Study and Performance Evaluation of a Glycerol-Based Drilling Fluid System with Strong Inhibition and High Lubricity

-

摘要:

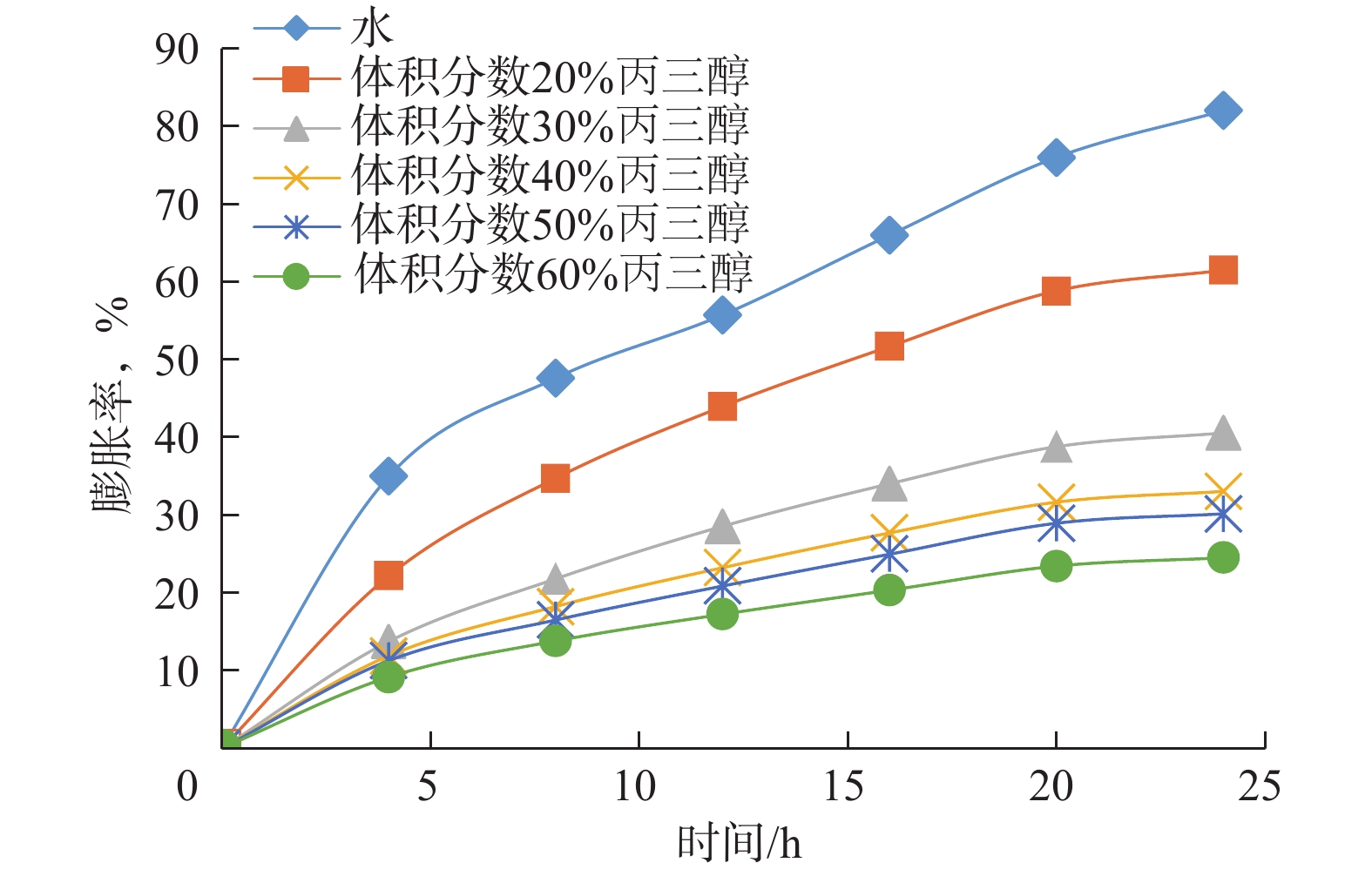

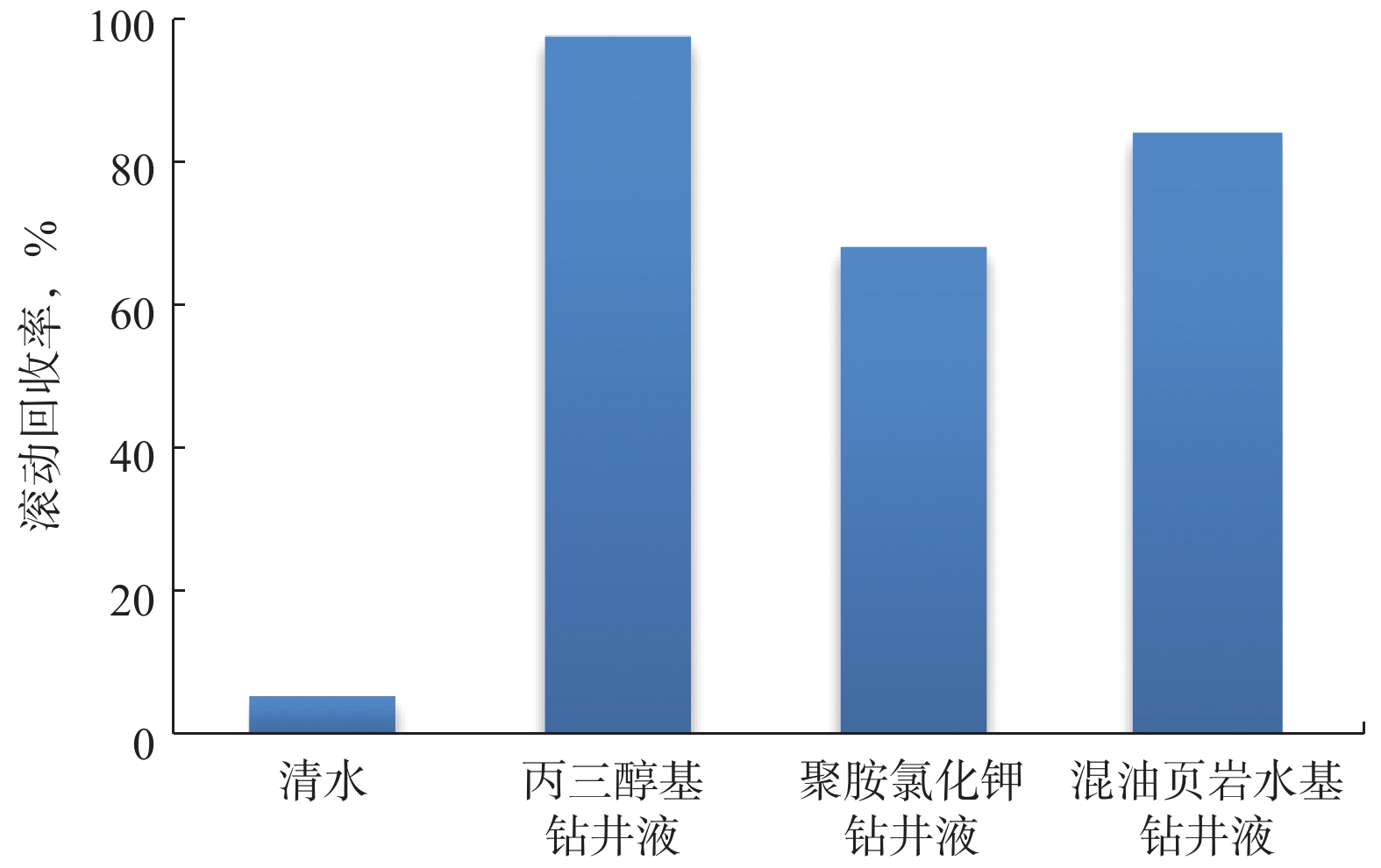

针对油基钻井液存在污染环境、环保处理工艺复杂和影响录井质量等问题,利用低碳醇具有强抑制性和高润滑性、能与水以任意比例互溶的优点,开发了适用于强水敏性地层的丙三醇基钻井液。考察了膨润土在不同低碳醇溶液中浸泡24 h后的膨胀率,据此优选丙三醇做为抑制润滑剂;丙三醇体积分数越大,丙三醇溶液的抑制性、润滑性越好,黏度越高。为了降低丙三醇的用量和提高抑制性,将30%丙三醇溶液与5%KCl复配作为基液,形成了丙三醇基钻井液。性能评价结果表明,丙三醇基钻井液的抑制性、润滑性与油基钻井液接近,抗温140 ℃,抗NaCl、CaCl2及钻屑污染,放置180 d后性能稳定,可重复使用;提高丙三醇加量,还可以进一步增强其抑制性和润滑性。丙三醇基钻井液对于强水敏性地层或对润滑性要求较高的地层具有较好的应用潜力,也为开发环保钻井液提供了新的方向。

Abstract:To address the problems of oil-based drilling fluid, such as environmental pollution, complex environmentaltreatment process and impact on logging quality, a glycerol-based drilling fluid suitable for strong water sensitive strata was developed for low-carbon alcohols strong inhibition, high lubricity and miscibility with water in any ratio. The swelling rate of bentonite in low-carbon alcohols solution for 24 h was investigated, and glycerol was selected as the optimal inhibition lubricant. The higher the volume fraction of glycerol, the better the inhibition, lubricity and viscosity of glycerol solution. In order to reduce alcohol consumption and further improve the inhibition, a glycerol-based drilling fluid system was formed by using 30% glycerol mixed with 5% KCl. The results of the performance evaluation show that the inhibition and lubricity of glycerol-based drilling fluid system are similar to those of oil-based drilling fluid, with temperature resistance of 140 ℃ and antipollution of NaCl, CaCl2 and drill cuttings. After six months of storage, the drilling fluid has achieved stable performance and can be reused. The inhibition and lubricity of drilling fluid can be further improved by increasing the dosage of glycerol. Glycerol-based drilling fluids can be used in strong water-sensitive stratum or with high requirement of lubricity. It shows a great application potential and this study also provides a development trend in environmental friendly drilling fluids.

-

-

表 1 不同体积分数丙三醇溶液的流变性

Table 1 Rheological properties of glycerol solutions with different volume fractions

丙三醇体积

分数,%表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

Pa10 1.0 1.0 0 20 1.5 1.5 0 30 3.5 3.0 0.5 40 4.5 4.0 0.5 50 6.5 6.0 0.5 60 11.5 11.0 0.5 70 34.5 34.0 0.5 80 58.5 58.0 0.5 表 2 KCl加量对丙三醇溶液性能的影响

Table 2 Effect of KCl dosage on the properties of glycerol solution

KCl加量/

g表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动塑比 溶解性 0 3.5 3.0 0.5 溶解 5.0 3.5 3.0 0.5 溶解 10.0 3.5 3.0 0.5 溶解 15.0 3.5 3.0 0.5 溶解 19.5 3.5 3.0 0.5 溶解 20.0 3.5 3.0 0.5 有白色悬浮物 20.5 3.5 3.0 0.5 白色悬浮物增多 25.0 3.5 3.0 0.5 大量白色悬浮物 表 3 丙三醇基钻井液在不同温度下热滚后的流变性

Table 3 Rheological properties of glycerol-based drilling fluid after heat rolling at different temperatures

温度/

℃表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

PaAPI滤失

量/mL高温高压

滤失量/mL25 40.0 28 12.0 3.7 7.2 120 42.0 39 13.0 3.4 6.9 130 38.0 26 10.5 4.2 7.6 140 36.5 26 10.5 5.1 8.9 150 44.0 30 14.0 16.0 29.0 表 4 丙三醇基钻井液抗污染能力测试结果

Table 4 The antipollution capacity of glycerol-based drilling fluids

钻井液体系 测试条件 表观黏度/(mPa·s) 塑性黏度/(mPa·s) 动切力/Pa API滤失量/mL 丙三醇基钻井液 热滚前 40.0 28 12.0 3.7 丙三醇基钻井液+10.0%NaCl 热滚前 38.0 28 10.0 3.2 热滚后 37.0 27 10.0 3.8 丙三醇基钻井液+1.5%CaCl2 热滚前 36.0 26 10.0 6.3 热滚后 34.5 24 10.5 8.6 丙三醇基钻井液+10.0%钻屑 热滚前 44.0 32 12.0 3.0 热滚后 45.0 33 12.0 5.7 表 5 丙三醇基钻井液稳定性测试结果

Table 5 Stability test results of a glycerol-based drilling fluid

放置时间/

d测试

条件表观黏度/

(mPa·s)塑性黏度/

(mPa·s)动切力/

PaAPI滤失

量/mL0 热滚前 40.0 28 12.0 3.7 30 热滚前 40.0 28 12.0 3.4 热滚后 38.0 26 10.5 4.2 90 热滚前 40.0 28 12.0 3.2 热滚后 37.0 26 11.0 4.8 180 热滚前 38.5 28 12.0 4.1 热滚后 35.0 24 11.0 6.4 -

[1] SIMPSON J P, WALKER T O, JIANG G Z. Environmentally acceptable water-based mud can prevent shale hydration and maintain borehole stability[R]. SPE 27496, 1995.

[2] 于雷,张敬辉,李公让,等. 低活度强抑制封堵钻井液研究与应用[J]. 石油钻探技术, 2018, 46(1): 44–48. YU Lei, ZHANG Jinghui, LI Gongrang, et al. Research and application of plugging drilling fluid with low-activity and high inhibition properties[J]. Petroleum Drilling Techniques, 2018, 46(1): 44–48.

[3] PATEL A, STAMATAKIS S, YOUNG S, et al. Advances in inhibitive water-based drilling fluids: can they replace oil-based muds?[R]. SPE 106476, 2007.

[4] 张伟国,狄明利,卢运虎,等. 南海西江油田古近系泥页岩地层防塌钻井液技术[J]. 石油钻探技术, 2019, 47(6): 40–47. doi: 10.11911/syztjs.2019103 ZHANG Weiguo, DI Mingli, LU Yunhu, et al. Anti-sloughing drilling fluid technology for the Paleogene shale stratum of the Xijiang Oilfield in the South China Sea[J]. Petroleum Drilling Techniques, 2019, 47(6): 40–47. doi: 10.11911/syztjs.2019103

[5] 罗健生,蒋官澄,王国帅,等. 一种无氯盐环保型强抑制水基钻井液体系[J]. 钻井液与完井液, 2019, 36(5): 594–599. doi: 10.3969/j.issn.1001-5620.2019.05.012 LUO Jiansheng, JIANG Guancheng, WANG Guoshuai, et al. Development of an environmentally friendly strongly inhibitive chloride-free water base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(5): 594–599. doi: 10.3969/j.issn.1001-5620.2019.05.012

[6] ISMAIL I, HUANG A P. The application of methyl glucoside as shale inhibitor in sodium chloride mud[J]. Journal Teknologi, 2009, 50(F): 53–65.

[7] ZHANG Yan, CHENG Zhu, YAN Jienian. Investigation on formation damage control of the methylglucoside fluids[R]. SPE 39442, 1998.

[8] 司西强,王中华,王伟亮. 聚醚胺基烷基糖苷类油基钻井液研究[J]. 应用化工, 2016, 45(12): 2308–2312. SI Xiqiang, WANG Zhonghua, WANG Weiliang. Study on the similar oil based drilling fluid of polyether amine alkyl glucoside[J]. Applied Chemical Industry, 2016, 45(12): 2308–2312.

[9] PETERSON T E, GONZALES T. Drilling and completion fluid: US 4780220[P]. 1988-10-25.

[10] GREEN D, PETERSON T E. Glycerine based drilling fluid to prevent wellbore collapse[J]. World Oil, 1989, 209(3): 50–51.

[11] LEE L, PATEL A D, STAMATAKIS E. Glycol based drilling fluid: US6291405 B1[P]. 2001-09-18.

[12] POMERLEAU D G. Glycerol based drilling fluids: US8071509B2[P]. 2011-12-06.

[13] POMERLEAU D G. Glycerol based drilling fluids: US201113280149[P]. 2015-03-03.

[14] MALGARESI G V C, VAZ A S L Jr, CORRÊA C C. A new crude-glycerin-based drilling fluid[J]. Journal of Petroleum Science and Engineering, 2018, 160: 401–411. doi: 10.1016/j.petrol.2017.10.039

[15] CORRÊA C C, CRUZ G F da, VAZ A S L Jr, et al. Use potential of bioglycerin as a basis for aqueous drilling fluids formulation of oil and gas wells[J]. Química. Nova, 2017, 40(4): 378–387.

[16] 张敬辉, 李公让, 于雷, 等.一种低活度醇基钻井液及其配制方法: CN110016326A[P].2019-07-16. ZHANG Jinghui, LI Gongrang, YU Lei, et al. A low activity alcohol-based drilling fluid and its preparation method: CN110016326A[P]. 2019-07-16.

[17] 褚奇,薛玉志,李涛,等. 新型聚合醇钻井液抑制性能研究[J]. 科学技术与工程, 2015, 15(3): 208–211. doi: 10.3969/j.issn.1671-1815.2015.03.040 CHU Qi, XUE Yuzhi, LI Tao, et al. Research on inhibition behavior of new polyalcohol drilling fluid[J]. Science Technology and Engineering, 2015, 15(3): 208–211. doi: 10.3969/j.issn.1671-1815.2015.03.040

[18] 陈聪,李维仲. 甘油水溶液氢键特性的分子动力学模拟[J]. 物理化学学报, 2009, 25(3): 507–512. doi: 10.3866/PKU.WHXB20090318 CHEN Cong, LI Weizhong. Molecular dynamics simulation of hydrogen bonding characteristics in aqueous glycerol solutions[J]. Acta Physico-Chimica Sinica, 2009, 25(3): 507–512. doi: 10.3866/PKU.WHXB20090318

[19] 邱正松,黄维安,徐加放,等. 一种新型多元醇钻井液的研制及应用[J]. 钻采工艺, 2006, 29(6): 5–7. doi: 10.3969/j.issn.1006-768X.2006.06.002 QIU Zhengsong, HUANG Weian, XU Jiafang, et al. Development and application of a new polyalcohol drilling fluid[J]. Drilling & Production Technology, 2006, 29(6): 5–7. doi: 10.3969/j.issn.1006-768X.2006.06.002

[20] 司西强,王中华. 绿色高性能水基钻井液研究进展及发展趋势[J]. 应用化工, 2019, 48(8): 1980–1984. doi: 10.3969/j.issn.1671-3206.2019.08.048 SI Xiqiang, WANG Zhonghua. Research progress and development trend of green high performance water-based drilling fluids[J]. Applied Chemical Industry, 2019, 48(8): 1980–1984. doi: 10.3969/j.issn.1671-3206.2019.08.048

[21] 杨彦东,薛连云,孙晓瑞,等. 准噶尔南缘水基钻井液多元协同抑制机理[J]. 钻井液与完井液, 2015, 32(5): 32–36. YANG Yandong, XUE Lianyun, SUN Xiaorui, et al. Mechanism of synergistic inhibition of water base drilling fluids on south edge of the Dzungaria Basin[J]. Drilling Fluid & Completion Fluid, 2015, 32(5): 32–36.

[22] 李旭方,熊正强. 抗高温环保水基钻井液研究进展[J]. 探矿工程(岩土钻掘工程), 2019, 46(9): 32–39. LI Xufang, XIONG Zhengqiang. Research progress on high temperature resistant and environment friendly water-based drilling fluids[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 2019, 46(9): 32–39.

[23] 陈聪,李维仲,宋永臣,等. 甘油-水-氯化钠三元溶液中甘油浓度对甘油自扩散系数的影响[J]. 化学学报, 2012, 70(8): 1043–1046. doi: 10.6023/A1107153 CHEN Cong, Li Weizhong, SONG Yongchen, et al. Effects of glycerol concentrations on self-diffusion coefficients of glycerol in glycerol-water-sodium chloride ternary solutions[J]. Acta Chimica Sinica, 2012, 70(8): 1043–1046. doi: 10.6023/A1107153

[24] PACHECO L V, de OLIVEIRA BORGES R F, de OLIVEIRA B R, et al. Study on the dissolution kinetics of NaCl in environmentally friendly drilling fluids containing glycerin[J]. Journal of Petroleum Science and Engineering, 2019, 182: 106165. doi: 10.1016/j.petrol.2019.06.029

下载:

下载: