Research and Application of Structured Flooding Fracturing Technology in the Qingcheng Shale Oil Reservoir

-

摘要:

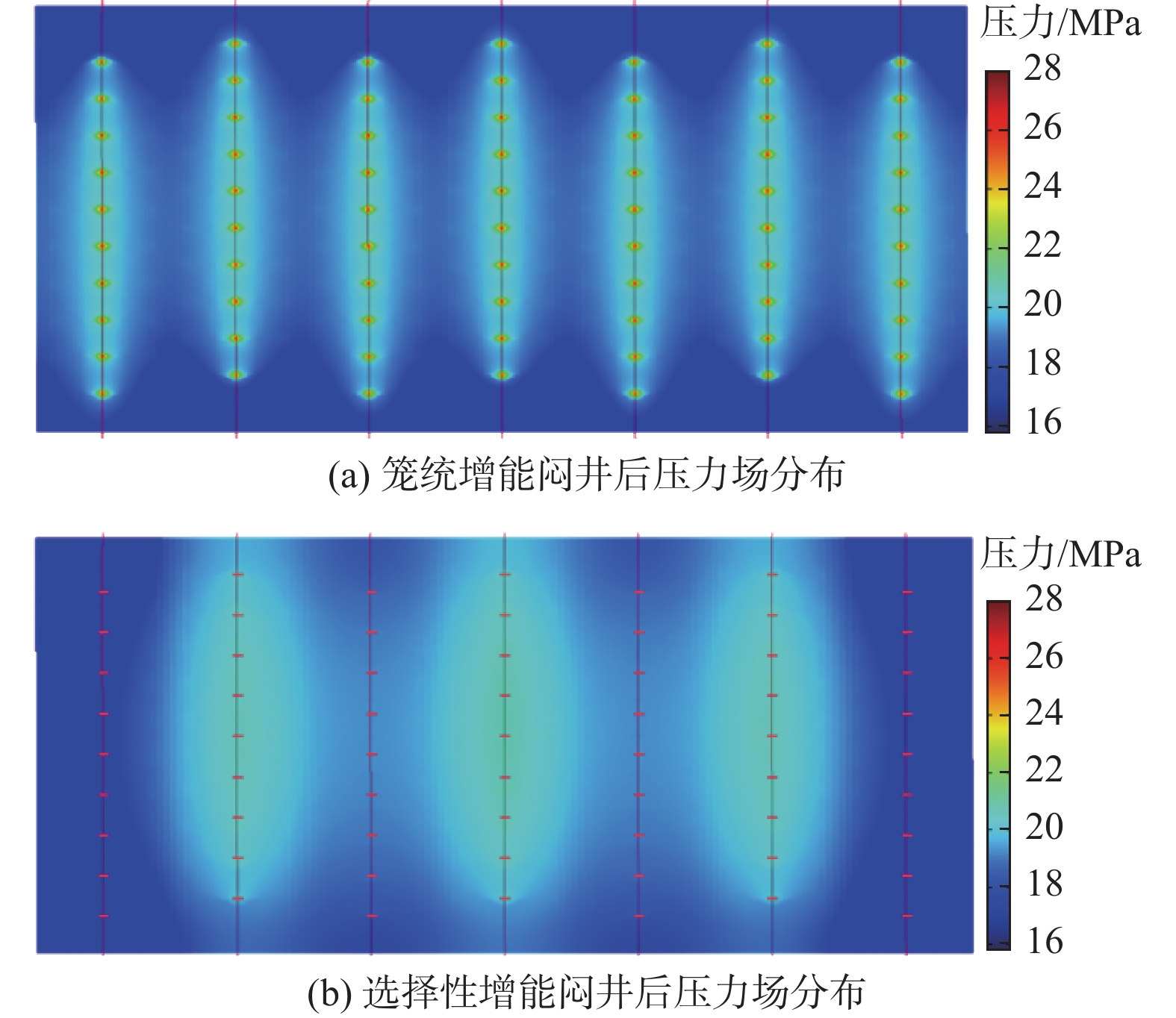

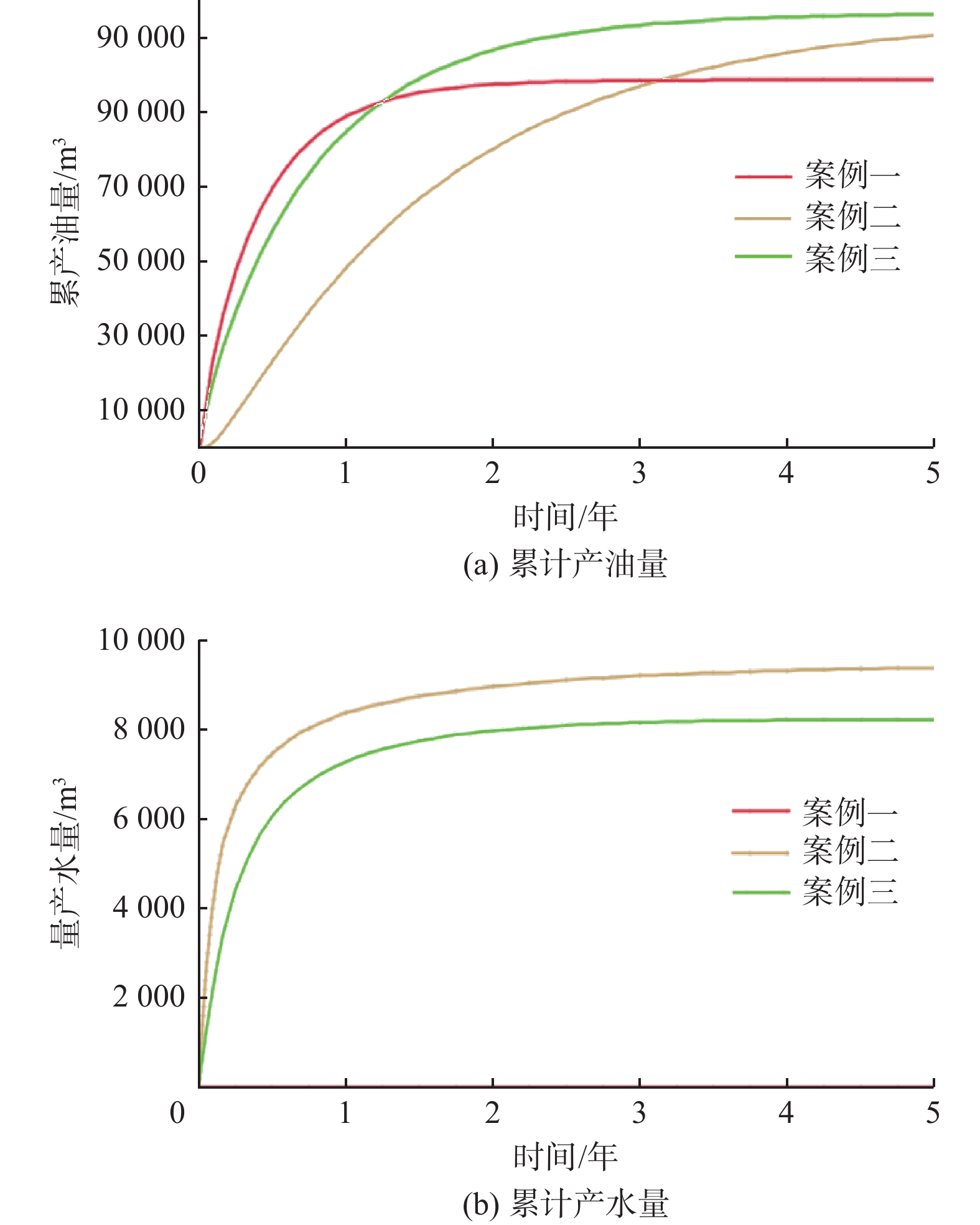

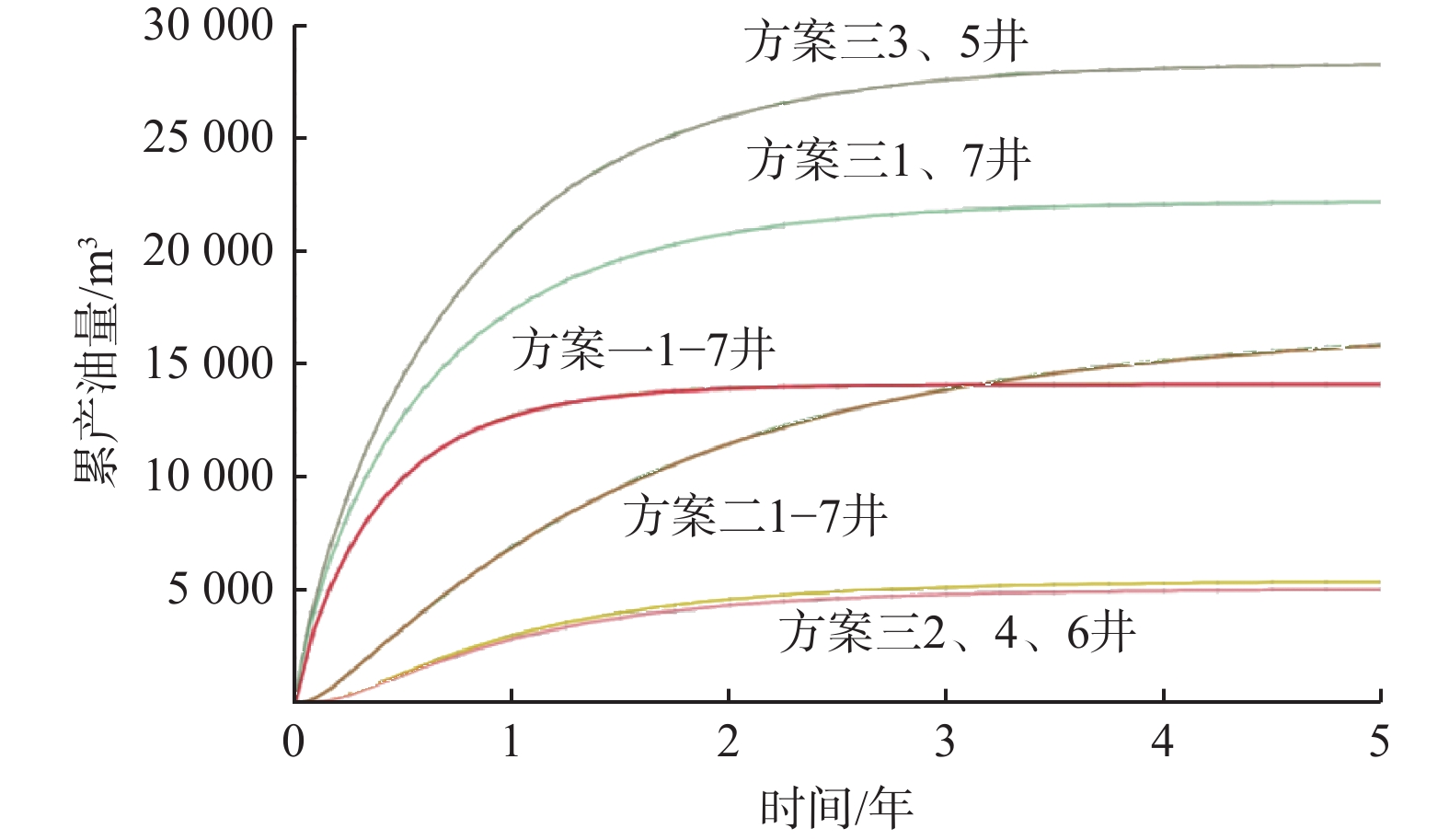

庆城页岩油储层纵横向非均质性强,脆性指数和储层压力系数小,需进行大规模体积压裂,但黄土高原地貌复杂,干旱缺水,大规模体积压裂存在供水不足的问题。针对以上问题,采用数值模拟方法优选了压裂增能模式,将内部井分为增能井与非增能井,以提高液体利用率,实现了兼顾增能与减水的目标;采用增能井与非增能井差异化压裂工艺参数,采取优化调整压裂顺序等措施,创新形成了结构化驱油压裂技术,不仅提高了井组内部地层能量、实现了缝控程度最大化,还改善了压裂用水供应不足的问题。该技术在庆城页岩油藏应用效果良好,与常规体积压裂相比平均单井节省压裂液5 000 m3,支撑剂1 200 m3,初期产油量提高1.1 t/d。研究表明,结构化驱油压裂技术能够实现降本增效,具有较好的现场推广应用价值。

Abstract:Qingcheng shale oil reservoirs have strong lateral and vertical heterogeneity, a low brittleness index, and a small reservoir pressure coefficient, necessitating large-scale volume fracturing. However, the complex topography of the Loess Plateau, characterized by arid conditions and water scarcity, poses the challenge of insufficient water supply for large-scale volume fracturing. In response to these issues, a numerical simulation method was used to optimize the fracturing energy enhancement mode. The internal wells were divided into energy enhancement wells and non-energy enhancement wells to improve the liquid utilization rate and achieve the goals of both energy enhancement and water usage reduction. Through differentiated fracturing process parameters for energy enhancement and non-energy enhancement wells and the optimization of fracturing sequences, a structured flooding fracturing technology was innovatively developed. This structured flooding fracturing technology not only increased the formation energy within the well group and maximized the degree of fracture control but also ameliorated the issue of insufficient water supply for fracturing. The technology showed good application results in Qingcheng shale oil. Compared with conventional volume fracturing, the new technology saved an average of 5 000 m3 of fracturing fluid and 1 200 m3 of proppant per well, with an initial oil production increase of 1.1 t/d. The results show that structured flooding fracturing technology can reduce costs and increase efficiency, and it has good value for field promotion and application.

-

-

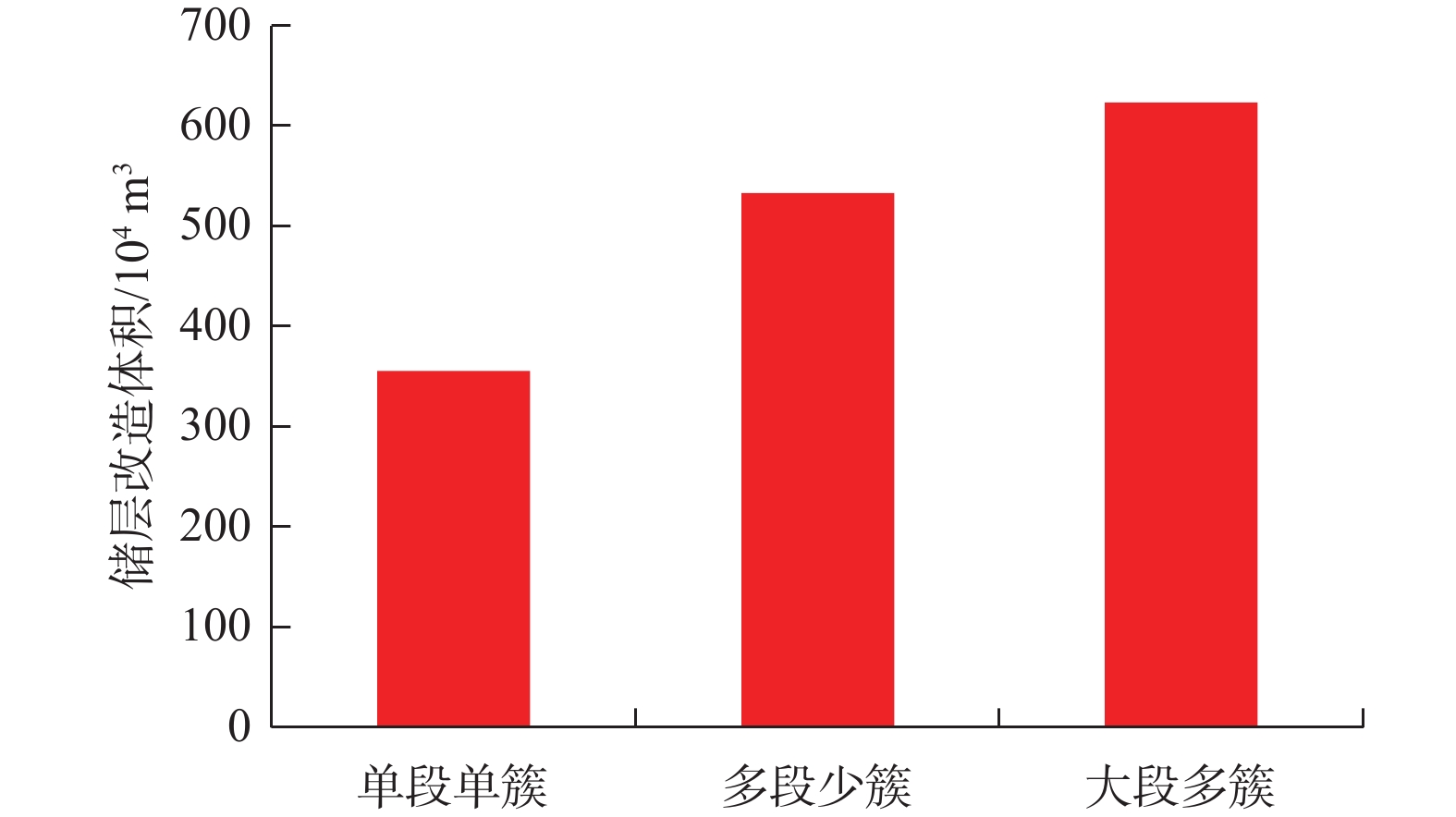

表 1 不同段簇组合情况下的压裂参数

Table 1 Fracturing parameters under different segment cluster combinations

段簇组合 单段簇数量/簇 簇间距/m 入地液量/m³ 加砂量/m³ 总排量/(m3·min−1) 单簇排量/(m3·min−1) 单段单簇 1 9.5 622.9 96.4 9.3 9.3 多段少簇 3 7.9 748.9 109.5 9.7 3.2 大段多簇 8~12 5.6 1 766.8 261.7 14 1.6 表 2 HH60平台结构化驱油压裂井储层钻遇率及压裂参数

Table 2 Drilling ratio and fracturing parameters for structured flooding fracturing well on the HH60 Platform

井号 压裂工艺 水平段长/m 钻遇率,% 压裂段数 段内簇数 入地液量/m3 加砂量/m3 压裂排量/(m3∙min−1) HH60–3 可溶球座 1 602.0 93.8 17.0 3.6 27 955.0 2 221.3 9.5 HH60–5 可溶球座 1 602.0 79.5 18.0 3.4 27 965.5 2 469.9 9.3 HH60–2 连续油管 1 952.0 95.4 36.0 1.0 15 468.6 2 889.8 5.0 HH60–4 连续油管 1 920.0 94.8 38.0 1.1 20 353.0 3 357.8 5.5 HH60–6 连续油管 2 035.0 92.9 40.0 1.1 18 499.6 3 043.9 5.1 平均 1 822.2 91.3 29.8 2.0 22 048.3 2 796.5 6.9 表 3 HH60平台常规压裂井储层钻遇率及压裂参数

Table 3 Drilling ratio and fracturing parameters for conventional fracturing well on the HH60 Platform

井号 压裂工艺 水平段长/m 钻遇率,% 压裂段数 段内簇数 入地液量/m3 加砂量/m3 压裂排量/(m3∙min−1) HH60–9 可溶球座 1 730.0 94.9 20.0 3.4 22 717.2 3 442.6 10.2 HH60–10 可溶球座 1 730.0 92.6 26.0 3.2 23 976.2 3 442.5 10.4 HH60–11 可溶球座 1 875.0 98.9 35.0 3.4 30 480.9 4 347.0 9.7 HH60–12 可溶球座 1 935.0 98.9 31.0 3.5 29 556.0 4 511.7 11.0 HH60–13 可溶球座 1 935.0 90.5 28.0 3.3 28 532.5 4 148.1 8.8 平均 1 841.0 95.2 28.0 3.3 27 052.6 3 978.4 10.0 -

[1] 付金华,李士祥,牛小兵,等. 鄂尔多斯盆地三叠系长7段页岩油地质特征与勘探实践[J]. 石油勘探与开发,2020,47(5):870–883. doi: 10.11698/PED.2020.05.03 FU Jinhua, LI Shixiang, NIU Xiaobing, et al. Geological characteristics and exploration of shale oil in Chang 7 Member of Triassic Yanchang Formation, Ordos Basin, NW China[J]. Petroleum Exploration and Development, 2020, 47(5): 870–883. doi: 10.11698/PED.2020.05.03

[2] 金之钧,张谦,朱如凯,等. 中国陆相页岩油分类及其意义[J]. 石油与天然气地质,2023,44(4):801–819. doi: 10.11743/ogg20230401 JIN Zhijun, ZHANG Qian, ZHU Rukai, et al. Classification of lacustrine shale oil reservoirs in China and its significance[J]. Oil & Gas Geology, 2023, 44(4): 801–819. doi: 10.11743/ogg20230401

[3] 焦方正. 陆相低压页岩油体积开发理论技术及实践:以鄂尔多斯盆地长7段页岩油为例[J]. 天然气地球科学,2021,32(6):836–844. JIAO Fangzheng. Theoretical technologies and practices concerning “volume development” of low pressure continental shale oil: case study of shale oil in Chang 7 member, Ordos Basin, China[J]. Natural Gas Geoscience, 2021, 32(6): 836–844.

[4] 赵振峰,李楷,赵鹏云,等. 鄂尔多斯盆地页岩油体积压裂技术实践与发展建议[J]. 石油钻探技术,2021,49(4):85–91. doi: 10.11911/syztjs.2021075 ZHAO Zhenfeng, LI Kai, ZHAO Pengyun, et al. Practice and development suggestions for volumetric fracturing technology for shale oil in the Ordos Basin[J]. Petroleum Drilling Techniques, 2021, 49(4): 85–91. doi: 10.11911/syztjs.2021075

[5] 蒋廷学. 非常规油气藏新一代体积压裂技术的几个关键问题探讨[J]. 石油钻探技术,2023,51(4):184–191. doi: 10.11911/syztjs.2023023 JIANG Tingxue. Discussion on several key issues of the new-generation network fracturing technologies for unconventional reser-voirs[J]. Petroleum Drilling Techniques, 2023, 51(4): 184–191. doi: 10.11911/syztjs.2023023

[6] 赵文智,朱如凯,张婧雅,等. 中国陆相页岩油类型、勘探开发现状与发展趋势[J]. 中国石油勘探,2023,28(4):1–13. doi: 10.3969/j.issn.1672-7703.2023.04.001 ZHAO Wenzhi, ZHU Rukai, ZHANG Jingya, et al. Classification, exploration and development status and development trend of continental shale oil in China[J]. China Petroleum Exploration, 2023, 28(4): 1–13. doi: 10.3969/j.issn.1672-7703.2023.04.001

[7] 焦方正,邹才能,杨智. 陆相源内石油聚集地质理论认识及勘探开发实践[J]. 石油勘探与开发,2020,47(6):1067–1078. doi: 10.11698/PED.2020.06.01 JIAO Fangzheng, ZOU Caineng, YANG Zhi. Geological theory and exploration & development practice of hydrocarbon accumulation inside continental source kitchens[J]. Petroleum Exploration and Development, 2020, 47(6): 1067–1078. doi: 10.11698/PED.2020.06.01

[8] 付金华,郭雯,李士祥,等. 鄂尔多斯盆地长7段多类型页岩油特征及勘探潜力[J]. 天然气地球科学,2021,32(12):1749–1761. FU Jinhua, GUO Wen, LI Shixiang, et al. Characteristics and exploration potential of muti-type shale oil in the 7th Member of Yanchang Formation, Ordos Basin[J]. Natural Gas Geoscience, 2021, 32(12): 1749–1761.

[9] 雷启鸿,何右安,郭芪恒,等. 鄂尔多斯盆地页岩油水平井开发关键科技问题[J]. 天然气地球科学,2023,34(6):939–949. LEI Qihong, HE You’an, GUO Qiheng, et al. Key scientific and technological issues in the development of horizontal shale oil wells in the Ordos Basin[J]. Natural Gas Geoscience, 2023, 34(6): 939–949.

[10] 慕立俊,拜杰,齐银,等. 庆城夹层型页岩油地质工程一体化压裂技术[J]. 石油钻探技术,2023,51(5):33–41. doi: 10.11911/syztjs.2023079 MU Lijun, BAI Jie, QI Yin, et al. Geological engineering integrated fracturing technology for Qingcheng interlayer shale oil[J]. Petroleum Drilling Techniques, 2023, 51(5): 33–41. doi: 10.11911/syztjs.2023079

[11] 张衍君,王鲁瑀,刘娅菲,等. 页岩油储层压裂-提采一体化研究进展与面临的挑战[J]. 石油钻探技术,2024,52(1):84–95. doi: 10.11911/syztjs.2024012 ZHANG Yanjun, WANG Luyu, LIU Yafei, et al. Advances and challenges of integration of fracturing and enhanced oil recovery in shale oil reservoirs[J]. Petroleum Drilling Techniques, 2024, 52(1): 84–95. doi: 10.11911/syztjs.2024012

[12] 张矿生,齐银,薛小佳,等. 鄂尔多斯盆地页岩油水平井CO2区域增能体积压裂技术[J]. 石油钻探技术,2023,51(5):15–22. doi: 10.11911/syztjs.2023091 ZHANG Kuangsheng, QI Yin, XUE Xiaojia, et al. CO2 regional enhanced volumetric fracturing technology for shale oil horizontal wells in Ordos Basin[J]. Petroleum Drilling Techniques, 2023, 51(5): 15–22. doi: 10.11911/syztjs.2023091

[13] 党永潮,梁晓伟,罗锦昌,等. 国家示范工程陆相湖盆夹层型页岩油高效开发技术[J]. 石油钻采工艺,2024,46(2):208–219. DANG Yongchao, LIANG Xiaowei, LUO Jinchang, et al. High-efficiency development technology for interbedded shale oil in terrestrial lake basin of national demonstration project[J]. Oil Drilling & Production Technology, 2024, 46(2): 208–219.

[14] 张矿生,薛小佳,陶亮,等. 页岩油水平井体积压裂缝网波及体积评价新方法及应用[J]. 特种油气藏,2023,30(5):127–134. doi: 10.3969/j.issn.1006-6535.2023.05.017 ZHANG Kuangsheng, XUE Xiaojia, TAO Liang, et al. New Method for evaluating the volume fracturing fracture network sweep volume in shale oil horizontal wells and its application[J]. Special Oil & Gas Reservoirs, 2023, 30(5): 127–134. doi: 10.3969/j.issn.1006-6535.2023.05.017

[15] 马立军,梁晓伟,贾剑波,等. 陆相夹层型页岩油超长水平井开发技术[J]. 石油钻采工艺,2024,46(2):220–227. MA Lijun, LIANG Xiaowei, JIA Jianbo, et al. Ultra-long horizontal well development technology for continental interbedded shale oil[J]. Oil Drilling & Production Technology, 2024, 46(2): 220–227.

[16] 刘洪,廖如刚,李小斌,等. 页岩气 “井工厂” 不同压裂模式下裂缝复杂程度研究[J]. 天然气工业,2018,38(12):70–76. doi: 10.3787/j.issn.1000-0976.2018.12.008 LIU Hong, LIAO Rugang, LI Xiaobin, et al. A comparative analysis on the fracture complexity in different fracking patterns of shale gas “well factory”[J]. Natural Gas Industry, 2018, 38(12): 70–76. doi: 10.3787/j.issn.1000-0976.2018.12.008

[17] 马泽元,胥云,翁定为,等. 水平井体积改造井距和簇间距优化研究[J]. 西南石油大学学报(自然科学版),2024,46(2):114–124. MA Zeyuan, XU Yun, WENG Dingwei, et al. Well spacing and cluster spacing optimization for horizontal well volume stimulation[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2024, 46(2): 114–124.

下载:

下载: