Drilling Speed Enhancement Method for Extended Reach Wells Based on Machine Learning and Bayesian Optimization

-

摘要:

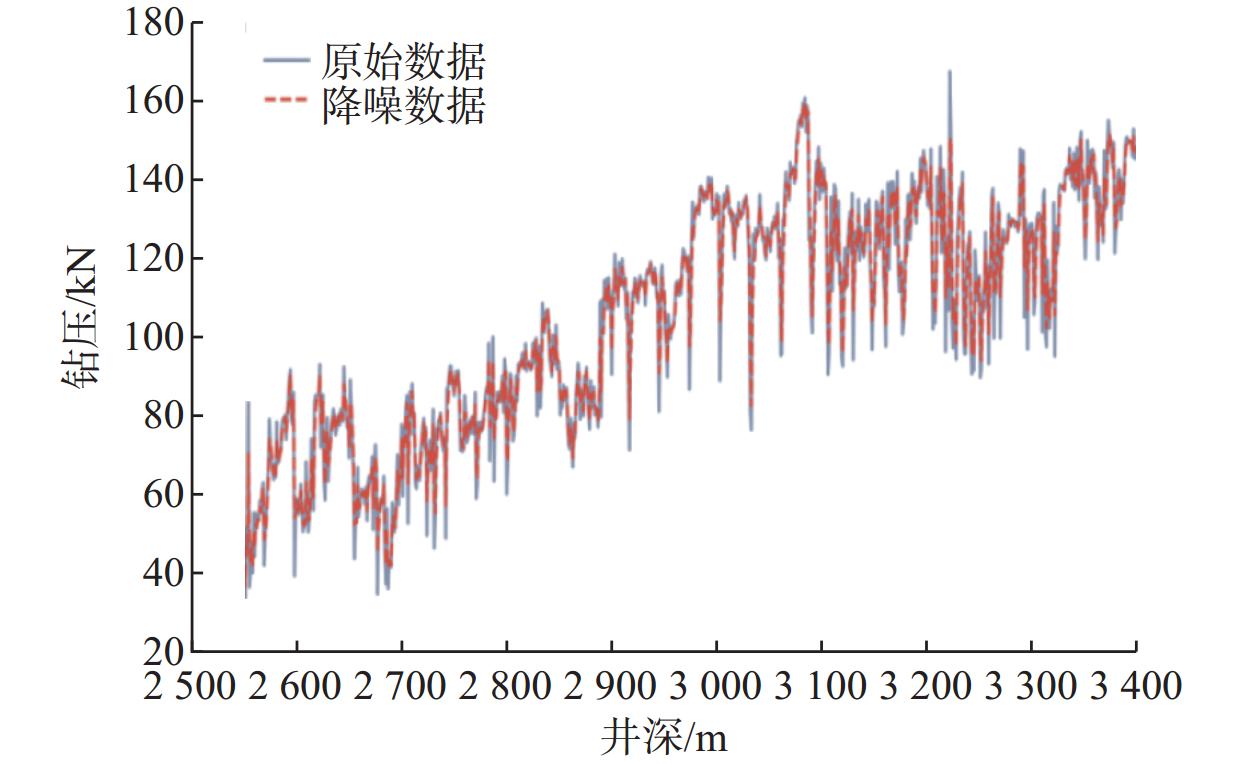

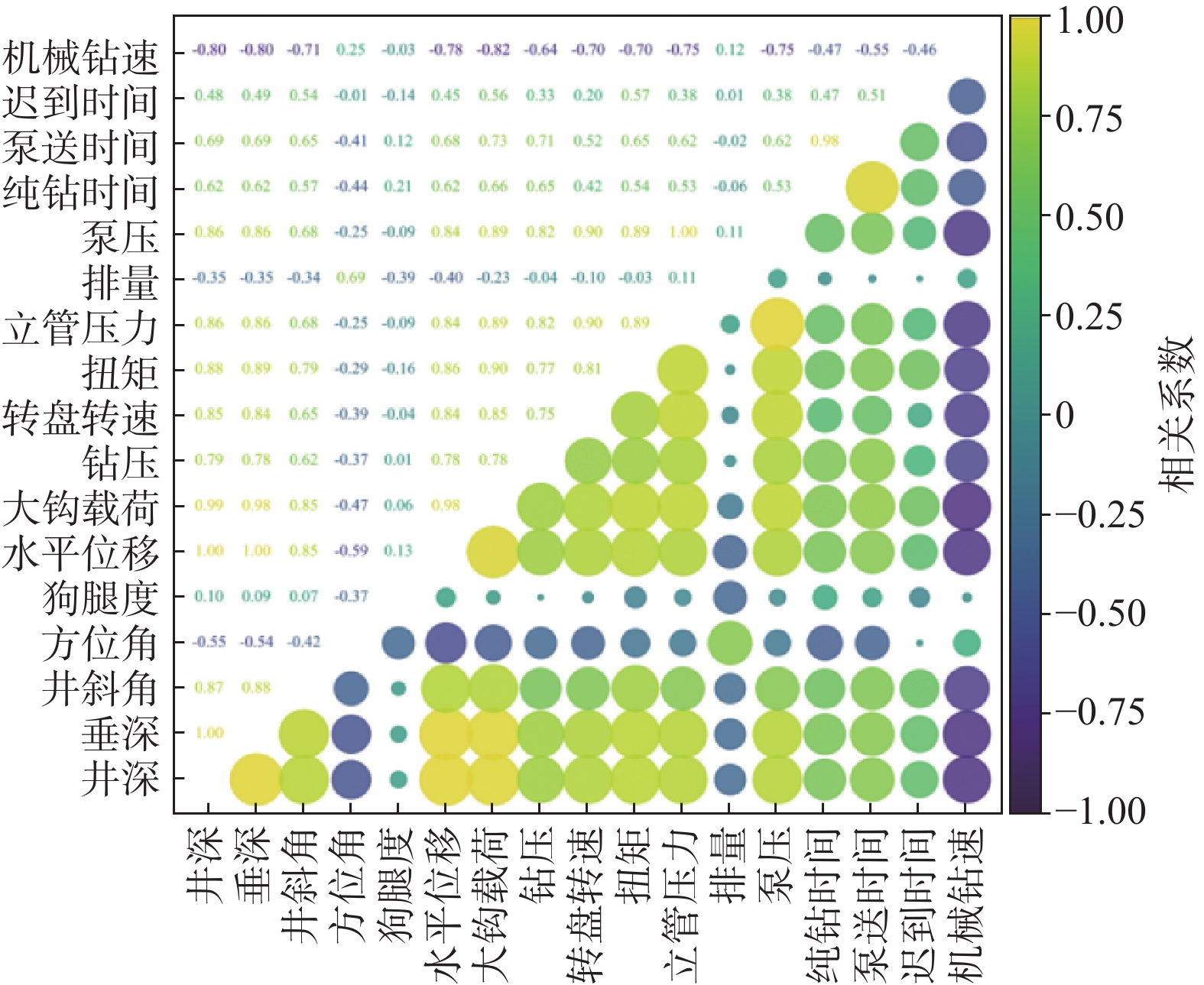

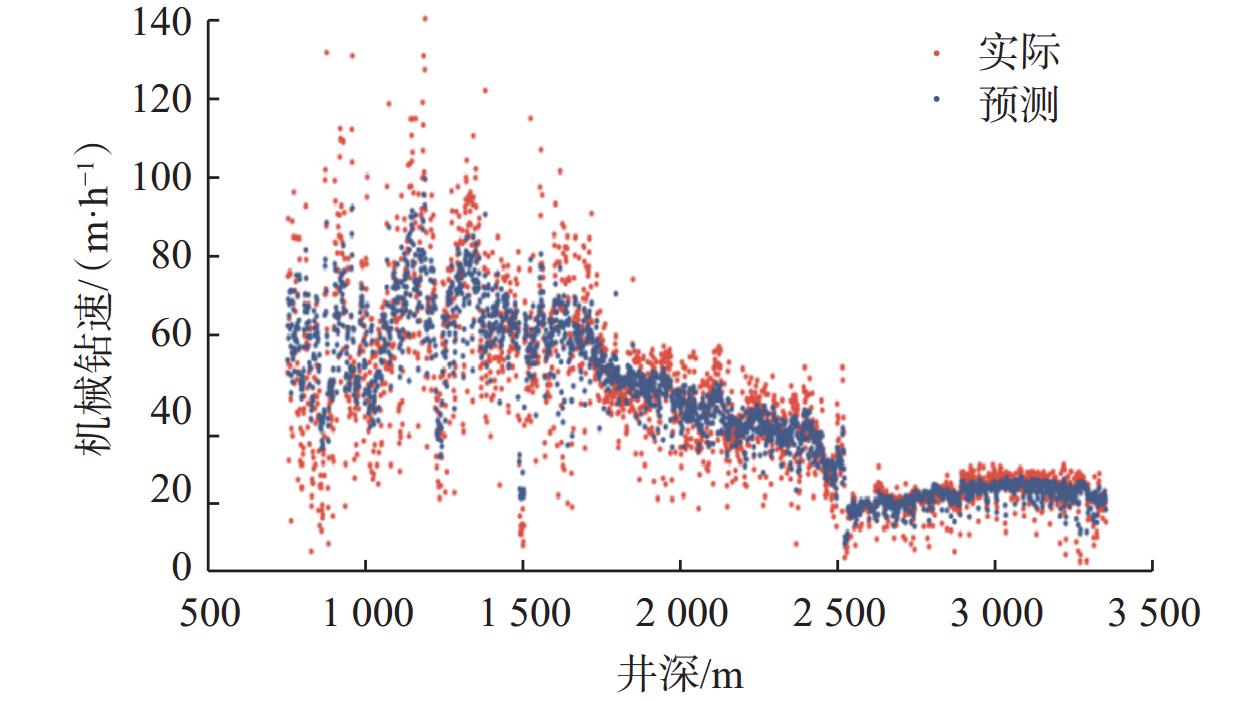

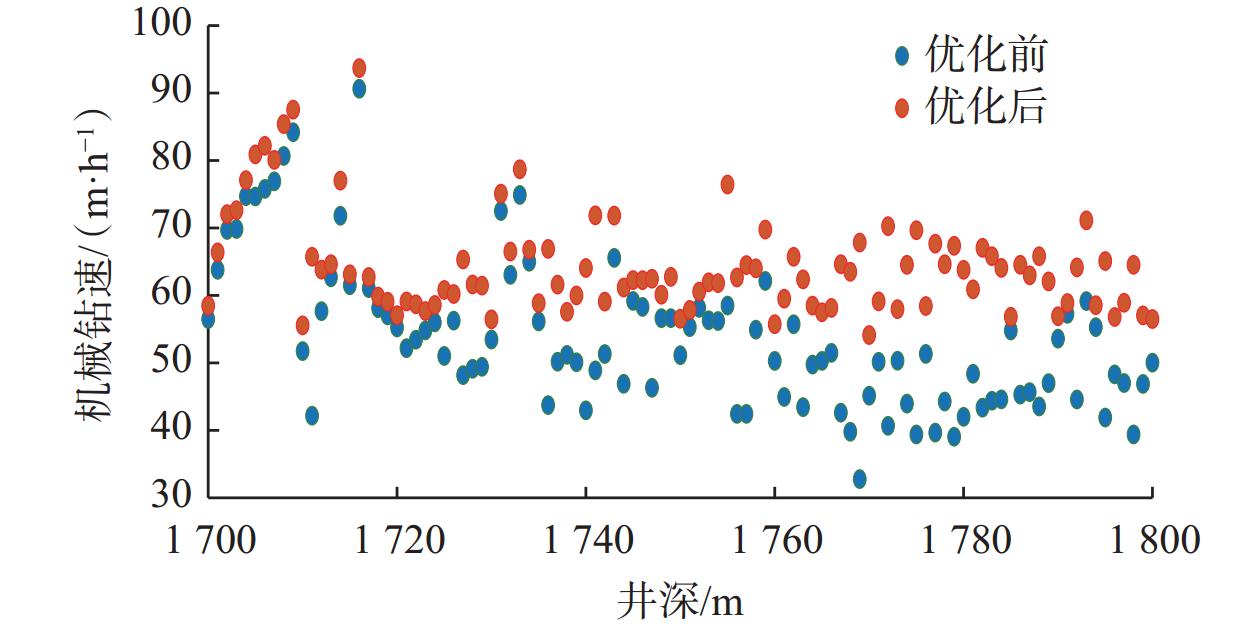

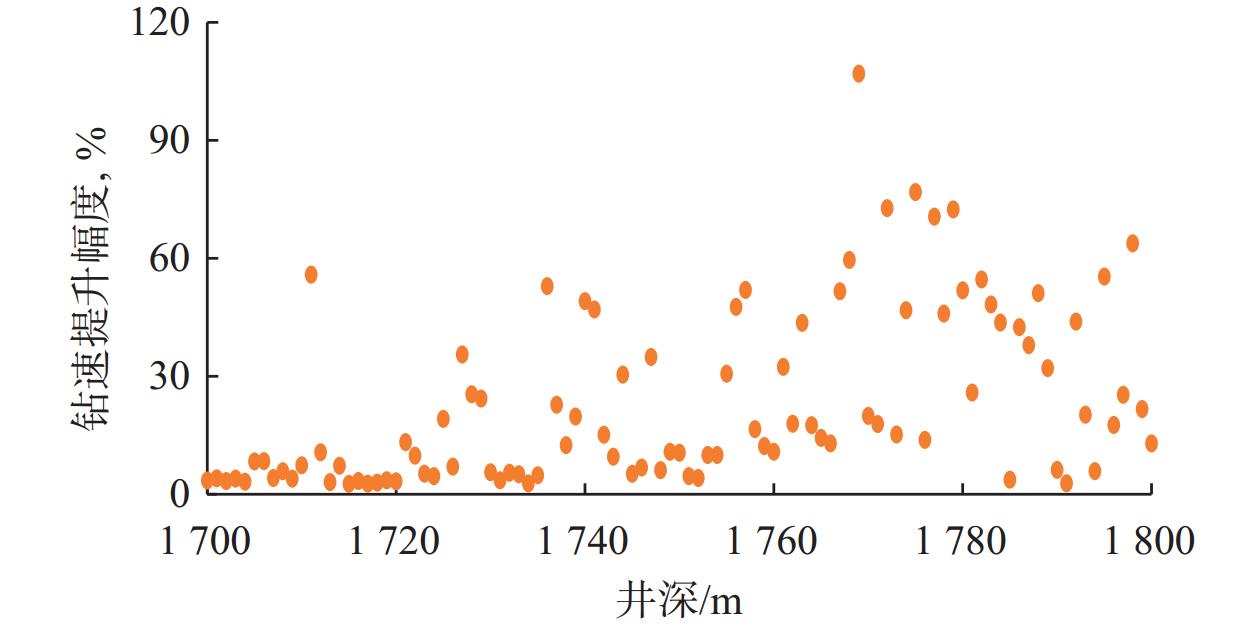

海上大位移井井眼轨迹复杂,水平位移较大,导致井下摩阻高,严重影响了钻井效率。为此,根据钻井数据和录井数据等,提出了一种基于机器学习钻速预测与钻井参数优化的大位移井钻井提速方法。首先,对现场原始数据进行滤波、归一化等预处理,进行相关性分析,发现钻压、转盘转速等钻井参数及井斜角、水平位移等井眼轨迹参数与钻速有显著的相关性;然后,构建了基于BP神经网络、随机森林和支持向量机的钻速预测模型,评价结果表明,BP神经网络模型表现最优,可以较为准确地预测海上大位移井的机械钻速;最后,采用贝叶斯优化算法,以提高钻速为目标对钻压、转盘转速和排量等参数进行优化。优化结果表明,钻井参数优化后,机械钻速平均提升了18.86%。研究结果揭示了钻井参数和井眼轨迹参数对大位移井钻速的影响规律,为大位移井钻井提速提供了理论依据。

Abstract:The complex wellbore trajectories and significant horizontal displacements of offshore extended reach wells lead to increased downhole friction, severely affecting drilling efficiency. By leveraging drilling and logging data, this study proposes a novel method for rate of penetration (ROP) enhancement in extended reach wells with ROP prediction and drilling parameter optimization based on machine learning. Firstly, the original field data were pre-processed by filtering and normalization, followed by correlation analysis, revealing that ROP has strong correlation with drilling parameters such as weight on bit (WOB) and rotary speed, as well as wellbore trajectory parameters such as inclination angle and horizontal displacement. Based on these findings, ROP prediction models were developed using BP neural networks, random forests, and support vector machines. The results show that the BP neural network model outperforms the others, providing relatively accurate ROP predictions for offshore extended reach wells. Finally, the Bayesian optimization algorithm was employed to optimize parameters such as WOB, rotary speed, and displacement for ROP enhancement. The optimization results show that the ROP increases by 18.86% on average after the optimization of drilling parameters. The research results reveal the influence of drilling parameters and wellbore trajectory parameters on the ROP of extended reach wells and provide a theoretical basis for increasing the ROP of extended reach wells.

-

干热岩(hot dry rock,HDR)是指埋藏于地下3~10 km、温度150~650 ℃、不含或微含不流动流体的高温岩体[1]。保守估计,地壳3~10 km深处干热岩所蕴含的能量相当于全球所有石油、天然气和煤炭所蕴藏能量的30倍[2]。在干热岩概念基础上发展而来的增强型地热系统(enhanced geothermal systems,EGS),是指通过水力压裂等工程手段,在地下深部低渗透性干热岩体中形成人工热储,进而长期、经济地采出相当数量地热能的人造水热系统[3]。

共和盆地目前是我国干热岩勘查与开发的试验田,位于昆仑—秦岭纬向构造带与河西系构造复合部位,是在新近纪初形成的断陷盆地,其北侧是青海南山断褶隆起带,南侧是河卡山—贵南南山断褶隆起带,西为鄂拉山断褶隆起带,东为瓦里贡山断褶隆起带。根据区域地质构造分析、地热地质调查和地球物理(航磁、地震)解译等的结果,在共和盆地恰卜恰岩体内钻了5口井深为2 927.00~4 200.00 m的干热岩勘查井。GR1井位于青海省共和县恰卜恰镇恰卜恰河谷内,是目前国内完钻温度最高的一口干热岩井,井底温度236 ℃[4-8]。

为了构建青海共和盆地干热岩井的流动和传热通道,掌握该地区干热岩井水力压裂后的裂缝走向和裂缝参数,利用地面测斜仪监测了X1井3个压裂阶段的裂缝,采集了倾斜角度的变化信号,并利用数据解释软件反演求取了裂缝参数,获得了每一压裂阶段的裂缝方位、裂缝长度与裂缝复杂性,可以为优化压裂设计、评价压裂效果以及干热岩注入–采出井的井位部署提供依据。

1. 地面测斜仪测试原理

通过水力压裂将地层压开,使之形成1条一定宽度的裂缝。压裂裂缝引起的岩石变形场向各个方向辐射,引起地面及地下地层变形。地面变形为微米级,几乎不可测量,但变形场的变形梯度(倾斜场)是比较容易测量的。因此,可以在井下或压裂井井口周围布设一组测斜仪来测量由于压裂引起岩石变形而导致的地面倾斜角度,再用地球物理反演[9]方法反演出压裂裂缝参数。图1所示为测斜仪监测垂直裂缝的原理,显示了从地面测斜仪和邻井井下测斜仪观察到的水力裂缝造成的地层变形。

在监测压裂裂缝之前,基于相关的施工参数,可以提前计算出压裂裂缝产生过程中所造成的地面最大倾斜角,计算公式为:

Tmax (1) 式中:Tmax为最大倾斜角,μrad;V为裂缝内流体的体积,m3;D为射孔垂直深度,m。

X1井目的层埋深约3 650.00 m,利用式(1)计算其每个压裂阶段(300 m3液体)形成垂直裂缝能够造成的地面最大倾斜角约为1 000 nrad,而测斜仪传感器的测量精度为1 nrad,完全满足监测的需求。

利用地面测斜仪监测压裂裂缝的方法在国内外得到了广泛应用[10-14],但都是用于监测含油气资源沉积岩储层的压裂裂缝,笔者首次将其应用于监测干热岩压裂裂缝。

2. X1井目的层花岗岩储层特征

X1井压裂层段对应井深3 493.60~3 705.00 m,岩性主要为黑云母二长花岗岩,岩层致密且天然裂隙较发育。为进一步了解储层特性,分别进行了岩石力学和地应力试验,获取了岩石力学和地应力参数。

对共和盆地X1井所取储层岩心进行了岩石力学试验,获得了不同围压下的杨氏模量和泊松比:单轴下的杨氏模量为31.00~33.00 GPa,泊松比为0.216~0.225;围压下的杨氏模量为47.29~54.14 GPa,泊松比为0.319~0.343。40 MPa围压下的泊松比大于0.300,杨氏模量高于40 GPa。

X1井地层的各向异性较强,统计各向异性方向平均为53.5°,可知地层的各向异性方向主要为北东东—南西西,即最大主应力方向,与地面考察结果基本一致。通过地应力测试,获得X1井井深3 226.00 m处的最小水平主应力为68.94 MPa,最大水平主应力为77.67 MPa,折算到压裂段中部深度最小水平主应力为77.0 MPa,最大水平主应力为86.7 MPa,最大与最小水平主应力差为9.7 MPa。

受构造变形影响,X1井部分井段岩心裂隙发育,出现了完整岩体与裂隙岩体互层现象。X1井部分井段还有断层发育迹象,如取自井深2 250.00 m处的岩心呈角砾状,无充填物,厚34.10 m,推测为一断层。X1井井深3 000.00 m以深地应力较高,部分岩心严重饼化(见图2)。

3. X1井压裂裂缝监测方案设计

根据目的层深度和施工规模确定直井地面测斜仪的分布位置和数量。根据X1井目的层的实际井深(3 493.60~3 705.00 m)和压裂施工参数,确定该井压裂需布置42支测斜仪。结合设计方案和现场地表实际条件,在X1井井口3 km范围内布置了42支测斜仪(见图3)。图3中间是X1井的井口,黑旗代表分布在每一个测点的测斜仪,黑点是现场布置测斜仪实际走过的轨迹。每一个测点都是通过GPS定位确定的。

4. X1井裂缝监测结果及分析

在干热岩增强型地热(EGS)开发过程中,国际上一般采用对井进行取热和发电,换热井主要依据地热井热储裂缝的方位、缝长等部署。相比于微地震监测等其他监测方法,地面测斜仪能够明确给出裂缝的方位,据此可进行换热井井眼轨道设计。

青海共和X1井的压裂经历了吸水性测试、小型压裂测试、变排量注入压裂和胶液扩缝3个阶段,前2个阶段的压裂液为清水,第3个阶段的压裂液是胶液和清水。图4、图5和图6分别为3个压裂阶段测斜仪监测到的结果(左图均为矢量场图,右图均为裂缝放大图;图中绿色部分是压裂形成的垂直裂缝,红色部分是压裂形成的水平裂缝,对应了压裂过程中产生的复杂裂缝)。从图4—图6可看出,X1井3个压裂阶段形成垂直裂缝的方位都是北偏东方向,与最大水平主应力的方位一致,但每次方位略有不同,具体跟地质条件和压裂工艺参数有关。

表1为X1井3个阶段形成垂直裂缝的主要参数及监测结果。由于X1井的目的层天然裂隙比较发育,且前2个阶段的压裂液是清水,不但黏度低(1 mPa·s)而且排量低(0.5~1.5 m3/min),导致进入垂直裂缝压裂液的占比相对较低,分别为48%和53%(见表1),其余的清水都进入了被激活的水平天然裂隙,形成了一定程度的复杂裂缝。第3阶段采用了较高黏度的压裂液(胶液+清水),而且排量较高(2.0 m3/min),进入垂直裂缝压裂液的占比最高(58%),说明采用高黏胶液(20 mPa·s)进行初期造缝,造缝效果最好,所以此时的垂直裂缝缝方位最可靠,为北偏东22.32°,同时此时缝高也最高,达到64.00 m。

表 1 X1井3个压裂阶段垂直裂缝的监测结果Table 1. Mapping results of vertical fractures during three fracturing stages of Well X1压裂

阶段裂缝

方位裂缝

倾角半缝长/

m缝高/

m压裂液

体积/m3液体进入

垂直缝

比例,%第1阶段 NE28.73° SE29.38° 81.00 51.00 163.50 48 第2阶段 NE43.50° SE60.00° 76.20 51.00 190.61 53 第3阶段 NE22.32° SE60.00° 76.20 64.00 330.10 58 青海共和X1井也利用地面微地震监测了裂缝,前2个阶段没有明确监测到裂缝的方位,第3阶段监测到裂缝方位为北偏东28.50°;根据地面测斜仪监测数据解释第3阶段裂缝方位为北偏东22.32°,两者相差6.18°。该结果从侧面证明了利用测斜仪可以监测干热岩压裂裂缝方位。

5. 结 论

1)利用地面测斜仪成功监测了青海共和干热岩X1井的压裂裂缝,监测结果表明,可以利用地面测斜仪监测干热岩井压裂裂缝的方位,为干热岩换热井井位部署和压裂设计方案优化提供依据。

2)X1井3个压裂阶段形成垂直裂缝的方位都是北偏东方向,但方位略有不同,当排量和压裂液黏度都较大时,垂直裂缝方位为北偏东22.32°。该结果与地面微地震解释结果基本相同。

3)X1井目的层天然裂隙发育,对形成适度的复杂热储裂缝非常有利。X1井3个压裂阶段都形成了既包含垂直裂缝,又包含被注入压裂液激活水平天然裂隙的复杂裂缝。

-

表 1 预测模型评价指标

Table 1 Evaluation Metrics for Prediction Models

算法 决定系数 平均绝对误差 均方误差 均方根误差 BP神经网络 0.883 4.81 57.64 7.59 随机森林 0.838 5.59 69.95 8.36 支持向量机 0.680 8.79 215.25 14.67 -

[1] 高德利,黄文君,李鑫. 大位移井钻井延伸极限研究与工程设计方法[J]. 石油钻探技术,2019,47(3):1–8. GAO Deli, HUANG Wenjun, LI Xin. Research on extension limits and engineering design methods for extended reach drilling[J]. Petroleum Drilling Techniques, 2019, 47(3): 1–8.

[2] 张剑,肖禹涵,周忠易,等. 基于TDCSO优化CNN-Bi-LSTM网络的井底钻压预测方法[J]. 石油钻探技术,2024,52(5):82–90. ZHANG Jian, XIAO Yuhan, ZHOU Zhongyi, et al. Downhole WOB prediction method based on CNN-Bi-LSTM network optimized by TDCSO[J]. Petroleum Drilling Techniques, 2024, 52(5): 82–90.

[3] 李乾,王磊,王喜杰,等. 东海大位移水平井降摩减阻技术研究与实践[J]. 中国海上油气,2022,34(6):149–156. LI Qian, WANG Lei, WANG Xijie, et al. Research and practice of friction and drag reduction technology for extended reach horizontal wells in the East China Sea[J]. China Offshore Oil and Gas, 2022, 34(6): 149–156.

[4] 纪国栋,陈畅畅,郭建华,等. 万米深井钻柱减振增能提速方法研究[J]. 石油钻探技术,2024,52(2):100–107. doi: 10.11911/syztjs.2024038 JI Guodong, CHEN Changchang, GUO Jianhua, et al. Research on vibration reduction, energy enhancement, and acceleration methods for drilling strings of 10 000-meter deep wells[J]. Petroleum Drilling Techniques, 2024, 52(2): 100–107. doi: 10.11911/syztjs.2024038

[5] 呼怀刚,黄洪春,汪海阁,等. 国内外PDC钻头新进展与发展趋势展望[J]. 石油机械,2024,52(2):1–10. HU Huaigang, HUANG Hongchun, WANG Haige, et al. New progress and development trends of PDC bits in China and Abroad[J]. China Petroleum Machinery, 2024, 52(2): 1–10.

[6] 佘朝毅. 四川盆地超深层钻完井技术进展及其对万米特深井的启示[J]. 天然气工业,2024,44(1):40–48. doi: 10.3787/j.issn.1000-0976.2024.01.004 SHE Zhaoyi. Progress in ultra-deep drilling and completion technology in the Sichuan Basin and its implications for extra-deep wells of more than ten thousand meters in depth[J]. Natural Gas Industry, 2024, 44(1): 40–48. doi: 10.3787/j.issn.1000-0976.2024.01.004

[7] 李中. 渤海深层探井钻井关键技术现状及展望[J]. 钻采工艺,2024,47(2):35–41. doi: 10.3969/J.ISSN.1006-768X.2024.02.05 LI Zhong. Challenges and technology trends prediction of deep exploration well drilling in Bohai Sea[J]. Drilling & Production Technology, 2024, 47(2): 35–41. doi: 10.3969/J.ISSN.1006-768X.2024.02.05

[8] HEGDE C, GRAY K. Evaluation of coupled machine learning models for drilling optimization[J]. Journal of Natural Gas Science and Engineering, 2018, 56: 397–407. doi: 10.1016/j.jngse.2018.06.006

[9] 郑双进,江厚顺,熊梦园,等. 基于数据驱动和机理模型的机械钻速预测[J]. 钻采工艺,2025,48(1):78–87. doi: 10.3969/J.ISSN.1006-768X.2025.01.10 ZHENG Shuangjin, JIANG Houshun, XIONG Mengyuan, et al. Data driven and mechanistic model based prediction of rate of penetration[J]. Drilling & Production Technology, 2025, 48(1): 78–87. doi: 10.3969/J.ISSN.1006-768X.2025.01.10

[10] 伊鹏,刘衍聪,郭欣,等. 基于改进自适应遗传算法的钻井参数优化设计[J]. 石油机械,2010,38(2):30–33. YI Peng, LIU Yancong, GUO Xin, et al. Optimized design of drilling darameters based on enhanced adaptive genetic algorithm[J]. China Petroleum Machinery, 2010, 38(2): 30–33.

[11] 刘光星,李巧花. 基于改进蚁群算法的钻进参数优化[J]. 西安石油大学学报(自然科学版),2019,34(4):31–36. doi: 10.3969/j.issn.1673-064X.2019.04.006 LIU Guangxing, LI Qiaohua. Optimization of drilling parameters based on improved ant colony algorithm[J]. Journal of Xi’an Shiyou University(Natural Science Edition), 2019, 34(4): 31–36. doi: 10.3969/j.issn.1673-064X.2019.04.006

[12] 刘兆年,赵颖,孙挺. 渤海区域基于数据驱动的钻井提速[J]. 西南石油大学学报(自然科学版),2020,42(6):35–41. LIU Zhaonian, ZHAO Ying, SUN Ting. Data-driven drilling acceleration in Bohai XX Block[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2020, 42(6): 35–41.

[13] GAN Chao, CAO Weihua, WU Min, et al. Prediction of drilling rate of penetration (ROP) using hybrid support vector regression: a case study on the Shennongjia Area, Central China[J]. Journal of Petroleum Science and Engineering, 2019, 181: 106200.

[14] SOARES C, GRAY K. Real-time predictive capabilities of analytical and machine learning rate of penetration (ROP) models[J]. Journal of Petroleum Science and Engineering, 2019, 172: 934–959. doi: 10.1016/j.petrol.2018.08.083

[15] NAJJARPOUR M, JALALIFAR H, NOROUZI-APOURVARI S. Half a century experience in rate of penetration management: application of machine learning methods and optimization algorithms: a review[J]. Journal of Petroleum Science and Engineering, 2022, 208(Part D): 109575.

[16] FENG Hao, ZHOU Yadong, ZENG Weili, et al. A physics-based PSO-BPNN model for civil aircraft noise assessment[J]. Applied Acoustics, 2024, 221: 109992. doi: 10.1016/j.apacoust.2024.109992

[17] 苏兴华,孙俊明,高翔,等. 基于GBDT算法的钻井机械钻速预测方法研究[J]. 计算机应用与软件,2019,36(12):87–92. doi: 10.3969/j.issn.1000-386x.2019.12.014 SU Xinghua, SUN Junming, GAO Xiang, et al. Prediction method of drilling rate of penetration based on GBDT algorithm[J]. Computer Applications and Software, 2019, 36(12): 87–92. doi: 10.3969/j.issn.1000-386x.2019.12.014

[18] 张宏韬,唐芳,吴坤,等. 基于粒子群优化BP神经网络的激光扫描投影系统畸变预测方法[J]. 光子学报,2024,53(6):0611001. doi: 10.3788/gzxb20245306.0611001 ZHANG Hongtao, TANG Fang, WU Kun, et al. Distortion prediction method of laser scanning projection system based on PSO-BP neural network[J]. Acta Photonica Sinica, 2024, 53(6): 0611001. doi: 10.3788/gzxb20245306.0611001

[19] 陈亮,郝祎纯,李巧茹,等. 改进SSA优化的BP神经网络交通量预测模型[J]. 哈尔滨工业大学学报,2024,56(7):94–101. CHEN Liang, HAO Yichun, LI Qiaoru, et al. Traffic volume forecast model based on BP neural network optimized by improved sparrow search algorithm[J]. Journal of Harbin Institute of Technology, 2024, 56(7): 94–101.

[20] 邹红梅,朱成涛. 基于LSTM和BP神经网络的水库入库径流中长期预测比较研究[J]. 水文,2024,44(4):27–31. ZOU Hongmei, ZHU Chengtao. Comparative study on mid-long term prediction of reservoir inflow based on LSTM and BP neural network[J]. Journal of China Hydrology, 2024, 44(4): 27–31.

[21] 秦长坤,赵武胜,贾海宾,等. 基于模态分解和深度学习的煤矿微震时序预测方法[J]. 煤炭学报,2024,49(9):3781–3797. QIN Changkun, ZHAO Wusheng, JIA Haibin, et al. A method for predicting the time series of microseismic events in coal mines based on modal decomposition and deep learning[J]. Journal of China Coal Society, 2024, 49(9): 3781–3797.

[22] 盖建. 基于自动机器学习的采油井压裂效果预测方法[J]. 油气地质与采收率,2023,30(1):161–170. GE Jian. Prediction method for hydraulic fracturing effect of oil production well based on automatic machine learning technology[J]. Petroleum Geology and Recovery Efficiency, 2023, 30(1): 161–170.

[23] 郝杨杨,邹宇. 基于BP神经网络的上海生鲜农产品物流需求预测[J]. 上海海事大学学报,2024,45(1):39–45. HAO Yangyang, ZOU Yu. Logistics demand forecast of fresh agricultural products in Shanghai based on BP neural network[J]. Journal of Shanghai Maritime University, 2024, 45(1): 39–45.

[24] 雍锐. 智能钻井多目标协同优化系统研究与应用[J]. 钻采工艺,2024,47(3):9–14. YONG Rui. Research and application of intelligent drilling advisory system[J]. Drilling & Production Technology, 2024, 47(3): 9–14.

[25] 葛亮,滕怡,肖国清,等. 基于井下环空参数的溢流智能预警技术研究[J]. 西南石油大学学报(自然科学版),2023,45(2):126–134. GE Liang, TENG Yi, XIAO Guoqing, et al. Research on overflow intelligent warning technology based on downhole annulus parameters[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2023, 45(2): 126–134.

[26] 高云伟,罗利民,薛凤龙,等. 基于Stacking集成学习的机械钻速预测方法[J]. 石油机械,2024,52(5):17–24. GAO Yunwei, LUO Limin, XUE Fenglong, et al. ROP prediction method based on stacking ensemble learning[J]. China Petroleum Machinery, 2024, 52(5): 17–24.

[27] 姜宝胜,白玉湖,徐兵祥,等. 基于集成学习的致密气藏产能预测新方法[J]. 中国海上油气,2024,36(5):120–127. JIANG Baosheng, BAI Yuhu, XU Bingxiang, et al. A novel approach for predicting production capacity of tight gas reservoirs based on ensemble learning[J]. China Offshore Oil and Gas, 2024, 36(5): 120–127.

[28] CHEN Xuyue, WENG Chengkai, DU Xu, et al. Prediction of the rate of penetration in offshore large-scale cluster extended reach wells drilling based on machine learning and big-data techniques[J]. Ocean Engineering, 2023, 285(part 2): 115404.

[29] 汤明,王汉昌,何世明,等. 基于PCA-BP算法的机械钻速预测研究[J]. 石油机械,2023,51(10):23–31. TANG Ming, WANG Hanchang, HE Shiming, et al. Prediction for rate of penetration based on PCA-BP algorithm[J]. China Petroleum Machinery, 2023, 51(10): 23–31.

[30] 黄哲. 探管式智能钻头参数测量装置研制与现场试验[J]. 石油钻探技术,2024,52(4):34–43. doi: 10.11911/syztjs.2024004 HUANG Zhe. Development and field test of probe-type intelligent bit parameter measurement device[J]. Petroleum Drilling Techniques, 2024, 52(4): 34–43. doi: 10.11911/syztjs.2024004

-

期刊类型引用(7)

1. 考佳玮,杨康,谭鹏,陈作. 干热岩储层裂缝扩展及采热一体化数值模型. 吉林大学学报(地球科学版). 2025(02): 575-586 .  百度学术

百度学术

2. 邹剑,兰夕堂,高尚,符杨洋,张丽平,代磊阳. 示踪剂裂缝监测技术在气藏水平井压裂中的应用. 精细与专用化学品. 2024(02): 20-23 .  百度学术

百度学术

3. 刘汉青,胡才博,赵桂萍. 增强地热系统停止运行后温度恢复过程的数值模拟. 中国科学院大学学报. 2024(02): 222-230 .  百度学术

百度学术

4. 陈作,赵乐坤,卫然,刘星. 深层地热热储改造技术进展与发展建议. 石油钻探技术. 2024(06): 10-15 .  本站查看

本站查看

5. 刘汉青,胡才博,赵桂萍,石耀霖. 利用热-孔隙流体耦合有限元数值模拟研究干热岩开发温度下降过程——以青海共和盆地恰卜恰地区干热岩开发为例. 地球物理学报. 2023(07): 2887-2902 .  百度学术

百度学术

6. 王旭,刘得军,吴世伟,李洋,翟颖. 基于大地电磁监测方法的水力裂缝响应模拟. 石油钻探技术. 2023(06): 115-119 .  本站查看

本站查看

7. 张德龙,郭强,杨鹏,卢彤,吴烁,翁炜,刘宝林. 地热井花岗岩地层钻进提速技术研究与应用进展. 地质与勘探. 2022(05): 1082-1090 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: