Status and the Future Perspective of Drilling Engineering Technologies in Middle East Carbonate Reservoirs

-

摘要:

中国石油自进入中东地区以来在该地区5个国家获得14个项目,已钻井3 200余口,其中作业者项目1 100余口。中东地区碳酸盐岩油藏通常从上到下分布4~7套储层,井深及温度压力变化范围大,主要采用立体井网多井型组合丛式平台钻井。巨厚碳酸盐岩地层岩性及压力系统复杂,地层软硬交错,漏失通道复杂,同层漏垮矛盾突出,钻井过程中普遍存在漏失、垮塌阻卡频发等问题。为此,系统总结了十多年来中国石油及西方石油技术服务公司在该地区的钻井工程技术进展与实践成果,着重介绍了中东碳酸盐岩防漏堵漏技术、典型薄弱地层防塌技术及定向井钻井技术,分析了中国石油在该地区与西方公司在钻井工程技术方面存在的差距,并结合中东地区油田目前钻井存在的问题及未来开发面临的新形势与新要求,指出中东地区未来钻井工程将面临深部油藏、低渗透及超低渗透油藏、大平台钻井、分层规模注采和老井利用等方向的发展需求,为该地区未来钻井工程技术发展提供了参考。

Abstract:PetroChina has acquired 14 assets in five countries in the Middle East, with more than 3200 wells drilled, including more than 1100 wells drilled in the operator’s assets. Middle East carbonate reservoirs typically have 4–7 sets of reservoirs from the top to the bottom, and well depth, temperature, and pressure exhibit a dramatic variations. A cluster platform for drilling is usually adopted based on a three-dimensional well network and multi-well type combination. The lithology and pressure system of the thick carbonate formations are complex, with alternating soft and hard formations and complex lost circulation channels. The paradox of loss and wellbore collapse in the same zone is prominent, and lost circulation, wellbore collapse, and pipe sticking frequently occur while drilling. Therefore, the drilling engineering technology progress and practical achievements of PetroChina and western drilling service companies in this region over more than 10 years were systematically summarized, and the preventive measures for lost circulation in carbonate rocks as well as the remedies were introduced. Also introduced were Middle East-based typical weak formation collapse prevention technology, and directional well drilling technology. The gap between PetroChina and western companies in drilling in this region was analyzed. In addition, based on the current drilling problems and the new situation and requirements of future development of oilfields in the Middle East, it was pointed out that future drilling engineering in the Middle East will face the development needs of deep reservoirs, low and ultra-low permeability reservoirs, large pad drilling, intensified zonal injection and production, and the reentry of old wells. All provide a reference for the future development of drilling engineering technologies in the Middle East.

-

Keywords:

- carbonate rock /

- drilling engineering /

- technology status /

- trend of development /

- Middle East

-

碳酸盐岩破碎性地层天然裂缝、层理面和弱面发育,胶结性差,钻井过程中易发生井壁坍塌掉块,严重时会造成卡钻,导致钻井周期增长、钻井成本增加[1-3]。顺北油气田5号断裂带深层油气勘探开发时,遇到了超深碳酸盐岩破碎性地层井壁坍塌问题[4-5]。2018年以来,多口井因钻遇碳酸盐岩破碎性地层,出现了井壁坍塌掉块(掉块呈多边形,长度和宽度约2.0 cm,棱角磨圆)严重的情况,阻卡频繁,导致多次回填侧钻,情况最严重的5口井钻井周期共延长913 d,钻井成本增加1.3亿元,严重影响了顺北油气田的勘探开发速度。因此,分析顺北油气田超深碳酸盐岩破碎性地层井壁坍塌原因,并提出技术对策,对提高钻井速度、降低钻井成本具有重要现实意义。目前,国内外超深碳酸盐岩破碎性地层钻井防塌的案例较少,可借鉴的技术措施不多[6-8]。为此,笔者针对顺北油气田奥陶系碳酸盐岩破碎性地层井壁坍塌的问题,从地质构造特征、地层裂缝发育情况(破碎程度)和井壁岩块受力等方面分析了井壁坍塌的原因,根据井壁坍塌原因,借鉴国内外钻井液封堵防塌技术,优选并级配微米与亚微米级刚性、塑性封堵材料,使钻井液中的固相能封堵地层中所有尺度的裂缝,阻止压力传递,同时钻井液保持较高的密度,以支撑井壁,现场试验取得了良好的封堵防塌效果。

1. 碳酸盐岩破碎性地层井壁坍塌原因

1.1 地质构造特征

顺北油气田5号断裂带北段以挤压构造为主,挤压构造地层存在一个“中性面”,“中性面”以浅地层处于拉张状态,“中性面”以深地层处于挤压状态,如图1所示(图中,蓝色线条为井眼轨迹)。

由图1可知,“中性面”以深地层存在应力集中(最大水平主应力和最小水平主应力之差大),钻开井眼后应力释放,井内钻井液液柱压力取代原地层对井壁的支撑,破坏了地层原有的应力平衡,引起井眼周围应力重新分布,造成井壁坍塌掉块。

利用同区块某井取自压隆构造的全尺寸岩心,在其水平方向上每间隔45°钻取3个岩样,进行了基于岩石kaiser效应的地应力测试。结果发现:最大水平主应力为175 MPa,最小水平主应力为140 MPa,其差值高达35 MPa。这说明断裂破碎带地层应力集中,钻开井眼后应力释放,易导致井壁坍塌。

1.2 地层裂缝发育及裂缝充填情况

受强构造运动影响,断裂破碎带地层发育大量微裂缝,其岩心薄片照片见图2。

由图2可知,虽然岩心整体上完整,但发育大量的微裂缝,裂缝尺寸为微米—纳米级别,形成了一种“破而不碎”的结构。如果钻井液封堵能力不强,钻井液滤液进入微裂缝,一方面会使黏土发生水化(如果胶结物中存在黏土),产生膨胀压力;另一方面会增大微裂缝中的孔隙压力,导致井壁坍塌掉块。

另外,裂缝被硅质胶结物、方解石等充填,胶结强度低,钻井过程中钻头转动、钻具撞击和压力波动均会破坏岩石的胶结作用,使岩石的整体强度降低,导致井壁坍塌掉块。

1.3 井壁岩块受力情况

破碎性地层井周岩体是非连续碎块,可以假设为由离散单元块体和割理组成的模型,如图3所示。图3中:①,②,…,⑤为岩块编号;a,b为破碎性岩块的尺寸,mm;σ1和σ2为岩块受到的压应力,MPa;σ31为岩块③和①接触面的压应力,MPa;σ41为岩块④和①接触面的压应力,MPa;σ51为岩块⑤和①接触面的压应力,MPa;τ31为岩块③和①接触面的剪应力,MPa;τ41为岩块④和①接触面的剪应力,MPa;τ51为岩块⑤和①接触面的剪应力,MPa;pi为井筒内的液柱压力,MPa。

对于井壁岩块来说,岩块①夹在2个裂缝面之间,最容易发生掉块,因此以岩块①为例分析其受力情况:对于直井,其受到σ31,τ31,σ41,τ41,σ51,τ51和pi的共同作用;而对于定向井和水平井,岩块①还受到重力分量的作用,其对井壁坍塌掉块是不利因素。因此,对于相同条件下的破碎性地层,定向井和水平井更容易发生井壁坍塌掉块,分析结果如图4所示。

2. 防塌钻井液关键技术

由上述分析可知,导致顺北油气田碳酸盐岩破碎性地层井壁坍塌的主要原因是地层破碎、应力集中和微裂缝发育。其中,地层破碎、应力集中是内因,无法改变;只有微裂缝可以利用钻井液充填、封堵,阻止压力传递,使破碎性地层不“破碎”,同时保持较高的钻井液密度以支撑井壁,从而解决井壁坍塌问题。

2.1 防塌钻井液基本配方

以取自顺北A井、顺北B井和顺北C井奥陶系碳酸盐岩破碎性地层的岩心为研究对象,利用X射线衍射仪分析其矿物组成,结果见表1。

表 1 顺北油气田3口井所取岩心的矿物组成Table 1. Mineral composition of cores from 3 wells in Shunbei Oil and Gas Field取心井 岩样中矿物含量,% 石英 斜长石 方解石 白云石 方沸石 赤铁矿 黏土 顺北A井 11.6 2.0 0 81.3 1.2 3.9 0 顺北B井 2.9 0 72.1 23.7 0 1.3 0 顺北C井 2.5 0.6 96.9 0 0 0 0 由表1可知,其地层岩石矿物组成主要为方解石和白云石,不含黏土。对于不含黏土矿物的地层,不考虑水化作用对井壁稳定性的影响,主要是利用固相颗粒对微裂缝进行全面封堵。相对于油基钻井液,微纳米固相颗粒在水基钻井液中的分散性更好,同时考虑成本、环保要求和储层录井效果等因素,选用水基防塌钻井液,其基本配方为:2.0%~3.0%膨润土+0.2%~0.3%烧碱+0.1%~0.2%纯碱+3.0%~4.0%SMP–Ⅲ+3.0%~4.0%SPNH+1.0%~2.0%抗高温降滤失剂+1.0%~3.0%高软化点沥青+0.5%~1.5%高温高压屏蔽剂+石灰石。

2.2 钻井液性能的强化

2.2.1 封堵性能

在钻进碳酸盐岩破碎性地层时,对其所有尺度的裂缝进行全面有效封堵是保持井壁稳定的必要条件[9]。根据水基钻井液中黏土粒径1~3 μm、加重材料粒径30~100 μm的实际情况,要全面封堵裂缝需要在钻井液中补充粒径3~30 μm的固相颗粒。为此,设计加入2种刚性颗粒材料(GWQH Ⅰ和GWQH Ⅱ)、2种塑性可变形颗粒材料(SWQHⅠ、SWQH Ⅱ)和1种微纳米乳液(NFT)。刚性颗粒材料的主要作用是利用架桥原理形成致密封堵层;塑性可变形颗粒材料的主要作用是变形填充刚性颗粒间的微空隙,使封堵层更加致密;微纳米乳液的主要作用是填充更小的空隙,使封堵层更加致密。其粒径分布如图5所示。

由图5可知,5种材料的粒径分布:d50为3~14 μm,d80为7~32 μm。

2.2.2 其他性能

防塌钻井液其他性能的强化,主要包括:控制高温高压滤失量,使其在井底温度下不大于10 mL,初始滤失量不大于1 mL,且滤失量越低越好;动塑比控制在0.50左右,以保证钻井液具有良好的携岩能力。

2.3 钻井液密度的选择

对于碳酸盐岩破碎性地层,提高钻井液密度进行应力支撑,只会在初期有一定的防塌效果[10-11]。当钻井液或滤液进入裂缝,裂缝张开后,会出现以下2方面的问题:1)缝面间的摩擦力大大降低,使坍塌压力大幅度上升;2)如果地层中含有黏土,因其具有水化膨胀特性,将会促进和激化井壁坍塌掉块。因此,应该根据工程经验或理论计算确定合理的钻井液密度。

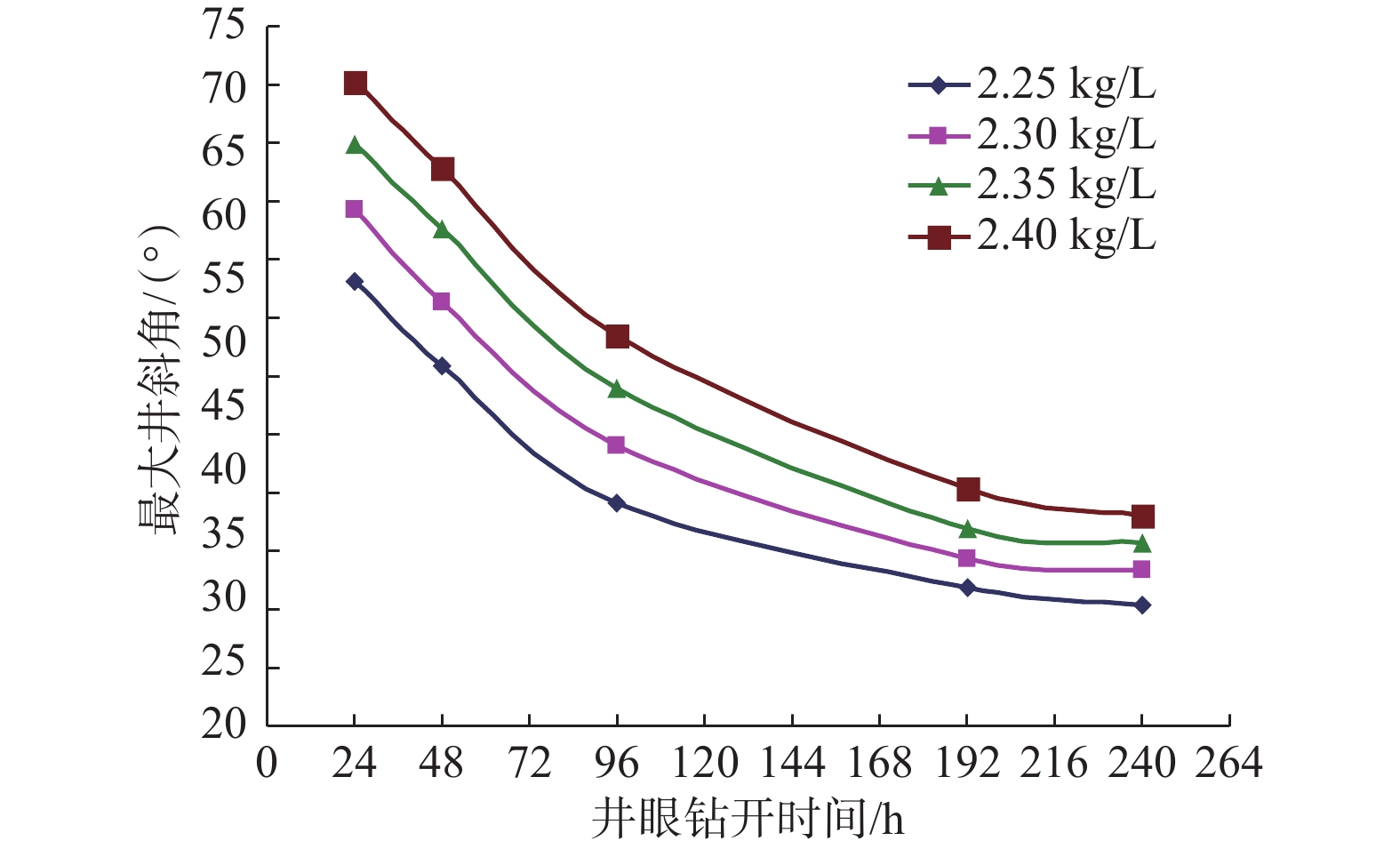

3. 现场试验

顺北X井是位于顺北油气田5号断裂带北部的大斜度井,设计井深8 012.99 m,垂深7 710.00 m,最大井斜角70.3°。与其水平距离698.00 m的邻井共进行了4次侧钻,侧钻过程中垮塌严重,阻卡频繁;预测该井在7 830.00~7 920.00 m井段钻遇断裂面,可能发生地层破碎和应力集中,存在垮塌掉块风险。因此,该井在钻进碳酸盐岩破碎性地层时试验应用了防塌钻井液技术。

基于“合适的钻井液密度”+“强化封堵防塌”的思路,将钻井液密度确定为1.29 kg/L,并在钻井液基本配方的基础上添加以下封堵材料:1.5%井壁强化剂GWQH Ⅰ+1.5%井壁强化剂GWQH Ⅱ+1.0%~3.0%磺化沥青SWQH Ⅰ+1.0%~3.0%磺化沥青SWQH Ⅱ+2.0%~3.0% NFT–Ⅱ。钻井液的粒径分布如图6所示。

由图6可知,封堵颗粒的粒径分布为0.2~200.0 μm,85%以上的颗粒粒径在100 μm以内(粒径100 nm~46 μm的颗粒占70.0%)。

同时,采取了处理掉块、防掉块卡钻和防蹩跳钻的配套技术措施。钻进中扭矩正常,泵压正常,钻速较快,短起下钻正常,各趟钻起下钻无阻卡,下钻一次到底。该井破碎带地层钻进过程中的钻时与扭矩情况如图7所示。

由图7可知,钻时主要集中在10~20 min/m,说明机械钻速较高;扭矩平稳,在10~12 kN·m。

另外,顺北X井奥陶系碳酸盐岩层段的井径曲线如图8所示。

由图8可知,顺北X井奥陶系碳酸盐岩层段井径整体比较规则,平均井径扩大率仅7.4%。

顺北X井使用防塌钻井液钻进碳酸盐岩破碎性地层的过程中,扭矩平稳,钻速较高,未发生坍塌掉块,说明采用防塌钻井液可以解决碳酸盐岩破碎性地层坍塌掉块的问题。

4. 结论与建议

1)强挤压构造地层应力集中、地层破碎并存在微裂缝和定向井中非连续岩块受重力作用,是造成顺北油气田碳酸盐岩破碎性地层井壁坍塌掉块的主要原因。

2)顺北油气田碳酸盐岩破碎性地层井壁防塌的关键是强化钻井液的封堵性能,阻止或减缓压力传递。

3)根据微裂缝尺寸,优选了相应粒径的刚性颗粒材料、塑性可变形颗粒材料和微纳米乳液,形成了致密封堵层;同时选择了合适的钻井液密度,并控制滤失量、将动塑比控制在0.50左右,形成了顺北油气田碳酸盐岩破碎性地层防塌钻井液技术。现场试验结果表明,该防塌钻井液技术防塌效果良好,钻进中扭矩平稳、钻速较高,完钻后井径规则。

-

表 1 2022年中东地区主要项目的主要钻井KPI指标

Table 1 Main drilling KPIs of key projects in the Middle East in 2022

项目 合同模式 井身结构 平均井深/m 钻井承包商 平均钻井

周期/d钻井速度/

(m∙d−1)平均非生产作业

时间(NPT),%鲁迈拉 大包/日费 三开(直井/定向井) 2 167 大庆/中曼 19.2 112.9 14.00 哈法亚 日费 四开(定向井)/五开(水平井) 3 283 大庆/渤钻/

安东38.6 85.1 5.75 西古尔纳-1 大包 三开(定向井)/四开(水平井) 4 810 SLB 34.1 141.1 14.80 阿曼五区 日费 三开(定向井)/四开(水平井) 2 312 长城 15.5 149.2 3.70 阿布扎比(2021) 日费 五开(水平井/分支井) 5 285 ADNOC Drilling 70.5 75.0 4.50 -

[1] 聂臻, 邹科. 伊拉克哈法亚油田井筒安全钻井工程关键技术[M]. 北京: 石油工业出版社, 2021: 23−285. NIE Zhen, ZOU Ke. Key technologies for safe drilling engineering in Halfaya Oilfield, Iraq[M]. Beijing: Petroleum Industry Press, 2021: 23−285.

[2] 张丽华,杨培高,靳恒涛,等. 伊拉克米桑油田Abu区块储层防漏堵漏技术[J]. 钻井液与完井液,2017,34(6):62–66. ZHANG Lihua, YANG Peigao, JIN Hengtao, et al. Prevention and control of mud losses in reservoirs in Block Abu of Missan Oilfield (Iraq)[J]. Drilling Fluid & Completion Fluid, 2017, 34(6): 62–66.

[3] 谢春来,胡清富,张凤臣,等. 伊拉克哈法亚油田Mishrif组碳酸盐岩储层防漏堵漏技术[J]. 石油钻探技术,2021,49(1):41–46. XIE Chunlai, HU Qingfu, ZHANG Fengchen, et al. Antileaking and lost circulation control technology for the Mishrif carbonate reservoir in the Halfaya Oilfield of Iraq[J]. Petroleum Drilling Techniques, 2021, 49(1): 41–46.

[4] 张希文,耿东士,聂臻,等. Halfaya油田钻井液技术研究与应用[J]. 科学技术与工程,2015,15(1):38–41. ZHANG Xiwen, GENG Dongshi, NIE Zhen, et al. Study and application of drilling fluid technology in Halfaya Oilfield[J]. Science Technology and Engineering, 2015, 15(1): 38–41.

[5] SUYAN K M, BANERJEE S, DASGUPTA D. A practical approach for preventing lost circulation while drilling[R]. SPE 105251, 2007.

[6] ARSHAD U, JAIN B, RAMZAN M, et al. Engineered solution to reduce the impact of lost circulation during drilling and cementing in Rumaila Field, Iraq[R]. IPTC 18245, 2015.

[7] 康毅力,王海涛,游利军,等. 基于层次分析法的地层钻井液漏失概率判定[J]. 西南石油大学学报(自然科学版),2013,35(4):180–186. KANG Yili, WANG Haitao, YOU Lijun, et al. Probability determination for loss circulation of drilling fluids based on analytic hierarchy process[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2013, 35(4): 180–186.

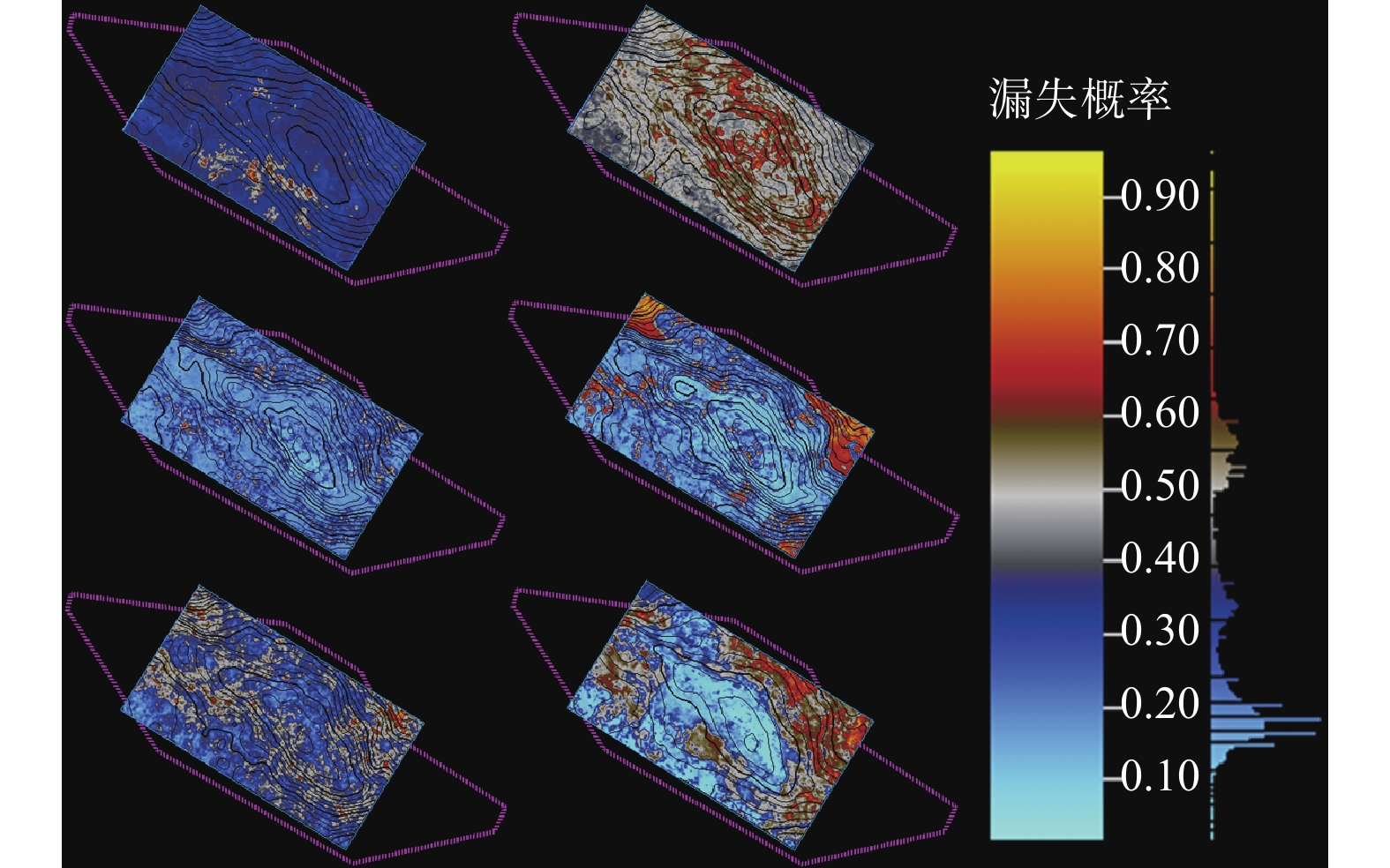

[8] 张炳军,周扬,杨新宏,等. 基于随钻测井资料的井漏位置识别及压井液密度确定[J]. 测井技术,2016,40(6):751–754. ZHANG Bingjun, ZHOU Yang, YANG Xinhong, et al. Mud loss and well killing fluid density identification based on LWD data[J]. Well Logging Technology, 2016, 40(6): 751–754.

[9] GENG Zhi, WANG Hanqing, FAN Meng, et al. Predicting seismic-based risk of lost circulation using machine learning[J]. Journal of Petroleum Science and Engineering, 2019, 176: 679–688. doi: 10.1016/j.petrol.2019.01.089

[10] PANG Huiwen, MENG Han, WANG Hanqing, et al. Lost circulation prediction based on machine learning[J]. Journal of Petroleum Science and Engineering, 2022, 208(Part A): 109364.

[11] YU Baohua, YAN Chuanliang, NIE Zhen. Chemical effect on wellbore instability of Nahr Umr Shale[J]. The Scientific World Journal, 2013, 2013: 931034.

[12] ABOUSLEIMAN Y, EKBOTE S, TARE U. Time-dependent wellbore (in) stability predictions: theory and case study[R]. SPE 62796, 2000.

[13] ZHANG Rui, SHI Xianya, NIE Zhen, et al. Critical pressure of closure fracture reopening and propagation: modeling and applications[J]. Journal of Petroleum Science and Engineering, 2017, 158: 647–659. doi: 10.1016/j.petrol.2017.09.001

[14] TARE U A, MESE A I, MODY E K. Time dependent impact of water-based drilling fluids on shale properties[R]. ARMA-01−0107, 2001.

[15] FJÆR E, HOLT R M, NES O M, et al. Mud chemistry effects on time-delayed borehole stability problems in shales[J]. SPE 78163, 2002.

[16] SINGH H, YADAV P, IMTIAZ S, et al. Resolving shale drilling instabilities in the Middle East: A holistic & pragmatic geomechanical method[R]. SPE 188681, 2017

[17] ROJAS J C, CLARK D E, ZHANG J. Stressed shale drilling strategy: Water activity design improves drilling performance[R]. SPE 102498, 2006.

[18] MECKERT J P, STEPHENS M E. Case study: A step-change and continuous improvement in safety performance[R]. SPE 67701, 2001.

[19] 聂臻,许岱文,邹建龙,等. HFY油田高压盐膏层固井技术[J]. 石油钻采工艺,2015,37(6):39–43. NIE Zhen, XU Daiwen, ZOU Jianlong, et al. Cementing technology for high-pressure salt-anhydrate bed in HFY Oilfield[J]. Oil Drilling & Production Technology, 2015, 37(6): 39–43.

[20] NIE Zhen, LIU He, ZOU Jianglong, et al. New solutions for high-pressure and salt/anhydrite rocks casing cementing, a case study[R]. SPE 176203, 2015.

[21] NIE Zhen, DONG Benjing, XIA Boru, et al. New Cementing technologies successfully solved the problems in shallow gas, low temperature and easy leakage formations[R]. SPE 131810, 2010.

[22] NIE Zhen, LIU He, LIU Aiping, et al. The large temperature difference, long column and narrow clearance cementing best practices in Halfaya Oilfield[R]. SPE 158294, 2012.

[23] 刘爱萍,孙勤亮,聂臻,等. HFY油田ϕ177.8 mm套管固井技术[J]. 石油钻采工艺,2014,36(2):45–48. LIU Aiping, SUN Qinliang, NIE Zhen, et al. ϕ177.8 mm casing cementing technology used in HFY Oilfield[J]. Oil Drilling & Production Technology, 2014, 36(2): 45–48.

[24] LU Peiqing, SANG Laiyu, ZHOU Shiming, et al. An analysis and control method on preventing gas channeling in cementing operation[J]. International Journal of Oil, Gas and Coal Engineering, 2022, 10(3): 82–89.

[25] LIU Yunfeng, QIU Zhengsong, NIE Zhen, et al. Numerical simulation and analysis of the bitumen intrusion mechanism based on density difference between bitumen and drilling fluid in Halfaya Oilfield, Iraq[J]. Fresenius Environmental Bulletin, 2019, 28(11): 8275–8281.

[26] LIU Yunfeng, QIU Zhengsong, ZHONG Hanyi, et al. Bitumen recovery from crude bitumen samples from halfaya oilfield by single and composite solvents-process, parameters, and mechanism[J]. Materials, 2019, 12(17): 2656. doi: 10.3390/ma12172656

[27] LIU Yunfeng, QIU Zhengsong, ZHAO Chong, et al. Characterization of bitumen and a novel multiple synergistic method for reducing bitumen viscosity with nanoparticles, ethyl cellulose, and cationic surfactants[J]. RSC Advances, 2020, 10: 10471–10481. doi: 10.1039/D0RA00335B

[28] LIU Yunfeng, QIU Zhengsong, ZHONG Hanyi, et al. Experimental study on optimization of drilling fluid technology for bituminous formation[J]. Fresenius Environmental Bulletin, 2019, 28(7): 5591–5598.

[29] NIE Zhen, LUO Huihong, ZHANG Zhenyou, et al. Challenges and countermeasures of directional drilling through abnormal high pressure salt/anhydrite/calystone layer in HFY Oilfield of Iraq, a case study[R]. SPE 182975, 2016.

[30] 陈国军. 伊拉克米桑油田裂缝性地层非标井眼水平井钻井技术[J]. 天然气勘探与开发,2020,43(2):45–52. CHEN Guojun. Horizontal-well drilling technologies with non-standard borehole for fractured formations, Missan Oilfield, Iraq[J]. Natural Gas Exploration and Development, 2020, 43(2): 45–52.

[31] 许岱文,梅景斌,郑传奎,等. 分支水平井技术在伊拉克HFY油田的应用[J]. 石油钻采工艺,2014,36(2):38–41. XU Daiwen, MEI Jingbin, ZHENG Chuankui, et al. Application of branch horizontal well technology in HFY Oilfield of Iraq[J]. Petroleum Drilling Technology, 2014, 36(2): 38–41.

[32] 聂臻,张振友,罗慧洪,等. 高压膏盐层定向井钻井关键技术[J]. 天然气工业,2018,38(5):103–110. NIE Zhen, ZHANG Zhenyou, LUO Huihong, et al. Key technologies for directional well drilling in high-pressure anhydrite salt layers[J]. Natural Gas Industry, 2018, 38(5): 103–110.

[33] 宋新民,李勇. 中东碳酸盐岩油藏注水开发思路与对策[J]. 石油勘探与开发,2018,45(4):679–689. SONG Xinmin, LI Yong. Optimum development options and strategies for water injection development of carbonate reservoirs in the Middle East[J]. Petroleum Exploration and Development, 2018, 45(4): 679–689.

[34] 蒋海军,耿黎东,王晓慧,等. 国外石油工程碳减排技术与作业管理发展现状及启示[J]. 石油钻探技术,2022,50(5):125–134. JIANG Haijun, GENG Lidong, WANG Xiaohui, et al. Carbon emission reduction technologies and operation management in petroleum engineering abroad: Up-to-date status and implications[J]. Petroleum Drilling Techniques, 2022, 50(5): 125–134.

[35] 杨传书,李昌盛,孙旭东,等. 人工智能钻井技术研究方法及其实践[J]. 石油钻探技术,2021,49(5):7–13. YANG Chuanshu, LI Changsheng, SUN Xudong, et al. Research method and practice of artificial intelligence drilling technology[J]. Petroleum Drilling Techniques, 2021, 49(5): 7–13.

[36] 李根生,宋先知,祝兆鹏,等. 智能钻完井技术研究进展与前景展望[J]. 石油钻探技术,2023,51(4):35–47. LI Gensheng, SONG Xianzhi, ZHU Zhaopeng, et al. Research progress and the prospect of intelligent drilling and completion technologies[J]. Petroleum Drilling Techniques, 2023, 51(4): 35–47.

[37] GAO Erhu, BOOTH M, MACBEATH N. Continued improvements on high-pressure/high-temperature drilling performance on wells with extremely narrow drilling windows-experiences from mud formulation to operational practices, shearwater project[R]. SPE 59175, 2000.

[38] 张锦宏. 中国石化页岩油工程技术现状与发展展望[J]. 石油钻探技术,2021,49(4):8–13. ZHANG Jinhong. Present status and development prospects of Sinopec shale oil engineering technologies[J]. Petroleum Drilling Techniques, 2021, 49(4): 8–13.

[39] 曾义金. 中国石化深层超深层油气井固井技术新进展与发展建议[J]. 石油钻探技术,2023,51(4):66–73. ZENG Yijin. Novel advancements and development suggestions of cementing technologies for deep and ultra-deep wells of Sinopec[J]. Petroleum Drilling Techniques, 2023, 51(4): 66–73.

-

期刊类型引用(1)

1. 刘承诚. 基于KPI的裸眼封隔器应用效能评价. 石油矿场机械. 2025(01): 19-23 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: