Key Drilling Techniques of Liwan22-1-1 Ultra-Deepwater Well in East of South China Sea

-

摘要:

荔湾22–1–1超深水井位于南海东部海域,作业水深2 619.35 m,是目前国内作业水深最深的超深水井。针对该井钻井中存在的水深、海底低温、安全密度窗口极窄、浅部地层成岩性差、隔水管及钻柱力学行为复杂等技术难点,采取了周密的钻井工程设计和现场精细化管理,并应用了喷射下导管技术、FLAT-PRO恒流变合成基钻井液、低温早强水泥浆表层套管固井技术、钻井液当量循环密度随钻监测技术等关键技术措施,安全高效地完成了钻井作业,创造了国内外相同水深钻井周期最短纪录,工程质量全优。荔湾22–1–1超深水井的成功标志着我国超深水钻井技术取得重大突破,不但为我国超深水井钻井积累了宝贵的经验,也对国内外超深水钻井技术的发展具有一定的促进和借鉴作用。

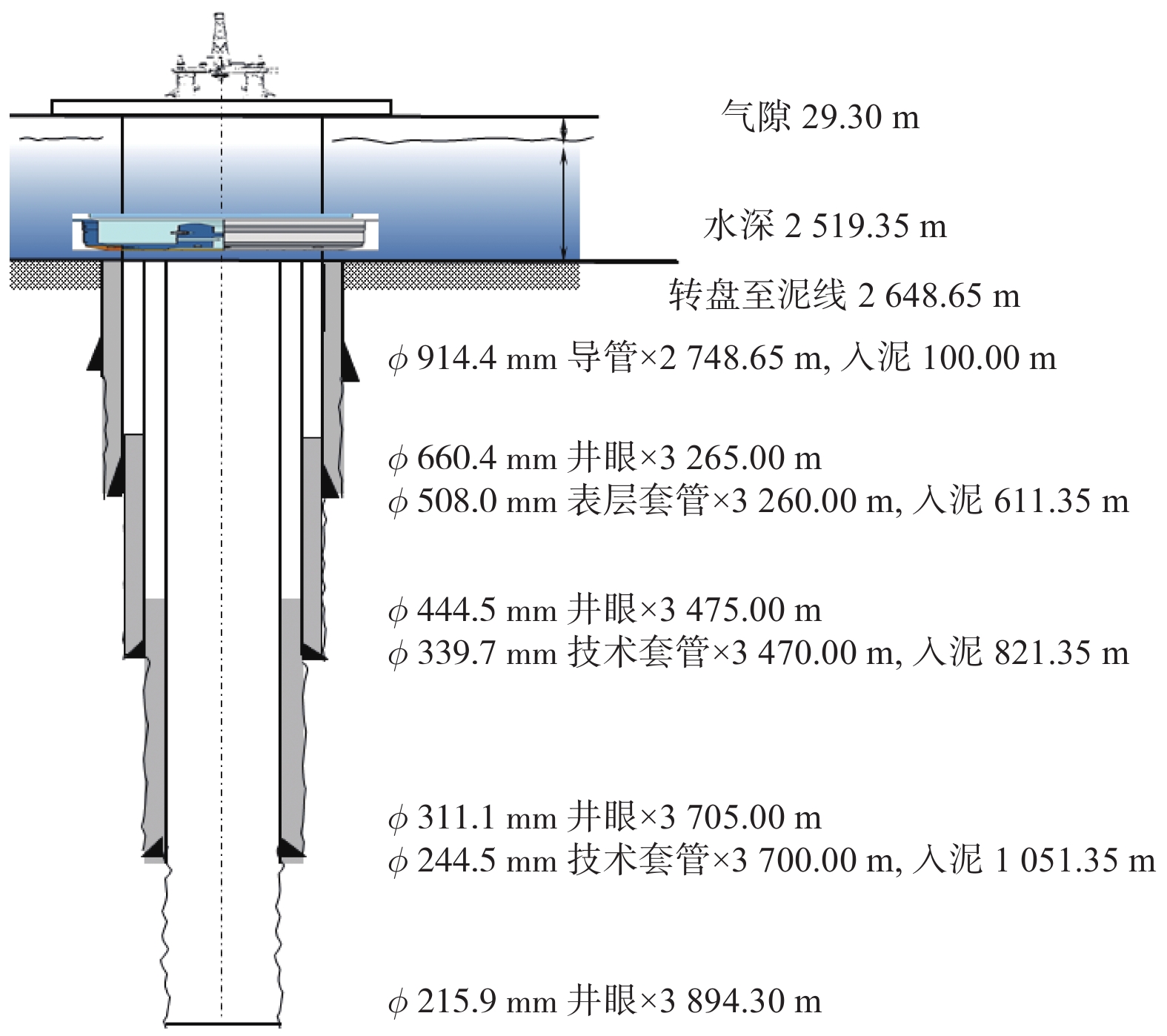

Abstract:Liwan 22-1-1 ultra-deep water well is located in the eastern section of the South China Sea, with an operating water depth of 2 199.35 m, and is the deepest deep water well in China. Addressing to technical challenges of ultra water depth, low seabed temperature, extremely narrow safety pressure window, poor diagenesis of shallow stratum, complicated mechanical behaviors of riser and drill string, mature drilling engineering design and precise on-site management had been implemented, and some key technical measures including jetting conductor driving in, FLAT-PRO constant rheological synthetic drilling fluid, low temperature early strength cement slurry surface casing cementing, drilling fluid equivalent circulation density (ECD) monitoring while drilling, etc, had been adopted to fulfill the drilling safely and efficiently, which established the record of shortest drilling cycle under the same water depth in the world, and achieved an excellent project engineering quality. The successful drilling of Liwan 22-1-1 ultra-deep water well marked a major breakthrough in China's ultra-deep water drilling technology. It not only accumulated valuable experience for China's ultra-deep water well drilling, but also promoted and guided the development of ultra-deep water drilling technologies across the globe.

-

Keywords:

- marine drilling /

- ultra-deepwater drilling /

- engineering design /

- Well Liwan22-1-1 /

- South China Sea

-

-

表 1 荔湾22–1–1井FLAT-PRO恒流变合成基钻井液基本性能

Table 1 Basic performance of FLAT-PRO constant rheological synthetic drilling fluid system in Well Liwan 22-1-1

井眼/mm 密度/(kg·L–1) 漏斗黏度/s 塑性黏度/(mPa·s) 动切力/Pa 油水比① ϕ6/ϕ3读数 444.5 1.06~1.08 60~90 尽量低 8~20 75:25~85:15 7~18/8~20 311.1 1.12 50 尽量低 7 75:25 7/6 注:①为基础油(Escaid110)与30.0%CaCl2盐水的比值。 表 2 荔湾22–1–1井隔水管系统配置

Table 2 Configuration of the riser system in Well Liwan 22-1-1

名称 数量 单根长度/m 区域长度/m 距离海底高度/m 转喷器+上挠性接头 1 5.10 5.10 2644.63 适配短节 1 10.67 10.67 2639.53 伸缩节 1 34.29 34.86 2628.86 短节 1 7.62 7.62 2594.01 隔水管裸单根 2 22.86 45.72 2586.39 隔水管单根/762 m浮力块① 4 22.86 91.44 2540.67 填充阀 1 6.10 6.10 2449.23 隔水管单根/762 m浮力块① 24 22.86 548.64 2443.13 隔水管单根/1 524 m浮力块① 26 22.86 594.36 1894.49 隔水管单根/2 286 m浮力块① 26 22.86 594.36 1300.13 隔水管单根/3 048 m浮力块① 30 22.86 685.80 705.77 下挠性接头、防喷器组 1 15.47 15.47 19.97 井口 1 4.50 4.50 4.50 注:①中的数值指该类型浮力块设计可以下入的最大水深。 -

[1] 周俊昌, 唐海雄, 刘正礼, 等. 深水钻井规程与指南[Z]. 北京: 中国海洋石油总公司, 2011: 71-80. ZHOU Junchang, TANG Haixiong, LIU Zhengli, et al. Deepwater drilling procedures and guidelines[M]. Beijing: CNOOC, 2011: 71-80.

[2] 王友华, 王文海, 蒋兴迅. 南海深水钻井作业面临的挑战和对策[J]. 石油钻探技术, 2011, 39(2): 50–55 doi: 10.3969/j.issn.1001-0890.2011.02.009 WANG Youhua, WANG Wenhai, JIANG Xinxun. South China Sea deepwater drilling challenges and solutions[J]. Petroleum Drilling Techniques, 2011, 39(2): 50–55 doi: 10.3969/j.issn.1001-0890.2011.02.009

[3] 刘正礼, 胡伟杰. 南海深水钻完井技术挑战及对策[J]. 石油钻采工艺, 2015, 37(1): 8–12 http://d.old.wanfangdata.com.cn/Periodical/syzcgy2015010005 LIU Zhengli, HU Weijie. Countermeasures and challenges of deepwater drilling and completion technology in South China Sea[J]. Oil Drilling & Production Technology, 2015, 37(1): 8–12 http://d.old.wanfangdata.com.cn/Periodical/syzcgy2015010005

[4] 孙宝江, 张振楠. 南海深水钻井完井主要挑战与对策[J]. 石油钻探技术, 2015, 43(4): 1–7 http://d.old.wanfangdata.com.cn/Periodical/syztjs201504001 SUN Baojiang, ZHANG Zhennan. Challenges and countermeasures for the drilling and completion of deepwater wells in the South China Sea[J]. Petroleum Drilling Techniques, 2015, 43(4): 1–7 http://d.old.wanfangdata.com.cn/Periodical/syztjs201504001

[5] 唐海雄, 刘正礼, 罗俊丰, 等. 深水探井钻井工程设计指南[Z]. 北京: 中国海洋石油总公司, 2011: 4-5. TANG Haixiong, LIU Zhengli, LUO Junfeng, et al. Guildline for drilling design of deepwater exploration well[M]. Beijing: CNOOC, 2011: 4-5.

[6] 韦红术, 刘正礼, 胡伟杰, 等.深水井的设计及建井基本要求[Z].北京: 中国海洋石油总公司, 2014: 33–35. WEI Hongshu, LIU Zhengli, HU Weijie, et al. General requirements for deepwater well design and construction[M]. Beijing: CNOOC, 2014: 33–35.

[7] 叶吉华, 刘正礼, 罗俊丰. 深水钻井设计的技术流程与工作方法[J]. 中国海上油气, 2014, 26(3): 93–97 http://d.old.wanfangdata.com.cn/Periodical/zghsyq-gc201403015 YE Jihua, LIU Zhengli, LUO Junfeng. Technical process and working method of deep water well drilling design[J]. China Offshore Oil and Gas, 2014, 26(3): 93–97 http://d.old.wanfangdata.com.cn/Periodical/zghsyq-gc201403015

[8] 刘正礼, 叶吉华, 田瑞瑞, 等. 南海深水表层导管水下打桩安装技术适应性分析[J]. 石油钻探技术, 2014, 42(1): 41–45 doi: 10.3969/j.issn.1001-0890.2014.01.008 LIU Zhengli, YE Jihua, TIAN Ruirui, et al. Adaptability of under-water tamping for deepwater drilling conductor installation in South China Sea[J]. Petroleum Drilling Techniques, 2014, 42(1): 41–45 doi: 10.3969/j.issn.1001-0890.2014.01.008

[9] AKERS T J. Improving hole quality and casing-running perfor-mance in riserless top holes: deepwater Angola[R]. SPE 112630, 2009.

[10] 周波, 杨进, 周建良, 等. 深水钻井喷射下导管排量设计方法[J]. 石油钻探技术, 2016, 44(3): 21–26 http://d.old.wanfangdata.com.cn/Periodical/syztjs201603004 ZHOU Bo, YANG Jin, ZHOU Jianliang, et al. A Jetting flow rate design method for conductor installation through jetting in deepwater drilling[J]. Petroleum Drilling Techniques, 2016, 44(3): 21–26 http://d.old.wanfangdata.com.cn/Periodical/syztjs201603004

[11] 刘和兴, 方满宗, 刘智勤, 等. 南海西部陵水区块超深水井喷射下导管技术[J]. 石油钻探技术, 2017, 45(1): 10–16 http://d.old.wanfangdata.com.cn/Periodical/syztjs201701002 LIU Hexing, FANG Manzong, LIU Zhiqin, et al. Jetting-based conductor running technology used in ultra-deep water well of Lingshui Block in the Western South China Sea[J]. Petroleum Drilling Techniques, 2017, 45(1): 10–16 http://d.old.wanfangdata.com.cn/Periodical/syztjs201701002

[12] 叶志, 樊洪海, 张国斌, 等. 深水钻井地质灾害浅层水流问题研究[J]. 石油钻探技术, 2010, 38(6): 48–52 doi: 10.3969/j.issn.1001-0890.2010.06.011 YE Zhi, FAN Honghai, ZHANG Guobin, et al. Investigation of shallow water flow in deepwater drilling[J]. Petroleum Drilling Techniques, 2010, 38(6): 48–52 doi: 10.3969/j.issn.1001-0890.2010.06.011

[13] 叶吉华,刘正礼,罗俊丰,等. 南海深水钻井井控技术难点及应对措施[J]. 石油钻采工艺, 2015, 37(1): 139–142 http://d.old.wanfangdata.com.cn/Periodical/syzcgy2015010038 YE Jihua, LIU Zhengli, LUO Junfeng, et al. Technical difficulties and countermeasures in well control of deepwater drilling in the South China Sea[J]. Oil Drilling & Production Technology, 2015, 37(1): 139–142 http://d.old.wanfangdata.com.cn/Periodical/syzcgy2015010038

[14] GRACE R D. Blowout and well control handbook[M]. Oxford: Gulf Professional Publishing, 2003.

[15] 高德利. 油气井管柱力学与工程[M]. 东营: 中国石油大学出版社, 2006: 88–89. GAO Deli. Mechanics and engineering string of oil and gas wells[M]. Dongying: China University of Petroleum Press, 2006: 88–89.

[16] YANG Jin, LIU Shujie, ZHOU Jianliang, et al. Research of conductor setting depth using jetting in the surface of deepwater[R]. SPE 130523, 2010.

[17] 赵琥, 邱超, 宋茂林, 等. 深水固井低温水泥外加剂的开发及应用[J]. 石油钻探技术, 2012, 40(4): 72–75 doi: 10.3969/j.issn.1001-0890.2012.04.014 ZHAO Hu, QIU Chao, SONG Maolin, et al. Development and application of additive in deepwater cementing[J]. Petroleum Drill-ing Techniques, 2012, 40(4): 72–75 doi: 10.3969/j.issn.1001-0890.2012.04.014

[18] 胡友林, 乌效鸣, 岳前升, 等. 深水钻井气制油合成基钻井液室内研究[J]. 石油钻探技术, 2012, 40(6): 38–42 doi: 10.3969/j.issn.1001-0890.2012.06.008 HU Youlin, WU Xiaoming, YUE Qiansheng, et al. Laboratory research on deepwater GTL synthetic-based drilling fluid[J]. Petroleum Drilling Techniques, 2012, 40(6): 38–42 doi: 10.3969/j.issn.1001-0890.2012.06.008

下载:

下载: