剂 润湿剂 1.0 1.0 1.5 520 1.0 1.5 1.5 550 1.5 1.0 1.5 458 1.5 1.5 1.5 468 1.5 2.0 1.5 495 表 4 不同加量PF−MOHFR对基浆滤失量和破乳电压的影响

Table 4 Effects of different dosage of PF−MOHFR on filtration loss and electrical stability

加量,% 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)高温高压

滤失量/mL破乳电压/V 0 7.5 7 8.4 465 1.5 9.0 8 6.4 525 2.0 9.5 8 4.4 535 2.5 8.5 7 4.2 636 3.0 9.0 7 4.0 658 表 5 加入不同流性调节剂合成基钻井液基浆的流变性

Table 5 Comparative evaluation of the performance of different flow modifiers

钻井液体系 试验条件 表观黏度/(mPa·s) 塑性黏度/(mPa·s) 动切力/Pa ϕ6读数 破乳电压/V 沉降因子 基浆+

1.0%PF−HIVIS老化前 21.5 13 8.5 10 637 老化后 19.0 12 7.0 7 728 0.529 基浆+

1.0%PF−HIRHEO-A老化前 24.5 14 10.5 14 888 老化后 21.5 13 8.5 11 1163 0.522 基浆+

1.0%PF−FSVIS老化前 28.5 12 16.5 15 1210 老化后 23.5 13 10.5 13 1420 0.517 注:钻井液密度为1.25 kg/L。 表 6 合成基钻井液和油基钻井液的常规性能

Table 6 Comparison of conventional properties of different drilling fluid systems

钻井液类型 试验条件 表观黏度/(mPa·s) 塑性黏度/(mPa·s) 动切力/Pa ϕ6读数 破乳电压/V 高温高压滤失量/mL 1# 老化前 35.0 21 14.0 21 925 老化后 27.0 17 10.0 12 1127 2.4 2# 老化前 27.5 18 9.5 15 963 老化后 29.0 20 9.0 10 1051 2.8 注:1#为BIODRILL S合成基钻井液,2#为油基钻井液,密度均为1.25 kg/L。 表 7 不同温度下BIODRILL S合成基钻井液的流变性能

Table 7 Performance evaluation under different temperature conditions

试验条件 温度/℃ 表观黏度/(mPa·s) 塑性黏度/(mPa·s) 动切力/Pa 静切力/Pa ϕ6读数 破乳电压/V 初切 终切 老化前 25 41.0 25 16.0 12 17 21 1 355 45 36.0 22 14.0 12 15 20 1 395 65 30.5 17 13.5 9 13 17 1 170 老化后 25 35.5 28 7.5 7 12 14 993 45 32.0 24 8.0 6 11 13 1 104 65 27.0 17 10.0 6 11 12 1 127 注:钻井液密度为1.25 kg/L。 表 8 BIODRILL S合成基钻井液与其他钻井液的岩屑回收率

Table 8 Evaluation of cuttings recovery of synthetic base drilling fluid and other systems

钻井液 一次回收率,% 二次回收率,% 清水 36.2 19.4 KCl聚合物钻井液 86.7 82.2 油基钻井液 97.6 95.4 BIODRILL S合成基钻井液 98.6 97.1 注:钻井液密度为1.25 kg/L。 表 9 BIODRILL S合成基钻井液与其他钻井液的润滑性

Table 9 Lubrication performance evaluation of synthetic base drilling fluid and other systems

钻井液体系 极压润滑系数 泥饼黏附系数 KCl聚合物钻井液 0.13~0.17 0.149 油基钻井液 0.06~0.08 0.058 BIODRILL S合成基钻井液 0.03~0.06 0.052 注:钻井液密度为1.25 kg/L。 表 10 BIODRILL S合成基钻井液抗污染性能评价结果

Table 10 Pollution resistance of synthetic base drilling fluid system

污染物 加量,% 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

Paϕ6

读数破乳

电压/V27 17 10 12 1 127 海水 5 28 18 10 12 1 146 10 34 20 14 14 994 15 38 22 16 16 887 钻屑 5 29 18 11 12 1 015 10 33 19 13 14 1 165 15 35 20 15 15 1 080 注:钻井液密度为1.25 kg/L。 表 11 BIODRILL S合成基钻井液封堵性能评价结果

Table 11 Sealing performance of synthetic base drilling fluid system

钻井液体系 瞬时滤失量/mL PPT滤失量/mL 基液 0.8 4.8 基液+2.0%PF−MOSHIELD 0.2 0.8 注:基液为未加入复合封堵剂的BIODRILL S合成基钻井液,密度为1.25 kg/L。 表 12 A1H井ϕ311.1 mm井段钻井液的性能

Table 12 Performance of drilling fluid in Well A1H ϕ311.1 mm

井深/m 密度/

(kg·L−1)漏斗黏度/s ϕ6/ϕ3读数 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/Pa 静切力/Pa 破乳电压/V 油水比 高温高压

滤失量/mL初切 终切 3193 1.15 62 9/8 38.0 30.0 8.0 6.0 9.0 575 75/25 2.8 3960 1.16 60 10/8 38.5 31.0 7.5 7.5 9.0 600 75/25 2.4 4507 1.20 63 11/9 42.0 35.0 7.0 9.0 12.0 721 77/23 2.4 5730 1.24 58 13/12 38.5 29.0 9.5 10.0 14.0 1 050 79/21 2.4 6950 1.25 60 13/12 38.0 29.0 9.0 10.0 14.0 1 000 81/19 2.8 7659 1.25 64 14/13 45.0 34.0 11.0 9.0 12.0 1 038 81/19 2.6 8131 1.25 65 14/13 44.5 34.0 10.5 9.0 14.0 1 030 82/18 2.6 表 13 A1H井ϕ215.9 mm井段钻井液的性能

Table 13 Performance of drilling fluid in Well A1H ϕ215.9 mm

井深/m 密度/

(kg·L−1)漏斗黏度/s ϕ6/ϕ3读数 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

Pa静切力/Pa 破乳电压/

V油水比 高温高压滤失量/mL 初切 终切 8189 1.10 57 9/8 23.0 16.0 7.0 5 9 415 80/20 3.0 8485 1.10 53 10/9 24.5 17.0 7.5 6 10 410 80/20 3.0 8723 1.10 54 9/8 25.5 18.0 7.5 5 9 415 80/20 2.8 9011 1.10 55 9/8 27.0 20.0 7.0 6 10 420 80/20 2.8 9229 1.10 56 9/8 27.5 20.0 7.5 5 9 450 80/20 2.8 9508 1.10 57 9/8 30.0 21.0 9.0 6 10 450 80/20 2.8 -

[1] 汪海阁,黄洪春,毕文欣,等. 深井超深井油气钻井技术进展与展望[J]. 天然气工业,2021,41(8):163–177. WANG Haige, HUANG Hongchun, BI Wenxin, et al. Deep and ultra-deep oil/gas well drilling technologies: Progress and prospect[J]. Natural Gas Industry, 2021, 41(8): 163–177.

[2] 陈宗琦,刘湘华,白彬珍,等. 顺北油气田特深井钻井完井技术进展与发展思考[J]. 石油钻探技术,2022,50(4):1–10. CHEN Zongqi, LIU Xianghua, BAI Binzhen, et al. Technical progress and development consideration of drilling and completion engineering for ultra-deep wells in the Shunbei Oil & Gas Field[J]. Petroleum Drilling Techniques, 2022, 50(4): 1–10.

[3] 汪海阁,黄洪春,纪国栋,等. 中国石油深井、超深井和水平井钻完井技术进展与挑战[J]. 中国石油勘探,2023,28(3):1–11. WANG Haige, HUANG Hongchun, JI Guodong, et al. Progress and challenges of drilling and completion technologies for deep, ultra-deep and horizontal wells of CNPC[J]. China Petroleum Exploration, 2023, 28(3): 1–11.

[4] 苏义脑,路保平,刘岩生,等. 中国陆上深井超深井钻完井技术现状及攻关建议[J]. 石油钻采工艺,2020,42(5):527–542. SU Yinao, LU Baoping, LIU Yansheng, et al. Status and research suggestions on the drilling and completion technologies for onshore deep and ultra deep wells in China[J]. Oil Drilling & Production Technology, 2020, 42(5): 527–542.

[5] 谢彬强,邱正松,黄维安,等. 大位移井钻井液关键技术问题[J]. 钻井液与完井液,2012,29(2):76–82. XIE Binqiang, QIU Zhengsong, HUANG Weian, et al. Summary on key technical issues of drilling fluid for extended reach well[J]. Drilling Fluid & Completion Fluid, 2012, 29(2): 76–82.

[6] 蔡利山,林永学,王文立. 大位移井钻井液技术综述[J]. 钻井液与完井液,2010,27(3):1–13. CAI Lishan, LIN Yongxue, WANG Wenli. Review of the drilling fluids for extended reach well[J]. Drilling Fluid & Completion Fluid, 2010, 27(3): 1–13.

[7] 万绪新,张海青,沈丽,等. 合成基钻井液技术研究与应用[J]. 钻井液与完井液,2014,31(4):26–29. WAN Xuxin, ZHANG Haiqing, SHEN Li, et al. Study and application of synthetic base drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2014, 31(4): 26–29.

[8] 史赫,蒋官澄,王国帅,等. 恒流变合成基钻井液关键机理研究[J]. 钻井液与完井液,2020,37(1):31–37. SHI He, JIANG Guancheng, WANG Guoshuai, et al. Study on key mechanisms of constant rheology synthetic base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2020, 37(1): 31–37.

[9] 蒋官澄,黄胜铭,侯博,等. 增效型无土相仿生油基钻井液技术的研究与应用[J]. 钻采工艺,2024,47(2):93–103. JIANG Guancheng, HUANG Shengming, HOU Bo, et al. Research and application of enhanced soil-free phase bionic oil-based drilling fluid technology[J]. Drilling & Production Technology, 2024, 47(2): 93–103.

[10] 赵春花,罗健生,夏小春,等. 高性能合成基钻井液体系的研制及性能研究[J]. 钻井液与完井液,2018,35(3):25–31. ZHAO Chunhua, LUO Jiansheng, XIA Xiaochun, et al. Development of and study on a high performance synthetic base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2018, 35(3): 25–31.

[11] 罗健生,刘刚,李超,等. 深水FLAT-PRO合成基钻井液体系研究及应用[J]. 中国海上油气,2017,29(3):61–66. LUO Jiansheng, LIU Gang, LI Chao, et al. Research and application of FLAT-PRO synthetic based drilling fluid system in deep water[J]. China Offshore Oil and Gas, 2017, 29(3): 61–66.

[12] 耿铁. 深水恒流变合成基钻井液技术研究[D]. 青岛:中国石油大学(华东),2019. GENG Tie. Study on flat-rheology synthetic-based drilling fluid for deepwater drilling[D]. Qingdao: China University of Petroleum(East China), 2019.

[13] 马磊,袁学强,张万栋,等. 乌石17-2油田强封堵合成基钻井液体系[J]. 钻井液与完井液,2022,39(5):558–564. MA Lei, YUAN Xueqiang, ZHANG Wandong, et al. A synthetic based drilling fluid with strong plugging capacity for Block Wushi 17-2[J]. Drilling Fluid & Completion Fluid, 2022, 39(5): 558–564.

[14] 彭三兵,李斌,韩东东,等. BIODRILL S合成基钻井液在垦利区块首次应用[J]. 钻井液与完井液,2024,41(1):60–67. PENG Sanbing, LI Bin, HAN Dongdong, et al. First application of the synthetic-based drilling fluid BIODRILL S in Block Kenli of Bohai Oilfield[J]. Drilling Fluid & Completion Fluid, 2024, 41(1): 60–67.

[15] 赵景芳,刘雪婧,耿铁. BIO-OIL环保基液的研制与现场试验[J]. 石油钻探技术,2019,47(3):75–81. ZHAO Jingfang, LIU Xuejing, GENG Tie. Development and field test of a BIO-OIL environmental protection base fluid for synthetics-based drilling fluids[J]. Petroleum Drilling Techniques, 2019, 47(3): 75–81.

[16] 罗健生,莫成孝,刘自明,等. 气制油合成基钻井液研究与应用[J]. 钻井液与完井液,2009,26(2):7–11. LUO Jiansheng, MO Chengxiao, LIU Ziming, et al. The study and application of a GTL based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2009, 26(2): 7–11.

[17] 周定照,邢希金,蒋世全,等. 一种深水合成基钻井流体流变稳定剂的研发[J]. 石油钻采工艺,2015,37(1):83–86. ZHOU Dingzhao, XING Xijin, JIANG Shiquan, et al. Research and development of rheological stabilizer with deepwater synthetic base used indrilling fluid[J]. Oil Drilling & Production Technology, 2015, 37(1): 83–86.

[18] 李超,罗健生,刘刚,等. FLAT-PRO深水合成基钻井液恒流变作用机理研究[J]. 广东化工,2021,48(4):242–243. LI Chao, LUO Jiansheng, LIU Gang, et al. Study on the flat-rheological mechanism of FLAT-PRO flat-rheology synthetic-based drilling fluid system in deepwater[J]. Guangdong Chemical Industry, 2021, 48(4): 242–243.

[19] 陈一鸣,谢明英,闫正和,等. 珠江口盆地恩平凹陷海相高泥质砂岩储层特征及主控因素[J]. 石油地质与工程,2022,36(1):14–19. CHEN Yiming, XIE Mingying, YAN Zhenghe, et al. Reservoir characteristics and main controlling factors of marine high argillaceous sandstone in Enping sag of Pearl River Mouth basin[J]. Petroleum Geology and Engineering, 2022, 36(1): 14–19.

[20] 李晶晶,马积贺. 浅层大位移井表层钻井的关键技术与应用[J]. 化工管理,2024(5):87–90. LI Jingjing, MA Jihe. Key technologies and applications of surface drilling in shallow extended reach wells[J]. Chemical Enterprise Management, 2024(5): 87–90.

-

期刊类型引用(7)

1. 王忠良,徐文远,王文泽,梁梅,贺杰,钱晨,邹华宝. 结合伽马成像技术的三维地质建模在页岩油地质导向中的应用. 西安石油大学学报(自然科学版). 2024(02): 112-119 .  百度学术

百度学术

2. 曲博文,谭宝海,张凯,陈雪莲. 自适应声波测井换能器激励电路设计. 石油钻探技术. 2024(06): 141-147 .  本站查看

本站查看

3. 孙轶伦,潘磊,李海滨,王来智,周建新. 旋转导向近钻头随钻伽马数据成像处理技术. 石油地质与工程. 2022(01): 99-103+108 .  百度学术

百度学术

4. 刘卫彬,徐兴友,张君峰,陈珊,白静,刘畅,李耀华. 陆相页岩地层地质-工程一体化水平井精确钻探技术——以松辽盆地吉页油1HF井为例. 中国地质. 2022(06): 1808-1822 .  百度学术

百度学术

5. 马荣华,赵嵩. 基于果蝇算法的空间机械臂最优抑振轨迹规划方法. 机械设计与研究. 2022(06): 49-52 .  百度学术

百度学术

6. 李继博,钱德儒,郑奕挺,张卫,吴金平. 近钻头伽马高精度实时成像技术研究与应用. 石油钻探技术. 2021(03): 135-141 .  本站查看

本站查看

7. 李洪强,王瑞和. 近钻头伽马成像仪测量结果环境校正方法研究. 石油钻探技术. 2021(03): 142-150 .  本站查看

本站查看

其他类型引用(4)

下载:

下载: