Treatment Technology of Waste Drilling Fluids in the Linxing-Shenfu Well Area

-

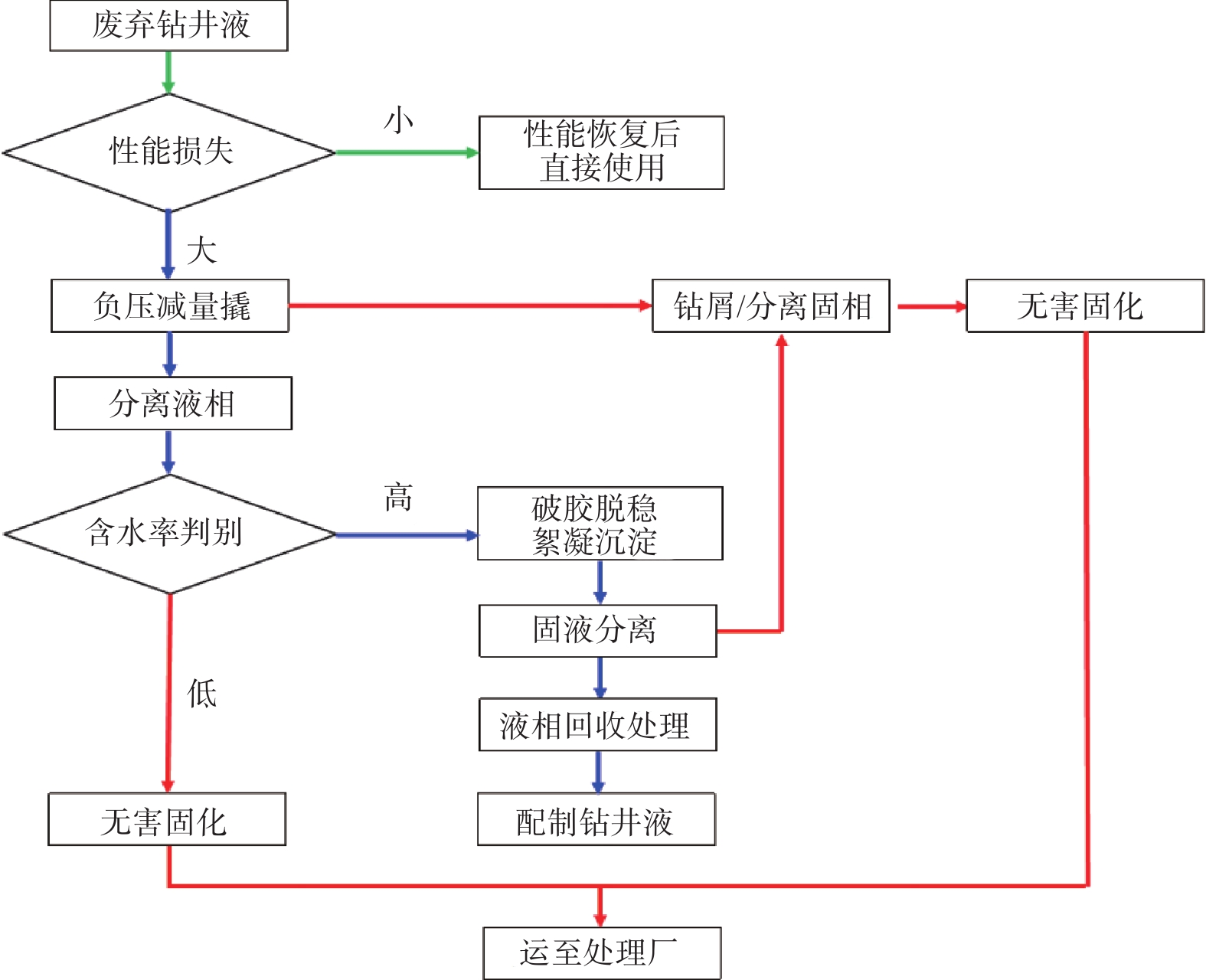

摘要: 为了解决临兴–神府井区废弃钻井液处理效率低、处理成本高等问题,开展了废弃钻井液无害化处理与重复利用技术研究。在分析废弃钻井液特性以及处理难点的基础上,研发了无毒、廉价的复合高效固化剂和复合铝盐破胶剂,产生的破胶压滤液经处理后用于配制钻井液;结合减量处理设备,研究形成了废弃钻井液无害化处理与重复利用技术。现场试验表明,废弃钻井液经减量处理设备分离后,钻屑含液率低于30%,钻屑质量减少20%~40%;固相含量大的废弃钻井液加入15%固化剂进行固化处理,24 h后即可直接运输,3 d后固化物浸出液满足环保要求;含水率较高的废弃钻井液中加入4.29%破胶剂,即可实现高效破胶,破胶压滤液经处理后可用来配制钻井液,其性能满足钻井要求。废弃钻井液无害化处理与重复利用技术解决了临兴–神府井区的废弃钻井液处理难题,具有较好的推广应用价值。Abstract: In order to solve the problems of low treatment efficiency, high treatment cost of waste drilling fluids in the Linxing-Shenfu Well Area, a technical research on harmless treatment and reuse technology of waste drilling fluids was carried out. After analyzing the characteristics of the waste drilling fluids and the difficulties in the treatment, a non-toxic composite curing agent with low cost and high efficiency, as well as aluminum salt gel breaker were developed, and the gel-breaking filtrate produced was processed for compound drilling fluids. Combined with the reduction treatment equipment, a harmless treatment and reuse technology of waste drilling fluids was formed. The field test results showed that the liquid content of cuttings was less than 30% and the weight of cuttings reduced by 20%–40% after the separation of the waste drilling fluids by reduction treatment equipment. The waste drilling fluids with high solid content can be directly transported 24 hours after the addition of 15% curing agent, and the leaching fluid can meet the requirements for environmental protection after 3 days. When a 4.29% gel breaker was added to the waste drilling fluids with high water content, a high-efficiency gel breaking can be achieved. The gel-breaking filtrate can be used for compound drilling fluids after treatment, which can meet the operational requirements for drilling. The harmless treatment and reuse technology of waste drilling fluids have solved the problem in treating waste drilling fluids in Linxing-Shenfu Well Area, with good promotion and application value.

-

Keywords:

- drilling fluids /

- gel breaking /

- curing /

- harmless treatment /

- reuse technology /

- Linxing-Shenfu well area

-

-

表 1 3种废弃钻井液的基本性能

Table 1 Basic properties of three kinds of waste drilling fluids

序号 钻井液类型 外观和气味 密度/

(kg·L–1)表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

PaAPI滤失

量/mL页岩回收率,

%总固相

含量,%1 聚合物钻井液 棕黑色,恶臭味 1.27 10.5 8 2.5 21.6 79.25 11.5 2 抗温聚合物钻井液 深黑色,刺激性气味 1.25 15.5 11 4.5 28.4 83.75 10.2 3 高密度聚合物钻井液 黄色,无特殊气味 1.23 80.0 55 25.0 6.0 90.55 22.7 表 2 3种废弃钻井液的污染物检测结果

Table 2 Detection result of pollutants in three kinds of waste drilling fluids

废弃钻井液 色度 石油类/

(mg·L–1)COD/

(mg·L–1)EC50/

(mg·L–1)1号 20 000 5 15 040 4 980 2号 30 000 9 45 000 1 040 3号 2 900 2 9 500 15 430 表 3 复合固化剂的固化效果

Table 3 Curing effect of composite curing agents

废弃钻

井液固化剂

加量,%浸出液COD/

(mg·L–1)浸出液

pH值色度 固化强度/

MPa1号 20 145.5 6.8 26 1.6 2号 20 133.4 6.5 20 1.7 表 4 破胶剂加量优选试验结果

Table 4 Test results of gel breaker dosage optimization

废弃钻

井液质量/g 破胶剂溶液

加量/g破胶剂加量,

%压滤时间/

min出水率,

%1号 300 10 1.07 35 28.75 300 20 2.15 40 42.08 300 30 3.22 30 53.33 300 40 4.29 30 60.42 2号 300 10 1.07 47 22.92 300 20 2.15 58 35.00 300 30 3.22 48 45.00 300 40 4.29 51 50.42 表 5 清水与破胶压滤液所配钻井液的性能

Table 5 Performance of drilling fluids prepared with clean water and gel-breaking filtrate

配制钻井液用液体 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

Pa静切力/Pa 中压滤失量/mL 24 h后是否沉降 初切 终切 清水 25 15 10 2.0 2.5 4.5 否 处理前压滤液 17 12 5 0.5 1.0 5.0 严重沉降 处理后压滤液 20 14 6 1.5 1.8 4.4 轻微沉降 处理后压滤液+等量清水 23 15 8 1.5 2.0 4.4 否 -

[1] 李建,冯雷,和鹏飞,等. 临兴地区浅层气井钻固井技术研究与应用[J]. 石油工业技术监督,2020,36(9):18–20. doi: 10.3969/j.issn.1004-1346.2020.09.006 LI Jian, FENG Lei, HE Pengfei, et al. Research and application of drilling and cementing technology for shallow gas wells in Linxing Area[J]. Technology Supervision in Petroleum Industry, 2020, 36(9): 18–20. doi: 10.3969/j.issn.1004-1346.2020.09.006

[2] 傅宁, 杨树春, 贺清, 等. 鄂尔多斯盆地东缘临兴–神府区块致密砂岩气高效成藏条件[J]. 石油学报, 2016, 37(增刊1): 111-120. FU Ning, YANG Shuchun, HE Qing, et al. High-efficiency reservoir formation conditions of tight sandstone gas in Linxing-Shenfu Blocks on the east margin of Ordos Basin[J]. Acta Petrolei Sinica, 2016, 37(supplement 1): 111-120.

[3] 郭明强. 储集空间类型对宏观物性的影响:以鄂东临兴神府地区为例[J]. 中国煤层气,2020,17(2):18–23. GUO Mingqiang. Effects of reservoir space types on macroscopic physical properties: a case study of Linxing-Shenfu in Eastern Ordos Basin[J]. China Coalbed Methane, 2020, 17(2): 18–23.

[4] 刘玲,王烽,汤达祯,等. 临兴地区上古生界煤系烃源岩评价及排烃特征[J]. 特种油气藏,2018,25(1):5–10. doi: 10.3969/j.issn.1006-6535.2018.01.002 LIU Ling, WANG Feng, TANG Dazhen, et al. Evaluation on upper Paleozoic coal-bearing source rocks and hydrocarbon expulsion feature in Linxing Region[J]. Special Oil & Gas Reservoirs, 2018, 25(1): 5–10. doi: 10.3969/j.issn.1006-6535.2018.01.002

[5] 吴泽舟,游靖,张勇,等. 钻井液环保性能标准的现状与对策[J]. 石油工业技术监督,2019,35(12):20–23. doi: 10.3969/j.issn.1004-1346.2019.12.007 WU Zezhou, YOU Jing, ZHANG Yong, et al. Current situation of standard for environmental protection performance of drilling fluid and countermeasures to it[J]. Technology Supervision in Petroleum Industry, 2019, 35(12): 20–23. doi: 10.3969/j.issn.1004-1346.2019.12.007

[6] 苏延辉,耿学礼,马成华,等. 临兴致密砂岩气区块废弃钻井液固液分离实验研究[J]. 石油化工应用,2016,35(5):116–119. doi: 10.3969/j.issn.1673-5285.2016.05.030 SU Yanhui, GENG Xueli, MA Chenghua, et al. Experimental research on solid-liquid separation of waste drilling fluid from Linxing tight sandstone gas area[J]. Petrochemical Industry Application, 2016, 35(5): 116–119. doi: 10.3969/j.issn.1673-5285.2016.05.030

[7] 龙怀远,王松,李行,等. 长庆油田废弃钻井液固化处理研究[J]. 长江大学学报(自科版),2017,14(7):50–52. LONG Huaiyuan, WANG Song, LI Hang, et al. Study on solidification of waste drilling fluids in Changqing Oilfield[J]. Journal of Yangtze University(Natural Science Edition), 2017, 14(7): 50–52.

[8] 赵宏波,李新宝,王冲,等. 废弃钻井液固液分离–化学处理技术在长北气田的应用[J]. 石油钻探技术,2017,45(3):48–56. ZHAO Hongbo, LI Xinbao, WANG Chong, et al. The application of solid liquid separation-chemistry processing technology for waste drilling fluid in the Changbei Gas Field[J]. Petroleum Drilling Techniques, 2017, 45(3): 48–56.

[9] 黎金明,陈在君,陈磊,等. 苏里格气田废弃钻井液固液分离及回用研究[J]. 钻采工艺,2018,41(4):89–91. doi: 10.3969/J.ISSN.1006-768X.2018.04.28 LI Jinming, CHEN Zaijun, CHEN Lei, et al. Research on solid-liquid separation and recycling of waste drilling fluid at Sulige Gasfield[J]. Drilling & Production Technology, 2018, 41(4): 89–91. doi: 10.3969/J.ISSN.1006-768X.2018.04.28

[10] 任雯,刘晓辉,李盛林,等. 废弃高性能水基钻井液循环利用电吸附处理方法[J]. 石油钻探技术,2020,48(4):50–55. doi: 10.11911/syztjs.2020046 REN Wen, LIU Xiaohui, LI Shenglin, et al. Electro-sorption treatment method for waste high performance water-based drilling fluid[J]. Petroleum Drilling Techniques, 2020, 48(4): 50–55. doi: 10.11911/syztjs.2020046

[11] 卓龙成,王波,张金焕,等. 苏北盆地ZC油田废弃钻井液再利用调剖工艺[J]. 石油钻探技术,2018,46(4):109–114. ZHUO Longcheng, WANG Bo, ZHANG Jinhuan, et al. Profile control for wasted drilling fluid recycling in ZC Oilfield of the Subei Basin[J]. Petroleum Drilling Techniques, 2018, 46(4): 109–114.

[12] 苏勤,何青水,张辉,等. 国外陆上钻井废弃物处理技术[J]. 石油钻探技术,2010,38(5):106–110. SU Qin, HE Qingshui, ZHANG Hui, et al. Foreign onshore drilling waste treatment technology[J]. Petroleum Drilling Techniques, 2010, 38(5): 106–110.

[13] 李文霞. 负压振动筛筛分机理研究[D]. 成都: 西南石油大学, 2018. LI Wenxia. Study on screening mechanism of negative pressure vibrating screen[D]. Chengdu: Southwest Petroleum University, 2018.

[14] 王丽,董娅玮,王文科. 废弃钻井液固化处理技术研究[J]. 应用化工,2015,44(12):2186–2188,2192. WANG Li, DONG Yawei, WANG Wenke. Treatment of waste drilling fluid curing technology[J]. Applied Chemical Industry, 2015, 44(12): 2186–2188,2192.

[15] 刘宇程, 吴冕, 陈明燕. 钻井废泥浆固化处理技术研究进展及展望[J]. 环境科学与技术, 2010, 33(增刊1): 534-537. LIU Yucheng, WU Mian, CHEN Mingyan. Research progress and prospection on technology of solidification of waste drilling mud treatment[J]. Environmental Science & Technology, 2010, 33(supplement 1): 534-537.

[16] 李雪光. 废弃钻井液的固化处理及低毒性钻井液研究[D]. 大庆: 东北石油大学, 2018. LI Xueguang. Research on the control system of oil extraction joint station based on PLC[D]. Daqing: Northeast Petroleum University, 2018.

-

期刊类型引用(7)

1. 彭博一,李晓东,王康,刘维平,冯美贵,蒋睿,金博. 废弃无固相钻井液无害化处理技术研究与应用. 钻探工程. 2025(02): 45-50 .  百度学术

百度学术

2. 刘均一,李公让,黄利民,马晓勇,夏晔. 胜利油田钻井液环保处理技术研究与应用. 石油钻探技术. 2024(03): 47-52 .  本站查看

本站查看

3. 彭博一,刘维平,高金华,于富安,李晓东. 废弃钻井液无害化处理技术研究进展. 地质装备. 2024(S1): 39-44 .  百度学术

百度学术

4. 徐梦冉,步玉环,赵恒仪,刘芳,庞学玉,张振,向刚. 氯氧镁水泥在石油领域的研究进展及应用前景. 特种油气藏. 2024(06): 10-23 .  百度学术

百度学术

5. 赵小光,孙俊刚,曹玉霞,李发旺. H油田废弃泥浆无害化处理技术研究与应用. 辽宁化工. 2023(04): 544-546+550 .  百度学术

百度学术

6. 丁新燕,李姝仪,闫君芝,邢艳,王伟. 粉煤灰固化体系对油田废钻井液的固化处理效果. 化工科技. 2023(05): 14-18 .  百度学术

百度学术

7. 王潇辉,王旭东,姜春丽,师浩林,薛迦文,徐加放. 高密度废弃水基钻井液电破胶条件的响应曲面法. 钻井液与完井液. 2023(05): 622-628 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: