Hydration Damage and Shear Characteristics of Regular Toothed Structural Planes of Shale

-

摘要:

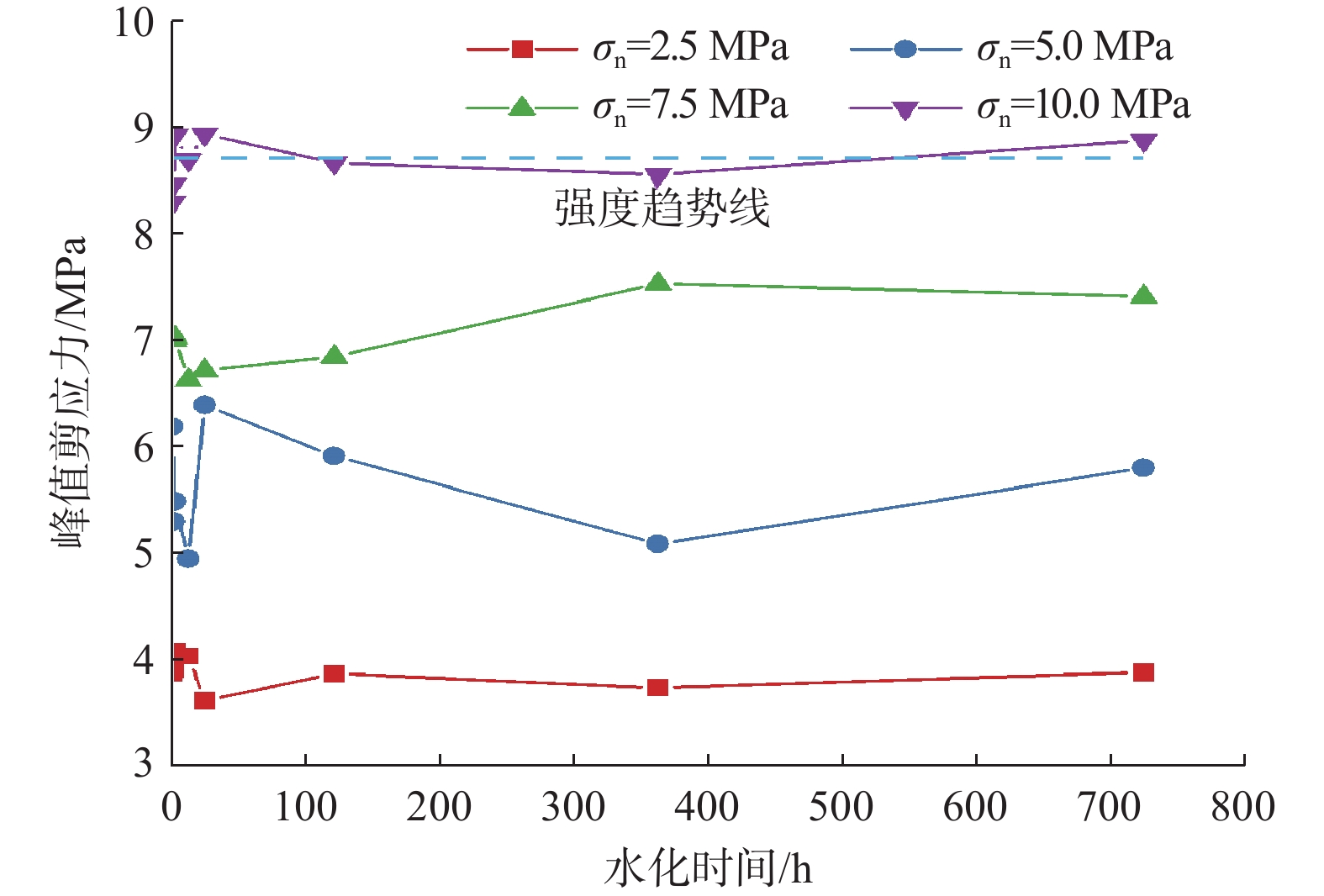

页岩储层压裂改造后,地层滑移使套管变形频繁出现,严重影响施工与生产。为了解页岩储层结构面水化损伤及水化前后的剪切特性,采用川南龙马溪组页岩试样,预制了10°和40°的2种规则齿形结构面,模拟了不同粗糙度的断层特征,并在四级法向应力下进行了水化直剪试验。试验结果表明:1)40°高起伏角度结构面在水化后表现出塑性变形特征,剪切位移−剪应力曲线呈阶梯式上升,剪切刚度下降约16.3%;而10°低起伏角度结构面则以摩擦滑移为主,剪切刚度波动较小;高法向应力(≥5 MPa)会加剧水化对结构面的破坏作用,但长时间(≥24 h)水化会使破坏促进作用趋于上限。2)在水化初期(1~2 h),40°高起伏角度结构面抗剪强度平均降低了13.05%,最终整体降低了18.19%,黏聚力与内摩擦角分别降低了16.31%和16.57%;10°低起伏角度结构面的抗剪强度参数受水化影响较小,波动范围小于5%。3)10°低起伏角度结构面在水化360 h后出现微孔洞连通和矿物分层现象,而40°高起伏角度结构面则形成大尺寸张拉裂缝,表面粗糙度增大,这是因为高角度结构面的黏土矿物分布更集中,水化软化效应更显著,导致脆性降低和塑性增强。研究结果可为页岩储层压裂设计与套管防护提供理论依据。

Abstract:Formation slip makes casing failure occur frequently after the fracturing of shale reservoirs, which seriously affects construction and production. In order to understand the damage caused by the hydration of shale reservoirs’ structural planes and shear characteristics before and after hydration, shale samples of Longmaxi Formation in southern Sichuan were adopted. Two kinds of regular toothed structural planes of 10° and 40° were prefabricated, and the fault characteristics at different roughness were simulated. Moreover, direct shear tests for hydration were carried out under four normal stresses.The results show that: 1) The structural plane with a high undulating angle of 40° shows plastic deformation characteristics after hydration. The shear displacement–shear stress curve shows the characteristics of stepped rise, and shear stiffness decreases by about 16.3%. However, the structural plane with a low undulating angle of 10° mainly exhibits frictional slip, and the shear stiffness fluctuates slightly. High normal stress (≥ 5 MPa) will aggravate the damage effect of hydration on the structural plane, but the damage promotion effect tends to the upper limit after a long time of hydration (≥ 24 h). 2) At the initial stage of hydration (1–2 h), the shear strength of the structural plane with a high undulating angle of 40° decreases by 13.05% on average, and the overall shear strength decreases by 18.19%; the cohesion and internal friction angle decrease by 16.31% and 16.57%, respectively. In contrast, the shear strength parameters of the structural plane with a low undulating angle of 10° are less affected by hydration, and the fluctuation range is less than 5%. 3) After 360 h of hydration, microporous connectivity and mineral stratification appear on the structural plane with a low undulating angle of 10°, while the structural plane with a high undulating angle of 40° forms large-size tensile fractures, and surface roughness increases. This difference is due to the more concentrated distribution of clay minerals and the more significant hydration softening effect on the structural plane with a high undulating angle, resulting in reduced brittleness and enhanced plasticity. The research results can provide a theoretical basis for shale reservoir fracturing design and casing protection.

-

Keywords:

- shale /

- toothed structural plane /

- hydration /

- rock mechanics /

- microstructure

-

页岩油气储层致密,能量保持难、流动阻力大,大规模压裂改造是其高效开发的主要技术手段[1-5]。东营凹陷陆相页岩油资源量丰富,亟需采用新技术实现高效开发[6-7]。超临界CO2具有低黏度、高渗透、低表面张力的物理特性,被认为是非常规储层改造新方法之一[8-10]。然而,超临界CO2压裂的相态和物理性质复杂,造缝机理尚不清楚,学者们多采用试验和数值模拟方法开展相关研究[11-15]。试验表明,CO2可降低破裂压力[16],超临界CO2压裂形成的裂缝表面相对于滑溜水压裂产生的裂缝表面更为粗糙[17],使用超临界CO2在降低岩石破裂压力和造缝方面具有很大的优势[18]。目前,相关研究多针对CO2低黏度特性对压裂的影响,对CO2对岩石物性影响的关注较少。此外,CO2压裂裂缝形态复杂,传统方法模拟裂缝多为单缝结构,采用现的数值模拟手段难以精确刻画前置CO2压裂缝网[19-21]。

赵辉等人[22-24]提出了基于闪电模拟的油藏压裂模型,可以很好地表征裂缝复杂性,但仅适用于水力压裂,未考虑压裂过程中CO2对裂缝扩展形态的影响。借鉴该方法,笔者考虑CO2的相态变化特征及CO2对岩石性质的影响,结合物理试验和数值模拟,提出了基于节点连接方法(NCM)的CO2增能压裂裂缝扩展模拟模型,在此基础上进一步讨论了前置CO2比例、地质参数、物性参数及压裂施工参数对裂缝形态的影响,并在东营凹陷陆相页岩油X井开展分析应用。

1. CO2增能压裂裂缝扩展模拟模型

1.1 CO2岩石压裂起裂压力与应力变化表征

为准确表征胜利油田东营凹陷陆相页岩经过CO2浸泡后的岩石力学与破裂特征,选取2口典型井12块岩样,利用岩石力学仪测试其不同CO2浸泡时间下和不同围压下的强度、弹性模量、泊松比、内聚力等岩石力学参数,结合破裂压力剪切压力等计算公式,发现东营凹陷陆相页岩油岩体破裂压力、天然裂缝剪切及张开应力和地应力随CO2浸泡时间增长呈现线性降低的趋势(见图1)。

1.2 CO2物性参数变化表征

前置CO2注入过程中,随着温度和压力条件变化,CO2的密度和黏度均会发生显著变化,影响压裂裂缝扩展。采用Pen-Robinson方程刻画CO2密度变化,其状态方程可表示为[25]:

p=8.314TV−26.667−396 306.77[1+0.707 979(1−√Tr)]2V(V+26.667)+26.667(V−26.667) (1) 式中:T为CO2的绝对温度,K;V为CO2的摩尔体积,L/mol;Tr为对比温度,即CO2绝对温度T与临界温度Tc(Tc=304.13K)之比。

根据式(1)确定CO2的体积后,即可进一步获得CO2在该温度和压力条件下的密度。

CO2黏度与温度的关系[21]为:

μ=36.344[√1.259 3TrΩuFc(1G2+E6cVe6)+η**]√MTc3√V2c (2) 其中,部分系数定义为:

Fc=1−0.275 6ω+0.059 035μ4r+κ (3) η**=E7y2G2exp(E8+E9T∗+E10T∗2) (4) G2=E1[1−exp(−E4y)]y+E21−0.5y(1−y)3exp(E5y)−E31−0.5y(1−y)3E1E4+E2+E3 (5) Ei=fi(ω,κ) (6) 式中:Tr为临界温度,K;Fc为形状和极性因子;Ve为气体体积,m3;ω为偏心因子;y为摩尔分数;T*为绝对温度,K;M为摩尔质量,g/mol;Vc为CO2的临界体积,m3;Ωu为碰撞积分;μr为约化偶极矩;κ为高极性物质的关联因子;c为单位体积物质的量,mol/m3。

1.3 基于NCM的CO2增能压裂裂缝扩展数学模型

基于节点体系扩展模拟方法(Node Connection Method, NCM)[22-23],考虑前置CO2注入后对岩石力学、物性参数的影响,构建前置CO2增能压裂裂缝扩展模拟模型。

1.3.1 前置CO2水力压裂力学机制

假设岩石为多孔弹性介质,根据测井资料获取地层物性参数,以三维弹性理论为基础,可以得到地下水平主应力的计算方法。结合试验研究结果,储层中岩石的泊松比、弹性模量等参数会随着CO2浸泡时间增长而变化,在模型中需要考虑。因此,水平主应力与时间的关系可以表示为:

{σth=νt1−νtσv−νt1−νtαvpp+αhpp+Et1−(νt)2ξh+νtEt1−(νt)2ξHσtH=νt1−νtσv−νt1−νtαvpp+αHpp+Et1−(νt)2ξH+νEt1−(νt)2ξh (7) 式中:σth为t时刻的最小水平主应力,MPa;σtH为t时刻的最大水平主应力,MPa;σv为垂向应力,MPa;αv、αh为垂向和水平的Biot系数;ξH、ξh为最大水平主应力和最小水平主应力的应变系数;νt为t时刻泊松比;Et为t时刻的弹性模量,GPa;pp为孔隙压力,MPa。

压裂过程中,新生缝会改变岩石的力学状态,影响后续裂缝扩展,简称应力阴影效应。采用诱导应力解析解和叠加原理描述全局应力状态[26]:

{σt+1xx(i,j)=σtxx(i,j)+N∑m=1pn,m(Lm√L1,mL2,mcos2θm−θ1,m−θ2,m2−2)−N∑m=1pn,mLma(a2L1,mL2,m)3/2sinθmsin32(θ1,m+θ2,m)σt+1yy(i,j)=σtyy(i,j)+N∑m=1pn,m(Lm√L1,mL2,mcos2θm−θ1,m−θ2,m2−2)+N∑m=1pn,mLma(a2L1,mL2,m)3/2sinθmsin32(θ1,m+θ2,m)τt+1xy(i,j)=τtxy(i,j)+N∑m=1pnet,mLma(a2L1,mL2,m)3/2⋅sinθmcos32(θ1,m+θ2,m) (8) 式中:σt+1xx和σtxx分别为t+1和t时间步下(i, j)位置处x轴向主应力,MPa;σt+1yy和σtyy分别为t+1和t时间步下(i, j)位置处y轴向主应力,MPa;τt+1xy和τtxy分别为t+1和t时间步下(i, j)位置处剪切应力,MPa;N为裂缝微元数量;pn,m为裂缝m微元的缝内净压力,MPa;a为裂缝微元半长,m;Lm,L1,m和L2,m为位置(i, j)到裂缝m微元的距离,m;θm,θ1,m和θ2,m为位置(i, j)到裂缝m微元的角度。

对裂缝内流体流动简化处理,不考虑裂缝在缝宽方向上的流动过程,且裂缝壁面上的流速为0,则流体在裂缝内为一维流动。对流体压降方程进行处理,可得到缝内压力分布为:

pti,m=−12μtmqmxmhf,mw3m+p0 (9) 式中:pti,m为t时间步时裂缝m微元的净压力,MPa;μtm为t时间步时裂缝m微元中流体的黏度,mPa·s;qm为裂缝m微元的流量;xm为裂缝m微元与井筒的距离,m;hf,m为裂缝m微元的高度,m;p0为初始压力,MPa。

对于前置CO2压裂,裂缝内流体黏度随着CO2性质而改变,采用式(2)修正不同时间步下前置CO2的黏度。

将临界起裂应力作为起裂判据,该值与岩石断裂韧性有关,则裂缝扩展条件为[23]:

σfr=1√2πrcosθ2(K1cos2θ2−32K2sinθ)−σcr⩾ (10) 式中:σfr为残余起裂应力,MPa;σcr为临界起裂应力,MPa;K1为Ⅰ型应力强度因子,MPa·m0.5;K2为Ⅱ型应力强度因子,MPa·m0.5。

分支裂缝密度表示为在裂缝的改造范围内共有的裂缝节点数量,其计算公式为:

{\rho }_{\text{if}}=\frac{{n}}{{L}_{\text{f}}{w}_{\text{f}}} (11) 式中:ρif为分支缝密度,条/m2;n为裂缝节点数量;Lf为裂缝长度,m;wf为裂缝的带宽,m。

1.3.2 前置CO2压裂模拟流程

基于NCM的CO2增能压裂裂缝扩展模型计算流程如图2所示。具体步骤为:1)依据实际储层大小划分地质单元,作为计算的离散体;2)结合地质资料给地质单元赋值;3)根据实际压裂规模,设置射孔参数;4)计算现存裂缝单元缝内流体压力分布;5)结合应力阴影效应及缝内流体流动特征,校正储层应力分布;6)计算裂缝尖端周向应力和临界起裂应力;7)判断是否存在满足起裂条件的裂缝单元,不满足时输出裂缝形态;8)引入随机函数及概率分布,确定新的裂缝单元;9)根据CO2物性的变化,更新缝内流体物性参数;10)重复步骤4)—9),直至输出裂缝形态。

2. 前置CO2增能压裂裂缝扩展模拟

选用胜利油田东营凹陷陆相页岩油储层地质力学参数以及物性参数,基于构建模型,分析不同影响因素下裂缝扩展形态。模型尺寸大小为160 m×300 m,1段射孔3簇,射孔点在模型中间位置处,模拟裂缝排量为16 m3/min,页岩基质的弹性模量为26.36 GPa,泊松比为0.30。

2.1 前置CO2比例对缝网形态的影响

模拟前置CO2比例分别为0.1、0.2和0.3时的裂缝形态(见图3),分析不同前置CO2比例与裂缝长度缝网带宽及分支缝密度的关系(见图4)。

前置CO2比例对整体缝网扩展长度影响最大,前置CO2比列由0.1增至0.3时,缝网长度缩短近40%。压裂缝网带宽主要受压裂簇数影响,前置CO2比例对整体缝网扩展带宽影响较小。前置CO2比例对分支缝密度的影响很大,当前置CO2比例由0.1增加至0.3时,分支缝网密度由0.06 条/m2增加至0.13 条/m2,增加了117%。这主要是因为超临界CO2易于进入基质孔隙和微裂隙中,促进了基质的破裂和微裂隙的开启,增加了分支裂缝的数量,形成了复杂的网状裂缝形态。

2.2 水平应力差对裂缝形态的影响

模拟水平应力差分别为0,15和30 MPa时的裂缝形态(见图5),分析不同水平应力差与裂缝长度缝网带宽及分支缝密度的关系(见图6)。

应力差与缝长相关性很大,与缝宽相关性较小,与分支缝密度相关性大,应力差主要影响缝长及分支缝密度。水平应力差由5 MPa增至30 MPa时,裂缝长度由175 m增至266 m,缝网带宽由63 m降至58 m,降低了3.18%,分支缝密度由0.095 条/m2降至0.074 条/m2,下降了31.85%。相较于滑溜水压裂,前置CO2增能压裂在高应力差下依然可以形成复杂裂缝网。因此,高应力差储层采用前置CO2进行压裂,可以提高压裂改造效果,实现高效增产。

2.3 储层渗透率对裂缝形态的影响

模拟储层渗透率分别为0.05,0.5和5 mD时的裂缝形态(见图7),分储层渗透率与裂缝长度、缝网带宽及分支缝密度的关系(见图8)。结果发现,储层渗透率对裂缝长度和带宽的影响较小,对分支缝密度的影响较大。总体而言,储层渗透率影响压裂流体的滤失性,前置CO2压裂对于储层渗透率的敏感程度要远大于滑溜水压裂。其原因在于,储层渗透率影响CO2向基质的滤失量和波及范围,对于开启天然裂缝和储层增压作用明显。因此,对于高渗透储层,应适当增大排量和压裂液量,从而增大压裂改造范围。

3. 实例分析

东营凹陷陆相页岩油X井目的层为沙四上纯上3层组,水平段长度1 976 m,钻遇岩相以泥质灰页岩(970 m)、灰质泥页岩(550 m)为主;前置CO2增能压裂完成34段、120簇压裂施工,平均3.5 簇/段,加砂4 300.6 m3(设计4 204.7 m3)、注入携砂液73 166 m3,平均单段加砂126.5 m3、加砂强度2.4 m3/m。结合实际施工参数模拟裂缝扩展形态,X井36段反演裂缝平均缝长为277.80 m,平均缝宽为59.85 m。X井压裂时的微地震监测结果见图9,裂缝扩展模拟结果见图10。

X 井压裂过程中进行单井尺度模拟时,由于模拟布点精度及显示尺度的原因,裂缝整体上呈双翼对称复杂裂缝形态。对比微地震监测结果发现,水力裂缝缝长在微地震的75.09%~99.63%,水力裂缝缝宽在微地震的78.79%~98.84%,模拟结果与实际监测具有较好的一致性。此方法可用于压裂前裂缝形态模拟,根据模拟结果制定压裂方案,提高压裂效率。

4. 结 论

1)综合考虑CO2对岩体破裂压力、地应力的影响以及CO2物性参数的变化,基于节点连接方法的CO2增能压裂裂缝扩展数学模型可实现CO2增能压裂复杂裂缝网络形态的模拟。

2)前置CO2比例、应力差和渗透率对分支缝密度的影响较大,在高应力差储层增加缝网密度时,可适当增加前置CO2比例。

3)实际区块模拟结果与微地震监测结果吻合度较高,具有一定的可靠性,基于节点连接方法的CO2增能压裂裂缝扩展数学模型具有一定的现场应用潜力,可以为压裂方案的制定提供理论指导。

-

表 1 不同结构面在不同条件下的剪切试验结果

Table 1 Shear test results of different structural planes under different conditions

水化时间/h 法向应力/MPa 峰值强度/MPa C/MPa ϕ/(°) R2 峰值强度/MPa C/MPa ϕ/(°) R2 起伏角度为10° 起伏角度为40° 0 2.5 3.90 2.29 33.02 0.931 11.32 9.44 42.60 0.975 5.0 6.20 14.45 7.5 7.03 16.74 10.0 8.29 18.22 1 2.5 3.93 2.36 31.75 0.995 10.98 8.53 41.34 0.973 5.0 5.31 12.33 7.5 7.19 15.61 10.0 8.46 17.22 2 2.5 4.09 2.38 32.66 0.995 10.46 8.30 37.87 0.990 5.0 5.50 11.98 7.5 7.03 13.90 10.0 8.92 16.30 12 2.5 4.05 2.19 31.95 0.973 9.96 7.93 36.07 0.949 5.0 4.96 10.93 7.5 6.63 14.02 10.0 8.69 15.00 24 2.5 3.64 2.37 32.93 0.930 9.56 7.71 35.13 0.988 5.0 6.40 11.26 7.5 6.72 12.62 10.0 8.93 14.97 120 2.5 3.89 2.36 32.47 0.991 10.51 8.06 35.24 0.837 5.0 5.92 11.19 7.5 6.85 12.14 10.0 8.66 16.08 360 2.5 3.76 2.23 32.86 0.982 9.60 7.96 35.82 0.904 5.0 5.10 11.30 7.5 7.53 12.37 10.0 8.55 15.58 720 2.5 3.90 2.37 33.44 0.996 9.94 7.84 35.97 0.919 5.0 5.81 11.53 7.5 7.41 12.30 10.0 8.87 15.73 -

[1] 高东伟,代林,刘湘,等. 鄂西地区二叠系页岩气钻完井难点及对策[J]. 世界石油工业,2024,31(4):81–93. doi: 10.20114/j.issn.1006-0030.20240201001 GAO Dongwei, DAI Lin, LIU Xiang, et al. Difficulties and countermeasures of drilling and completion of Permian shale gas in western Hubei[[J]. World Petroleum Industry, 2024, 31(4): 81–93. doi: 10.20114/j.issn.1006-0030.20240201001

[2] 袁建强. 中国石化页岩气超长水平段水平井钻井技术新进展与发展建议[J]. 石油钻探技术,2023,51(4):81–87. doi: 10.11911/syztjs.2023030 YUAN Jianqiang. New progress and development proposals of Sinopec’s drilling technologies for ultra-long horizontal shale gas wells[J]. Petroleum Drilling Techniques, 2023, 51(4): 81–87. doi: 10.11911/syztjs.2023030

[3] 张东清,万云强,张文平,等. 涪陵页岩气田立体开发优快钻井技术[J]. 石油钻探技术,2023,51(2):16–21. doi: 10.11911/syztjs.2022097 ZHANG Dongqing, WAN Yunqiang, ZHANG Wenping, et al. Optimal and fast drilling technologies for stereoscopic development of the Fuling Shale Gas Field[J]. Petroleum Drilling Techniques, 2023, 51(2): 16–21. doi: 10.11911/syztjs.2022097

[4] 刘建亮,王亚莉,陆家亮,等. 中国页岩气开发效益现状及发展策略探讨[J]. 断块油气田,2020,27(6):684–688. LIU Jianliang, WANG Yali, LU Jialiang, et al. Discussion on internal rate of return status and development strategy of China shale gas[J]. Fault-Block Oil & Gas Field, 2020, 27(6): 684–688.

[5] 李德旗,刘春亭,朱炬辉,等. 高闭合压力下深层页岩气促缝网强支撑压裂工艺[J]. 石油钻采工艺,2024,46(3):336–345. doi: 10.13639/j.odpt.202312014 LI Deqi, LIU Chunting, ZHU Juhui, et al. Fracturing technology with enhanced fracture network and reinforced support for deep shalegas under high closure pressure[J]. Oil Drilling & Production Technology, 2024, 46(3): 336–345. doi: 10.13639/j.odpt.202312014

[6] WANG H, LIAO X, DING H. Monitoring and evaluating the volume fracturing effect of horizontal well[J]. Journal of Natural Gas Science and Engineering, 2015, 22: 498–502. doi: 10.1016/j.jngse.2015.01.005

[7] 王强,赵金洲,胡永全,等. 页岩油储集层压后焖井时间优化方法[J]. 石油勘探与开发,2022,49(3):586–596. doi: 10.11698/PED.20210906 WANG Qiang, ZHAO Jinzhou, HU Yongquan, et al. Shut-in time optimization after fracturing in shale oil reservoirs[J]. Petroleum Exploration and Development, 2022, 49(3): 586–596. doi: 10.11698/PED.20210906

[8] ENGELDER T, CATHLES L M, BRYNDZIA L T. The fate of residual treatment water in gas shale[J]. Journal of Unconventional Oil and Gas Resources, 2014, 7: 33–48. doi: 10.1016/j.juogr.2014.03.002

[9] 蒋廷学,卞晓冰,王海涛,等. 页岩气水平井分段压裂排采规律研究[J]. 石油钻探技术,2013,41(5):21–25. doi: 10.3969/j.issn.1001-0890.2013.05.004 JIANG Tingxue, BIAN Xiaobing, WANG Haitao, et al. Flow back mechanism study of multi-stage fracturing of shale gas horizontal wells[J]. Petroleum Drilling Techniques, 2013, 41(5): 21–25. doi: 10.3969/j.issn.1001-0890.2013.05.004

[10] 雷群,翁定为,熊生春,等. 中国石油页岩油储集层改造技术进展及发展方向[J]. 石油勘探与开发,2021,48(5):1035–1042. doi: 10.11698/PED.2021.05.15 LEI Qun, WENG Dingwei, XIONG Shengchun, et al. Progress and development directions of shale oil reservoir stimulation technology of China National Petroleum Corporation[J]. Petroleum Exploration and Development, 2021, 48(5): 1035–1042. doi: 10.11698/PED.2021.05.15

[11] 王飞,阮颖琪,陈巧韵,等. 考虑压裂液渗吸换油效应的压裂焖井压降模型[J]. 石油勘探与开发,2021,48(6):1250–1257. doi: 10.11698/PED.2021.06.17 WANG Fei, RUAN Yingqi, CHEN Qiaoyun, et al. A pressure drop model of post-fracturing shut-in considering the effect of fracturing-fluid imbibition and oil replacement[J]. Petroleum Exploration and Development, 2021, 48(6): 1250–1257. doi: 10.11698/PED.2021.06.17

[12] 游利军,谢本彬,杨建,等. 页岩气井压裂液返排对储层裂缝的损害机理[J]. 天然气工业,2018,38(12):61–69. doi: 10.3787/j.issn.1000-0976.2018.12.007 YOU Lijun, XIE Benbin, YANG Jian, et al. Mechanism of fracture damage induced by fracturing fluid flowback in shale gas reservoirs[J]. Natural Gas Industry, 2018, 38(12): 61–69. doi: 10.3787/j.issn.1000-0976.2018.12.007

[13] 谭鹏,陈朝伟,赵庆,等. 页岩气多簇压裂断层活化机理与控制方法[J]. 石油钻探技术,2024,52(6):107–116. doi: 10.11911/syztjs.2024120 TAN Peng, CHEN Zhaowei, ZHAO Qing, et al. Mechanism and control method of fault activation by multi-cluster fracturing of shale gas [J]. Petroleum Drilling Techniques, 2024, 52(6): 107–116. doi: 10.11911/syztjs.2024120

[14] 陈朝伟,房超,朱勇,等. 四川页岩气井套管变形特征及受力模式[J]. 石油机械,2020,48(2):126–134. CHEN Zhaowei, FANG Chao, ZHU Yong, et al. Deformation characteristics and stress modes of casings for shale gas wells in Sichuan[J]. China Petroleum Machinery, 2020, 48(2): 126–134.

[15] LI Yang, LIU Wei, YAN Wei, et al. Mechanism of casing failure during hydraulic fracturing: Lessons learned from a tight-oil reservoir in China[J]. Engineering Failure Analysis, 2019, 98: 58–71. doi: 10.1016/j.engfailanal.2019.01.074

[16] YIN Fei, HAN Lihong, YANG Shangyu, et al. Casing deformation from fracture slip in hydraulic fracturing[J]. Journal of Petroleum Science and Engineering, 2018, 166: 235–241. doi: 10.1016/j.petrol.2018.03.010

[17] 童亨茂,张平,张宏祥,等. 页岩气水平井开发套管变形的地质力学机理及其防治对策[J]. 天然气工业,2021,41(1):189–197. TONG Hengmao, ZHANG Ping, ZHANG Hongxiang, et al. Geomechanical mechanisms and prevention countermeasures of casing deformation in shale gas horizontal wells[J]. Natural Gas Industry, 2021, 41(1): 189–197.

[18] 钱斌,朱炬辉,杨海,等. 页岩储集层岩心水化作用实验[J]. 石油勘探与开发,2017,44(4):615–621. doi: 10.11698/PED.2017.04.15 QIAN Bin, ZHU Juhui, YANG Hai, et al. Experiments on shale reservoirs plugs hydration[J]. Petroleum Exploration and Development, 2017, 44(4): 615–621. doi: 10.11698/PED.2017.04.15

[19] 王萍,屈展. 基于核磁共振的脆硬性泥页岩水化损伤演化研究[J]. 岩土力学,2015,36(3):687–693. WANG Ping, QU Zhan. NMR technology based hydration damage evolution of hard brittle shale[J]. Rock and Soil Mechanics, 2015, 36(3): 687–693.

[20] 王跃鹏,刘向君,熊健,等. 富有机质页岩水化特征的试验研究[J]. 地下空间与工程学报,2022,18(3):891–900. WANG Yuepeng, LIU Xiangjun, XIONG Jian, et al. Experimental study on hydration characteristics of organic-rich shale[J]. Chinese Journal of Underground Space and Engineering, 2022, 18(3): 891–900.

[21] 赵志红,金浩增,郭建春,等. 水化作用下深层页岩软化本构模型研究[J]. 岩石力学与工程学报,2022,41(增刊2):3189–3197. ZHAO Zhihong, JIN Haozeng, GUO Jianchun, et al. Study on softening constitutive model of deep shale under hydration[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(supplement 2): 3189–3197.

[22] 薛华庆,周尚文,蒋雅丽,等. 水化作用对页岩微观结构与物性的影响[J]. 石油勘探与开发,2018,45(6):1075–1081. doi: 10.11698/PED.2018.06.16 XUE Huaqing, ZHOU Shangwen, JIANG Yali, et al. Effects of hydration on the microstructure and physical properties of shale[J]. Petroleum Exploration and Development, 2018, 45(6): 1075–1081. doi: 10.11698/PED.2018.06.16

[23] LIU Jingping, YANG Zhi, SUN Jinsheng, et al. Experimental investigation on hydration mechanism of Sichuan shale (China)[J]. Journal of Petroleum Science and Engineering, 2021, 201: 108421. doi: 10.1016/j.petrol.2021.108421

[24] MA Tianshou, YANG Chunhe, CHEN Ping, et al. On the damage constitutive model for hydrated shale using CT scanning technology[J]. Journal of Natural Gas Science and Engineering, 2016, 28: 204–214. doi: 10.1016/j.jngse.2015.11.025

[25] 马天寿,陈平. 基于CT扫描技术研究页岩水化细观损伤特性[J]. 石油勘探与开发,2014,41(2):227–233. MA Tianshou, CHEN Ping. Study of meso-damage characteristics of shale hydration based on CT scanning technology[J]. Petroleum Exploration and Development, 2014, 41(2): 227–233.

[26] 刘向君,熊健,梁利喜. 龙马溪组硬脆性页岩水化实验研究[J]. 西南石油大学学报(自然科学版),2016,38(3):178–186. LIU Xiangjun, XIONG Jian, LIANG Lixi. Hydration experiment of hard brittle shale of the Longmaxi Formation[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2016, 38(3): 178–186.

[27] LIU Xiangjun, ZENG Wei, LIANG Lixi, et al. Experimental study on hydration damage mechanism of shale from the Longmaxi Formation in southern Sichuan Basin, China[J]. Petroleum, 2016, 2(1): 54–60. doi: 10.1016/j.petlm.2016.01.002

[28] 石秉忠,夏柏如. 硬脆性泥页岩水化过程的微观结构变化[J]. 大庆石油学院学报,2011,35(6):28–34. SHI Bingzhong, XIA Boru. The variation of microstructures in the hard brittle shale hydration process[J]. Journal of Daqing Petroleum Institute, 2011, 35(6): 28–34.

[29] 石秉忠,夏柏如,林永学,等. 硬脆性泥页岩水化裂缝发展的CT成像与机理[J]. 石油学报,2012,33(1):137–142. doi: 10.7623/syxb201201020 SHI Bingzhong, XIA Bairu, LIN Yongxue, et al. CT imaging and mechanism analysis of crack development by hydration in hard-brittle shale formations[J]. Acta Petrolei Sinica, 2012, 33(1): 137–142. doi: 10.7623/syxb201201020

[30] 丁乙,雷炜,刘向君,等. 页岩气储层自吸−水化损伤−离子扩散相关性试验研究[J]. 石油钻探技术,2023,51(5):88–95. doi: 10.11911/syztjs.2023088 DING Yi, LEI Wei, LIU Xiangjun, et al. Experimental research on the correlation of spontaneous imbibition-hydration damage-ion diffusion in shale gas reservoirs[J]. Petroleum Drilling Techniques, 2023, 51(5): 88–95. doi: 10.11911/syztjs.2023088

[31] 杨柳,冷润熙,常天全,等. 页岩气储层渗吸与盐离子扩散相关关系[J]. 中国海上油气,2020,32(2):112–119. YANG Liu, LENG Runxi, CHANG Tianquan, et al. Correlation between the imbibition and salt ion diffusion of shale gas reservoirs[J]. China Offshore Oil and Gas, 2020, 32(2): 112–119.

[32] 熊健,李羽康,刘向君,等. 水岩作用对页岩岩石物理性质的影响:以四川盆地下志留统龙马溪组页岩为例[J]. 天然气工业,2022,42(8):190–201. doi: 10.3787/j.issn.1000-0976.2022.08.015 XIONG Jian, LI Yukang, LIU Xiangjun, et al. Influences of water–rock interaction on the physical and mechanical properties of shales: a case study of the Lower Silurian Longmaxi Formation in the Sichuan Basin[J]. Natural Gas Industry, 2022, 42(8): 190–201. doi: 10.3787/j.issn.1000-0976.2022.08.015

[33] WANG Yuepeng, LIU Xiangjun, LIANG Lixi, et al. Experimental study on the damage of organic-rich shale during water-shale interaction[J]. Journal of Natural Gas Science and Engineering, 2020, 74: 103103. doi: 10.1016/j.jngse.2019.103103

[34] ZHOU Tong, ZHANG Shicheng, YANG Liu, et al. Experimental investigation on fracture surface strength softening induced by fracturing fluid imbibition and its impacts on flow conductivity in shale reservoirs[J]. Journal of Natural Gas Science and Engineering, 2016, 36(Part A): 893-905.

[35] 衡帅,刘晓,李贤忠,等. 张拉作用下页岩裂缝扩展演化机制研究[J]. 岩石力学与工程学报,2019,38(10):2031–2044. HENG Shuai, LIU Xiao, LI Xianzhong, et al. Study on the fracture propagation mechanisms of shale under tension[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(10): 2031–2044.

[36] 李芷,贾长贵,杨春和,等. 页岩水力压裂水力裂缝与层理面扩展规律研究[J]. 岩石力学与工程学报,2015,34(1):12–20. LI Zhi, JIA Changgui, YANG Chunhe, et al. Propagation of hydraulic fissures and bedding planes in hydraulic fracturing of shale[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(1): 12–20.

[37] XIE Heping, PARISEAU W G. Fractal estimation of joint roughness coefficients[J]. Science in China(Series B), 1994, 37(12): 1516–1524.

-

期刊类型引用(9)

1. 徐智颢,杜博,李东东. 裂缝内CO_2压裂液相态分布特征的数值模拟研究. 中国资源综合利用. 2024(04): 41-43 .  百度学术

百度学术

2. 孟宪波. 页岩油藏水平井分段多簇压裂全井段裂缝扩展数值模拟——以济阳坳陷沙河街组为例. 断块油气田. 2024(03): 459-466 .  百度学术

百度学术

3. 李阳,祝仰文,李宗阳,蒋廷学,薛兆杰,沈子齐,肖朴夫,于洪敏,程紫燕,赵清民,张庆福. 济阳坳陷页岩油注二氧化碳开发技术. 石油勘探与开发. 2024(04): 855-864 .  百度学术

百度学术

4. 孙丙向,成海,毕研涛. 石油工程“四提”技术进展与攻关方向. 石油科技论坛. 2024(03): 85-94 .  百度学术

百度学术

5. 李阳,曹小朋,赵清民,刘祖鹏,薛兆杰,蒋龙. 济阳坳陷陆相断陷盆地页岩油开发的几点思考. 石油钻探技术. 2024(04): 1-7 .  本站查看

本站查看

6. 吴壮坤,张宏录,池宇璇. 苏北页岩油二氧化碳强压质换技术. 石油钻探技术. 2024(04): 87-93 .  本站查看

本站查看

7. LI Yang,ZHU Yangwen,LI Zongyang,JIANG Tingxue,XUE Zhaojie,SHEN Ziqi,XIAO Pufu,YU Hongmin,CHENG Ziyan,ZHAO Qingmin,ZHANG Qingfu. Shale oil recovery by CO_2 injection in Jiyang Depression, Bohai Bay Basin, East China. Petroleum Exploration and Development. 2024(04): 981-992 .  必应学术

必应学术

8. 余前港,荣双,毛国扬,崔连文,彭根博,向传刚,王旭. 阳春沟区块页岩气超临界CO_2增能压裂研究与应用. 石油与天然气化工. 2024(05): 77-83 .  百度学术

百度学术

9. 李阳,赵清民,杨勇,张峰,曹功泽,张潦源,杨峰,鲁明晶. 胜利油田陆相页岩油前置CO_2压裂技术研究与实践. 断块油气田. 2024(06): 945-954 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: