Research on a Polygonal Quartz Sand Flushing Fluid for Cementing Oil and Gas Wells and Its Field Application

-

摘要:

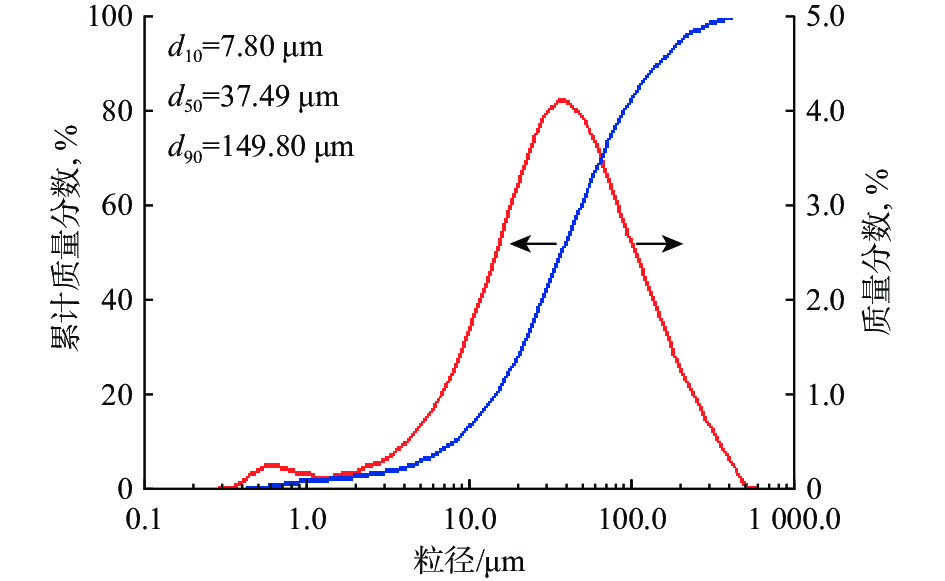

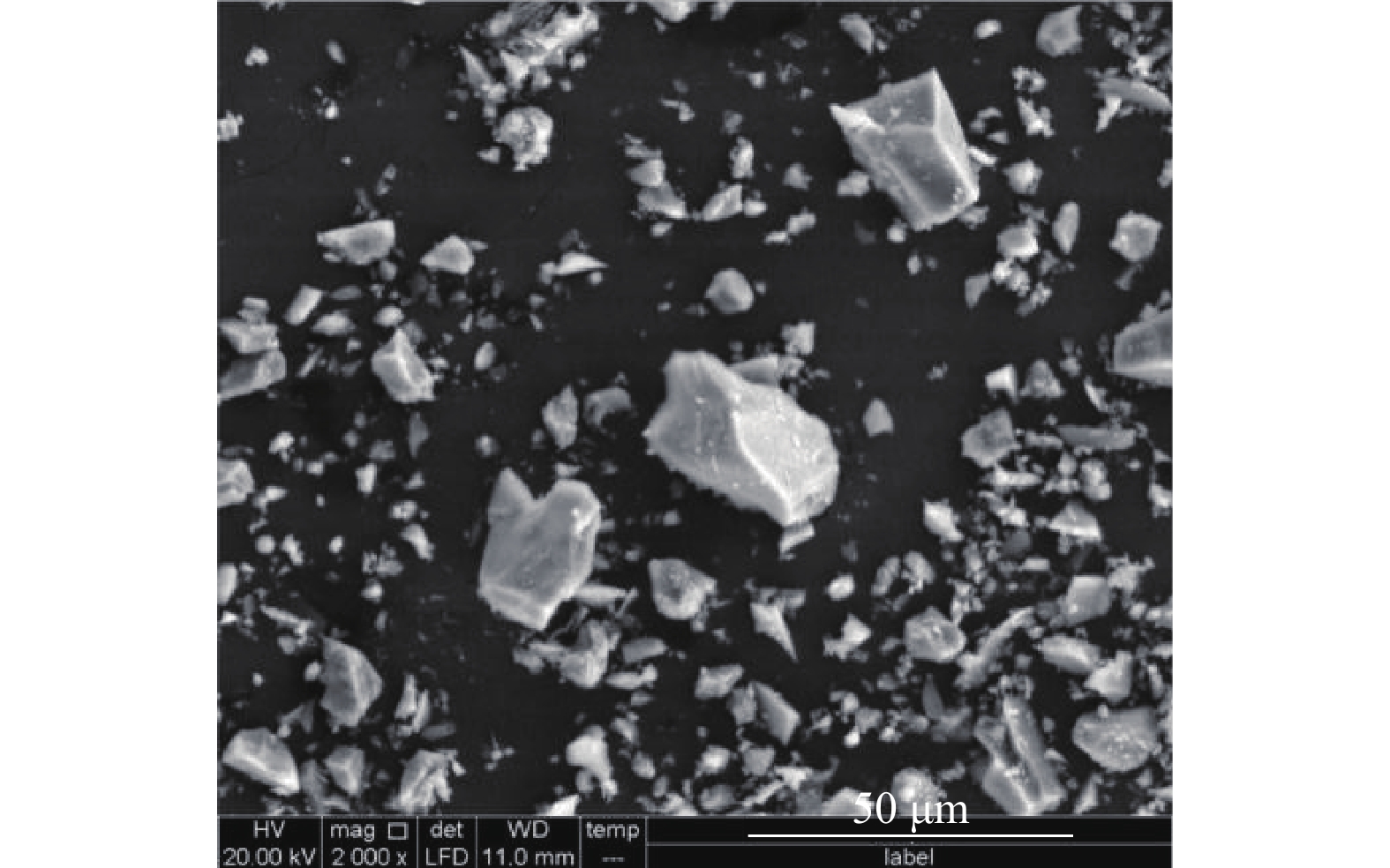

在油气井固井过程中,常规冲洗液存在难以有效清洗井壁上滤饼的问题,尤其是油基钻井液会在井壁形成含油滤饼、在套管壁会附着油膜,严重影响了固井质量。为此,基于加强冲洗液物理冲刷作用的理念,优选了具有尖锐棱角、形状不规则的多棱石英砂颗粒及悬浮剂,配制了多棱石英砂冲洗液。室内试验发现,该冲洗液具有稳定性好,与水泥浆、钻井液相容性好的特点,且冲洗效率比常规冲洗液高10~30百分点。多棱石英砂冲洗液在胜利油田4口井进行了成功应用,固井质量均有明显的提高。研究应用结果表明,多棱石英砂冲洗液能够有效清除井壁滤饼、油膜及岩屑,改善固井二界面胶结环境,从而提高固井质量,满足大型压裂对水泥环胶结质量的要求。

Abstract:Conventional flushing fluid cannot effectively remove the filter cake from the well walls during oil and gas wells cementing, especially oil-bearing filter cakes formed by oil-base drilling fluid on the well walls and the oil film attached to the casing walls, both of which seriously affect cementing quality. Therefore, it was hypothesized that polygonal quartz sand particles with sharp corners and irregular shapes mixed into an ideal suspending agent would strengthen the physical scouring capabilities of flushing fluid. With that in mind, a polygonal quartz sand flushing fluid was prepared. The laboratory test revealed that the prepared flushing fluid was highly stable and compatible with the cement slurry and drilling fluid, and the flushing efficiency was higher than that of conventional flushing fluid by 10 to 30 percentage points. After the successful laboratory results, the prepared flushing fluid was successfully applied in four wells in Shengli Oilfield, and the cementing quality was significantly improved. The research and application indicated that the prepared flushing fluid could effectively remove the filter cake, oil film, and cuttings on the well walls and improve the cementing environment of the cement-formation interface. In this way, the cementing quality was enhanced to meet the requirements of large-scale fracturing for the cementing quality of cement sheaths.

-

-

表 1 4种常用悬浮剂的悬浮能力测试结果

Table 1 Test results of suspension capacity of four common suspending agents

悬浮剂 悬浮剂加量,% 冲洗液密度/(kg·L−1) 试验现象 上部 下部 上下差 SYXF-1 0.5 1.14 1.44 0.30 上下明显分层 1.0 1.17 1.41 0.24 上下明显分层 2.0 1.21 1.35 0.14 上下明显分层 KCM004 0.3 1.21 1.36 0.15 上下明显分层 0.4 1.22 1.27 0.05 上下基本均匀 0.5 1.23 1.23 0 上下均匀 1.0 1.23 1.23 0 上下均匀 KCM006 0.4 1.20 1.26 0.06 上下基本均匀 0.5 1.21 1.25 0.04 上下基本均匀 0.6 浆体呈胶冻状 SYJ-1 0.9 1.02 石英砂基本全沉底 2.0 1.02 石英砂基本全沉底 3.0 1.03 石英砂基本全沉底 注:多棱石英砂质量分数为44%,冲洗液理论密度为1.23 kg/L。 表 2 不同配方多棱石英砂冲洗液的基本性能

Table 2 Basic performance of polygonal quartz sand flushing fluid with different formulas

配方 密度/(kg·L−1) 上下密度差/(kg·L−1) 漏斗黏度/s 1 1.11 0.01 43 2 1.21 0.01 44 3 1.31 0 60 4 1.42 0 68 5 1.52 0 130 注:配方1为0.4%悬浮剂KCM004+16.8%多棱石英砂+水;配方2为0.4%悬浮剂KCM004+36.6%多棱石英砂+水;配方3为0.6%悬浮剂KCM004+59.4%多棱石英砂+水;配方4为0.6%悬浮剂KCM004+86.2%多棱石英砂+水;配方5为0.6%悬浮剂KCM004+117.6%多棱石英砂+水。 表 3 4口井现场应用钻井液的基本性能

Table 3 Basic on-site application performance of drilling fluid system in four wells

序号 井号 钻井液 密度/

(kg·L−1)API滤失量/mL 塑性黏度/

(mPa·s)动切力/Pa 钻井液1 X50-xj1井 水基无固相 1.23 52 16 6.0 钻井液2 Cl20-x33井 水基聚合物 1.14 41 22 4.0 钻井液3 C13-x332井 水基聚合物 1.18 45 12 6.0 钻井液4 Fyp1井 合成基 1.60 26 35 8.5 表 4 不同冲洗液冲洗效率试验结果

Table 4 Flushing efficiency test results of different flushing fluid

钻井液 冲洗液配方 W0/g W1/g W2/g 冲洗效率,

%钻井液1 配方2(多棱石英砂) 164.70 167.92 165.96 60.8 配方2(普通石英砂) 164.70 167.51 166.07 51.2 配方2(重晶石) 164.70 167.18 166.03 46.4 钻井液3 配方1(多棱石英砂) 164.75 173.50 165.30 93.2 配方1(普通石英砂) 164.75 172.95 166.34 80.6 配方1(重晶石) 164.75 173.83 167.61 68.5 钻井液4 配方3(多棱石英砂) 164.91 166.93 165.34 78.7 配方3(普通石英砂) 164.91 166.81 165.61 63.2 配方3(重晶石) 164.91 167.23 166.06 50.4 表 5 多棱石英砂冲洗液与常用水泥浆、钻井液的相 容性试验结果

Table 5 Compatibility test results of polygonal quartz sand flushing fluid with common cement slurry and drilling fluid

混合液组成 掺混比例① 稠化时间/min 稠度/Bc 水泥浆∶冲洗液∶钻井液1 7∶2∶1 252 18 水泥浆∶冲洗液∶钻井液1 1∶1∶1 240 10 水泥浆∶冲洗液∶钻井液1 7∶3∶0 260 6 水泥浆∶冲洗液∶钻井液2 7∶2∶1 270 16 水泥浆∶冲洗液∶钻井液2 1∶1∶1 255 11 水泥浆∶冲洗液∶钻井液3 7∶2∶1 263 14 水泥浆∶冲洗液∶钻井液3 1∶1∶1 245 9 水泥浆∶冲洗液∶钻井液4 7∶2∶1 268 26 水泥浆∶冲洗液∶钻井液4 1∶1∶1 260 17 注:①为水泥浆、冲洗液和钻井液的体积比。 表 6 多棱石英砂冲洗液在3口井中的应用效果

Table 6 Application effect of polygonal quartz sand flushing fluid in three wells

井名 目的层井段长度/m 优良率,% 合格率,% 备注 C13-x330井 326 16.6 46.5 对比井 C13-x332井 350 71.7 88.5 应用井 C13-x112井 320 69.6 96.0 B17-x037井 252 56.6 86.0 对比井 B17-x292井 260 89.6 97.0 应用井 -

[1] 王辉,刘潇冰,耿铁,等. 微乳液型油基钻井液冲洗液作用机理及研究进展[J]. 钻井液与完井液,2015,32(4):96–100. WANG Hui, LIU Xiaobing, GENG Tie, et al. Functioning mechanism of and research progress in micro emulsion flushing fluid used in oil base mud drilling[J]. Drilling Fluid & Completion Fluid, 2015, 32(4): 96–100.

[2] 杨香艳,郭小阳,杨远光,等. 固井前置冲洗液的研究发展[J]. 西南石油学院学报,2005,27(1):70–74. YANG Xiangyan, GUO Xiaoyang, YANG Yuanguang, et al. The research and development of the well cementation preposition flushing fluid[J]. Journal of Southwest Petroleum Institute, 2005, 27(1): 70–74.

[3] 马文英,张辉,田军,等. 提高第二界面固井质量的钻井液与前置液研究[J]. 钻井液与完井液,2003,20(4):27–30. MA Wenying, ZHANG Hui, TIAN Jun, et al. Study on drilling fluid and preflush for improving cementing quality of the second contact surface[J]. Drilling Fluid & Completion Fluid, 2003, 20(4): 27–30.

[4] 齐奔,林志辉,朱禹,等. 固井用冲洗液BH-Q812L的研制与应用[J]. 油田化学,2018,35(4):603–607. QI Ben, LIN Zhihui, ZHU Yu, et al. Development and application of flushing fluid BH-Q812L for cementing[J]. Oilfield Chemistry, 2018, 35(4): 603–607.

[5] 赵启阳,张成金,严海兵,等. 提高油基钻井液固井质量的冲洗型隔离液技术[J]. 钻采工艺,2017,40(5):88–90. ZHAO Qiyang, ZHANG Chengjin, YAN Haibing, et al. Flush type spacer fluid technology used to improving cementing quality of OBM drilled wells[J]. Drilling & Production Technology, 2017, 40(5): 88–90.

[6] 孙坤忠,陶谦,周仕明,等. 丁山区块深层页岩气水平井固井技术[J]. 石油钻探技术,2015,43(3):55–60. SUN Kunzhong, TAO Qian, ZHOU Shiming, et al. Cementing technology for deep shale gas horizontal well in the Dingshan Block[J]. Petroleum Drilling Techniques, 2015, 43(3): 55–60.

[7] 赵常青,谭宾,曾凡坤,等. 长宁-威远页岩气示范区水平井固井技术[J]. 断块油气田,2014,21(2):256–258. ZHAO Changqing, TAN Bin, ZENG Fankun, et al. Cementing technology of horizontal well in Changning-Weiyuan shale gas reservoir[J]. Fault-Block Oil & Gas Field, 2014, 21(2): 256–258.

[8] 刘伟,刘学鹏,陶谦. 适合页岩气固井的洗油隔离液的研究与应用[J]. 特种油气藏,2014,21(6):119–122. LIU Wei, LIU Xuepeng, TAO Qian. Development and application of flushing spacer for cementing in shale gas reservoirs[J]. Special Oil & Gas Reservoirs, 2014, 21(6): 119–122.

[9] 陈小华,张福铭,赵琥,等. 油基钻井液用冲洗液PC-W31L的制备及性能研究[J]. 石油钻探技术,2019,47(2):81–86. CHEN Xiaohua, ZHANG Fuming, ZHAO Hu, et al. The development and properties of PC-W31L flushing fluid for oil-based drilling fluid[J]. Petroleum Drilling Techniques, 2019, 47(2): 81–86.

[10] 王翀,谢飞燕,刘爱萍,等. 油基钻井液用冲洗液BCS-020L研制及应用[J]. 石油钻采工艺,2013,35(6):36–39. WANG Chong, XIE Feiyan, LIU Aiping, et al. Research and application of flushing fluid BCS-020L for oil-based drilling fluid cleaning[J]. Oil Drilling & Production Technology, 2013, 35(6): 36–39.

[11] 由福昌,许明标. 一种固井前置冲洗液冲洗效率的评价方法[J]. 钻井液与完井液,2009,26(6):47–48. YOU Fuchang, XU Mingbiao. A method for the evaluation of a prepad flushing fluid for cementing[J]. Drilling Fluid & Completion Fluid, 2009, 26(6): 47–48.

[12] GB/T 19139—2003 油井水泥试验方法[S]. GB/T 19139—2003 Procedure for testing well cements[S].

[13] 王广雷,吴迪,姜增东,等. 固井冲洗效率评价方法探讨[J]. 石油钻探技术,2011,39(2):77–80. WANG Guanglei, WU Di, JIANG Zengdong, et al. Discussion of evaluation method of cementing flushing efficiency[J]. Petroleum Drilling Techniques, 2011, 39(2): 77–80.

[14] 唐世忠,饶富培,吴华,等. 固井冲洗液冲洗效率评价方法[J]. 石油钻采工艺,2016,38(5):601–605. TANG Shizhong, RAO Fupei, WU Hua, et al. Assessment method for flushing efficiency of flushing liquid in cementing[J]. Oil Drilling & Production Technology, 2016, 38(5): 601–605.

-

期刊类型引用(10)

1. 周涛,侯红意,陶亮,艾超. 渤海油田注水井环空保护封隔器的研制与应用. 工程机械. 2022(03): 96-104+13 .  百度学术

百度学术

2. 杜福云,刘国振,郭雯霖,张立波,郑金中,陈磊,李英松. 高性能注水井生产封隔器研制与试验. 机械工程师. 2021(05): 142-144 .  百度学术

百度学术

3. 李顺,贺启强,周大志,寸锡宏,任兆林,刘艳霞. 注水井环空带压统计分析及治理改进方向. 当代石油石化. 2021(05): 26-28 .  百度学术

百度学术

4. 韩祥海,平恩顺,安小萍,王林,贺燕飞,王志民,黄峰. 带压投送井口保护装置的研制及应用. 钻采工艺. 2021(04): 86-89 .  百度学术

百度学术

5. 宋辉辉,任从坤,任兆林,张福涛,田俊,刘艳霞. 海上油田分层防砂分层注水高效集成技术. 石油钻采工艺. 2021(03): 384-388 .  百度学术

百度学术

6. 刘红兰. 胜利海上油田安全可控长效分层注水技术. 石油钻探技术. 2019(01): 83-89 .  本站查看

本站查看

7. 张技. 油田安全环保隐患成因分析及治理技术探析. 石化技术. 2019(05): 235+237 .  百度学术

百度学术

8. 李勇. 埕岛油田长效细分注水关键技术及应用. 石油机械. 2019(10): 94-100 .  百度学术

百度学术

9. 杨建政. 适合海上低渗气田水平井固井的柔性水泥浆体系研究. 化工管理. 2019(32): 224 .  百度学术

百度学术

10. 刘红兰. 分层注水井测调一体化新技术. 石油钻探技术. 2018(01): 83-89 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: