The Improvement and Application of Fracturing Technology in the Nanchuan Shale Gas Field

-

摘要:

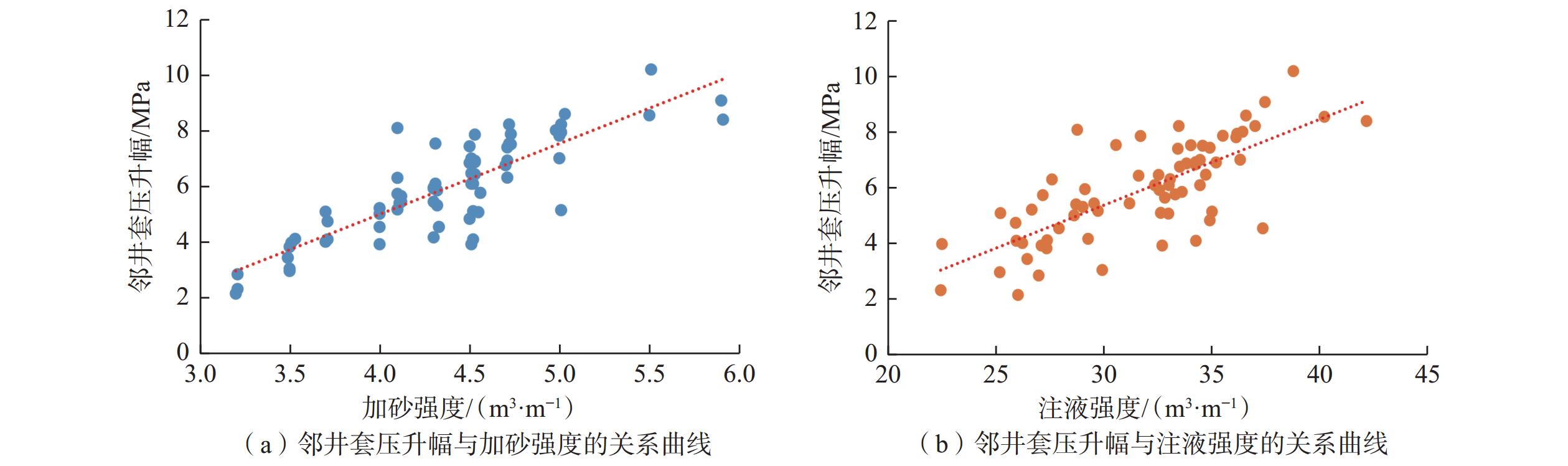

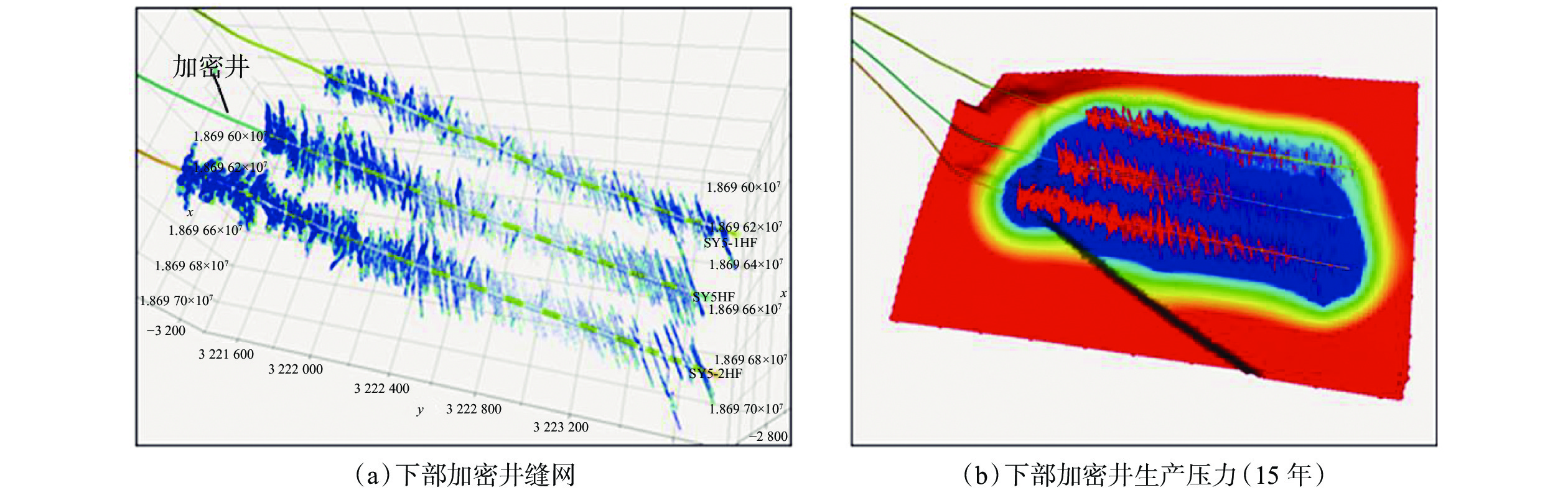

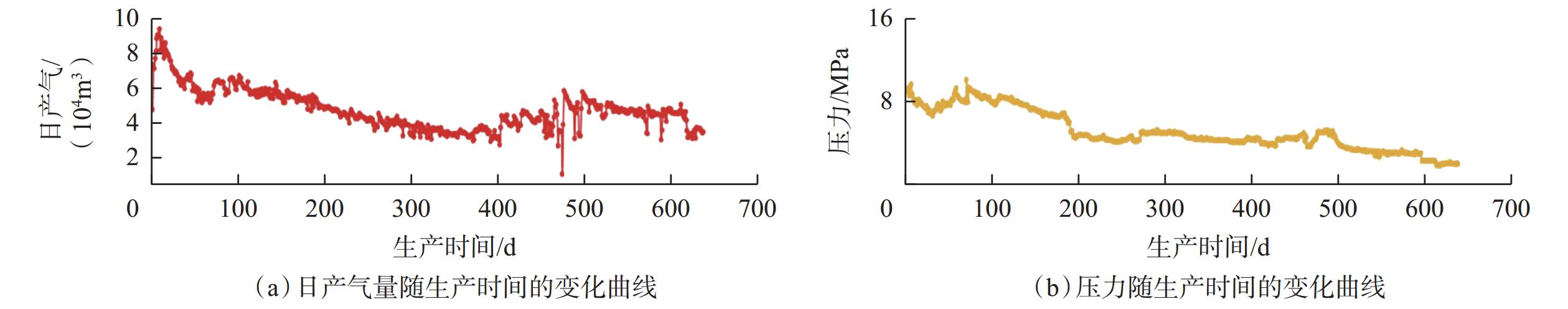

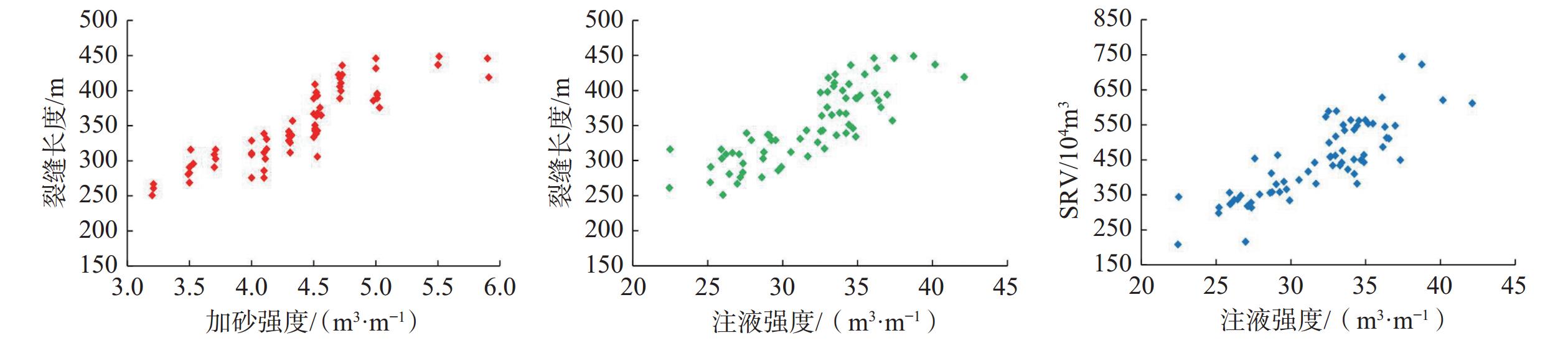

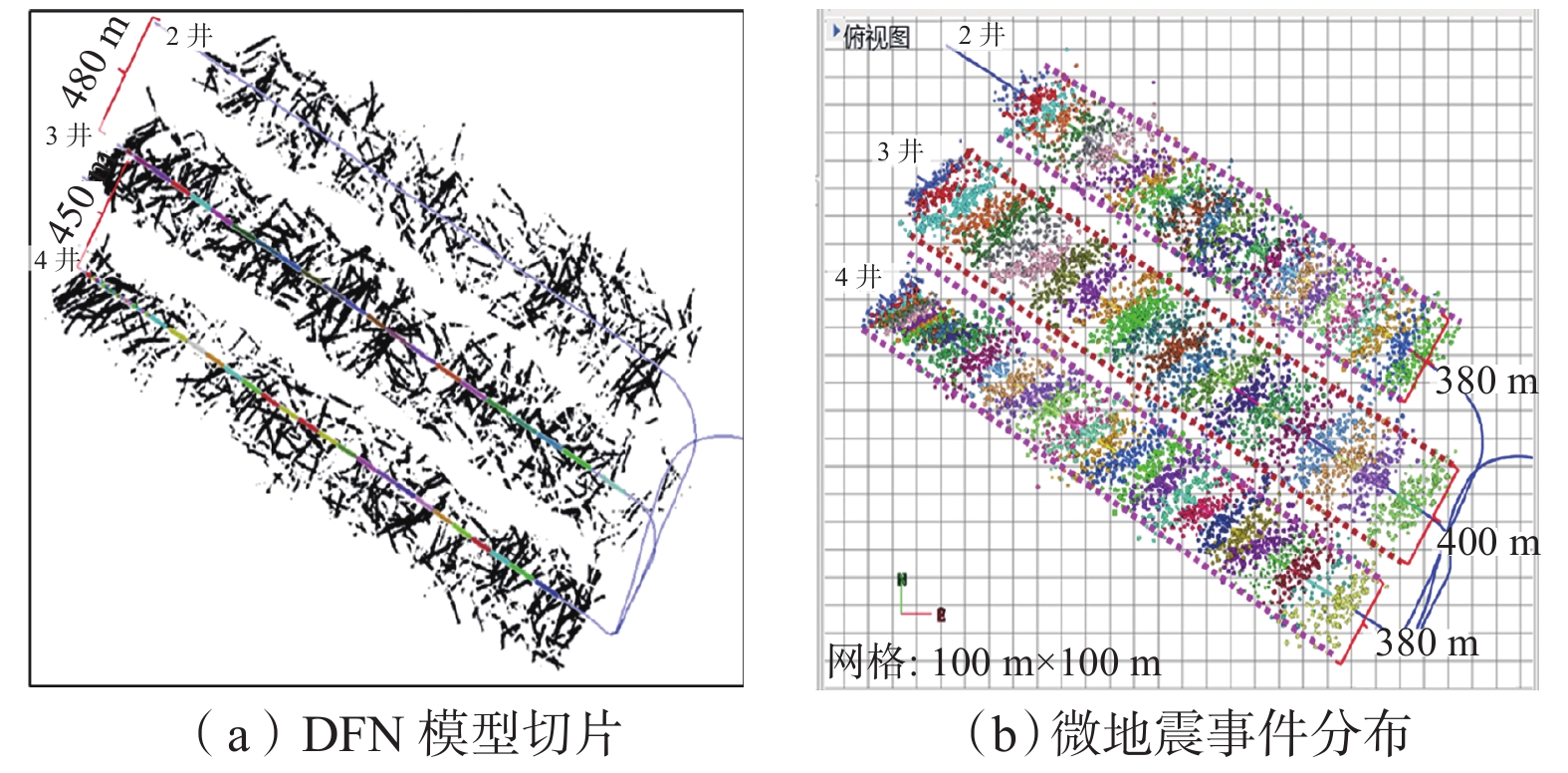

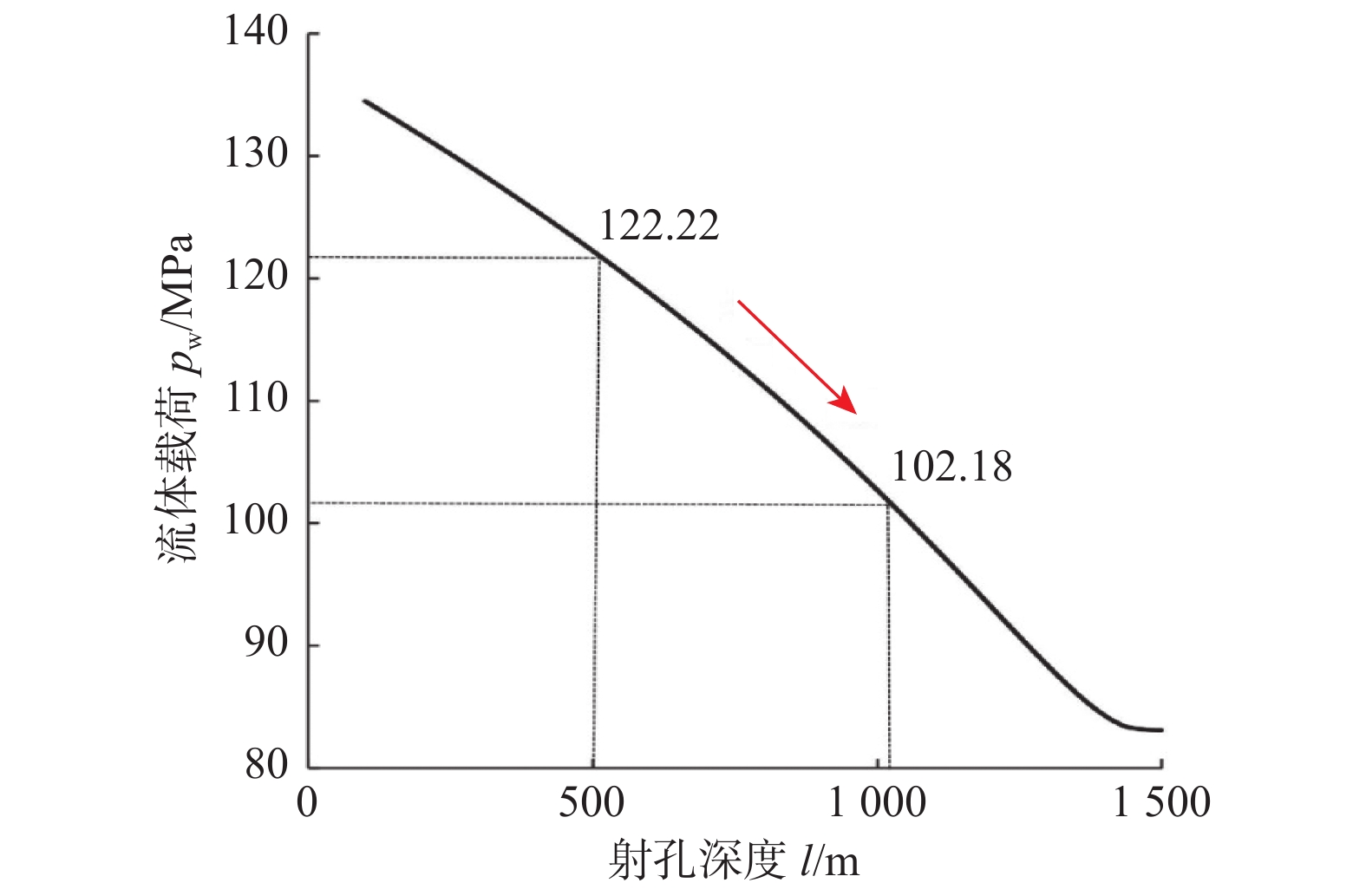

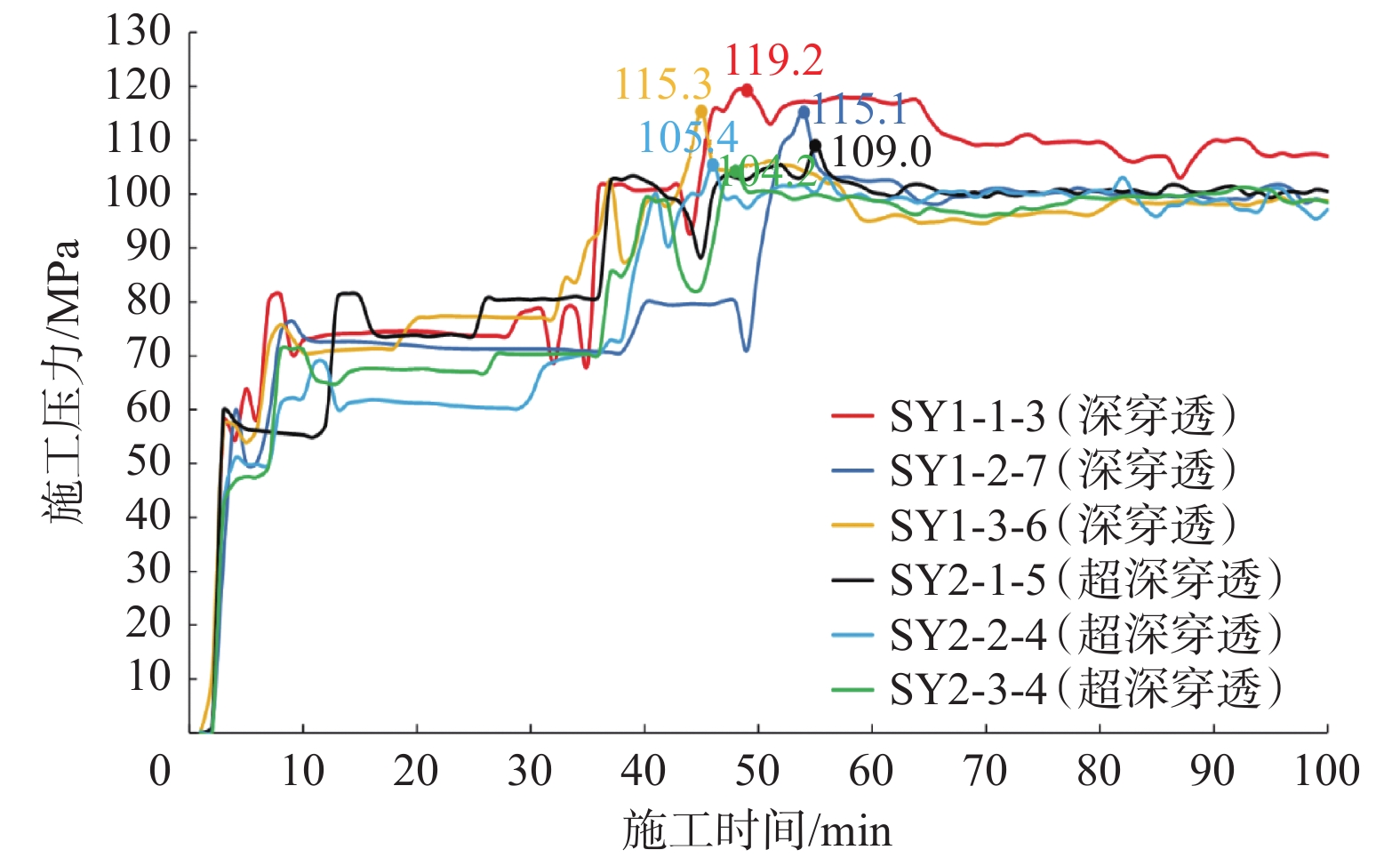

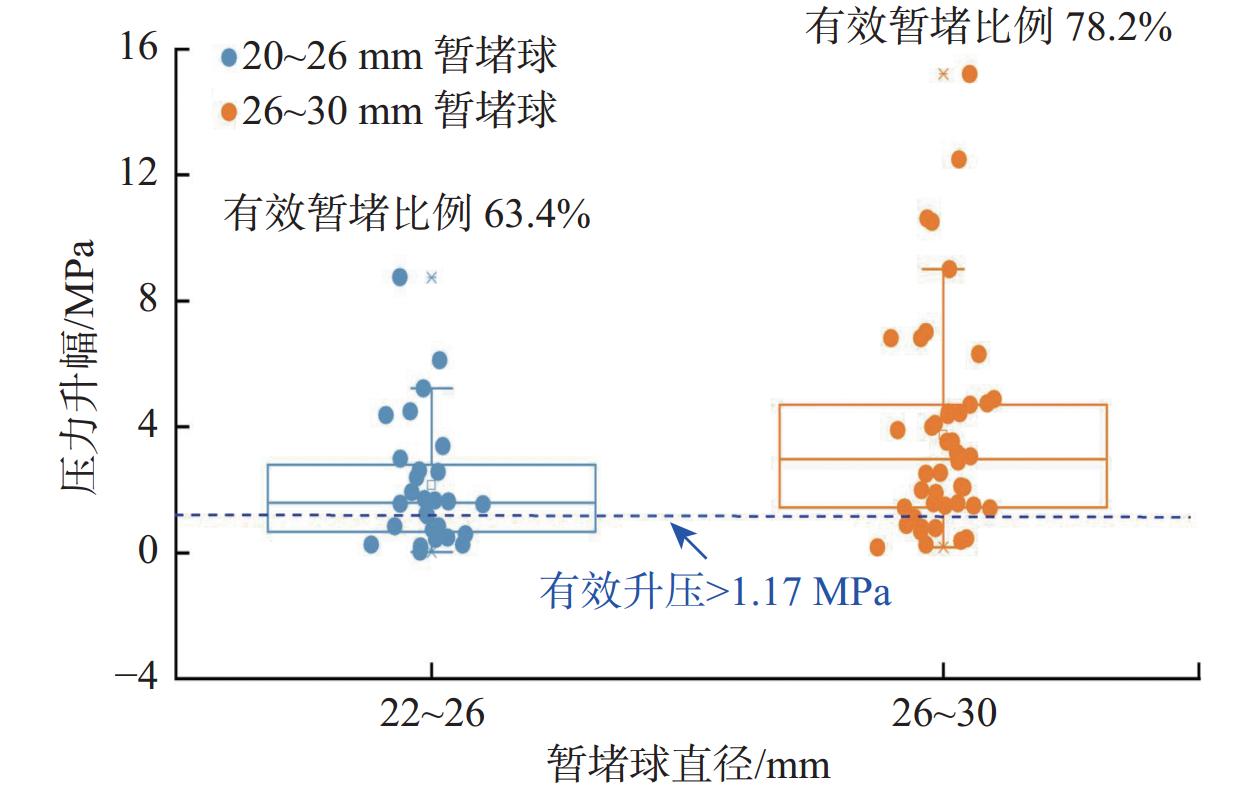

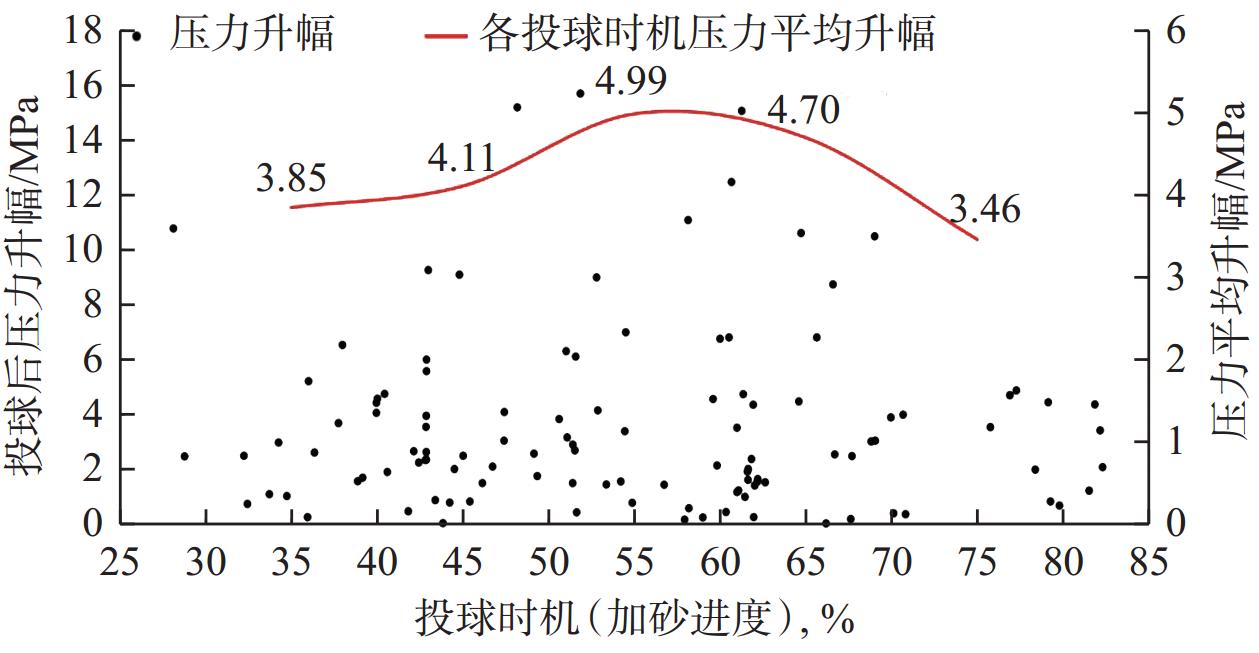

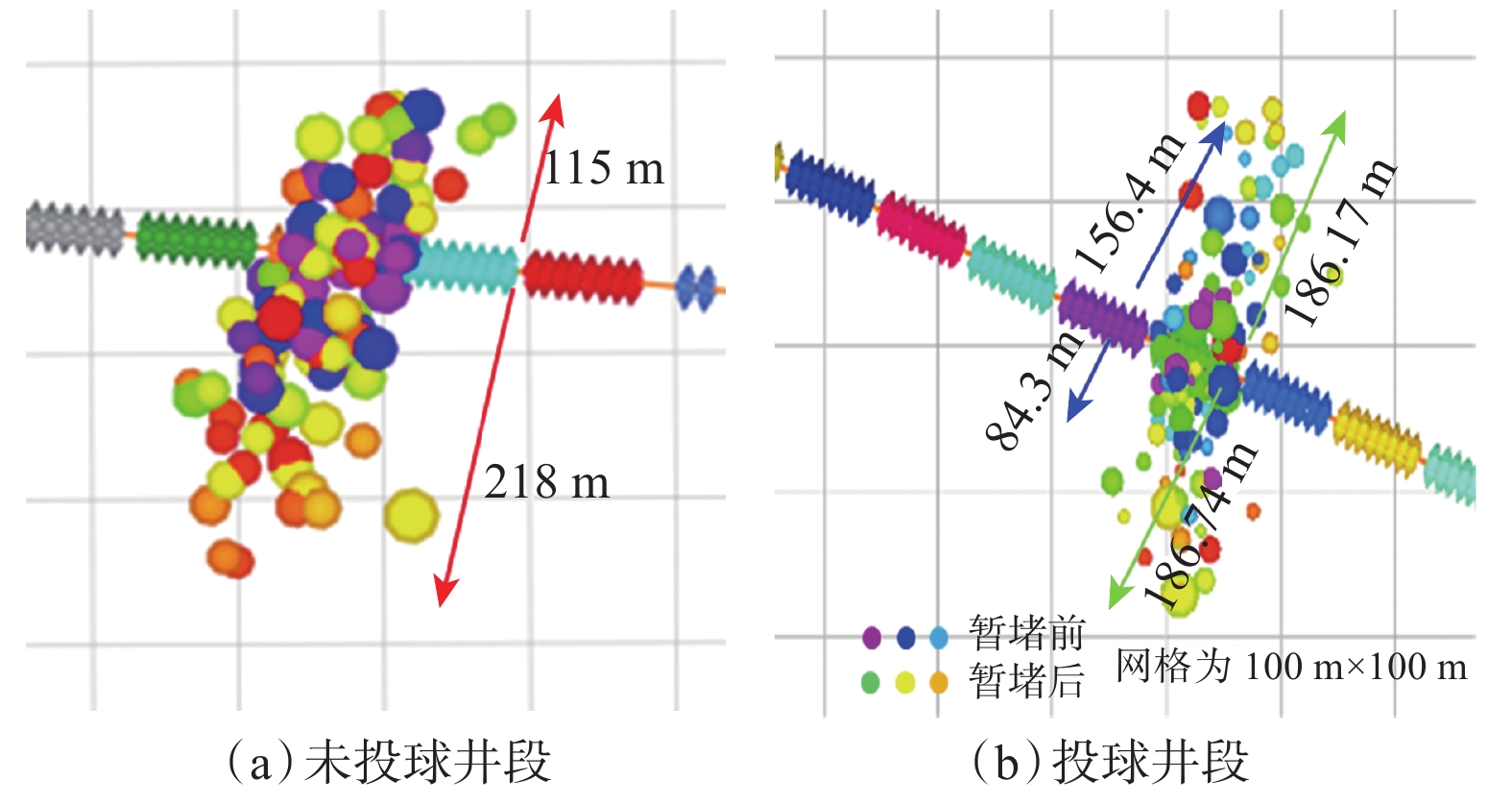

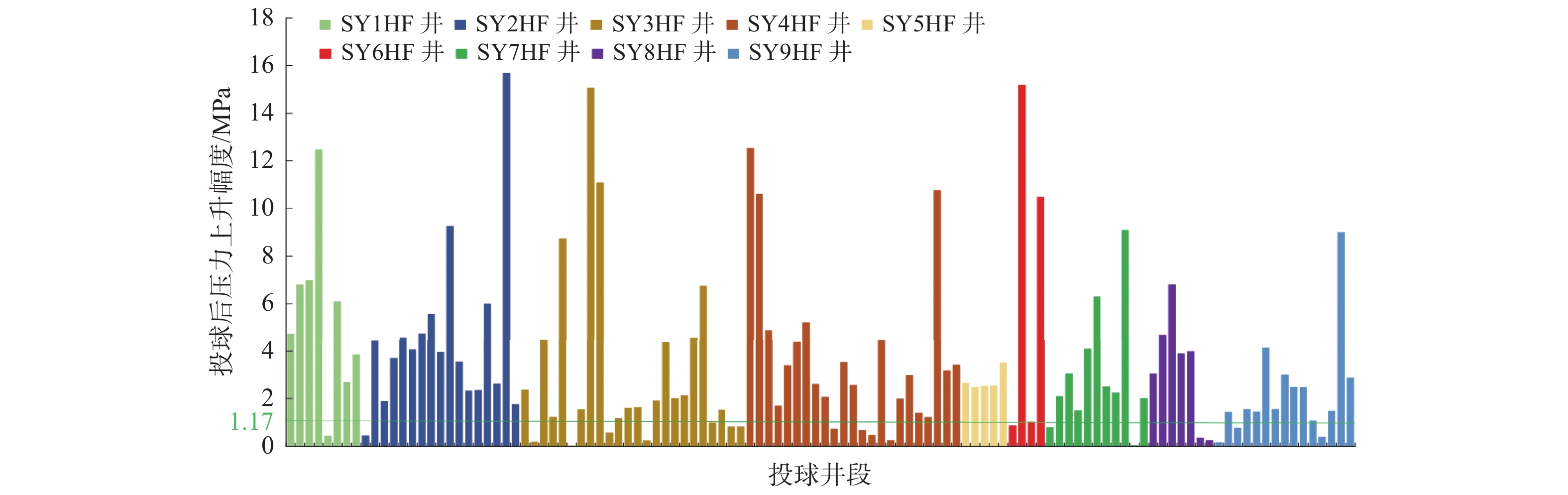

页岩储层具有低孔隙度和特低渗透性特征,必须进行大规模体积压裂改造以形成人工缝网。南川页岩气田开发已经形成相对完善的压裂工艺技术体系,但随着甜点储量规模化生产,亟需深入研究并进一步改进压裂工艺。从南川页岩气田不同井网储量动用、射孔方式、投球暂堵、加砂模式等方面提出了页岩气压裂工艺改进思路和方法,并通过现场应用效果评价了改进工艺的可行性。系统总结了压裂工艺改进措施:鉴于井网关系和开发目标的差异,对不同类型井组的压裂改造区域进行差异化控制;超深穿透射孔方式为深层高应力页岩储层压裂提供了重要的工艺基础,满足了电动压裂设备数量和压力等级的限制;借鉴重复压裂及加密井压裂工艺中的投球暂堵技术,优化了投球数量与时机,抑制了主裂缝过度延伸;精细化压裂,支撑剂体系趋于完善,形成了“初始小粒径远输前缘铺置+中段中粒径主流通道支撑+尾段大粒径缝口收尾”三级连续加砂模式。改进后的压裂工艺现场应用效果显著,在统计的现场投球暂堵中,封堵有效率79.8%,在超深穿透工艺下,为更多加砂和注液提供了压力窗口;提高了加砂强度和小粒径占比,显著提升了裂缝导流能力和支撑效果,压后日产气量从3.30×104 m3提高至8.46×104 m3。研究结果表明,通过综合应用差异化压裂设计、超深穿透射孔技术、优化投球暂堵以及精细化三级加砂模式,可显著提升南川页岩气田的压裂改造效果和经济效益,为南川页岩气田有效开发提供了技术保障。

Abstract:Due to the low porosity and extremely low permeability of shale reservoirs, they must undergo large-scale volume fracturing to create an artificial fracture network. The development of the Nanchuan Shale Gas Field has already formed a relatively mature fracturing technology system. However, with the large-scale production of sweet spot reserves, there is an urgent need for in-depth research and further improvement of fracturing technology. Improvement ideas and methods for shale gas technology were proposed for the Nanchuan Shale Gas Field. They involve the utilization of reserves in different well patterns, perforation methods, temporary plugging with ball injection, and sand addition modes. The feasibility of these improvements was evaluated through on-site application effect assessment. Fracturing technology process improvements were summarized systematically. In view of the difference in well pattern and development objectives, the fracturing modification area of different types of well groups was controlled differently. The application of an ultra-deep penetration perforation provided a crucial technological foundation for fracturing in deep and high-stress shale reservoirs, meeting limitations on the number of electric fracturing devices and pressure levels. Repeat fracturing and temporary plugging with ball injection during tight well fracturing resulted in the optimization of the quantity and timing of ball injection to suppress excessive extension of the main fracture. The fracturing process was refined, and the proppant system was improved, leading to a three-stage continuous sand addition mode featuring “long-distance transport placement of initial small particles at front edge + main flow channel support by medium particles in middle section + fracture closure by large particles in tail section.” The improved fracturing technology demonstrated significant on-site application effects. After statistically analyzing the on-site temporary plugging with ball injection, the effective plugging rate was 79.8%. The ultra-deep penetration technology provided a pressure window for more sand addition and fluid injection which increased the sand addition intensity and the proportion of small particles, the fracture conductivity and support effect were significantly enhanced. As a result, the daily production after fracturing increased from 3.30×104 m3 to 8.46×104 m3. It has demonstrated that the integrated application of differentiated fracturing design, ultra-deep penetration perforation technology, optimized temporary plugging with ball injection, and a refined three-stage sand addition mode can significantly enhance the fracturing stimulation effect and economic benefits of the Nanchuan Shale Gas Field. This provides strong technical support for the efficient development of the Nanchuan Shale Gas Field.

-

经过多年开发,渤海油田已进入注水开发阶段。截至2019年1月,注水井多达800余口,分层注水率约为96%,注水开发效果关系到油田的持续稳产、增产。但是,近些年随着注水井大幅度增加以及该油田对后期调配要求的不断提高,常规分层注水工艺(空心集成、同心分注和地面分注等)存在的问题逐渐暴露出来,如常规分层注水工艺测调作业占用井口时间长,影响平台其他作业;调配效率和合格率低;管柱不具备反洗井功能[1-7]。

为解决渤海油田分层注水井存在的问题,采用了自提升式反洗井分层注水工艺、智能分层注水工艺等[8-11],均取得了一定效果,但这些分层注水工艺的适用性、可靠性普遍较差。为此,笔者结合渤海油田注水井的地层条件、完井方式等,借鉴国内成熟的分层注水技术[12-16],研发了可反洗测调一体分层注水工艺。现场应用表明,该分层注水工艺在大幅度提高测调效率的基础上,可实现不动管柱反洗井,应用效果良好。

1. 常规分层注水工艺存在的问题

渤海油田应用的常规分层注水工艺主要有投捞式分注(空心集成、同心分注)和地面分注等[1-7],其中投捞式分层注水工艺是利用钢丝反复投捞井下水嘴进行分层调配,地面分层注水工艺是通过地面调节不同注入管汇的流量实现井下分层调配。这些常规分层注水工艺主要存在以下问题:

1)无反洗通道,无法实现不动管柱反洗井作业。海上油田由于受空间限制,生产水处理流程较短,停留时间短,注入水水质波动较大,长期注水容易导致井筒及近井地带堵塞。定期进行反洗井作业可以将井筒附近污染物及时冲洗至地面,既能减缓井筒及近井地带堵塞,降低注水压力,又可以防止污染物及地层出砂卡住注水管柱。但常规分层注水管柱多采用“定位密封+配水器+插入密封”的结构,尚不具备反洗井功能,无法满足海上日益迫切的不动管柱反洗井需求。

2)测调效率低,影响平台其他作业。常规投捞式分层注水工艺测调时,需要利用钢丝反复投捞水嘴,导致调配效率低,平均单井调配时间长达3~4 d;测调精度低,调配合格率仅有80%,而且测调作业时大量占用平台有限的空间和施工时间,影响了平台上其他作业。近些年,随着注水井数量增多和分层注水管理要求的不断提高,常规分层注水工艺已无法满足现场应用需求。

3)套管带压注水,不符合安全注水要求。地面分层注水工艺可以实现地面实时测调,无需井口作业,但该工艺采用的注水管柱结构复杂,需要套管带压注水,而长期带压注水容易对套管造成损伤。另外,该工艺最多只能实现3层注水,对于注水层位较多的井适应性差。

2. 可反洗测调一体分层注水工艺

2.1 工艺原理

针对常规分层注水工艺存在的问题,研发了可反洗测调一体分层注水工艺,主要通过入井电缆为测调仪供电,并传输数据、指令,其工艺原理如图1所示。

测调仪与配水器(水嘴内置)对接后,采用边测边调的方式进行流量测试与调配。通过地面仪器监测流量压力曲线,实时调节注水阀水嘴开度,无级调节,直至达到配注流量。工具一次下井即可完成所有层段测试和调配。

2.2 管柱结构

可反洗测调一体化管柱采用了分层防砂、分层注水一体化的设计理念,由外层的分层防砂管柱和内层的分层注水管柱组成,分层防砂管柱主要由顶部封隔器、隔离封隔器、筛管、盲管和油管锚组成,分层注水管柱主要由注水封隔器、测调一体配水器和反洗阀等组成(见图2)。分层防砂管柱和分层注水管柱分体设计,分层注水管柱可单独检换[5-7]。

2.3 工艺参数

可反洗测调一体分层注水工艺包括分层防砂管柱下入、分层防砂管柱验封、分层注水管柱下入、分层注水管柱验封和分层注水管柱测调等工艺过程。该工艺针对海上油田ϕ177.8 mm和ϕ244.5 mm套管射孔井研制,满足渤海油田多层、大排量注水的需求。具体的工艺参数为:流量<500 m3/d,井斜角≤60°,井温<140 ℃,工作压差<35 MPa,分层数<8层,调配合格率≥90%。

3. 反循环洗井工具及管柱设计

3.1 反循环洗井工具

反循环洗井工具的关键部件是防蠕动密闭自锁封隔器,其结构如图3所示,主要包括防蠕动机构、密闭自锁机构和解封机构。防蠕动机构是由第一胶筒、液缸和活塞构成独立的密闭压力系统,注水时,水流经上液孔推动液缸上移,挤压液压油,使第一胶筒膨胀坐封,第一胶筒承受管柱的蠕动力。密闭自锁机构的工作原理为:注水时,水流经下液孔进入,挤压第二胶筒膨胀坐封,同时液压力释放单向阀;停注后,单向阀自动关闭下液孔,将液压力密闭在第二胶筒内,第二胶筒始终处于坐封状态。解封机构:反洗井时,油套环空的压力液由反洗进液孔进入,打开下液压孔,密闭在第二胶筒内的液压力释放,第二胶筒解封。

3.2 反循环洗井管柱

注水时,防蠕动密闭自锁封隔器坐封,实现分层注水。反洗井时,通过油套环空加压,使防蠕动密闭自锁封隔器解封,洗井液进入防砂层段。进入防砂层段的洗井液,一部分进入筛管与套管环空,清洗筛网与炮眼;另一部分进入注水管柱与筛管环空,清洗配水器水嘴和管壁。最后,洗井液经洗井阀进入中心油管返至地面。反循环洗井管柱如图4所示。

4. 现场应用

可反洗测调一体分注工艺自2018年开始现场应用以来,已累计应用几十井次,取得了很好的应用效果。其中,10口注入困难的井进行了不动管柱反洗井作业,反洗井后各井的注水能力均得到了不同程度的提升,延长了酸化周期(平均可延长2个月);此外,完成了30井次的调配作业,平均单井调配工期仅需10 h,相较常规投捞式分层注水工艺2~3 d的调配工期,测调效率大幅提高。下面以A井为例具体介绍其应用情况。

渤海油田A井分6层注水,最大井斜角42.8°,部分注水层位因砂埋注不进水,决定采用“大修打捞+补射孔+分层防砂+分层注水”的方式恢复注水,后期“分层防砂+分层注水”部分采用可反洗测调一体化分层注水工艺。分层防砂管柱和分层注水管柱均顺利入井,分层防砂管柱和分层注水管柱验封均合格。分层注水初期,对A井进行了模拟测调。

4.1 测调作业

考虑A井恢复注水时间较短,地层注水还不稳定,故仅进行模拟测调,以验证测调工具的灵活性和可靠性。A井模拟测调结果见表1。

表 1 A井模拟测调结果Table 1. Simulation deployment results of Well A防砂层段 层位 配水器编号 配水器测调情况 第6防砂段 L50—L70 配6 将流量由490 m3/d调小到260 m3/d,再调大到480 m3/d,证明配水器测调正常 第5防砂段 L74—L80 配5 将流量由256 m3/d调小到188 m3/d,再调大到260 m3/d,证明配水器测调正常 第4防砂段 L82 配4 将流量由140 m3/d调小到60 m3/d,再调大到145 m3/d,证明配水器测调正常 第3防砂段 L84—L92 配3 转动配水器,调节流量不变,且电流由90 mA增大到118 mA,说明该层在此压力条件下不吸水,建议进行酸化处理 第2防砂段 L94—L96 配2 将流量由79 m3/d调小到45 m3/d,再调大到65 m3/d,证明配水器测调正常 第1防砂段 L100 配1 将流量由44 m3/d调小到15 m3/d,再调大到45 m3/d,证明配水器测调正常 现场作业中,6层模拟测调仅用时11 h,一体化配水器打开、关闭正常,大大提高了测调效率。

4.2 反洗井作业

由于A井注入水水质较差,注水3个月后地层吸水能力明显下降,判断井筒及近井地带出现了堵塞。为缓解地层堵塞问题,实施了反循环洗井作业,将井筒底部污染物携带至地面。

导通反洗井流程,环空注水排量16~25 m3/h,注水压力2.5~5.0 MPa,反洗井过程中控制注水排量,在保证地层无漏失或漏失较小的情况下,将反洗排量由小逐渐增大,待进出水水质一样时,停止反洗。洗井返出液的颜色如图5所示(从左向右按洗井作业时间的先后顺序排列)。

观察并分析图5可知,前期返出液较脏,含有大量的死油,静置后容器底部含有大量悬浮状泥质类物质;随着反洗水量增大,返出液逐渐变得清澈,说明反洗过程中携带出大量污染物。

该井于2018年9月17日后开始实施反洗作业,反洗作业前后的注水动态曲线如图6所示。

从图6可以看出,反洗后该井的日注水量由之前的不足800 m3提高到了950 m3左右,注水量增加明显,说明反洗井工艺起到了解堵增注作用。

5. 结 论

1)常规分层注水工艺不具备反洗井功能,同时测调效率低,无法解决渤海油田注水开发中因注入水水质普遍较差易堵塞井筒与近井地带以及测调作业大量占用平台有限空间、影响其他作业等问题。

2)通过优化注水管柱,研制不动管柱反洗井封隔器,同时配套测调一体工具,形成了渤海油田可反洗测调一体分层注水工艺。

3)现场应用表明,渤海油田可反洗测调一体分注工艺测调效率高,平均单井调配工期仅需10 h,同时反洗井取得良好的降压增注效果,工艺优势明显,有助于推动该油田高效注水开发。

-

表 1 层段矿物组成与力学参数

Table 1 Mineral composition and mechanical parameters of the rock layers

井段 埋深/m 层位 小层 矿物含量,% 弹性

模量/MPa泊松比 水平主应力/MPa 硅质 钙质 泥质 石英 碳酸盐 最小 最大 SY1−1−3 4 314 五峰组—龙马溪组 ③ 55.5 2.0 22.7 35.44 10.74 58.30 0.150 90.19 102.82 SY1−2−7 4 407 五峰组—龙马溪组 ③ 48.1 8.4 32.4 39.36 7.46 54.22 0.158 89.93 102.16 SY1−3−6 4 464 五峰组—龙马溪组 ③ 48.7 14.3 24.8 45.30 6.90 55.06 0.160 91.85 103.45 SY2−1−5 4 392 五峰组—龙马溪组 ③ 44.0 6.5 34.9 50.01 7.83 56.78 0.165 90.52 101.96 SY2−2−4 4 412 五峰组—龙马溪组 ③ 46.8 7.7 30.1 50.41 5.10 50.32 0.165 90.33 102.52 SY2−3−4 4 388 五峰组—龙马溪组 ③ 46.9 11.7 31.0 44.30 16.60 54.36 0.160 89.87 101.19 表 2 微地震监测数据

Table 2 Microseismic monitoring data

井号 压裂段 类型 微地震

事件数量M-SRV/

104 m3E-SRV/

104 m3SY2HF 1~6,8~10,16,18~22 非暂堵 112 297 168 7,11~15,17,23~32 暂堵 107 313 174 SY3HF 1~4 非暂堵 75 300 190 5~27 暂堵 101 422 280 SY4HF 1~3,5,7,11~15 非暂堵 139 377 203 4,6,8~10,16~22 暂堵 154 480 228 SY7HF 1~4,9~14,20,21,24~26 非暂堵 85 261 127 5~8,15~19,22,23 暂堵 94 296 143 表 3 部分应用井的压裂施工参数

Table 3 Fracturing parameters of some application wells

工艺 井号 类型 储层埋深/

m平均段长/

m射孔类型 暂堵类型 加砂强度/

(m3∙m−1)注液强度/

(m3∙m−1)小粒径

占比,%稳定测试产量/

(104m3∙d−1)常规 SY14−8HF 加密井 3 352 99 常规射孔 无暂堵 1.31 27.24 38 3.30 投球暂堵 SY14−6HF 加密井 3 363 105 常规射孔 投球暂堵 1.23 25.91 33 6.23 SY14−7HF 加密井 3 443 109 常规射孔 投球暂堵 1.17 23.94 33 6.30 深穿透+中等加砂+

小粒径高占比SY35−1HF 加密井 4 202 84 深穿透 无暂堵 2.05 20.14 76 8.20 SY35−2HF 加密井 4 071 79 深穿透 无暂堵 2.02 20.42 82 6.71 SY35−3HF 加密井 3 973 85 深穿透 无暂堵 2.04 20.44 74 8.46 SY35−4HF 加密井 3 834 87 深穿透 无暂堵 2.08 21.59 79 8.40 超深穿透+中等加砂+

小粒径高占比SY36−1HF 加密井 4 294 86 超深穿透 无暂堵 2.19 26.04 79 7.80 SY36−2HF 加密井 4 185 72 超深穿透 无暂堵 2.22 28.40 89 7.88 SY36−4HF 加密井 4 093 85 超深穿透 无暂堵 2.20 22.31 75 7.64 投球暂堵+高液强砂 SY4−1HF 扩边井 2 031 92 常规射孔 投球暂堵 4.51 33.12 15 9.76 SY4−3HF 扩边井 1 914 114 常规射孔 投球暂堵 4.02 35.06 34 9.30 SY4−4HF 扩边井 1 869 66 常规射孔 投球暂堵 3.93 31.91 35 8.60 -

[1] 聂海宽,党伟,张珂,等. 中国页岩气研究与发展20年:回顾与展望[J]. 天然气工业,2024,44(3):20–52. NIE Haikuan, DANG Wei, ZHANG Ke, et al. Two decades of shale gas research & development in China: review and prospects[J]. Natural Gas Industry, 2024, 44(3): 20–52.

[2] 邹才能,赵群,丛连铸,等. 中国页岩气开发进展、潜力及前景[J]. 天然气工业,2021,41(1):1–14. ZOU Caineng, ZHAO Qun, CONG Lianzhu, et al. Development progress, potential and prospect of shale gas in China[J]. Natural Gas Industry, 2021, 41(1): 1–14.

[3] 王光付,李凤霞,王海波,等. 四川盆地不同类型页岩气压裂难点和对策[J]. 石油与天然气地质,2023,44(6):1378–1392. doi: 10.11743/ogg20230604 WANG Guangfu, LI Fengxia, WANG Haibo, et al. Difficulties and countermeasures for fracturing of various shale gas reservoirs in the Sichuan Basin[J]. Oil & Gas Geology, 2023, 44(6): 1378–1392. doi: 10.11743/ogg20230604

[4] 易良平,杨长鑫,杨兆中,等. 天然裂缝带对深层页岩压裂裂缝扩展的影响规律[J]. 天然气工业,2022,42(10):84–97. doi: 10.3787/j.issn.1000-0976.2022.10.008 YI Liangping, YANG Changxin, YANG Zhaozhong, et al. Influence of natural fracture zones on the propagation of hydraulic fractures in deep shale[J]. Natural Gas Industry, 2022, 42(10): 84–97. doi: 10.3787/j.issn.1000-0976.2022.10.008

[5] 何希鹏,何贵松,高玉巧,等. 常压页岩气勘探开发关键技术进展及攻关方向[J]. 天然气工业,2023,43(6):1–14. HE Xipeng, HE Guisong, GAO Yuqiao, et al. Progress in and research direction of key technologies for normal-pressure shale gas exploration and development[J]. Natural Gas Industry, 2023, 43(6): 1–14.

[6] 姚红生,王伟,何希鹏,等. 南川复杂构造带常压页岩气地质工程一体化开发实践[J]. 油气藏评价与开发,2023,13(5):537–547. YAO Hongsheng, WANG Wei, HE Xipeng, et al. Development practices of geology-engineering integration in complex structural area of Nanchuan normal pressure shale gas field[J]. Petroleum Reservoir Evaluation and Development, 2023, 13(5): 537–547.

[7] 姚红生,房启龙,袁明进,等. 渝东南常压页岩气工程工艺技术进展及下一步攻关方向[J]. 石油实验地质,2023,45(6):1132–1142. doi: 10.11781/sysydz2023061132 YAO Hongsheng, FANG Qilong, YUAN Mingjin, et al. Progress of normal-pressure shale gas engineering technology in southeast Chongqing and the research direction of next steps[J]. Petroleum Geology and Experiment, 2023, 45(6): 1132–1142. doi: 10.11781/sysydz2023061132

[8] 倪锋,朱峰,孟庆利. 渝东南地区南川区块膝折构造模式解析[J]. 油气藏评价与开发,2024,14(3):373–381. NI Feng, ZHU Feng, MENG Qingli. Analysis of knee fold structure model in Nanchuan Block of southeastern Chongqing[J]. Petroleum Reservoir Evaluation and Development, 2024, 14(3): 373–381.

[9] 张莉娜,任建华,胡春锋. 常压页岩气立体开发特征及缝网干扰规律研究[J]. 石油钻探技术,2023,51(5):149–155. ZHANG Lina, REN Jianhua, HU Chunfeng. Three-dimensional development characteristics and fracture network interference of atmospheric shale gas reservoir[J]. Petroleum Drilling Techniques, 2023, 51(5): 149–155.

[10] 周博成,熊炜,赖建林,等. 武隆区块常压页岩气藏低成本压裂技术[J]. 石油钻探技术,2022,50(3):80–85. ZHOU Bocheng, XIONG Wei, LAI Jianlin, et al. Low-cost fracturing technology in normal-pressure shale gas reservoirs in Wulong Block[J]. Petroleum Drilling Techniques, 2022, 50(3): 80–85.

[11] 李龙,陈显举,彭安钰,等. 贵州正安地区常压页岩气压裂关键技术[J]. 钻探工程,2022,49(5):189–193. LI Long, CHEN Xianju, PENG Anyu, et al. Key technologies for hydraulic fracturing of normal pressure shale gas in the Zheng'an Area of Guizhou[J]. Drilling Engineering, 2022, 49(5): 189–193.

[12] 刘洪,廖如刚,李小斌,等. 页岩气 “井工厂” 不同压裂模式下裂缝复杂程度研究[J]. 天然气工业,2018,38(12):70–76. LIU Hong, LIAO Rugang, LI Xiaobin, et al. A comparative analysis on the fracture complexity in different fracking patterns of shale gas “well factory”[J]. Natural Gas Industry, 2018, 38(12): 70–76.

[13] 何希鹏,张培先,任建华,等. 渝东南南川地区东胜构造带常压页岩气勘探开发实践[J]. 石油实验地质,2023,45(6):1057–1066. HE Xipeng, ZHANG Peixian, REN Jianhua, et al. Exploration and development practice of normal pressure shale gas in Dongsheng Structural Belt, Nanchuan Area, southeast Chongqing[J]. Petroleum Geology and Experiment, 2023, 45(6): 1057–1066.

[14] 蒋恕,李园平,杜凤双,等. 提高页岩气藏压裂井射孔簇产气率的技术进展[J]. 油气藏评价与开发,2023,13(1):9–22. JIANG Shu, LI Yuanping, DU Fengshuang, et al. Recent advancement for improving gas production rate from perforated clusters in fractured shale gas reservoir[J]. Petroleum Reservoir Evaluation and Development, 2023, 13(1): 9–22.

[15] 郭建春,路千里,刘壮,等. “多尺度高密度”压裂技术理念与关键技术:以川西地区致密砂岩气为例[J]. 天然气工业,2023,43(2):67–76. GUO Jianchun, LU Qianli, LIU Zhuang, et al. Concept and key technology of “multi-scale high-density” fracturing technology: a case study of tight sandstone gas reservoirs in the western Sichuan Basin[J]. Natural Gas Industry, 2023, 43(2): 67–76.

[16] 刘善勇,尹彪,楼一珊,等. 粗糙裂缝内支撑剂运移与展布规律数值模拟[J]. 石油钻探技术,2024,52(4):104–109. LIU Shanyong, YIN Biao, LOU Yishan, et al. Numerical simulation of migration and placement law of proppants in rough fractures[J]. Petroleum Drilling Techniques, 2024, 52(4): 104–109.

[17] 唐堂,郭建春,翁定为,等. 基于PIV/PTV的平板裂缝支撑剂输送试验研究[J]. 石油钻探技术,2023,51(5):121–129. TANG Tang, GUO Jianchun, WENG Dingwei, et al. Experimental study of proppant transport in flat fracture based on PIV/PTV[J]. Petroleum Drilling Techniques, 2023, 51(5): 121–129.

[18] 刘建坤,蒋廷学,卞晓冰,等. 常压页岩气低成本高效压裂技术对策[J]. 钻井液与完井液,2020,37(3):377–383. LIU Jiankun, JIANG Tingxue, BIAN Xiaobing, et al. The countermeasure of low cost and high efficiency fracturing technology of normal pressure shale gas[J]. Drilling Fluid & Completion Fluid, 2020, 37(3): 377–383.

[19] TADA H, PARIS P C, IRWIN G R. The stress analysis of cracks handbook[M]. 3rd ed. New York: ASME Press, 2000.

[20] HSU Y C. The infinite sheet with two radial cracks from cylindrical hole under inclined tension or in-plane shear[J]. International Journal of Fracture, 1977, 13(6): 839–845. doi: 10.1007/BF00034326

[21] 唐世斌,刘向君,罗江,等. 水压诱发裂缝拉伸与剪切破裂的理论模型研究[J]. 岩石力学与工程学报,2017,36(9):2124–2135. TANG Shibin, LIU Xiangjun, LUO Jiang, et al. Theoretical model for tensile and shear crack initiation at the crack tip in rock subjected to hydraulic pressure[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(9): 2124–2135.

[22] 唐世斌,张恒. 基于最大周向拉应变断裂准则的岩石裂纹水力压裂研究[J]. 岩石力学与工程学报,2016,35(增刊1):2710–2719. TANG Shibin, ZHANG Heng. Hydraulic fracture prediction theory based on the maximum tangential strain criterion[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(supplement 1): 2710–2719.

[23] 刘明明,马收,刘立之,等. 页岩气水平井压裂施工中暂堵球封堵效果研究[J]. 钻采工艺,2020,43(6):44–48. LIU Mingming, MA Shou, LIU Lizhi, et al. Study on the effect of temporary plugging ball in fracturing of horizontal shale gas well[J]. Drilling & Production Technology, 2020, 43(6): 44–48.

[24] 郭建春,赵峰,詹立,等. 四川盆地页岩气储层暂堵转向压裂技术进展及发展建议[J]. 石油钻探技术,2023,51(4):170–183. doi: 10.11911/syztjs.2023039 GUO Jianchun, ZHAO Feng, ZHAN Li, et al. Recent advances and development suggestions of temporary plugging and diverting fracturing technology for shale gas reservoirs in the Sichuan Basin[J]. Petroleum Drilling Techniques, 2023, 51(4): 170–183. doi: 10.11911/syztjs.2023039

[25] 吕振虎,吕蓓,罗垚,等. 基于光纤监测的段内多簇暂堵方案优化[J]. 石油钻探技术,2024,52(1):114–121. LYU Zhenhu, LYU Bei, LUO Yao, et al. Optimization of in-stage multi-cluster temporary plugging scheme based on optical fiber monitoring[J]. Petroleum Drilling Techniques, 2024, 52(1): 114–121.

[26] 蒋廷学. 非常规油气藏新一代体积压裂技术的几个关键问题探讨[J]. 石油钻探技术,2023,51(4):184–191. doi: 10.11911/syztjs.2023023 JIANG Tingxue. Discussion on several key issues of the new-generation network fracturing technologies for unconventional reser-voirs[J]. Petroleum Drilling Techniques, 2023, 51(4): 184–191. doi: 10.11911/syztjs.2023023

[27] 吴峙颖,路保平,胡亚斐,等. 压裂多级裂缝内动态输砂物理模拟实验研究[J]. 石油钻探技术,2020,48(4):106–110. WU Shiying, LU Baoping, HU Yafei, et al. Experimental study on the physical simulation of dynamic sand transport in multi-stage fractures[J]. Petroleum Drilling Techniques, 2020, 48(4): 106–110.

[28] 任洪达,董景锋,高靓,等. 新疆油田玛湖砂岩储层自悬浮支撑剂现场试验[J]. 油气藏评价与开发,2023,13(4):513–518. REN Hongda, DONG Jingfeng, GAO Jing, et al. Field test of self-suspending proppant at Mahu sandstone reservoir in Xinjiang Oilfield[J]. Petroleum Reservoir Evaluation and Development, 2023, 13(4): 513–518.

[29] 郭建春,路千里,何佑伟. 页岩气压裂的几个关键问题与探索[J]. 天然气工业,2022,42(8):148–161. GUO Jianchun, LU Qianli, HE Youwei. Key issues and explorations in shale gas fracturing[J]. Natural Gas Industry, 2022, 42(8): 148–161.

[30] 曾波,冯宁鑫,姚志广,等. 深层页岩气储层水力压裂裂缝扩展影响机理[J]. 断块油气田,2024,31(2):246–256. ZENG Bo, FENG Ningxin, YAO Zhiguang, et al. Influence mechanism of hydraulic fracturing fracture propagation in deep shale gas reservoirs[J]. Fault-Block Oil & Gas Field, 2024, 31(2): 246–256.

[31] 杨兆中,袁健峰,张景强,等. 四川盆地海相页岩水平井压裂裂缝研究进展及认识[J]. 油气藏评价与开发,2024,14(4):600–609. YANG Zhaozhong, YUAN Jianfeng, ZHANG Jingqiang, et al. Research progress and understanding of fracturing fractures in horizontal wells of marine shale in Sichuan Basin[J]. Petroleum Reservoir Evaluation and Development, 2024, 14(4): 600–609.

-

期刊类型引用(10)

1. 胡晋军,韩广海,张海峰,史为纪. 北黄海太阳盆地复杂深井小间隙尾管固井技术. 石油钻探技术. 2023(01): 40-44 .  本站查看

本站查看

2. 李成,管志川,黄哲,袁晓琪,曹继飞,张伟强,孙健翔. 基于参数不确定性的井筒失效风险评价研究. 石油机械. 2023(08): 43-50 .  百度学术

百度学术

3. 丁士东,陆沛青,郭印同,李早元,卢运虎,周仕明. 复杂环境下水泥环全生命周期密封完整性研究进展与展望. 石油钻探技术. 2023(04): 104-113 .  本站查看

本站查看

4. 张超鹏,陈立超,张典坤,王扶静. 深层非常规油气固井材料发展现状及趋势浅析. 世界石油工业. 2023(06): 96-105 .  百度学术

百度学术

5. 冯瑞阁,李玮,孟仁洲,王俊杰. 星探1井韧性防窜水泥浆技术. 钻井液与完井液. 2023(05): 658-664 .  百度学术

百度学术

6. 杨燕,李路宽,朱宽亮,冯福平,刘圣源,韩旭. 稠油热采硅酸盐水泥抗高温技术研究进展. 科学技术与工程. 2022(01): 39-49 .  百度学术

百度学术

7. 何立成. 胜利油田沙河街组页岩油水平井固井技术. 石油钻探技术. 2022(02): 45-50 .  本站查看

本站查看

8. 郝海洋,刘俊君,何吉标,王建斌,彭博,张家瑞. 页岩气超长水平井预控水泥环封固失效水泥浆技术. 天然气勘探与开发. 2022(03): 108-115 .  百度学术

百度学术

9. 郭雪利,沈吉云,武刚,靳建洲,纪宏飞,徐明,刘慧婷,黄昭. 韧性材料对页岩气压裂井水泥环界面完整性影响. 表面技术. 2022(12): 232-242 .  百度学术

百度学术

10. 王丹净,李景魁. 石墨烯水泥基复合材料力学性能及增强机理研究. 新型建筑材料. 2021(04): 115-118 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: