Design and Mechanical Property Simulation of a Impact Source Tool for the Advanced Detection of Gas Drilling

-

摘要:

为了实现气体钻井钻头前方风险地层的超前探测,设计了适用于气体钻井环境的井下冲击震源工具,并对其力学性能进行了研究。基于气体钻井的环境,设计了冲击震源工具的关键结构;根据室内冲击试验,优化了震源工具的吸振结构和冲击能量;使用RecurDyn软件,分析了冲击块的运动过程,优化了关键结构的参数;模拟研究了底部吸振圆盘的抗冲击能力和传动杆限位结构的抗拉强度,以及冲击震源工具的力学性能;给出了现场施工方案,分析了其主要优势。研究结果表明:聚四氟乙烯能显著衰减钻铤波及尾波,有利于识别时域内的地层弱反射波信号;冲击能量为50 J时,冲击振动波的传播距离为18.61 m,可满足气体钻井超前探测的目的;聚四氟乙烯受到的最大冲击力为1 796.88 N时,其相对变形不超过0.03%,且传动杆限位结构处承受下部钻具的重量不能超过1 150 kN。通过气体钻井随钻超前探测震源工具结构设计及力学性能模拟研究,为近钻头冲击震源工具的研制与应用提供了依据。

Abstract:In order to detect of risky formations in advance and in front of the bit during gas drilling, a downhole impact source tool suitable for gas drilling environment was designed. Based on the gas drilling environment, the key structure of the impact source tool was designed. Through the indoor impact test, the vibration-absorbing structure and impact energy of the impact source tool were optimized. The RecurDyn simulation software was used to analyze impact block movements and optimize the parameters of the key structure. The impact resistance of the bottom vibration-absorbing disc and the tensile strength of the limit structure of the transmission rod were simulated to analyze the mechanical properties of the impact source tool. The field operation plan was made and the main advantages of the tool was analyzed. The results showed that polytetrafluoroethylene (PTFE) could significantly attenuate drill collar waves and coda waves, helpful in pinpointing weak reflection wave signals in the time domain. When the impact energy was 50 J, the propagation distance of impact vibration waves was 18.61 m, which could achieve advanced detection of gas drilling. The maximum impact force on PTFE was 1 796.88 N, and its relative deformation was not more than 0.03%. In addition, the weight of bottom hole assembly (BHA) borne by the limit structure of the transmission rod cannot exceed 1 150 kN. As a result, the structural design and mechanical property simulation of the impact tool for advanced detection while drilling for gas drilling could provide a theoretical basis for the development and application of near-bit impact source tools.

-

Keywords:

- gas drilling /

- advanced detection /

- impact source tool /

- impact source /

- PTFE /

- impact energy

-

气体钻井不仅用于提高机械钻速和治理井漏,还在发现和保护储层方面展现出广阔的应用前景[1]。然而,地层出水、井眼失稳等工程瓶颈使其受到严重制约,随钻超前探测技术可提前预测到钻头前方的地层界面、断层、溶洞和异常高压等风险地层,降低钻头前方地层信息的不确定性,保证气体钻井的安全性[2-5]。当井下冲击震源工具产生可控的振动波信号时,可根据钻柱顶端振动波的主频预测钻头前方地层的岩性,而牙轮钻头产生的轴向冲击能量弱、振动无规律,无法用于声波前探[6-7],因此气体钻井近钻头冲击震源工具的设计与研发成为迫切需要。国内外学者对井下冲击振动工具开展了大量研究,倪红坚等人[8]研制了自激振荡式旋转冲击钻井工具,王冠[9]对该工具结构进行了优化。为了克服钻头震源强度不足的问题,J. J. KOLLE等人[10]研制了一种扫频水力脉冲震击器。由于气体钻井的环空介质为空气,压缩性比较强,因此上述类型冲击结构不适合气体钻井的工况。管志川等人[11-12]设计了一种机械式井下吸振冲击钻井工具,基于此工具的功能,可考虑采用花键带动冲击块上下移动。张玉英[13]设计了一种整体机械式随钻震击器,由于卡瓦需要较大的阻力情况下才能产生震击力,因此卡瓦不能被用于井下冲击震源工具设计中,但可以借鉴随钻震击器上提、下放钻柱的方式,使工具产生冲击力。刘刚等人[14]设计了一种卡瓦式井下震源,由于井下环境比较复杂,其锚定装置可能会影响井壁的稳定性和引发井下故障,因此该震源不适合作为气体钻井的井下震源。

综合分析井下冲击震源工具的工作原理发现,采用摩擦卡瓦机构需要较大的井下阻力,且设计难度很大,因此设计气体钻井井下冲击震源工具时,可采用上提钻柱的方式带动冲击结构产生振动波信号。笔者基于气体钻井随钻声波探测原理,并结合室内冲击试验结果,优化了冲击震源工具的结构及尺寸,并对关键部件进行了力学性能分析,设计了适用于气体钻井的井下冲击震源工具。该工具可显著衰减钻柱振动波的尾波,有利于地层反射波信号的识别。

1. 冲击震源工具结构及工作原理

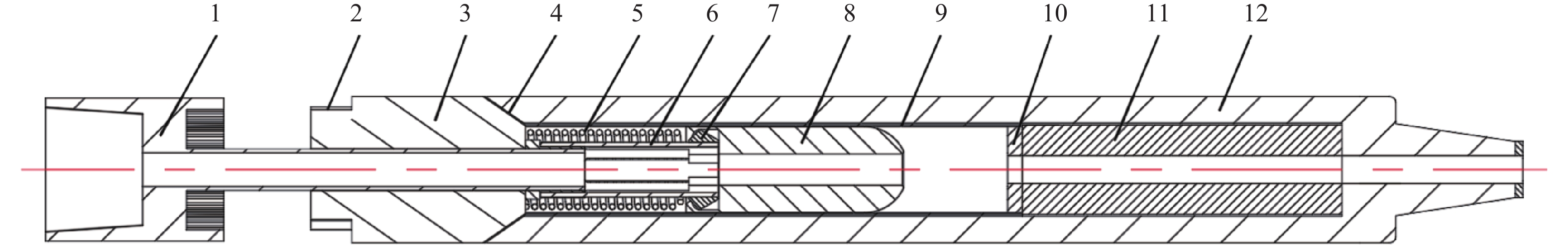

基于气体钻井环境下随钻前探工具自激自收的原理,确定了冲击震源工具的关键机构,设计了适用于气体钻井的随钻近钻头冲击震源工具(见图1),其主要由传动机构、冲击机构和吸振机构组成。冲击震源工具的上接头与弹片连接件通过螺纹连接,弹片肩带动冲击块一起上行并压缩弹簧。底部吸振机构由金属圆盘和减振材料组成,用于衰减纵向上的振动尾波,吸振圆筒用于衰减径向上的振动尾波。连接体的内花键与传动杆的外花键相连接,正常钻进时可为下部钻具组合传递钻压和扭矩。该震源工具采用上提钻柱的方式产生振动波信号,激发方式操作方便,冲击能量强且不需要井下供电,作业时间短,降低了卡钻、溢流风险。

根据冲击震源工具的结构,结合现场钻井工况,可知其工作原理为:

1)正常钻进时,上接头的花键与连接头的花键相连接,冲击震源工具处于关闭状态。冲击震源工具可为钻柱传递钻压和扭矩,保证气体的循环流通。起钻时,传动杆的限位机构带动下部钻具组合一起上行,更换钻头。

2)当钻遇需要超前探测的层段时,停止钻进,保持气体循环流通;上提钻柱,传动杆带动冲击块一起上行,并压缩弹簧;当弹簧被压缩到一定距离时,冲击块在重力和弹力的作用下脱离弹片肩,向下冲击吸振圆盘,产生标志性的振动波信号,实现超前探测的目的;下筒体内的吸振圆筒和吸振圆盘用于衰减钻铤振动波信号,提高识别地层反射波的能力。

3)当冲击震源工具完成一次冲击后,下放钻柱传动杆下行,弹片连接件的弹片肩与冲击块的凹槽相连接,冲击震源工具处于关闭状态。根据超前探测的需要,需要井下冲击震源产生振动波信号时,重复上提、下放钻柱即可。

2. 冲击震源工具机构优化

2.1 吸振机构优化

冲击源测距试验结果表明,聚四氟乙烯的衰减系数大,因此选用聚四氟乙烯作为吸振机构的减振材料[15]。为分析井下冲击震源内底部吸振机构对钻铤振动波的衰减效果,在地面建立了相应的冲击试验装置,模拟井下震源工具的冲击方式。用空心圆管和钢球来模拟钻铤和冲击块,用玻璃圆筒模拟冲击块所处的腔室,分析钢球冲击不同吸振机构对钻铤振动波的影响。

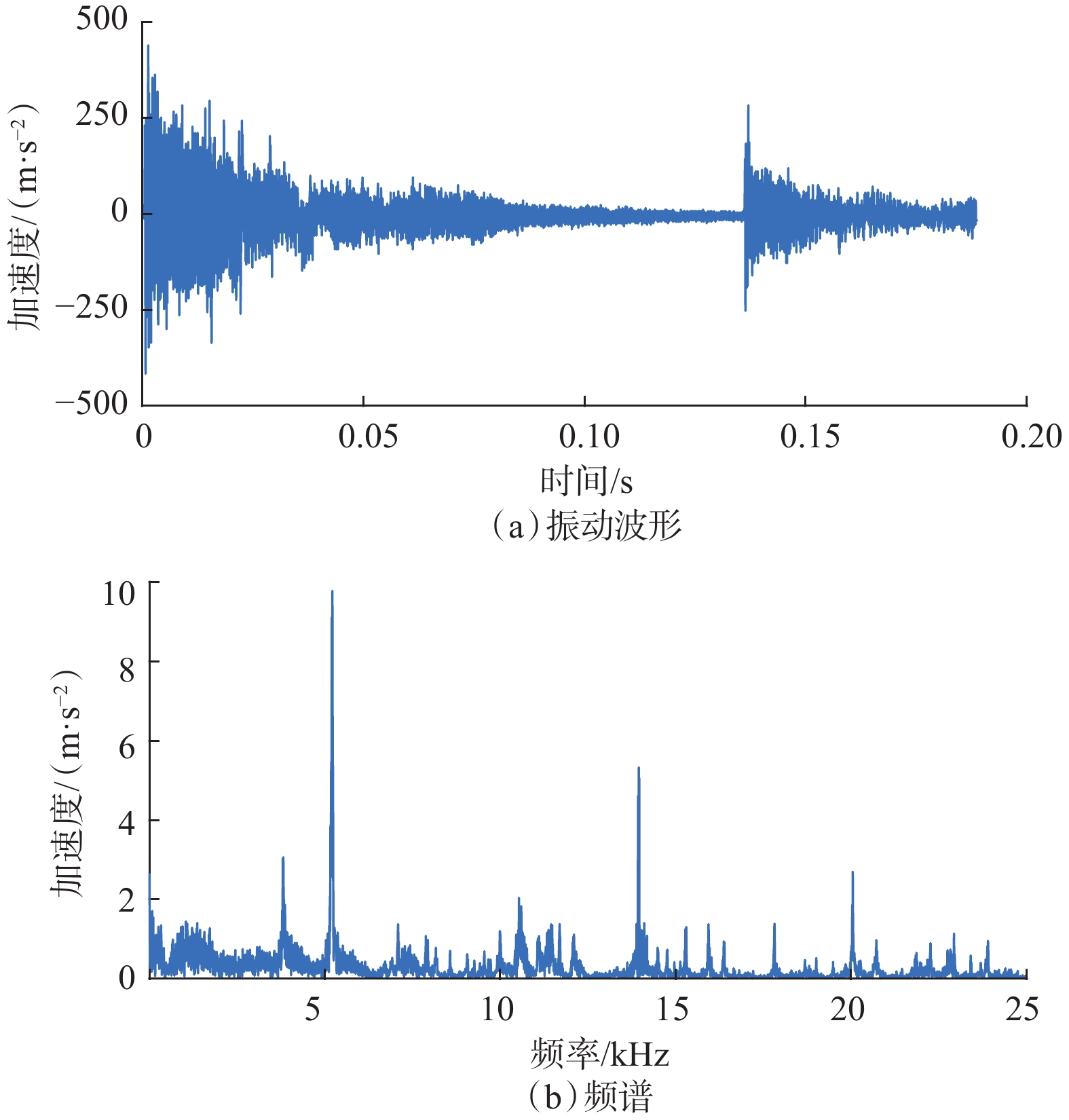

钢球冲击未使用聚四氟乙烯的吸振机构时,空心圆柱上接收到的振动波形和频谱如图2所示。从图2可以看出,振动波形中的尾波非常显著,并存在二次冲击振动波;频谱图中存在各种频率成分的振动波,主频在5 000 Hz左右。

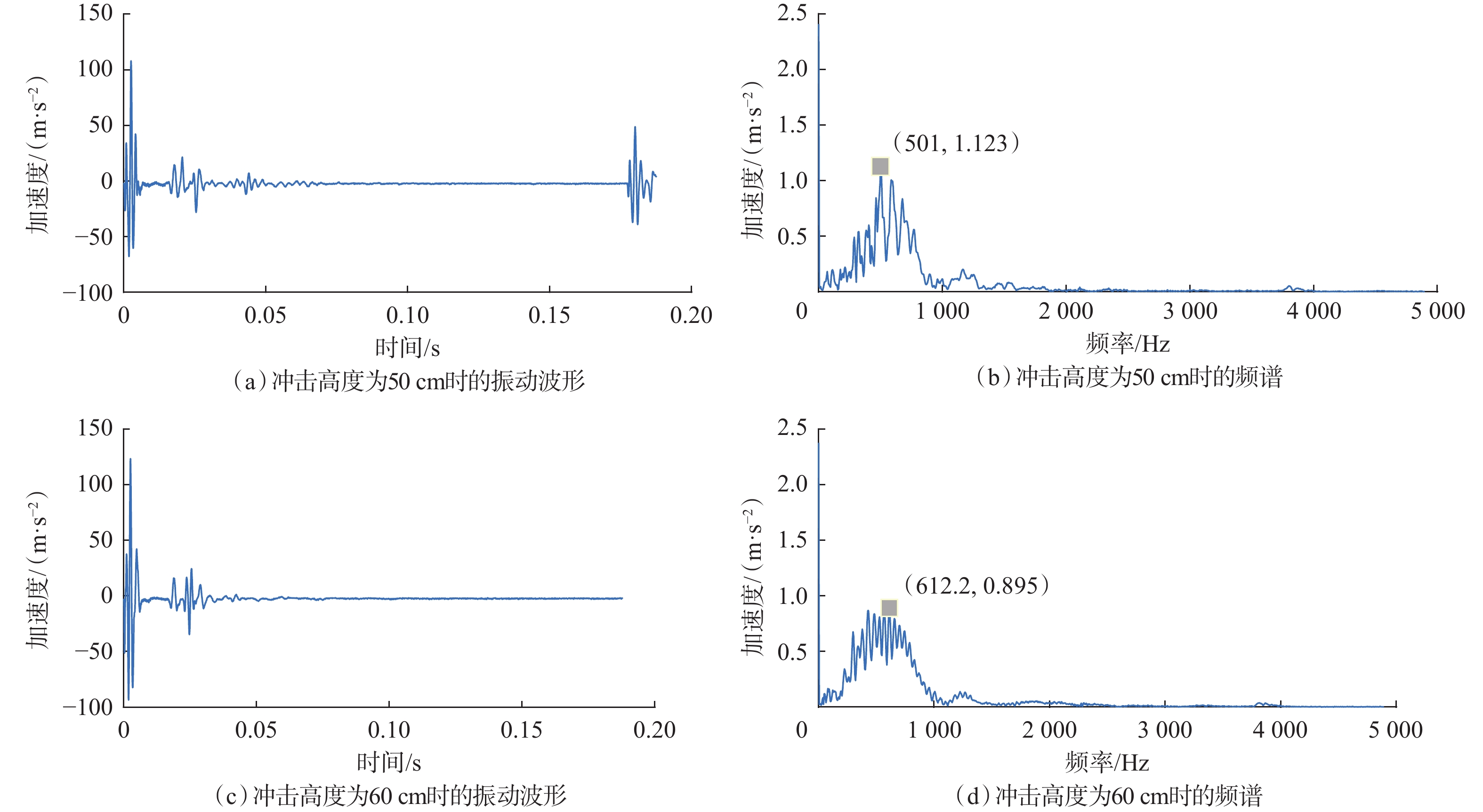

用同一钢球冲击使用聚四氟乙烯的吸振机构,不同冲击高度下加速度传感器接收到的振动波形和频谱如图3所示。

从图3可以看出,首波为雷克子波且加速度最大,振动波形中的尾波显著衰减,振动波形中存在二次冲击振动波,这是因为钢球在玻璃圆筒内落下时会多次冲击金属;随着冲击高度增大,首波的加速度逐渐增大。冲击高度大于50 cm时,振动波内未发现二次冲击振动波,这是因为随着冲击高度增大,钢球第一次冲击金属与第二次冲击金属的时间间隔增长,导致加速度传感器未记录到二次冲击振动波。不同冲击高度下冲击振动波的主频分别为501和612 Hz,表明聚四氟乙烯可以显著衰减振动波的高频成分,且介于地震勘探和测井的频率之间,可实现高分辨率、远距离探测的目的。随着冲击高度增大,振动波形中的二次冲击振动波减少,频谱图中的低频成分减少。因此,为了更好地提取钻铤振动波内弱地层的反射波信号,选用聚四氟乙烯衰减钻铤振动波的尾波。同时,提高冲击块的冲击高度,可增大首波的加速度幅值,降低二次冲击振动波对地层反射波信号的干扰。

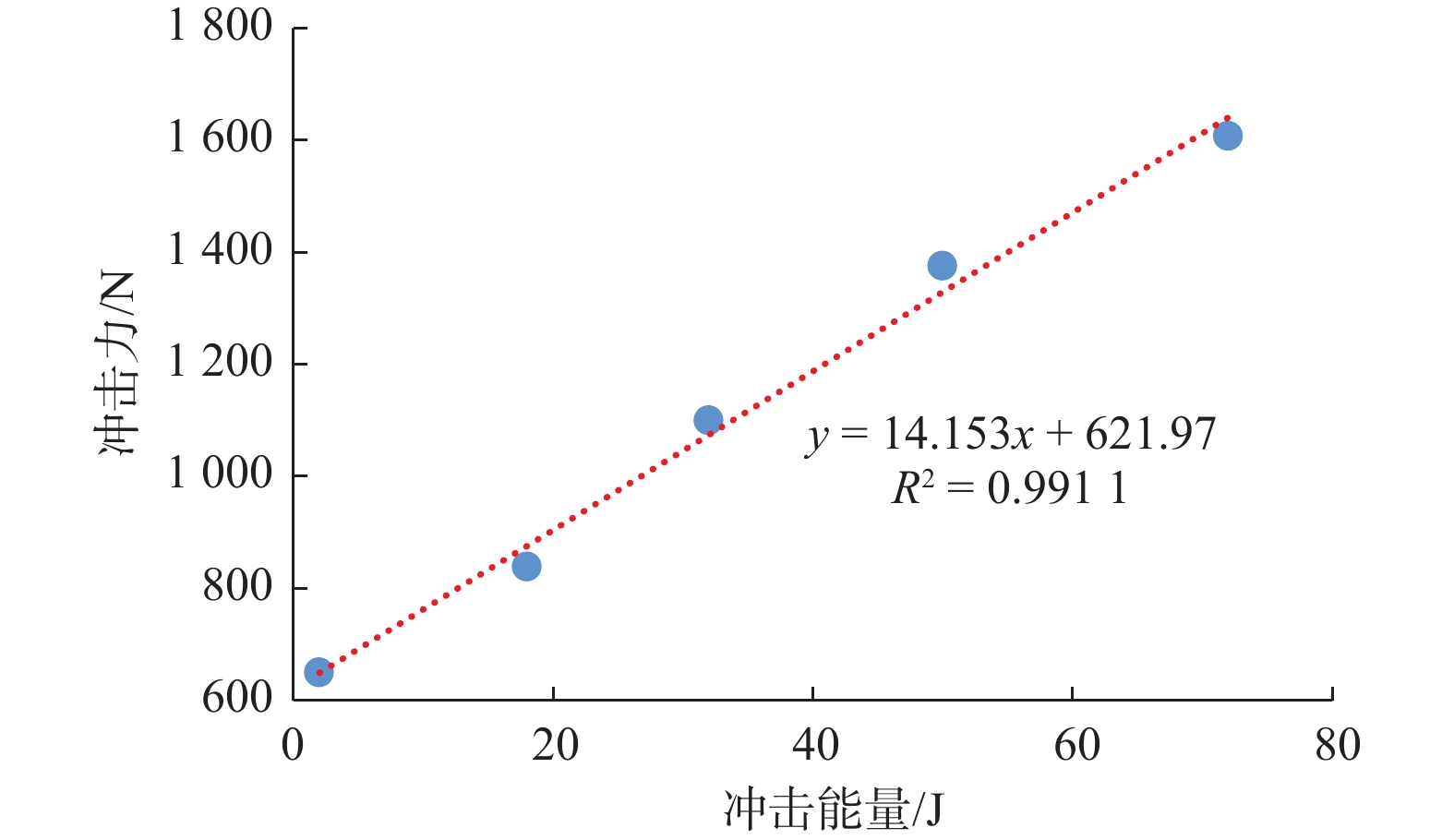

使用钢球冲击聚四氟乙烯吸振机构,得到冲击力与冲击能量的关系(见图4)。由图4可知,冲击力随冲击能量增加呈线性增加,并在落石冲击力研究中得到验证[16]。根据图4的拟合关系式可求得,当冲击能量为50 J时,冲击力为1 330 N,再根据牛顿第二定律可计算出质量为12.94 kg金属圆盘的振动加速度为102.75 m/s2。

砂岩中的振动波加速度幅值与传播距离呈负指数关系[17],可表示为:

y=A0e−αx (1) 式中:y为不同传播距离时接收到的振动波幅值,m/s2;x为振动波的传播距离,m;

α 为砂岩的衰减系数,取0.25;A0为震源强度,m/s2。冲击试验时加速度传感器的最小分辨率为0.98 m/s2,当冲击能量为50 J时,砂岩上振动波的最远传播距离为18.61 m,可实现气体钻井超前探测的目的。

2.2 冲击机构优化

VIBSIT-50微型可控震源单次冲击的能量为50 J,可产生频率高达1 500 Hz的震源信号,在较长时间内而不是在短时间用大功率发射,可以在不损失分辨率或略有损失的情况下达到较大的穿透深度[18-19]。聚四氟乙烯在长时间载荷的作用下会发生塑性变形,冲击能量越强,聚四氟乙烯的塑性变形越大,从而影响底部吸振机构的性能。因此,选择冲击震源的激发能量为50 J,冲击块的质量为10 kg,不仅能实现超前探测的目的,同时也可延长吸振机构的使用寿命。

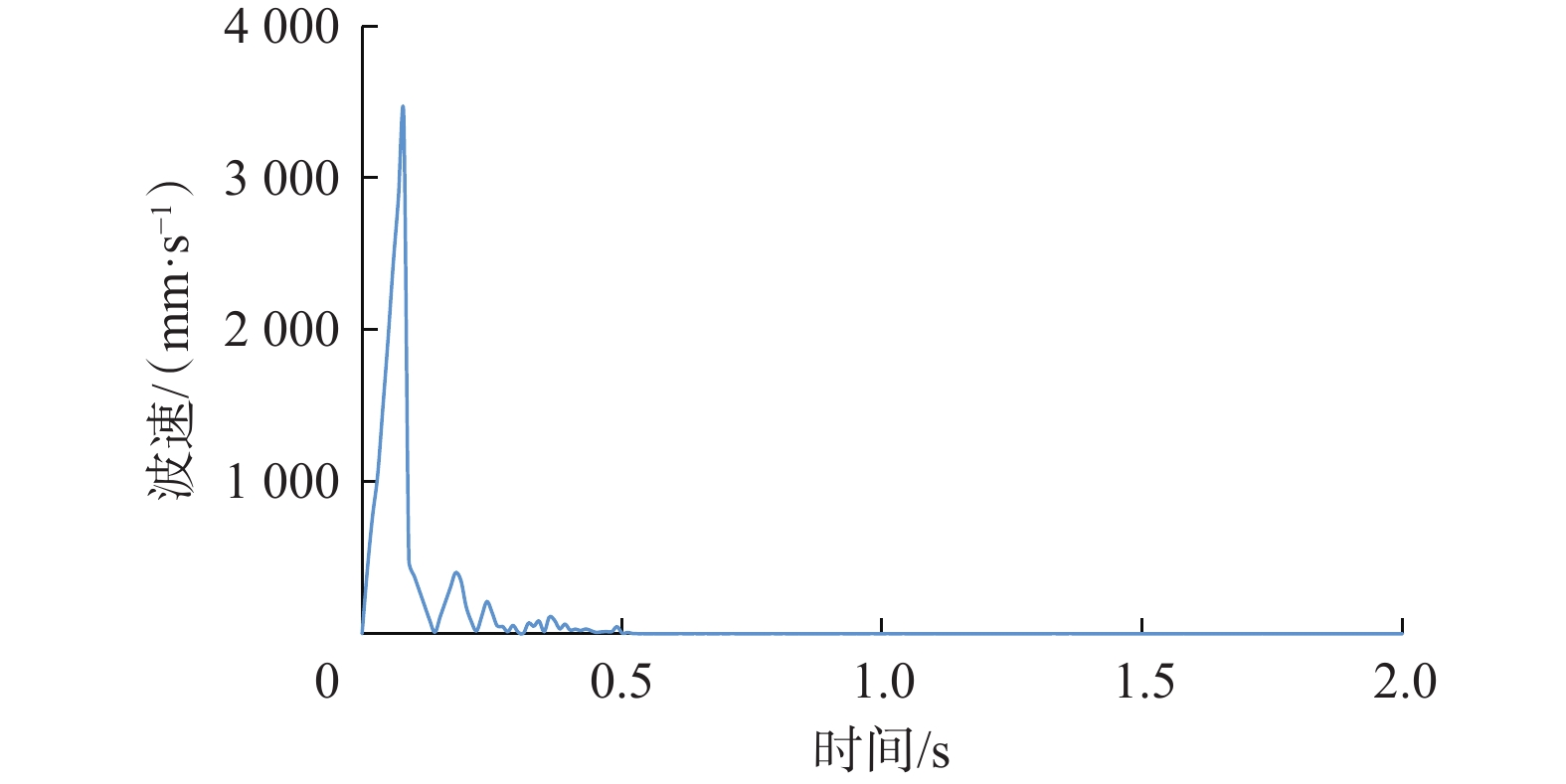

根据冲击震源的激发能量,利用RecurDyn软件对冲击块的运动过程进行模拟计算,得到震源装置外筒的长度为1 076 mm,传动杆的长度为1 064 mm。冲击块的运动速度与时间的关系曲线如图5所示,冲击块与底部金属圆盘碰撞时的速度为3 411.1 mm/s,根据动能方程,计算得到碰撞时的能量为58.18 J。

底部金属圆盘受到的冲击力与时间的关系曲线如图6所示,此时金属圆盘受到的最大冲击力为1 652.98 N,远小于金属的屈服强度。底部聚四氟乙烯受到的冲击力与时间的关系曲线如图7所示,此时聚四氟乙烯受到的最大冲击力为1 796.88 N。

3. 工具关键部件的力学性能研究

3.1 底部吸振圆盘的力学性能

为了增强吸振圆盘的强度,考虑将不锈钢和聚四氟乙烯复合为一体,以增强聚四氟乙烯的抗冲击能力。为分析复合吸振圆盘的抗冲击能力,首先通过单轴压缩试验获取聚四氟乙烯的应力−应变关系,优选出准确描述聚四氟乙烯力学性能的本构模型;然后利用Abaqus软件分析吸振圆盘中聚四氟乙烯变形量与冲击力的关系,为震源冲击力设计提供依据。

单轴压缩试验中,聚四氟乙烯的长度为50 mm,直径为25 mm,在Abaqus软件中设置其泊松比为0.40,输入聚四氟乙烯的单轴应力−应变数据;选择适用于小应变的超弹性材料的Mooney-Rivlin模型。将聚四氟乙烯网格模型的底端固定,顶部施加载荷,模拟单轴压缩试验。模拟结果表明,顶部中心处应力较小,边缘处应力较大。随着聚四氟乙烯压缩位移的增加,顶部中心处的应力逐渐增加。将该模拟结果与试验结果进行对比(见表1),发现模拟结果与试验结果的相对误差在±20%以内,验证了该本构模型及试验参数的准确性。

表 1 不同压缩位移下聚四氟乙烯的模拟结果与试验结果Table 1. Simulation results and test results of PTFE under different compression displacements聚四氟乙烯变形

后的位移/mm模拟得到的

应力/MPa单轴试验得到

的应力/MPa相对

误差,%0.50 2.88 3.11 −7.4 0.75 4.45 5.08 −12.4 1.00 6.12 6.52 −6.1 1.25 7.87 7.43 5.9 1.50 9.72 8.42 15.4 基于选取的本构模型和试验参数,利用Abaqus软件对冲击机构中聚四氟乙烯进行力学性能模拟研究。冲击机构的网格模型从上到下依次为冲击块、金属垫片和聚四氟乙烯。该模型中聚四氟乙烯和金属垫片固定在一起,然后将模型底部固定,在顶部施加载荷,分析不同压缩位移下冲击块的冲击力。模拟结果表明,不同冲击力下聚四氟乙烯的中心处应力较小,边缘处的应力最大;随着冲击力增大,聚四氟乙烯中心处的压力显著增大。根据不同压缩位移下聚四氟乙烯的应力,计算得到了聚四氟乙烯所承受的冲击力(见表2)。聚四氟乙烯的压缩位移为0.1 mm时,聚四氟乙烯承受的冲击力为2 003.95 N,此时聚四氟乙烯的相对变形仅为0.03%。由图7可知,冲击震源工具优化后,聚四氟乙烯受到的最大冲击力为1 796.88 N,因此该冲击震源工具中的底部吸振机构可以承受冲击块的冲击。

表 2 聚四氟乙烯不同压缩位移下承受的冲击力Table 2. Impact force on PTFE under different compression displacements聚四氟乙烯变形后

的位移/mm聚四氟乙烯变形后

的最大应力/MPa聚四氟乙烯承受

的冲击力/kN0.1 0.139 2.004 0.2 0.279 4.017 0.3 0.420 6.038 0.4 0.561 8.068 0.5 0.702 10.105 1.0 1.420 20.427 2.0 2.900 41.725 5.0 7.706 110.884 3.2 传动杆限位机构的力学性能

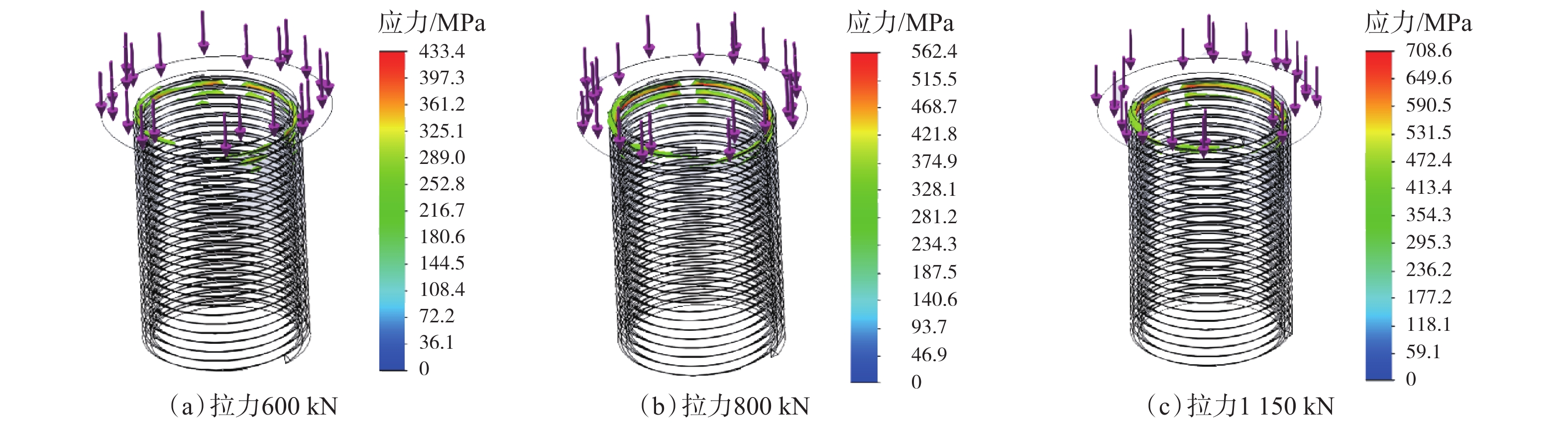

利用SolidWorks软件对传动杆螺纹连接面处进行力学性能模拟研究,确定该限位机构的抗拉能力。传动杆参数采用钻铤材质参数,其弹性模量为216 GPa,泊松比为0.30,屈服强度为710 MPa。将传动杆的顶端固定,在限位机构处施加相当于下部钻具组合重量的拉力,得到传动杆台阶在拉力600,800和1 150 kN下的应力分布云图(见图8)。

从图8可以看出,随着传动杆台阶处载荷增大,螺纹面的应力主要集中在螺纹第一圈和第二圈上,因此第一圈和第二圈螺纹容易产生疲劳失效;当台阶处的拉力增大到1 150 kN时,螺纹面的应力主要集中在第一圈螺纹处,且已经达到了材料的屈服强度。因此,限位机构处承受下部钻具的重量不能超过1 150 kN。

4. 现场施工方案及其主要优势

气体钻井过程中,可将冲击震源工具安装在两根钻铤间(要尽可能靠近钻头),传动杆承受下面钻铤的拉力,钻铤的重量全部施加到钻头上,保证钻头与地层紧密耦合,提高识别弱地层反射波信号的能力。当钻遇需要超前探测的层位时,停止顶驱钻进,保持气体循环,上提钻具使冲击震源工具激发低频振动波信号,安装于空气锤上的检波器接收钻头前方地层的反射波信号,利用钻柱内微波中继器接力传输的方式将探测数据传输至地面。

目前,随钻声波探测技术主要采用单极纵波源、偶极横波源和方位纵波源,随钻条件下声源激发的波场容易受到环空介质和钻柱的强烈调制,且钻铤模式波会严重干扰地层反射波的识别[20-23]。因此,上述施工方案中,利用钻头与地层的接触将冲击振动波信号传入地层,可降低振动波在环空介质中的衰减,提高振动波的透射能力。吸振圆盘结构可承受冲击块的冲击,吸振圆盘内的聚四氟乙烯能显著衰减钻铤上的振动尾波,提高识别地层弱反射波信号的能力。起下钻作业过程中,传动杆限位结构可承受下部钻具的拉力。该震源工具产生的冲击能量强且不需井下供电,冲击振动波的频率介于地震勘探和测井频率之间,可满足气体钻井条件下高分辨率、远距离探测的目的。

5. 结 论

1)基于气体钻井的环境,设计了冲击震源工具的关键结构,优化了震源工具的吸振机构和冲击机构。在气体钻井过程中,当钻遇到需要超前探测的风险地层时,停止钻进,通过上提钻柱的方式产生高能量的低频振动波信号,该震源激发方式可降低钻进过程中噪音的干扰,震源能量强且不需要供电系统,可以很好地适应气体钻井的井下环境。

2)震源工具关键部件的抗冲击能力有限元分析结果表明,金属垫片和聚四氟乙烯组成的吸振机构可承受冲击块的冲击,可用于衰减钻柱的振动尾波。起下钻过程中,传动杆的限位机构可承受下部钻具的拉力,其可靠性满足气体钻井作业要求。

3)该随钻冲击震源工具可在钻井液环境中应用,当钻遇需要超前探测的地层时,停止钻进和钻井液循环,可以减少井底的噪音干扰,更易于识别钻头前方的弱地层反射波信号,提高随钻前探的能力。

-

表 1 不同压缩位移下聚四氟乙烯的模拟结果与试验结果

Table 1 Simulation results and test results of PTFE under different compression displacements

聚四氟乙烯变形

后的位移/mm模拟得到的

应力/MPa单轴试验得到

的应力/MPa相对

误差,%0.50 2.88 3.11 −7.4 0.75 4.45 5.08 −12.4 1.00 6.12 6.52 −6.1 1.25 7.87 7.43 5.9 1.50 9.72 8.42 15.4 表 2 聚四氟乙烯不同压缩位移下承受的冲击力

Table 2 Impact force on PTFE under different compression displacements

聚四氟乙烯变形后

的位移/mm聚四氟乙烯变形后

的最大应力/MPa聚四氟乙烯承受

的冲击力/kN0.1 0.139 2.004 0.2 0.279 4.017 0.3 0.420 6.038 0.4 0.561 8.068 0.5 0.702 10.105 1.0 1.420 20.427 2.0 2.900 41.725 5.0 7.706 110.884 -

[1] 李皋,李诚,孟英峰,等. 气体钻井随钻安全风险识别与监控[J]. 天然气工业,2015,35(7):66–72. doi: 10.3787/j.issn.1000-0976.2015.07.010 LI Gao, LI Cheng, MENG Yingfeng, et al. While-drilling safety risk identification and monitoring in air drilling[J]. Natural Gas Industry, 2015, 35(7): 66–72. doi: 10.3787/j.issn.1000-0976.2015.07.010

[2] 简旭,李皋,王军,等. 气体钻井声波超前测距方法与数值模拟[J]. 石油钻探技术,2022,50(3):132–138. doi: 10.11911/syztjs.2022016 JIAN Xu, LI Gao, WANG Jun, et al. Acoustic advance ranging method in gas drilling and its numerical simulation[J]. Petroleum Drilling Techniques, 2022, 50(3): 132–138. doi: 10.11911/syztjs.2022016

[3] 杨书博,乔文孝,赵琪琪,等. 随钻前视声波测井钻头前方声场特征研究[J]. 石油钻探技术,2021,49(2):113–120. doi: 10.11911/syztjs.2021020 YANG Shubo, QIAO Wenxiao, ZHAO Qiqi, et al. The characteristics of the acoustic field ahead of the bit in “look-ahead” acoustic logging while drilling[J]. Petroleum Drilling Techniques, 2021, 49(2): 113–120. doi: 10.11911/syztjs.2021020

[4] 康正明,柯式镇,李新,等. 随钻电阻率成像测井仪定量评价地层界面探究[J]. 石油钻探技术,2020,48(4):124–130. doi: 10.11911/syztjs.2020087 KANG Zhengming, KE Shizhen, LI Xin, et al. Probe into quantitative stratigraphic interface evaluation using a resistivity imaging LWD tool[J]. Petroleum Drilling Techniques, 2020, 48(4): 124–130. doi: 10.11911/syztjs.2020087

[5] 李亨,刘迪仁,倪小威,等. 钻井液侵入情况下随钻电磁波电阻率测井的响应[J]. 断块油气田,2019,26(5):675–680. LI Heng, LIU Diren, NI Xiaowei, et al. Logging responses of electromagnetic wave resistivity while drilling with drilling fluid intrusion[J]. Fault-Block Oil & Gas Field, 2019, 26(5): 675–680.

[6] 许军富,赵洪山,于海叶,等. 空气锤钻井技术在哈深201井火成岩地层的应用[J]. 石油钻采工艺,2017,39(6):683–687. doi: 10.13639/j.odpt.2017.06.004 XU Junfu, ZHAO Hongshan, YU Haiye, et al. Application of air hammer drilling technology in the igneous strata of Well Hashen 201[J]. Oil Drilling & Production Technology, 2017, 39(6): 683–687. doi: 10.13639/j.odpt.2017.06.004

[7] 朱宽亮,周岩,胡中志. PDC–牙轮复合钻头在南堡油田大斜度井的应用[J]. 石油钻探技术,2017,45(6):60–64. doi: 10.11911/syztjs.201706011 ZHU Kuanliang, ZHOU Yan, HU Zhongzhi. Application of a PDC-roller hybrid bit in highly-deviated wells of the Nanpu Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(6): 60–64. doi: 10.11911/syztjs.201706011

[8] 倪红坚,韩来聚,马清明,等. 水力脉冲诱发井下振动钻井工具研究[J]. 石油钻采工艺,2006,28(2):15–17. doi: 10.3969/j.issn.1000-7393.2006.02.005 NI Hongjian, HAN Laiju, MA Qingming, et al. Study on downhole vibration drilling tool induced by hydropulse[J]. Oil Drilling & Production Technology, 2006, 28(2): 15–17. doi: 10.3969/j.issn.1000-7393.2006.02.005

[9] 王冠. 自激振荡式旋转冲击钻井工具结构优化设计[D]. 青岛: 中国石油大学(华东), 2018. WANG Guan. Design and optimization for the self-oscillating rotary percussive drilling tool[D]. Qingdao: China University of Petroleum(East China), 2018.

[10] DENNEY D. Seismic-while-drilling using a swept-impulse source[J]. Journal of Petroleum Technology, 2005, 57(8): 67–69. doi: 10.2118/0805-0067-JPT

[11] 管志川, 刘永旺, 史玉才. 机械式井下吸振冲击钻井工具: CN201010617044.0[P]. 2014-06-25. GUAN Zhichuan, LIU Yongwang, SHI Yucai. Mechanical downhole vibration absorption percussion drilling tool: CN201010617044.0[P]. 2014-06-25.

[12] 刘永旺,管志川,张洪宁,等. 一种转化钻柱振动能量的井底高压喷射钻井装置[J]. 天然气工业,2017,37(9):91–96. doi: 10.3787/j.issn.1000-0976.2017.09.012 LIU Yongwang, GUAN Zhichuan, ZHANG Hongning, et al. A downhole high-pressure jet drilling device transforming drilling string vibration energy[J]. Natural Gas Industry, 2017, 37(9): 91–96. doi: 10.3787/j.issn.1000-0976.2017.09.012

[13] 张玉英. QJ159A整体机械式随钻震击器的研制及应用[J]. 石油机械,2008,36(9):88–89. doi: 10.16082/j.cnki.issn.1001-4578.2008.09.022 ZHANG Yuying. Development and application of integral mechanical jar while drilling[J]. China Petroleum Machinery, 2008, 36(9): 88–89. doi: 10.16082/j.cnki.issn.1001-4578.2008.09.022

[14] 刘刚, 史少宇. 井下震源: CN201910003744.1[P]. 2019-05-10. LIU Gang, SHI Shaoyu. Downhole seismic source: CN201910003744.1[P]. 2019-05-10.

[15] JIAN Xu, LI Hongtao, LI Gao, et al. Lithological interface detection using an impact source[J]. Shock and Vibration, 2020, 2020: 4189419.

[16] 孙宗磊,杨少军,刘琛,等. 基于UHPC板和EPS耗能层的落石冲击力研究[J]. 铁道标准设计,2021,65(7):88–92. doi: 10.13238/j.issn.1004-2954.202008110006 SUN Zonglei, YANG Shaojun, LIU Chen, et al. Study on rockfall impact based on UHPC plate and EPS energy dissipation layer[J]. Railway Standard Design, 2021, 65(7): 88–92. doi: 10.13238/j.issn.1004-2954.202008110006

[17] 刘刚,杨全枝,何保生,等. 冲击震动波在砂岩介质中传播规律的试验研究[J]. 工程勘察,2012,40(12):75–78. LIU Gang, YANG Quanzhi, HE Baosheng, et al. Experimental study on shock vibration wave for transmitting law in sandstone medium[J]. Geotechnical Investigation & Surveying, 2012, 40(12): 75–78.

[18] 迟少林,冯进,张慢来,等. 井下震源发生器动力学研究及性能优化[J]. 石油机械,2020,48(2):15–22. CHI Shaolin, FENG Jin, ZHANG Manlai, et al. Dynamics research and performance optimization of downhole seismic generator[J]. China Petroleum Machinery, 2020, 48(2): 15–22.

[19] 王俊秋, 林君, 陈祖斌, 等. 小型可控震源在油页岩地震勘探中的应用试验[J]. 吉林大学学报(地球科学版), 2012, 42(增刊3): 265-270. WANG Junqiu, LIN Jun, CHEN Zubin, et al. Experiment and application of mini vibrators seismic exploration in oil shale[J]. Journal of Jilin University(Earth Science Edition), 2012, 42(supplement 3): 265 − 270.

[20] 夏文鹤,孟英峰,唐波,等. 变内径钻柱中微波传输衰减规律[J]. 石油勘探与开发,2018,45(3):500–506. doi: 10.11698/PED.2018.03.15 XIA Wenhe, MENG Yingfeng, TANG Bo, et al. Attenuation of microwave transmission in a diameter-variable drill string bore[J]. Petroleum Exploration and Development, 2018, 45(3): 500–506. doi: 10.11698/PED.2018.03.15

[21] 王菁, 张秀梅. 偶极声波实现钻前地质探测的方法研究[J]. 应用声学, 2015, 34(6): 539-546. WANG Jing, ZHANG Xiumei. Study on the method of formation detection ahead of the drill-bit using downhole dipole source[J]. Applied Acoustics, 2015, 34(6): 539-546.

[22] 楚泽涵,徐凌堂,尹庆文,等. 远探测反射波声波测井方法实验研究进展[J]. 测井技术,2005,29(2):98–101. CHU Zehan, XU Lingtang, YIN Qingwen, et al. Progress of lab study on remote exploration acoustic reflection logging methods[J]. Well Logging Technology, 2005, 29(2): 98–101.

[23] 王瑞甲, 乔文孝. 三维随钻反射声波成像测井的数值模拟[J]. 地球物理学报, 2015, 58(6): 2201-2209. WANG Ruijia, QIAO Wenxiao. Numerical modeling of three-dimensional acoustic reflection logging while drilling[J]. Chinese Journal of Geophysics, 2015, 58(6): 2201-2209.

-

期刊类型引用(3)

1. 刘旭东. 面向煤矿挖掘勘探的随掘超前探测及地震震源特征研究. 能源与环保. 2025(03): 129-135 .  百度学术

百度学术

2. 杨志刚,马世忠,田欢. 基于改进人工蜂群算法与随掘超前探测的地震去噪技术研究. 能源与环保. 2024(11): 81-87 .  百度学术

百度学术

3. 尹家峰,王晓军,鲁政权,步文洋,孙磊,景烨琦,孙云超,闻丽. 辽河大民屯凹陷页岩油储层强封堵恒流变油基钻井液技术. 特种油气藏. 2023(04): 163-168 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: