Study on Evolution Law of Fracture Toughness of Ultra-Deep Layered Shale

-

摘要:

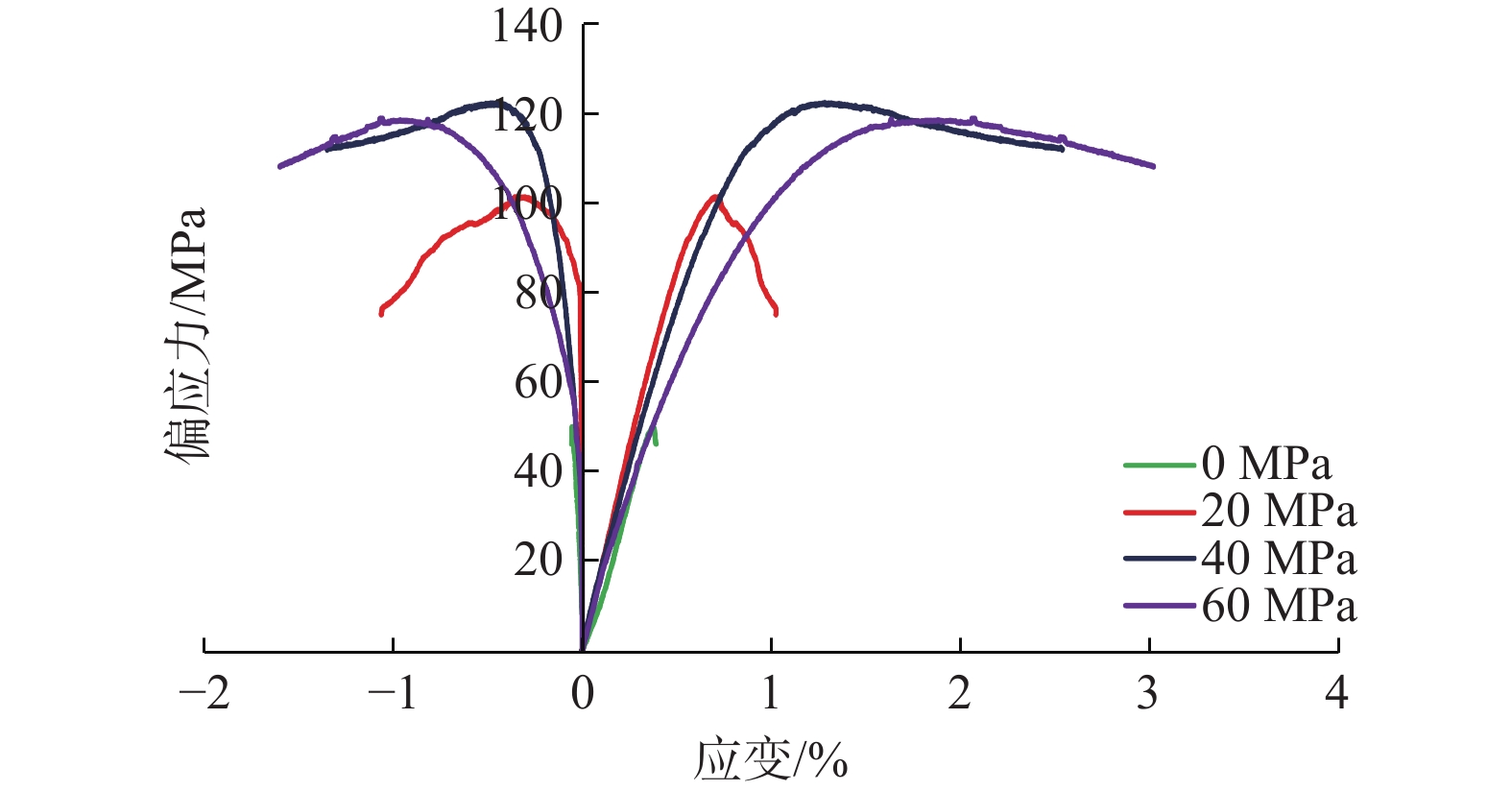

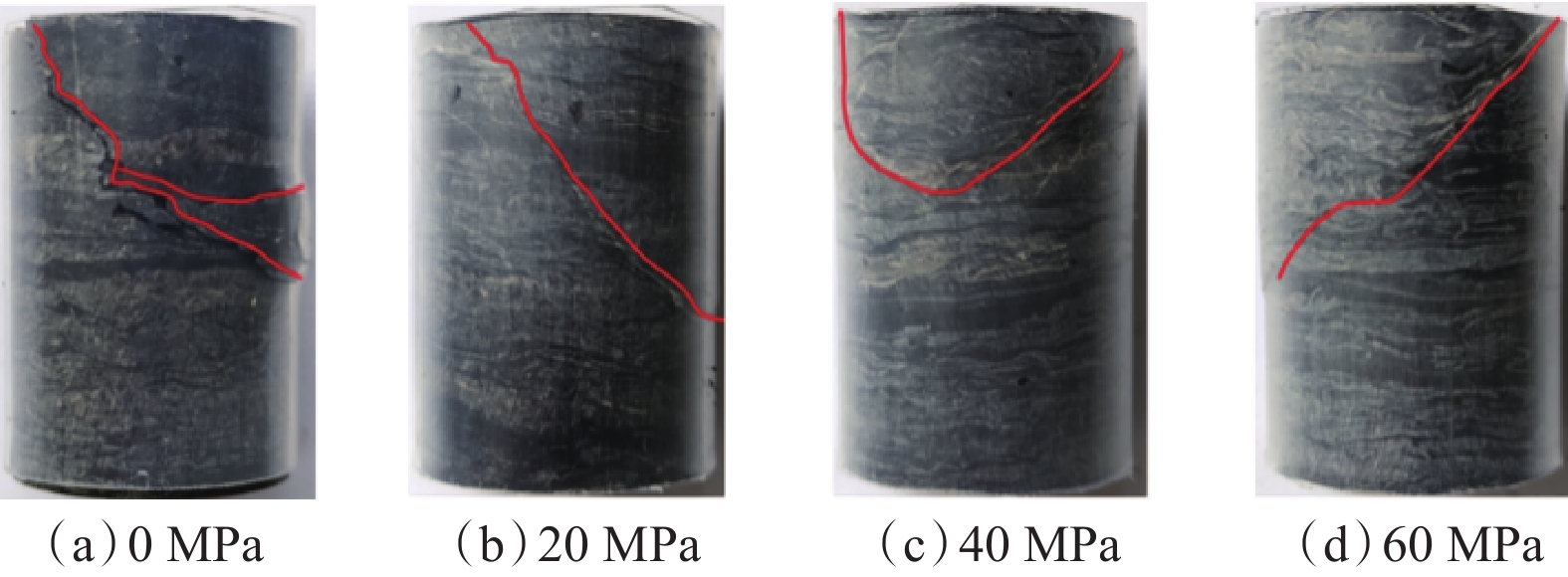

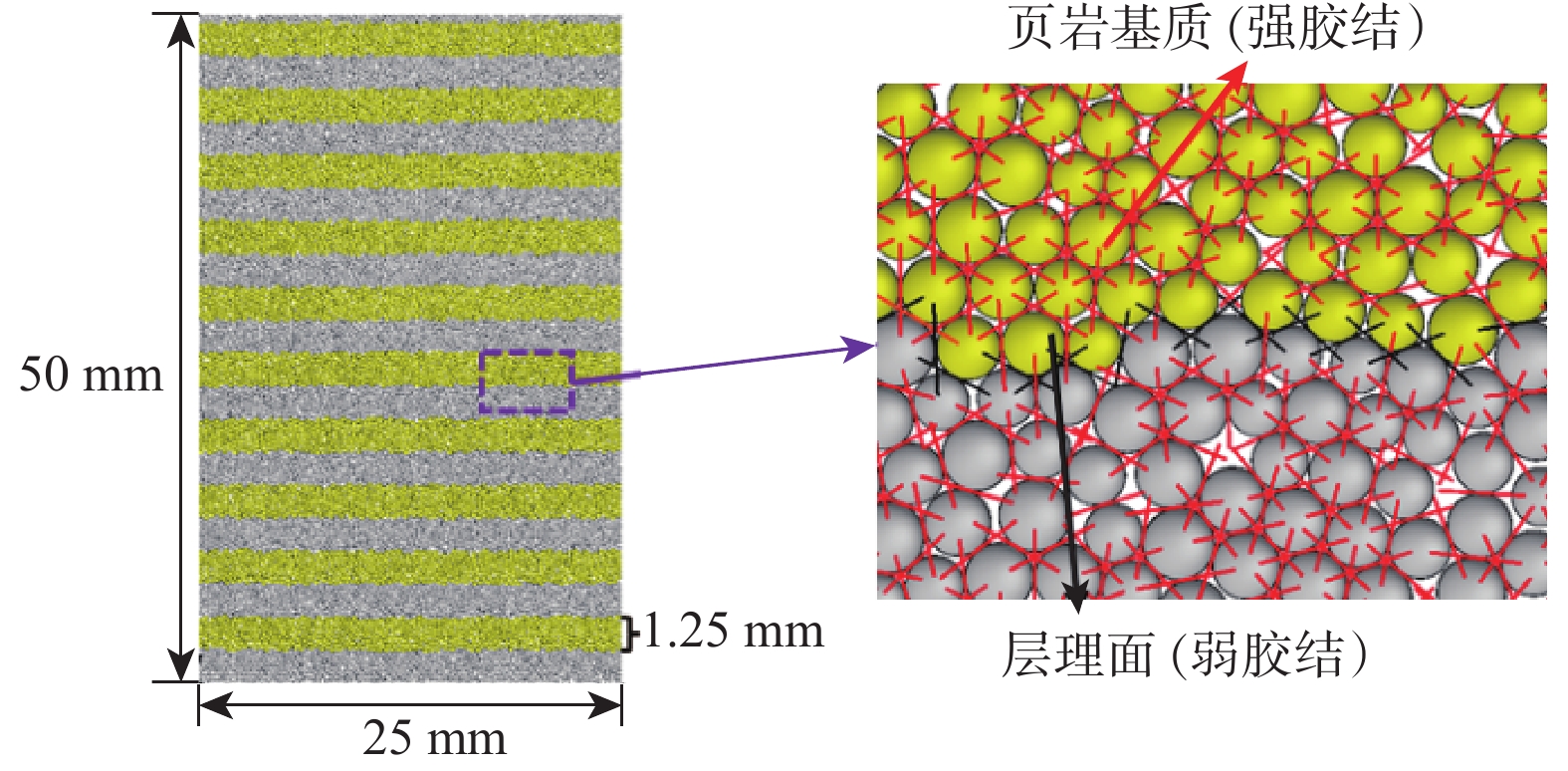

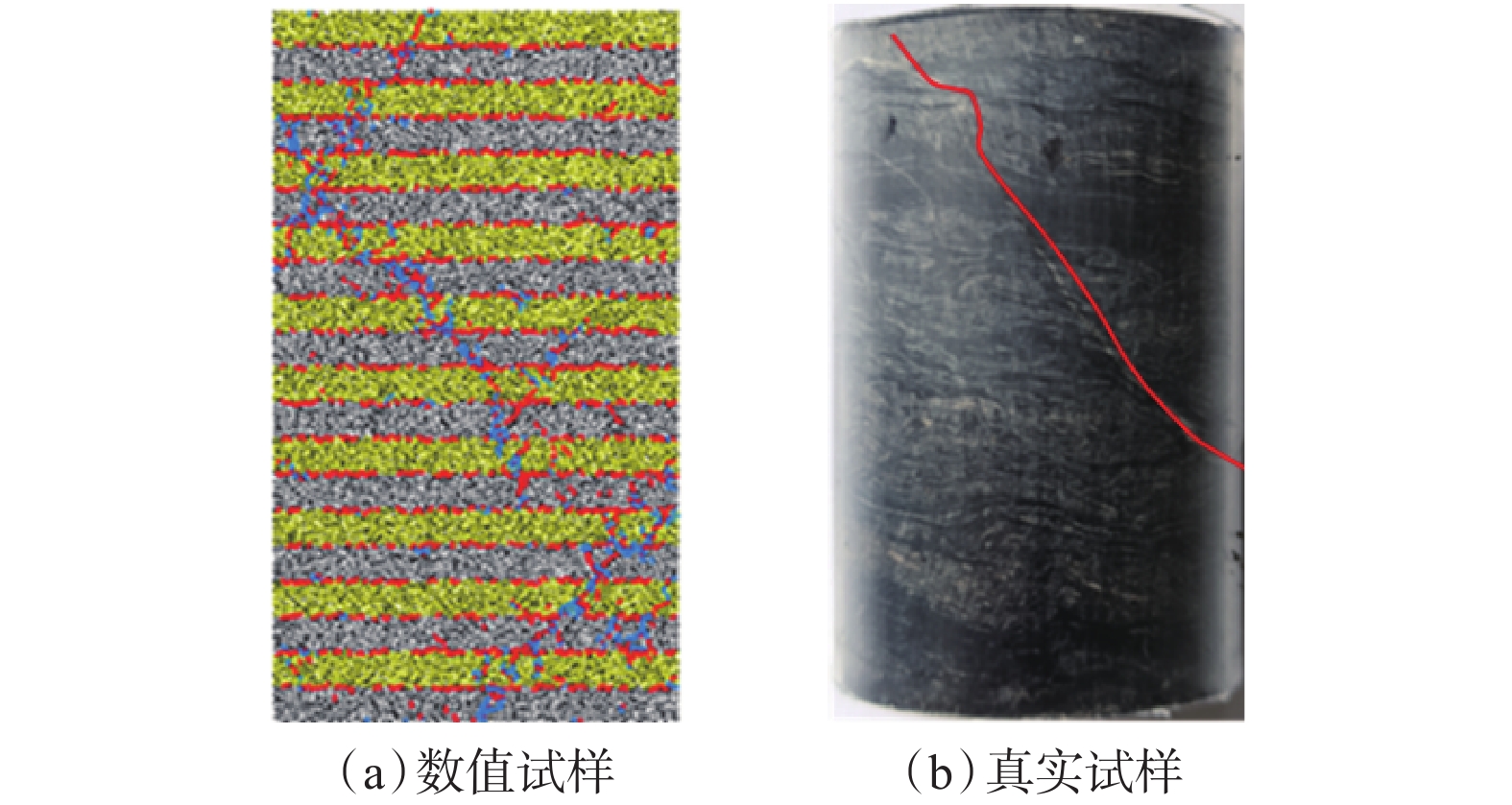

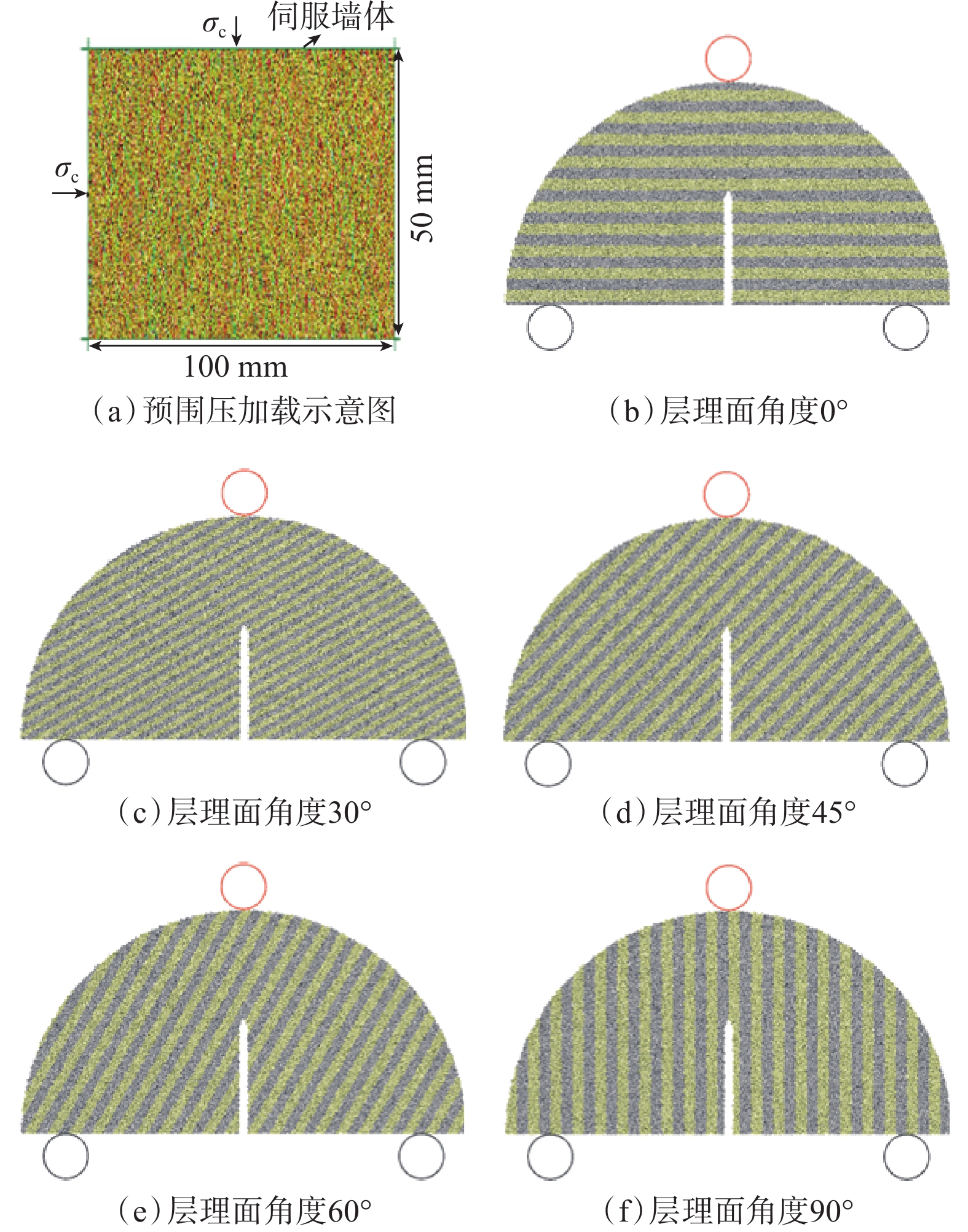

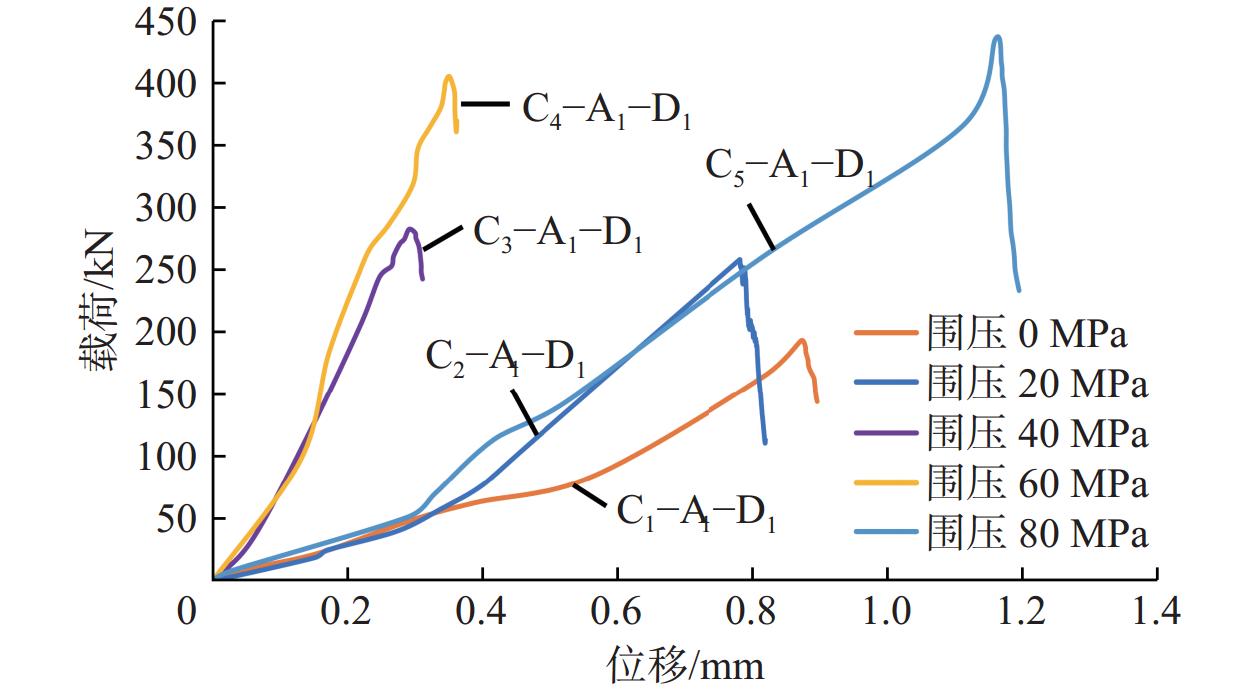

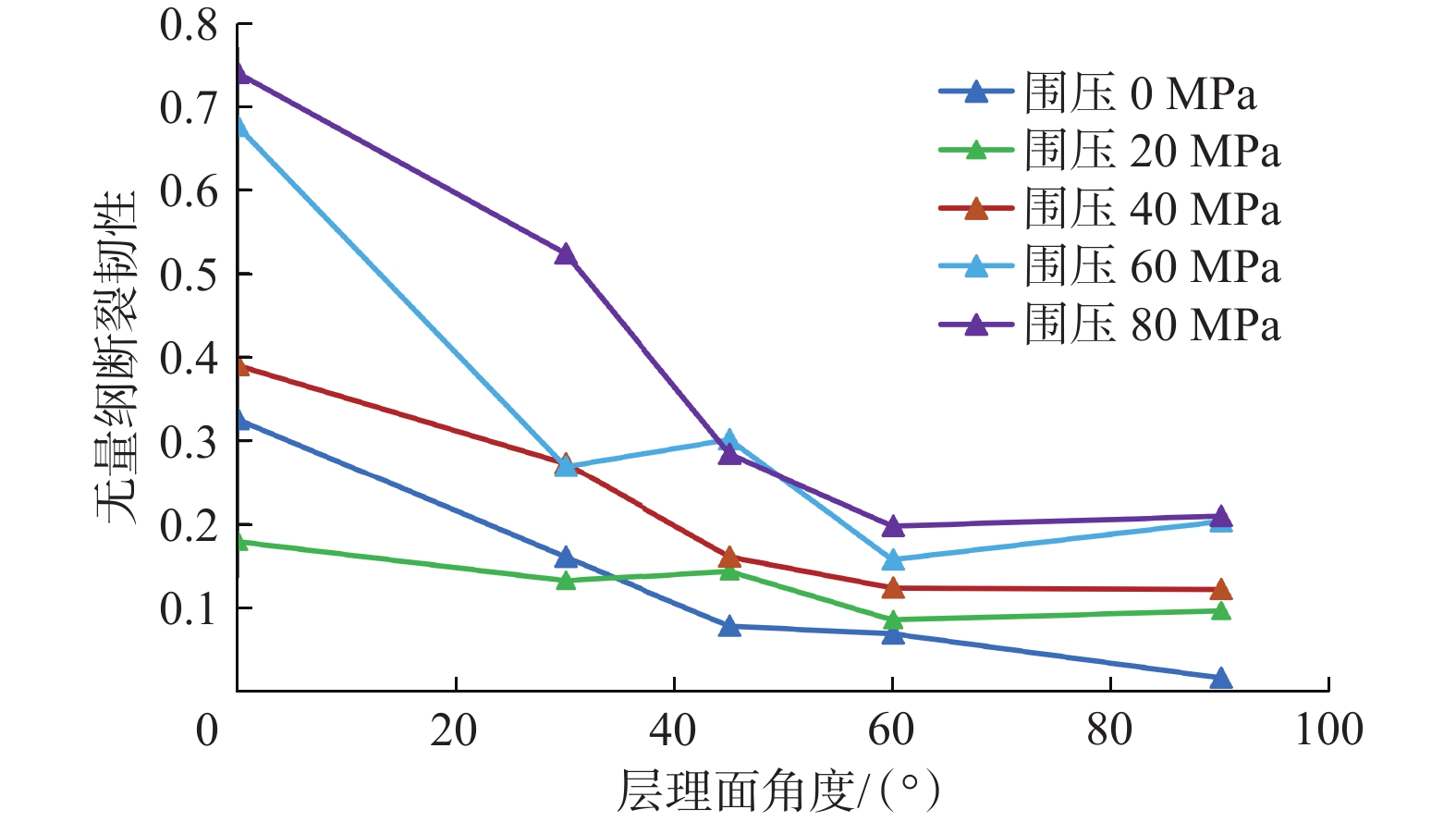

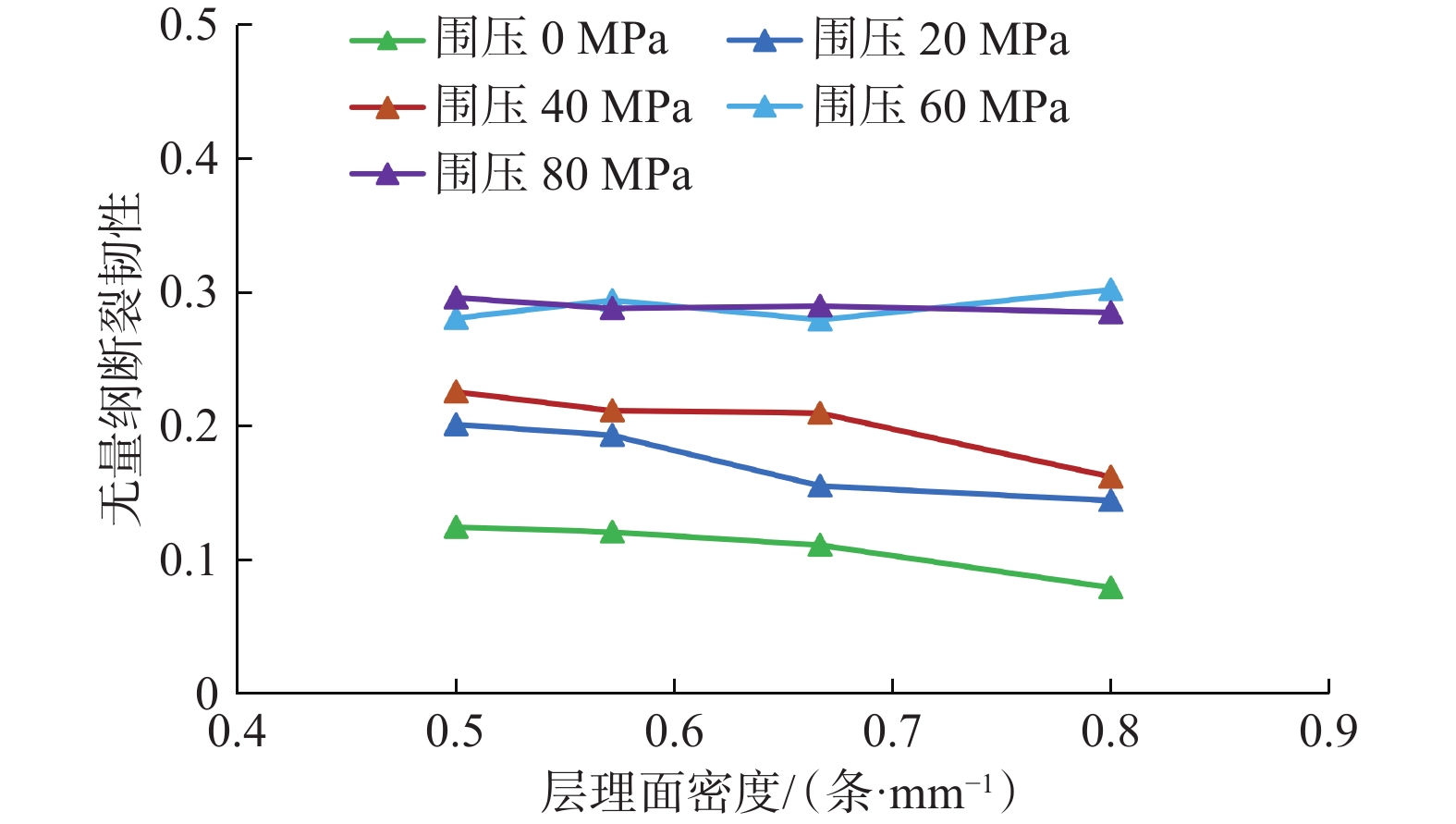

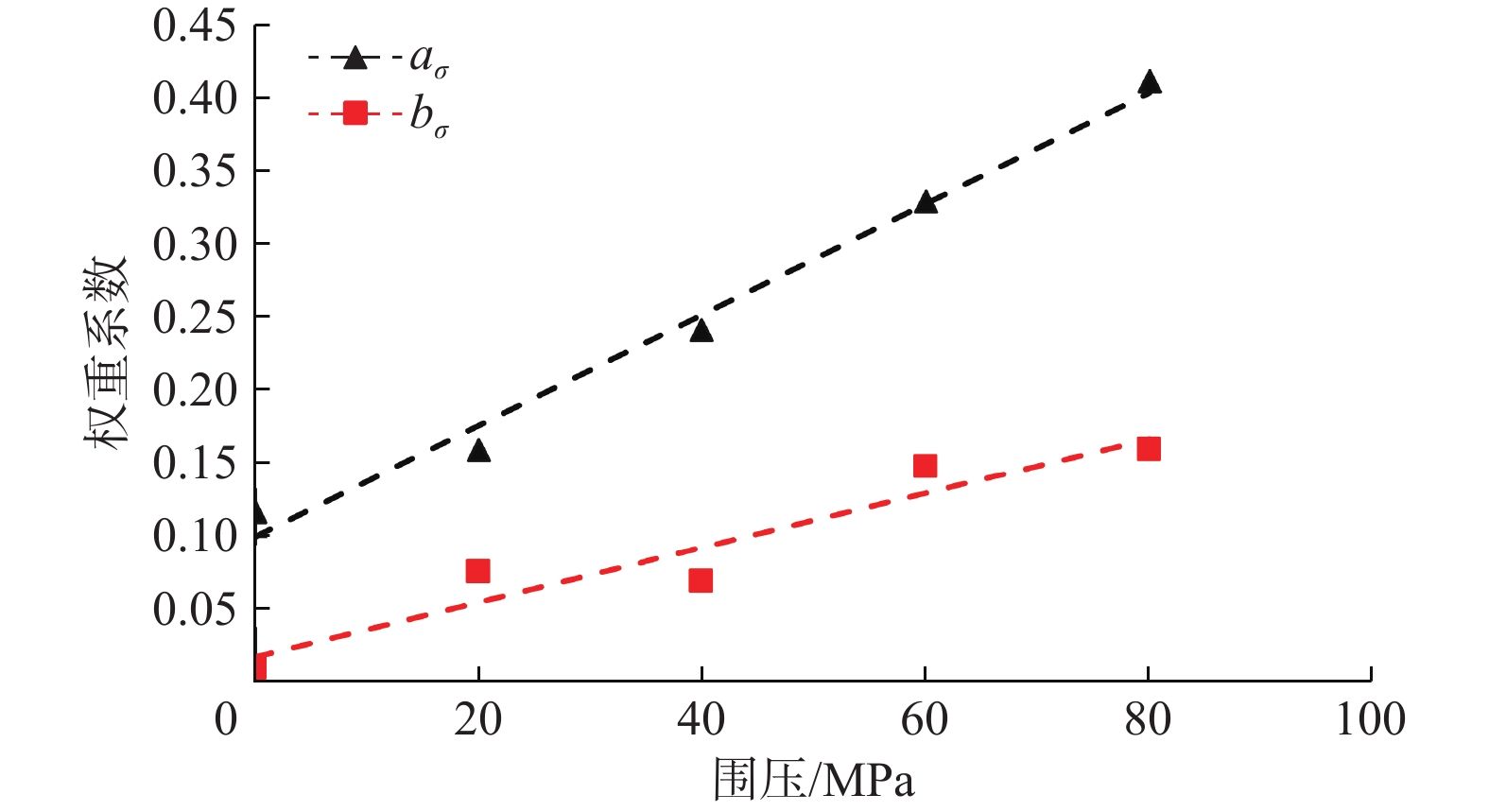

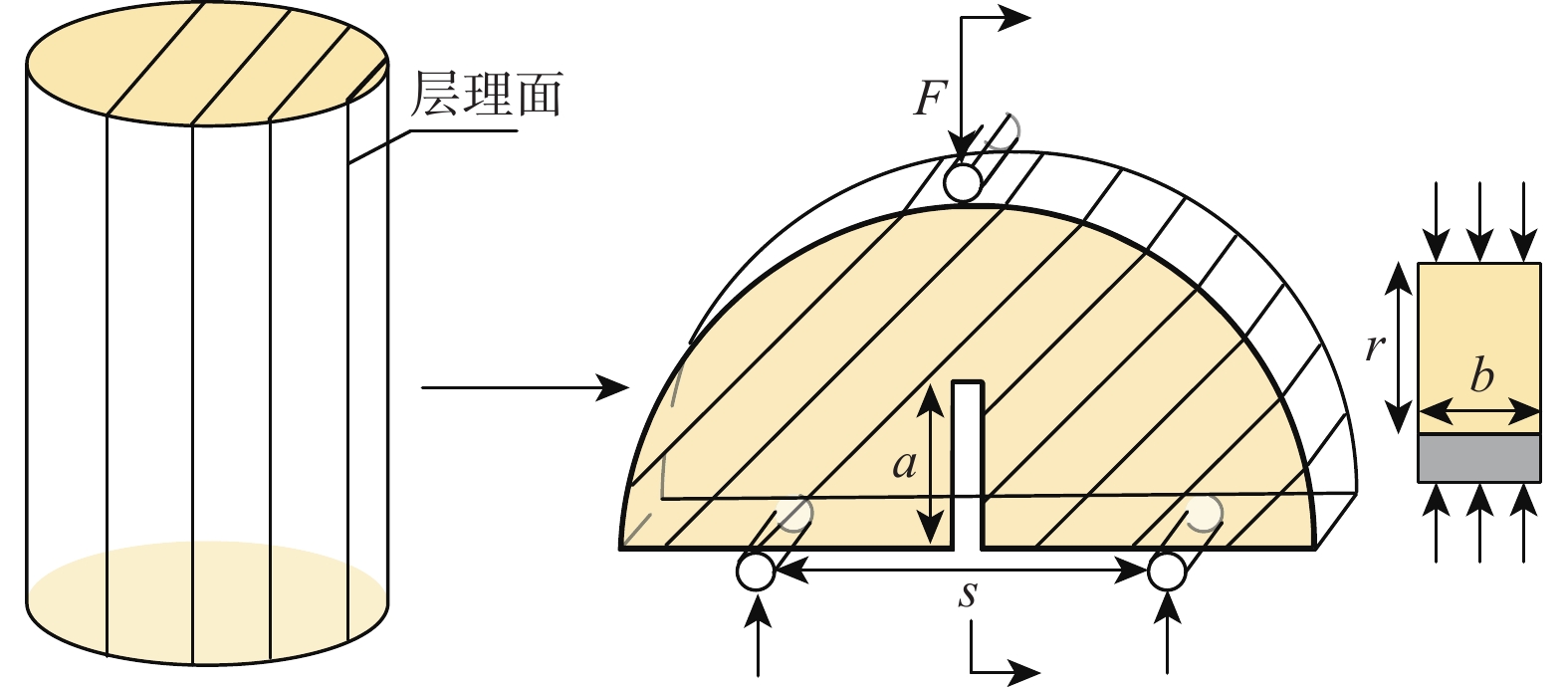

为深入探究超深页岩储层中水力裂缝纵向穿层机制,针对高应力及层理性质对页岩断裂特性的影响进行了系统性分析。首先,利用三轴压缩试验获取了页岩力学参数;其次,采用颗粒离散元法构建了带围压的半圆板页岩三点弯曲数值模型,模拟了页岩在不同工况下的断裂过程。数值模拟结果表明,围压增大显著提升了页岩的断裂韧性,且层理面角度和密度对断裂韧性的影响随着围压增大而增强:相同围压下,断裂韧性随着层理面角度增加而降低,随着层理面密度增加呈现小幅差异,表明层理面密度对断裂韧性的强化作用优于层理面角度。基于此,拟合了断裂韧性与围压、层理面角度和密度的定量关系,并构建了不同围压及层理面性质对页岩断裂韧性的量化图版。研究结果揭示了高应力条件下超深页岩储层层理性质对断裂特性的复杂影响,为优化水力压裂方案、有效控制水力裂缝穿层行为提供了理论依据。

Abstract:To gain a comprehensive understanding of the longitudinal hydraulic fracture propagation mechanism in ultra-deep shale reservoirs, the study systematically analyzes the influence of high stress and bedding properties on shale fracture characteristics. Initially, shale mechanical parameters are obtained through triaxial compression experiments. Subsequently, a three-point bending numerical model of a semi-circular shale plate with confining pressure is constructed using the particle discrete element method to simulate the fracture process under various conditions. The numerical simulation results demonstrate that increasing confining pressure significantly enhances shale fracture toughness, and the influence of bedding plane angle and density on fracture toughness is amplified with increasing confining pressure. Specifically, at the same confining pressure, fracture toughness decreases with an increase in bedding plane angle and exhibits a minor variation with an increase in bedding plane density, indicating that bedding plane density has a greater strengthening effect on fracture toughness than bedding plane angle. Based on these findings, a quantitative chart illustrating the impact of varying confining pressure and bedding plane properties on shale fracture toughness is developed, and a quantitative relationship between fracture toughness and confining pressure, bedding plane angle, and density is fitted. The study reveals the complex influence of bedding properties on fracture characteristics under high stress conditions in ultra-deep shale reservoirs, potentially providing a theoretical basis for optimizing hydraulic fracturing designs and effectively controlling hydraulic fracture propagation behavior.

-

-

表 1 数值模型细观胶结参数取值

Table 1 Meso-bond parameters of the numerical model

页岩 颗粒密度/

(kg·m−3)颗粒有效

模量/GPa胶结有效

模量/GPa胶结刚度比 胶结拉伸

强度/MPa胶结内聚力/MPa 胶结摩擦角/(°) 基质 2 640 5.0 19.20 1.35 117.6 70.4 25 层理面 2 640 5.0 3.84 1.35 23.5 14.1 14 表 2 页岩数值模型的断裂韧性计算结果

Table 2 Fracture toughness of the numerical model for shale

试样编号 Fmax/kN K′ 试样编号 Fmax/kN K′ C1−D1−A1 257.80 0.326 C2−D1−A1 194.49 0.180 C1−D2−A1 192.39 0.175 C2−D2−A1 205.05 0.204 C1−D3−A1 167.62 0.118 C2−D3−A1 248.98 0.305 C1−D4−A1 214.57 0.226 C2−D4−A1 241.07 0.287 C1−D1−A2 186.42 0.161 C2−D1−A2 174.28 0.133 C1−D2−A2 147.85 0.072 C2−D2−A2 194.47 0.180 C1−D3−A2 144.99 0.065 C2−D3−A2 186.92 0.162 C1−D4−A2 169.39 0.122 C2−D4−A2 176.83 0.139 -

[1] MAHANTA B, TRIPATHY A, VISHAL V, et al. Effects of strain rate on fracture toughness and energy release rate of gas shales[J]. Engineering Geology, 2017, 218: 39–49. doi: 10.1016/j.enggeo.2016.12.008

[2] ATKINSON C, SMELSER R E, SANCHEZ J. Combined mode fracture via the cracked Brazilian disk test[J]. International Journal of Fracture, 1982, 18(4): 279–291.

[3] 吕有厂. 层理性页岩断裂韧性的加载速率效应试验研究[J]. 岩石力学与工程学报,2018,37(6):1359–1370. LYU Youchang. Effect of bedding plane direction on fracture toughness of shale under different loading rates[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(6): 1359–1370.

[4] 陈勉,金衍,袁长友. 围压条件下岩石断裂韧性的实验研究[J]. 力学与实践,2001,23(4):32–35. doi: 10.3969/j.issn.1000-0879.2001.04.010 CHEN Mian, JIN Yan, YUAN Changyou. Study on the experiment for fracture toughness under confining pressure[J]. Mechanics in Engineering, 2001, 23(4): 32–35. doi: 10.3969/j.issn.1000-0879.2001.04.010

[5] 董京楠,金衍,陈勉,等. 页岩Ⅰ型断裂韧性测试及跨尺度裂缝表征研究[J]. 地下空间与工程学报,2019,15(增刊1):205–210. DONG Jingnan, JIN Yan, CHEN Mian, et al. Study on shale fracture toughness and micro-characterization of mode Ⅰ crack using DCB specimen and SEM method[J]. Chinese Journal of Underground Space and Engineering, 2019, 15(supplement 1): 205–210.

[6] 余海棠,丁乙,刘艳梅,等. 考虑水化损伤作用的页岩动态自吸模型[J]. 石油钻探技术,2023,51(5):139–148. doi: 10.11911/syztjs.2023054 YU Haitang, DING Yi, LIU Yanmei, et al. A dynamical spontaneous imbibition model for shale considering hydration damage[J]. Petroleum Drilling Techniques, 2023, 51(5): 139–148. doi: 10.11911/syztjs.2023054

[7] 金衍,薄克浩,张亚洲,等. 深层硬脆性泥页岩井壁稳定力学化学耦合研究进展与思考[J]. 石油钻探技术,2023,51(4):159–169. doi: 10.11911/syztjs.2023024 JIN Yan, BO Kehao, ZHANG Yazhou, et al. Advancements and considerations of chemo-mechanical coupling for wellbore stability in deep hard brittle shale[J]. Petroleum Drilling Techniques, 2023, 51(4): 159–169. doi: 10.11911/syztjs.2023024

[8] 谭鹏,陈朝伟,赵庆,等. 页岩气多簇压裂断层活化机理与控制方法[J]. 石油钻探技术,2024,52(6):107–116. doi: 10.11911/syztjs.2024120 TAN Peng, CHEN Zhaowei, ZHAO Qing, et al. Mechanism and control method of fault activation by multi-cluster fracturing of shale gas[J]. Petroleum Drilling Techniques, 2024, 52(6): 107–116. doi: 10.11911/syztjs.2024120

[9] 刘彧轩,杨兴贵,郭建春. 纵向无限级多薄层储层裂缝穿层扩展规律[J]. 断块油气田,2024,31(6):1076–1082. LIU Yuxuan, YANG Xinggui, GUO Jianchun. Fracture through-layer propagation law in longitudinal infinite multiple thin layer reservoirs[J]. Fault-Block Oil & Gas Field, 2024, 31(6): 1076–1082.

[10] 田建超,张艺,李凝,等. 页岩油水力压裂裂缝特征场地级数值模拟优化方法[J]. 石油钻采工艺,2024,46(3):326–335. TIAN Jianchao, ZHANG Yi, LI Ning, et al. Numerical simulation optimization method for site-level hydraulic fracturing fracture characteristics in shale oil[J]. Oil Drilling & Production Technology, 2024, 46(3): 326–335.

[11] 赵彦昕,许文俊,王雷,等. 陆相页岩储层水力裂缝穿层扩展规律[J]. 石油钻采工艺,2023,45(1):76–84. ZHAO Yanxin, XU Wenjun, WANG Lei, et al. Through-layer propagation laws of hydraulic fractures in continental shale reservoirs[J]. Oil Drilling & Production Technology, 2023, 45(1): 76–84.

[12] 熊健,吴俊,刘向君,等. 陆相页岩储层地质力学特性及对压裂效果的影响[J]. 西南石油大学学报(自然科学版),2023,45(5):69–80. XIONG Jian, WU Jun, LIU Xiangjun, et al. The geomechanical characteristics of the continental shale reservoirs and their influence on the fracturing effect[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2023, 45(5): 69–80.

[13] 张景轩,范晓,陈波,等. 硬脆性页岩断裂韧性二维数值模拟研究[J]. 复杂油气藏,2019,12(1):73–80. ZHANG Jingxuan, FAN Xiao, CHEN Bo, et al. Two-dimensional numerical simulation of fracture toughness of hard brittle shale[J]. Complex Hydrocarbon Reservoirs, 2019, 12(1): 73–80.

[14] XU Yuan, DAI Feng, ZHAO Tao, et al. Fracture toughness determination of cracked chevron notched Brazilian disc rock specimen via Griffith energy criterion incorporating realistic fracture profiles[J]. Rock Mechanics and Rock Engineering, 2016, 49(8): 3083–3093. doi: 10.1007/s00603-016-0978-0

[15] YIN Tubing, ZHANG Shuaishua, LI Xibing, et al. A numerical estimate method of dynamic fracture initiation toughness of rock under high temperature[J]. Engineering Fracture Mechanics, 2018, 204: 87–102. doi: 10.1016/j.engfracmech.2018.09.034

[16] KURUPPU M D, OBARA Y, AYATOLLAHI M R, et al. ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen[J]. Rock Mechanics and Rock Engineering, 2014, 47(1): 267–274. doi: 10.1007/s00603-013-0422-7

[17] 张昊天,周文,曹茜,等. 基于应力—应变模型的脆塑性测井评价[J]. 测井技术,2018,42(3):331–337. ZHANG Haotian, ZHOU Wen, CAO Qian, et al. Log evaluation method of the brittle-plastic parameters based on stress-strain model[J]. Well Logging Technology, 2018, 42(3): 331–337.

[18] POTYONDY D O, CUNDALL P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329–1364. doi: 10.1016/j.ijrmms.2004.09.011

[19] 李庆辉,陈勉,金衍,等. 页岩气储层岩石力学特性及脆性评价[J]. 石油钻探技术,2012,40(4):17–22. doi: 10.3969/j.issn.1001-0890.2012.04.004 LI Qinghui, CHEN Mian, JIN Yan, et al. Rock mechanical properties and brittleness evaluation of shale gas reservoir[J]. Petroleum Drilling Techniques, 2012, 40(4): 17–22. doi: 10.3969/j.issn.1001-0890.2012.04.004

-

期刊类型引用(8)

1. 陈浩,孙文常,邹顺良. FAST阵列仪器三相流产出剖面测试技术应用研究. 江汉石油职工大学学报. 2024(01): 23-25+32 .  百度学术

百度学术

2. 黄卫国. 涪陵地区页岩气易碎地层随钻识别研究. 江汉石油职工大学学报. 2024(03): 20-23 .  百度学术

百度学术

3. 商永涛,林新宇,李相亮,李辉. 基于机器学习的压裂参数优化方法研究及应用. 石油化工应用. 2022(08): 33-38 .  百度学术

百度学术

4. 李红岩,王鹏涛,郭世炎,刘斌,张献喻,赵宇璇. 水基钻井液用新型页岩抑制剂的制备及性能研究. 当代化工. 2021(02): 418-421 .  百度学术

百度学术

5. 舒志国,刘莉,梁榜,陆亚秋,郑爱维,包汉勇. 基于物质平衡原理的页岩气井产能评价方法. 天然气地球科学. 2021(02): 262-267 .  百度学术

百度学术

6. 谭判,张祥,李明军,刘斌,蒋勇兵,蔡健博. 长水平段页岩气井旋转导向随钻技术应用试验. 江汉石油职工大学学报. 2020(01): 52-54 .  百度学术

百度学术

7. 陈四平,谭判,石文睿,赵红燕. 涪陵页岩气优质储层测井综合评价方法. 石油钻探技术. 2020(04): 131-138 .  本站查看

本站查看

8. 胡琴,李志强,任航. 模糊正交法在弧形盘式齿破岩性能评价中的应用. 断块油气田. 2019(03): 389-393 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: