Liner Cementing Techniques with Small Annular Space for Complicated Deep Wells in the Sun Basin, North Yellow Sea

-

摘要:

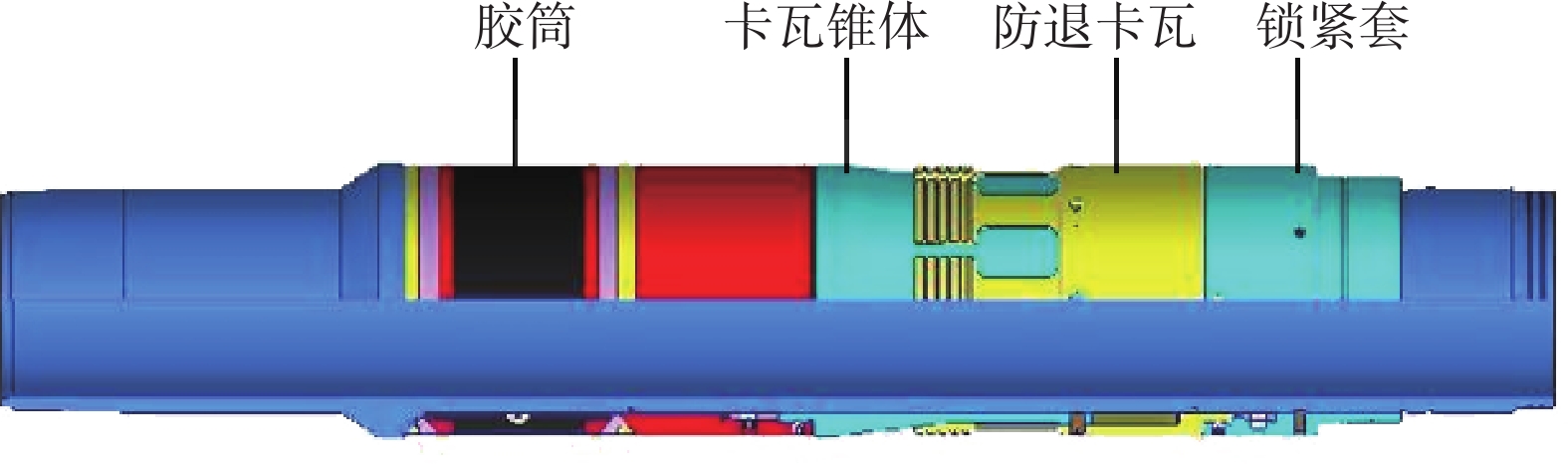

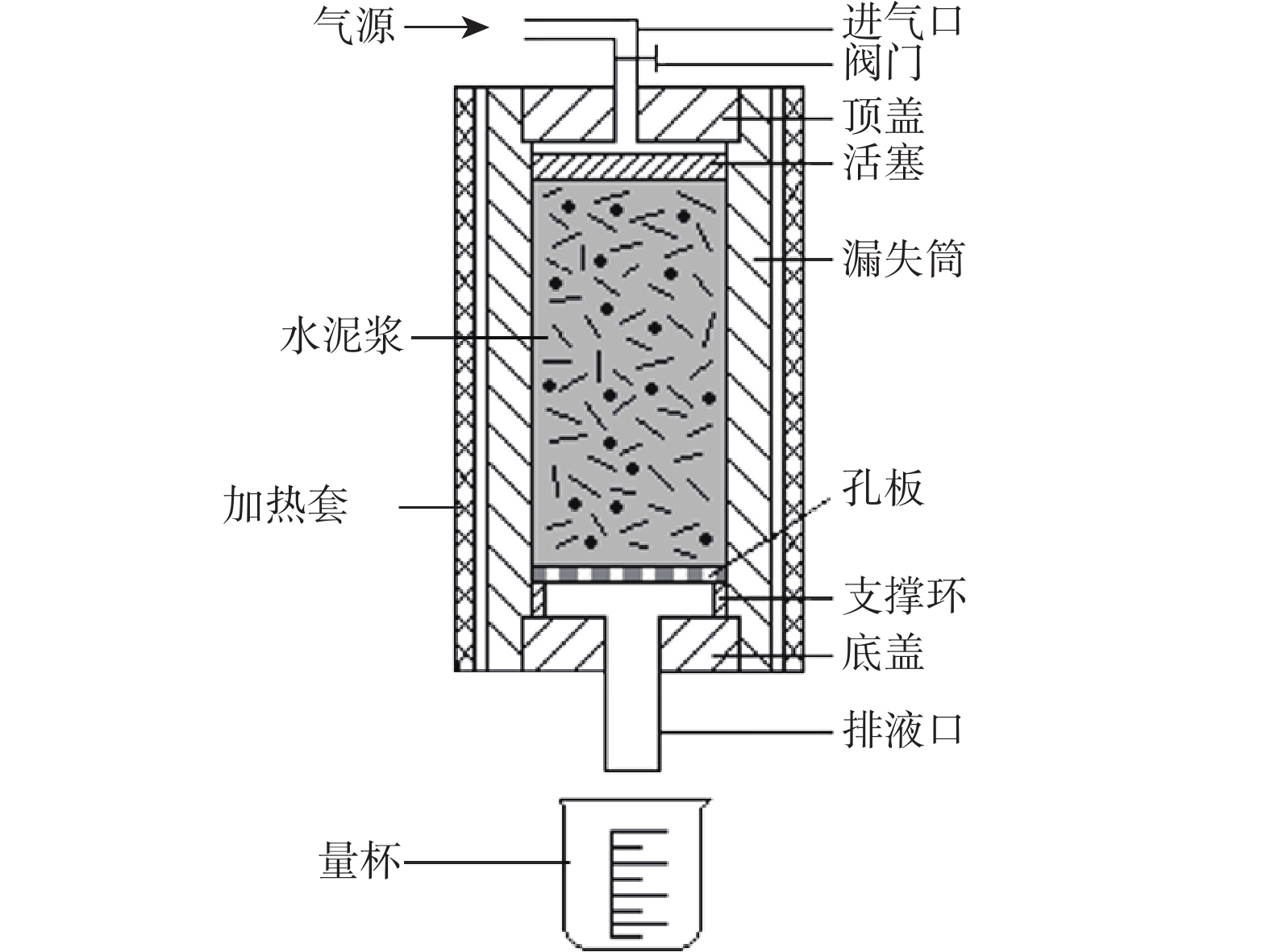

北黄海太阳盆地小间隙尾管固井时,砾石层漏失严重,煤层掉块造成环空憋堵,导致顶替效率低,固井质量差。为此,从固井工具和水泥浆着手,优化井眼准备措施,应用封隔式内嵌卡瓦尾管悬挂器增大环空过流面积,采用基体抗侵纤维防漏水泥浆降低漏失风险,研究形成了一套适合北黄海太阳盆地复杂深井的防憋堵、防漏失小间隙尾管固井技术。该固井技术在4 口井进行了现场应用,均取得了良好的应用效果,固井施工未发生憋堵和漏失,固井质量合格。研究结果表明,该技术可以有效解决北黄海太阳盆地尾管固井质量差的问题,有利于该区域油气资源的进一步勘探开发,具有一定的推广应用价值。

Abstract:During the liner cementing with small annular space in the Sun Basin of the North Yellow Sea, lost circulation is severe in gravel layers, and chippings of coal seams cause annular blockage, resulting in low displacement efficiency and poor cementing quality. Considering these problems, this study selected suitable cementing tools and cementing slurry, optimized the wellbore preparation measures, and expanded the annular flow area using the slip-embedded liner hanger with packer. In addition, anti-leakage cement slurry with matrix invasion-resistant fiber was adopted to reduce the risk of lost circulation. In this way, a set of cementing techniques with small annular space were formed for complicated deep wells in the Sun Basin to prevent blockage and lost circulation. These techniques were applied to 4 wells on site, and the results revealed that no blockage and lost circulation occurred during liner cementing. As a result, the cementing quality met standards. Field applications indicated that the developed techniques could effectively solve the problem of poor liner cementing quality in the Sun Basin, suggesting that they could be further promoted and applied. Overall, these techniques are conducive to the further exploration and development of oil and gas resources in this area.

-

Keywords:

- liner cementing /

- cement slurry /

- lost circulation /

- liner hanger /

- blockage /

- Sun Basin /

- North Yellow Sea

-

随着我国超深页岩油气勘探开发取得突破性进展,对超深页岩储层进行水力压裂时亟需提高裂缝的穿层效果。页岩断裂韧性是指其抵抗微裂缝扩张的能力,即断裂发生时的能量吸收率和延展性,可作为复杂裂缝起裂与扩展的关键力学判据,并直接影响超深页岩储层的水力压裂效果。相较于传统层状结构页岩储层,超深页岩具有更低的孔渗和更复杂的高应力环境,且层理发育,使得水力裂缝纵向穿层扩展困难。

目前,国内外学者针对页岩断裂韧性的研究主要可以分为室内试验和数值模拟。页岩断裂韧性测试方法较多,需要根据关注的重点选取合适的方法。B. Mahanta等人[1]采用缺口半圆弯曲页岩试样开展了三点弯曲试验,研究了应变速率对页岩断裂韧性和能量释放速率的影响,并构建了相关应变率函数。C. Atkinson等人[2]采用巴西圆盘法测量断裂韧性,并推导了Ⅰ型和Ⅱ型断裂韧性计算公式。吕有厂[3]通过三点弯曲断裂韧性试验,研究了不同加载速率对层理性页岩I型断裂韧性的影响规律。陈勉等人[4]基于预裂缝厚壁筒,建立了新的断裂韧性测试方法。董京楠等人[5]借助双悬臂梁断裂韧性试验并结合电子显微镜,完成了层理页岩本征尖锐裂缝的跨尺度表征。前人在页岩断裂韧性数值模拟方面也做了很多研究工作,常用数值方法包括边界元法、有限元法、扩展有限元法和离散元法等[6–12]。张景轩等人[13]基于RFPA模拟了CCNBD渐进破裂的过程,并进一步探究了页岩断裂韧性与脆性的关系。Xu Yuan等人[14]采用离散元法对CCNBD试样的渐进压裂进行了数值研究,评估了真实裂缝轮廓对I型断裂韧性测量的影响。Yin Tubing等人[15]结合室内试验和DEM,提出了一种测量高温岩石动态混合断裂韧性的方法。

综合分析可知,以上研究主要考虑了层理面角度、加载速率对页岩断裂韧性的影响,忽略了页岩所处的实际地质环境和原始应力场对页岩的断裂韧性的影响。因此,笔者在前人研究的基础上,以四川盆地凉高山组页岩为研究对象,采用颗粒离散元法,结合室内三轴压缩试验,进行了带围压三点弯数值仿真模型的校正;同时,探讨了不同围压条件下页岩层理面角度和层理面密度对断裂韧性的演化规律,形成了考虑不同因素对断裂韧性影响的定量评价方法。

1. 页岩三点弯曲物理模型及室内试验

1.1 三点弯曲半圆盘模型

页岩断裂韧性研究方法采用国际岩石力学学会(International Society of Rock Mechanics,ISRM)规定的中心直切槽三点弯曲半圆盘法(the semi-circular bend specimen,SCB)[16]。采用的三轴压缩试验样品取自四川盆地凉高山组露头,考虑页岩的层理特性,制备了层理面角度0°,30°,45°,60°和90°的页岩试样。根据ISRM推荐的制备方法进行现场取心,试样直径50 mm,厚度20 mm,裂缝长12 mm,裂缝宽度2 mm,跨距长30 mm(见图1;图中,

S 为底端2个支撑点间的距离,m;F 为轴向压载,N;a 为预制裂缝的长度,m)。后续试验和数值模拟的断裂韧性均按照ISRM推荐的Ⅰ型断裂韧性方法来计算[16]:

KIC=γ⋅Fmax√πa2rb (1) 其中γ=−1.297+9.516(S2r)−[0.47+16.457(S2r)]β+[1.071+34.401(S2r)]β2 (2) β=ar (3) 式中:

KIC 为Ⅰ型断裂韧性,MPa·m1/2;Fmax 为SCB试样破坏时的极限轴向载荷,N;r 为SCB试样半径,m;b 为SCB试样厚度;γ 为应力强度因子。1.2 页岩三轴压缩变形特征

试验钻取了不同层理面角度的ϕ25 mm×50 mm岩心柱,为与后续数值模型验证保持一致,岩心的层理面角度均取0°。采用了RTR–1500岩石力学试验系统,最大伺服围压为150 MPa,最大伺服温度为200 ℃,符合超深页岩储层岩石力学参数及特性评价要求。同时,试验机还可对高压条件下岩心的声速、渗透率和地应力等参数进行测试和分析。

试验伺服围压设置为0,20,40和60 MPa,进行页岩三轴压缩试验,传感器连续监测轴向和径向应变,并得到应力−应变曲线(见图2)。

从图2可以看出,层理页岩的三轴压缩峰值强度随围压的增加而增加。三轴围压为0~20 MPa时,峰后卸载段斜率较大,页岩仍表现出较高的脆性特征,并呈现贯穿层理的剪切破坏(见图3);围压增大至40 MPa时,页岩峰后应力−应变曲线开始出现屈服平台,表现出较理想的延性特征;当围压继续增加到60 MPa时,页岩应力−应变曲线呈现出与围压40 MPa类似的现象,但试样仅呈现单条剪切缝。分析认为,该试样取样位置附近的风化程度可能更大,导致其力学强度远小于其他3组试样。虽然围压60 MPa下曲线的峰值点低于围压40 MPa的,但页岩的轴向应变和径向应变更大,即试样呈现一定的应变硬化趋势。

由于本次的页岩试验样品取自露头,力学强度预估不会太高,因此可以将围压40~60 MPa作为该试样的转化围压。当加载条件低于转化围压时,层理页岩的应力−应变曲线表现出明显的拐点(即峰值偏应力点)。可以预见,若继续增大试验围压,层理页岩将表现出延性−塑性的转换特征,这与前人对于层理页岩力学行为的认识一致[17]。

2. 数值模型参数选取与结果验证

2.1 颗粒离散元法原理

颗粒离散元法(discrete element method,DEM)是P. A. Cundall等人[18]最早提出的数值模拟方法,使用基于颗粒的模型来描述材料的力学行为。DEM的优势在于能够模拟岩石材料在载荷作用下裂缝萌生和扩展的完整过程。在DEM模拟中,当2个粒子之间的胶结键断裂时,就会产生微裂缝。这些微裂缝的断裂机理可分为2类:当作用在接触点上的法向应力大于其法向强度时,生成拉伸裂缝;而当切向应力超过胶结键的剪切强度时,则生成剪切裂缝。

考虑层理页岩细观结构的周期性,采用DEM模拟因微裂缝扩展导致的断裂问题。为探究超深层页岩断裂韧性随页岩层理和地下应力的变化规律,可采用颗粒离散元法来弥补传统半圆板页岩试样断裂韧性测试方法的不足,如取样数量不够、试样质量不一和高围压施加困难等限制,以获得层理页岩的细观破坏规律。

2.2 数值模型参数标定

进行三点弯曲数值模拟试验时,需要首先对建立的数值模型进行细观参数标定,以匹配相同围压条件下试样的三轴抗压强度、弹性模量、泊松比和失效形式。将数值模型划分为基质部分和层理面部分,两部分颗粒之间均采用线性平行胶结模型(linear parallel bond model,LPBM)。假设颗粒之间的胶结界面具有一定的厚度,可在颗粒之间传递力和力矩;其中,层理面的胶结强度远小于基质颗粒,以模拟层理页岩的横观各向同性特征。为与室内试验保持一致,数值模型的层理面角度也设置为0°(见图4)。

由于颗粒离散元法的仿真速度受制于数值模型的颗粒数量,因此需要确定合适的层理面厚度,保证每层页岩基质具有足够数量的颗粒,防止模拟失真。现有模型尺寸多为ϕ50 mm×100 mm,层厚10 mm[19]。针对小尺寸岩心柱,层厚采用1.25 mm较为合理。

确定数值模型的尺寸后,对基质和层理面颗粒分别设置不同强度的胶结参数。假设基质强度和刚度系数均为1.0,并试取层理面的强度弱化系数为0.15,刚度弱化系数为0.10。围压20 MPa条件下,采用试错法进行标定,不断调整强度弱化系数和刚度弱化系数,直至数值模型的双轴压缩结果(二维)与试验值满足误差要求,并最终确定页岩数值模型的细观参数(见表1)。数值试验和室内试验测得的页岩力学强度误差小于3.0% ,满足后续模拟要求(见图5)。

表 1 数值模型细观胶结参数取值Table 1. Meso-bond parameters of the numerical model页岩 颗粒密度/

(kg·m−3)颗粒有效

模量/GPa胶结有效

模量/GPa胶结刚度比 胶结拉伸

强度/MPa胶结内聚力/MPa 胶结摩擦角/(°) 基质 2 640 5.0 19.20 1.35 117.6 70.4 25 层理面 2 640 5.0 3.84 1.35 23.5 14.1 14 此外,在单轴压缩条件下,利用表1的胶结参数,对层理面角度30°的页岩进行了数值模拟与室内试验对比,验证了该参数集对不同层理面角度页岩力学行为的普适性。数值试样的失效形式为条带剪切破坏(通过切/法向力和力矩计算判断),这与相同围压条件下的试验结果高度吻合(见图6)。

2.3 三点弯曲数值模型建立

首先,对模型设置围压,以模拟真实的高压地层环境;其次,对规则的矩形颗粒模型施加各项同向载荷至设定值,并将所有颗粒速度清零,确保生成的试样颗粒不会因为内部巨大的接触力而溢出边界;最后,按照图1中ISRM规定的样品标准删除模型部分颗粒,得到SCB试样。在此基础上,生成3个边界圆形墙体,以模拟顶部载荷施加点和底部固定支点(见图7)。

建立半圆板三点弯曲数值模型后,选取层理面倾角为90°的样品,并同步开展页岩半圆盘压缩试验和相应数值模拟,完成无围压条件下数值模型的标定(见图8)。

从图8可以看出,数值模型的最大压缩载荷

Fmax 为74.2 kN,是实验室结果的41.1倍。这种差异主要是因为式(1)涉及的2D模型和3D物理样本之间的几何参数不匹配,特别是厚度(2D模型的厚度默认为1.0 m)。这表明,如果采用半圆板数值弯曲试验标定I型断裂韧性,最大加载力必须比室内试验值高得多。2.4 断裂韧性数值模拟结果

对SCB数值试样进行编号,C代表施加到试样上的围压,下角标1~5分别表示0,20,40,60和80 MPa;A代表数值试样的层理面方向,下角标1~5分别表示0°,30°,45°,60°和90°;D代表试样层理面密度,下角标1~4分别表示0.50,0.60,0.70和0.80条/mm。为满足静态加载条件,加载速度为0.05 mm/s,记录不同载荷下的位移。

将每组数值试验的峰值载荷代入式(1),计算层理页岩的断裂韧性

Ks 。由于模拟成本的限制,采用有限球形刚体颗粒来模拟层理页岩存在一定的局限性,最显著的表现是数值试样的峰值载荷Fmax 远高于室内试验值。因此,计算得到所有围压下的页岩数值断裂韧性Ks 后,进行归一化处理,得到无量纲断裂韧性K′ ,部分计算结果见表2。表 2 页岩数值模型的断裂韧性计算结果Table 2. Fracture toughness of the numerical model for shale试样编号 Fmax/kN K′ 试样编号 Fmax/kN K′ C1−D1−A1 257.80 0.326 C2−D1−A1 194.49 0.180 C1−D2−A1 192.39 0.175 C2−D2−A1 205.05 0.204 C1−D3−A1 167.62 0.118 C2−D3−A1 248.98 0.305 C1−D4−A1 214.57 0.226 C2−D4−A1 241.07 0.287 C1−D1−A2 186.42 0.161 C2−D1−A2 174.28 0.133 C1−D2−A2 147.85 0.072 C2−D2−A2 194.47 0.180 C1−D3−A2 144.99 0.065 C2−D3−A2 186.92 0.162 C1−D4−A2 169.39 0.122 C2−D4−A2 176.83 0.139 根据数值试验结果,可以得到试样在不同载荷下的位移,部分围压下试样的载荷−位移曲线如图9所示。从图9可以看出,随着围压增大,页岩试样的峰值载荷也随之增大,即页岩抵抗断裂的能力提高;所有曲线的峰后斜率均快速跌落,显示了页岩的脆性特征。

3. 超深页岩储层断裂韧性影响因素分析

层理面对页岩断裂韧性具有重要影响,研究时考虑了层理面的倾角和密度2个因素。超深层页岩层理面倾角的存在可能会产生不同的应力场分布,导致断裂时微裂缝的转向和分叉等行为差异。因此,在相同的水力能量作用下将产生不同的压裂效果。

3.1 层理面角度

根据表2所列数据,可得到不同层理面角度下的SCB试样断裂韧性。以无量纲断裂韧性为纵坐标,层理面角度为横坐标,设置层理面密度为0.80条/mm,绘制SCB试样无量纲断裂韧性随层理面角度的变化曲线(见图10)。

从图10可知,相同围压条件下,SCB试样的无量纲断裂韧性随着层理面倾角的增加呈现下降趋势,同时每组围压下层理面倾角为60°时,SCB断裂韧性达到最小值。层理面角度增加到90°时,试样断裂韧性并没有明显增加,这与现有相关试验研究结论有所差异。分析认为:一方面,进行三轴压缩试验标定时采用的岩心并非具有平整层理面的页岩,层理面局部具有一定迂曲度,对层理面整体角度带来一定影响;另一方面,数值模型简化后也会对计算结果产生影响,试样预制裂缝如果处在层理界面附近,在轴向载荷作用下微裂缝很快沿预制裂缝尖端扩展至加载端,层理面表现为近乎完整剥离。由于层理面的胶结强度相较页岩基质更小,所以峰值载荷不会恢复至接近层理面0°的水平。

随着围压增大,相同条件下SCB试样的无量纲断裂韧性基本呈增大趋势。每组围压下试样断裂韧性均值与围压的变化呈正相关,拟合结果如下:

K′=0.0036σc+0.0946(R2=0.9353) (4) 式中:

σc 为SCB试样施加的围压,MPa。通过建立数值化仿真方法,可以分析加载后微裂缝的扩展规律和试样失效形式,这有助于深入理解层理页岩的断裂韧性演化机制。部分SCB试样断裂情况如图11所示(图中,红色表示剪切破坏;蓝色表示拉伸破坏)。层理面角度为0°时,SCB试样断裂需要克服的阻力几乎全部来自于页岩基质颗粒,导致加载端产生最高的峰值载荷。随着层理面角度增加至60°,SCB试样的主裂缝路径起点逐渐靠近预制裂缝尖端附近的层理面,随后沿该层理面扩展,并产生不同程度的偏折。该路径终点随着围压的增加逐渐远离加载端,表明静态加载条件下,围压增大可能导致SCB试样更倾向于沿着层理面发生断裂。这在一定程度上可以反映层理页岩的真实压裂产状,即随着地应力增加,一方面页岩的断裂韧性增强,另一方面导致较长的缝长和较窄的缝宽,使得压裂效果不佳。

3.2 层理面密度

超深层页岩层理面密度可能会改变页岩的断裂韧性,从而影响压裂后的缝网形态和增产效果。通过前文分析认为,页岩断裂韧性的增加可能是由于部分微裂缝沿着平行层理面方向扩展,导致SCB试样要形成轴向断裂,就必须要克服很大的拉伸应力。因此,有必要研究层理面密度在加载中对SCB试样断裂韧性的影响方式。

根据表2所列数据,可以得到不同层理面密度下的SCB试样断裂韧性。以无量纲断裂韧性为纵坐标,层理面密度为横坐标,设置层理面角度为45°,绘制SCB试样无量纲断裂韧性随层理面密度的变化曲线(见图12)。

从图12可知,围压0~40 MPa时,SCB试样的断裂韧性值随着层理面密度的增加呈减小趋势,且不同密度下断裂韧性离差值较大。层理面密度为0.50条/mm时,试样的断裂韧性存在极大值,表明中—低围压条件下,层理面密度对SCB试样断裂韧性的贡献较为明显;围压60~80 MPa条件下,层理面密度的变化对SCB试样的断裂韧性影响甚微。此时,层理的致密性相比层理面角度,成为影响页岩抗断裂能力的次要因素。

随着围压增加,相同条件下SCB试样的无量纲断裂韧性基本呈增大趋势。每组围压下试样断裂韧性均值与围压的变化呈正相关关系,拟合结果如下:

K′=0.0047σc+0.0828(R2=0.9754) (5) 不同SCB试样断裂路径显示,层理面角度30°时试样以拉伸断裂为主,且断裂路径终点与加载端均产生不同程度的错位(见图13;图中,红色表示剪切破坏;蓝色表示拉伸破坏)。这说明主断裂仍优先沿着层理面方向发展,围压增加,会导致这种错位现象愈加明显(如试样C4−D1−A2、C4−D3−A2、C4−D4−A2和C5−D1−A2)。相同围压条件下,随着层理面密度减小,SCB试样的断裂路径逐渐趋于平直。这可能是由于单层页岩基质厚度增加,主裂缝尖端扩展阻力远大于层理面滑移摩擦所致。然而,随着围压增大,层理面密度对断裂路径的影响将减弱,如试样C3−D3−A2、C4−D4−A2和C4−D2−A2的主裂缝扩展路径能克服多个页岩基质,并最终趋于靠近加载端。

4. 超深页岩断裂韧性定量评价方法

根据前文分析,超深层页岩断裂韧性随着围压变化的总体趋势是由层理面角度和层理面密度共同影响的。因此,可考虑建立能够量化不同围压下层理性质对页岩断裂韧性影响的评价指标。

为分析不同围压下页岩层理对其断裂韧性的影响,将无量纲断裂韧性

K′ 表征为层理面角度与层理面密度的定量关系:K′=aσPA+bσPD (6) 式中:

PA 为归一化的层理面角度;PD 为归一化的层理面密度;aσ 和bσ 为权重系数。根据多因素分析方法,计算得到不同围压下各个权重系数的定量关系(见图14)。

从图14的权重系数拟合结果可得,不同围压条件下层理面角度对页岩断裂韧性的影响均比层理面密度大,且这种影响效应增加更快。围压0~80 MPa时,层理面角度对页岩断裂韧性的增强效果是持续增加的,而层理面密度的这种作用在20~40 MPa会略微减小。因此,拟合得到权重系数

aσ 和bσ 随围压的变化关系:aσ=0.0038σc+0.0994(R2=0.987) (7) bσ=0.0019σc+0.0175(R2=0.906) (8) 结合式(4)、式(5)、式(7)和式(8),建立了不同围压条件下层理面性质对页岩断裂韧性影响的评价图版(见图15)。任一围压条件下,页岩断裂韧性随着层理面角度的增加而减小。当层理面密度分别为0.80和0.50 条/mm时,页岩具有最大和最小的断裂韧性。随着围压增大,断裂韧性极值对应的层理面角度将出现小幅变化。基于此,建立的断裂韧性图版可以为超深层页岩压裂工程设计提供一定的参考:首先,可借助测井解释等方法,预先获取超深层页岩地应力状态和层理发育情况;其次,对照该图版,将获取的无量纲断裂韧性反归一化,即可得到页岩真实断裂韧性,这有助于后续进行页岩储层的可压性评价。

5. 结论与建议

1)层理页岩在不同的围压下表现出脆性−延性的转变。试验采用的四川盆地凉高山组页岩转换围压在40~60 MPa,且在不同围压下加载和卸载后,试样均表现出贯穿层理的剪切破坏,这种模式在转换围压附近更明显。

2)颗粒离散元模型可以准确再现页岩的力学强度和剪切失效形式,如层理面卸载、主断裂迂曲和90°层理完全剥离等。建立的预围压下页岩断裂韧性定量化公式表明,页岩断裂韧性随着围压增大呈线性增加。

3)层理面角度和层理面密度在不同的围压下会强烈影响页岩的断裂韧性。随着围压增大,层理面角度对断裂韧性的影响增强;而层理面密度对低围压较为敏感,当围压大于40 MPa时可忽略后者的影响。基于此建立的量化评价图版对于分析超深页岩储层断裂韧性具有一定的参考价值。

4)井下页岩层理面往往错杂分布,力学特征存在巨大的差异。建议针对真三轴应力及高温作用下的页岩断裂韧性,改进颗粒离散元模型和试验方法,以适应超深层的压裂作业环境。

-

表 1 基体抗侵纤维防漏水泥浆的流变性能

Table 1 Rheological properties of anti-leakage cement slurry with matrix invasion-resistant fiber

温度/℃ 塑性黏度/

(mPa·s)动切力/

Pa静切力/

Pa静切力差/

Pa70 150 26.6 7.1/31.2 24.1 90 144 24.3 6.3/29.2 22.9 110 123 21.5 5.5/27.2 21.7 130 120 20.1 5.1/26.5 21.4 表 2 基体抗侵纤维防漏水泥浆的堵漏性能

Table 2 Performance of anti-leakage cement slurry with matrix invasion-resistant fiber

缝隙类型 尺寸/mm 堵漏压力/MPa 漏失量/mL 孔缝 0.5 7.0 10 1.0 7.0 11 2.0 7.0 27 3.0 7.0 41 裂缝 0.5 3.5 14 1.0 3.5 19 2.0 3.5 35 3.0 3.5 49 -

[1] 刘金萍,王改云,简晓玲,等. 北黄海东部次盆地层序地层格架中烃源岩发育特征与影响因素[J]. 吉林大学学报(地球科学版),2020,50(1):1–17. LIU Jinping, WANG Gaiyun, JIAN Xiaoling, et al. Development and influencing factors of source rock in sequential stratigraphic framework in the eastern sub-basin, North Yellow Sea[J]. Journal of Jilin University(Earth Science Edition), 2020, 50(1): 1–17.

[2] 简晓玲,刘金萍,王改云. 北黄海东部次盆地中新生代原型盆地分析[J]. 中国海上油气,2019,31(1):22–31. JIAN Xiaoling, LIU Jinping, WANG Gaiyun. Analysis of Meso-Cenozoic prototype basins in the east sub-basin, northern Yellow Sea[J]. China Offshore Oil and Gas, 2019, 31(1): 22–31.

[3] 何将启,梁世友,赵永强,等. 北黄海盆地地质构造特征及其在油气勘探中的意义[J]. 海洋地质与第四纪地质,2007,27(2):101–105. HE Jiangqi, LIANG Shiyou, ZHAO Yongqiang, et al. Characteristics of geologic structures of the North Yellow Sea Basin: implications for petroleum explorations[J]. Marine Geology & Quaternary Geology, 2007, 27(2): 101–105.

[4] 吴朗,聂世均,曾凡坤,等. 深井小间隙尾管固井作业风险评价方法[J]. 中国海上油气,2015,27(1):91–95. WU Lang, NIE Shijun, ZENG Fankun, et al. Risk evaluation method of small clearance liner cementing in deep wells[J]. China Offshore Oil and Gas, 2015, 27(1): 91–95.

[5] 张峰,刘子帅,李宁,等. 塔里木库车山前深井窄间隙小尾管固井技术[J]. 钻井液与完井液,2019,36(4):473–479. doi: 10.3969/j.issn.1001-5620.2019.04.014 ZHANG Feng, LIU Zishuai, LI Ning, et al. Cementing small liner strings with narrow clearance in deep wells in the Kuche piedmont structure in Tarim Basin[J]. Drilling Fluid & Completion Fluid, 2019, 36(4): 473–479. doi: 10.3969/j.issn.1001-5620.2019.04.014

[6] 房恩楼, 王晓亮, 张利利, 等. 渤中19-6尾管固井质量提升措施[J]. 石油钻采工艺, 2018, 40(增刊1): 146−149. FANG Enlou, WANG Xiaoliang, ZHANG Lili, et al. Technologies to improve the quality of liner cementing in BZ19-6 Block[J]. Oil Drilling & Production Technology, 2018, 40(supplemnet 1): 146−149.

[7] 高飞,田宝振,费中明,等. 磴探1井疏松砂岩油层ϕ139.7 mm尾管固井技术[J]. 石油钻采工艺,2021,43(6):727–731. GAO Fei, TIAN Baozhen, FEI Zhongming, et al. ϕ139.7 mm liner cementing technology in the unconsolidated sandstone oil layers of Well Dengtan 1[J]. Oil Drilling & Production Technology, 2021, 43(6): 727–731.

[8] 邓昌松,何思龙,段永贤,等. 复杂超深井KS1井四开尾管固井技术[J]. 石油钻采工艺,2019,41(6):708–713. doi: 10.13639/j.odpt.2019.06.005 DENG Changsong, HE Silong, DUAN Yongxian, et al. Fourth-section liner cementing technology used in the complex ultradeep Well KS1[J]. Oil Drilling & Production Technology, 2019, 41(6): 708–713. doi: 10.13639/j.odpt.2019.06.005

[9] 杨红歧,陈会年,邓天安,等. 元坝气田超深探井小尾管防气窜固井技术[J]. 石油钻采工艺,2020,42(5):592–599. YANG Hongqi, CHEN Huinian, DENG Tian’an, et al. The anti-gas channeling small-liner cementing technology for ultra deep exploration wells of Yuanba Gasfield[J]. Oil Drilling & Production Technology, 2020, 42(5): 592–599.

[10] 张瑞,侯跃全,郭朝辉,等. 川西长裸眼水平井下尾管循环解阻关键技术[J]. 石油钻探技术,2020,48(3):52–57. doi: 10.11911/syztjs.2020040 ZHANG Rui, HOU Yuequan, GUO Zhaohui, et al. Key techniques for eliminating resistance while running liner with circulation in long horizontal openhole wells in the western Sichuan[J]. Petroleum Drilling Techniques, 2020, 48(3): 52–57. doi: 10.11911/syztjs.2020040

[11] 张冠林,徐星,赵聪,等. 国内外高温高压尾管悬挂器技术新进展[J]. 断块油气田,2020,27(1):113–116. ZHANG Guanlin, XU Xing, ZHAO Cong, et al. New development of high temperature and high pressure liner hanger technology in China and abroad[J]. Fault-Block Oil & Gas Field, 2020, 27(1): 113–116.

[12] 马开华,谷磊,叶海超. 深层油气勘探开发需求与尾管悬挂器技术进步[J]. 石油钻探技术,2019,47(3):34–40. doi: 10.11911/syztjs.2019055 MA Kaihua, GU Lei, YE Haichao. The demands on deep oil/gas exploration & development and the technical advancement of liner hangers[J]. Petroleum Drilling Techniques, 2019, 47(3): 34–40. doi: 10.11911/syztjs.2019055

[13] 阮臣良,马兰荣,姜向东,等. 内嵌卡瓦尾管悬挂器的优势与现场应用分析[J]. 钻采工艺,2013,36(2):84–86. doi: 10.3969/J.ISSN.1006-768X.2013.02.24 RUAN Chenliang, MA Lanrong, JIANG Xiangdong, et al. Advantages and application of inner-slip liner hanger[J]. Drilling & Production Technology, 2013, 36(2): 84–86. doi: 10.3969/J.ISSN.1006-768X.2013.02.24

[14] 朱晓丽,张金法,魏书雷. 尾管用内嵌式卡瓦坐挂机构承载能力分析[J]. 石油矿场机械,2018,47(5):84–87. doi: 10.3969/j.issn.1001-3482.2018.05.018 ZHU Xiaoli, ZHANG Jinfa, WEI Shulei. Analysis of carrying capacity of embedded slips for tail pipe[J]. Oil Field Equipment, 2018, 47(5): 84–87. doi: 10.3969/j.issn.1001-3482.2018.05.018

[15] 高果成. 内嵌卡瓦尾管悬挂器在老井侧钻中的优势综合分析[J]. 钻采工艺,2020,43(1):77–80. doi: 10.3969/J.ISSN.1006-768X.2020.01.22 GAO Guocheng. Comprehensive analysis on the advantages of applying inner embedded slips liner hanger in the sidetracking wells[J]. Drilling & Production Technology, 2020, 43(1): 77–80. doi: 10.3969/J.ISSN.1006-768X.2020.01.22

[16] 肖勇,李丹阳,牛阁,等. 新型尾管悬挂器在塔里木油田的适应性研究应用[J]. 钻采工艺,2018,41(2):30–32. doi: 10.3969/J.ISSN.1006-768X.2018.02.09 XIAO Yong, LI Danyang, NIU Ge, et al. Study on applicability of new style liner hanger at Tarim Oilfield[J]. Drilling & Production Technology, 2018, 41(2): 30–32. doi: 10.3969/J.ISSN.1006-768X.2018.02.09

[17] 郭朝辉,李振,罗恒荣. ϕ273.1 mm无限极循环尾管悬挂器在元坝气田的应用研究[J]. 石油钻探技术,2021,49(5):64–69. doi: 10.11911/syztjs.2021004 GUO Zhaohui, LI Zhen, LUO Hengrong. Research and application of a ϕ273.1 mm infinite circulation liner hanger in Yuanba Gas Field[J]. Petroleum Drilling Techniques, 2021, 49(5): 64–69. doi: 10.11911/syztjs.2021004

[18] 路飞飞,于洋,王伟志,等. 顺北油气田防漏固井用封隔式分级箍研制与应用[J]. 石油钻探技术,2022,50(4):31–36. doi: 10.11911/syztjs.2022076 LU Feifei, YU Yang, WANG Weizhi, et al. Development and application of a leakproof stage cementing collar with packer in the Shunbei Oil & Gas Field[J]. Petroleum Drilling Techniques, 2022, 50(4): 31–36. doi: 10.11911/syztjs.2022076

[19] 刘国祥,郭朝辉,孙文俊,等. 新型封隔式尾管悬挂器的研制及应用[J]. 石油钻采工艺,2014,36(5):120–123. doi: 10.13639/j.odpt.2014.05.030 LIU Guoxiang, GUO Zhaohui, SUN Wenjun, et al. Development and application of new isolated liner hanger[J]. Oil Drilling & Production Technology, 2014, 36(5): 120–123. doi: 10.13639/j.odpt.2014.05.030

[20] 胡晋军,张立丽,张耀,等. 埕海油田大斜度井超短尾管固井技术[J]. 石油钻探技术,2021,49(3):81–86. doi: 10.11911/syztjs.2020132 HU Jinjun, ZHANG Lili, ZHANG Yao, et al. Ultra-short liner cementing technology for highly deviated wells in the Chenghai Oilfield[J]. Petroleum Drilling Techniques, 2021, 49(3): 81–86. doi: 10.11911/syztjs.2020132

[21] 李宗要,张海涛,魏群宝,等. 青海油田英西深层水平井固井技术[J]. 钻井液与完井液,2019,36(5):622–628. doi: 10.3969/j.issn.1001-5620.2019.05.017 LI Zongyao, ZHANG Haitao, WEI Qunbao, et al. Technology for cementing deep reservoirs in Yingxi Area, Qinghai Oilfield[J]. Drilling Fluid & Completion Fluid, 2019, 36(5): 622–628. doi: 10.3969/j.issn.1001-5620.2019.05.017

[22] 邹双,冯明慧,张天意,等. 多尺度纤维韧性水泥浆体系研究与应用[J]. 石油钻探技术,2020,48(6):40–46. doi: 10.11911/syztjs.2020084 ZOU Shuang, FENG Minghui, ZHANG Tianyi, et al. Research and application of tough cement slurry systems with multi-scale fiber[J]. Petroleum Drilling Techniques, 2020, 48(6): 40–46. doi: 10.11911/syztjs.2020084

[23] 李斐. 抗高温弹韧性水泥浆体系优化研究[J]. 钻井液与完井液,2021,38(5):623–627. LI Fei. Study on optimization of high temperature cement slurry with elasticity and toughness[J]. Drilling Fluid & Completion Fluid, 2021, 38(5): 623–627.

下载:

下载: