Field Test of Fishbone Multi-Branch Hole Stimulation Technology in Bohai Oilfield

-

摘要:

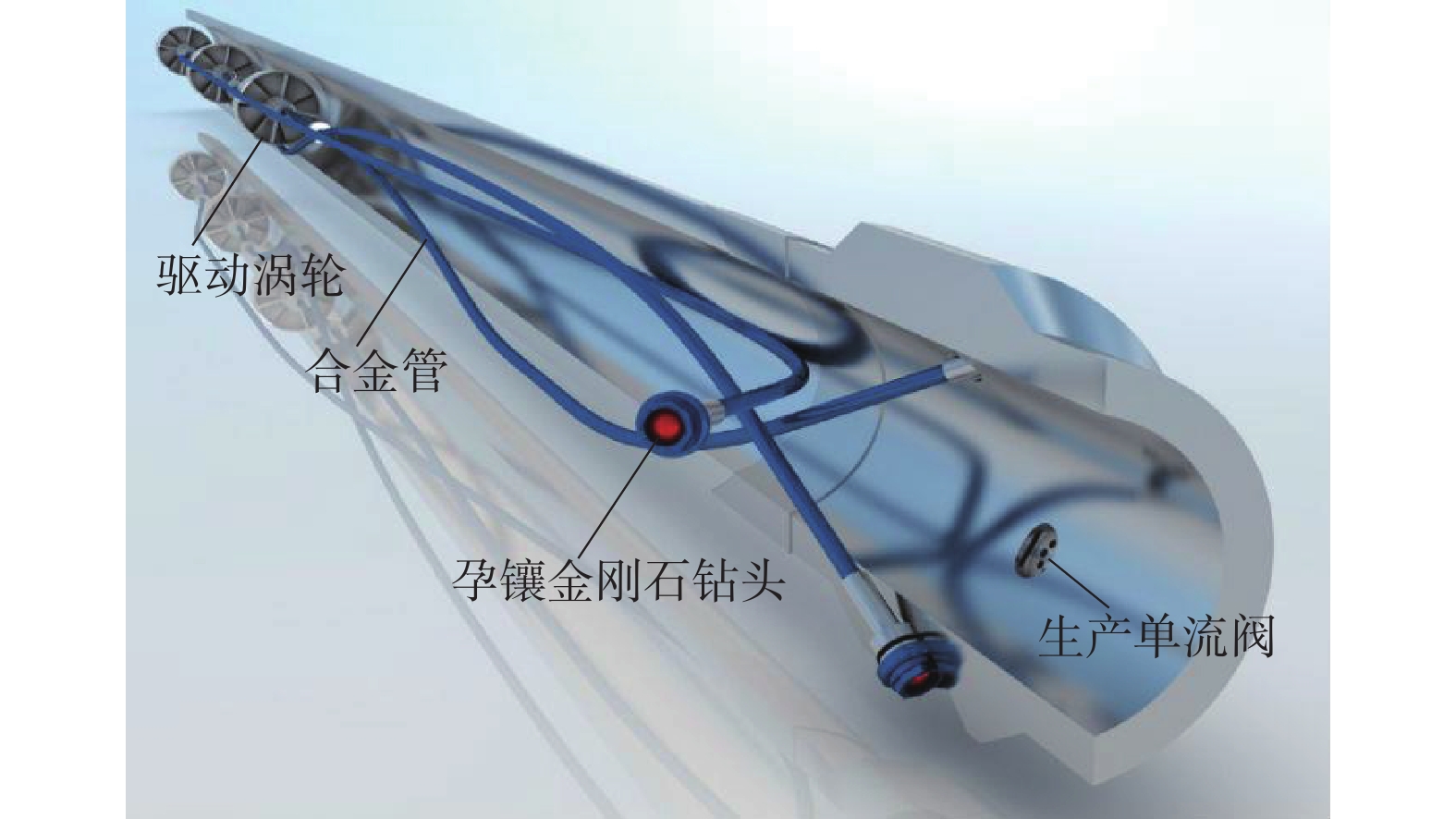

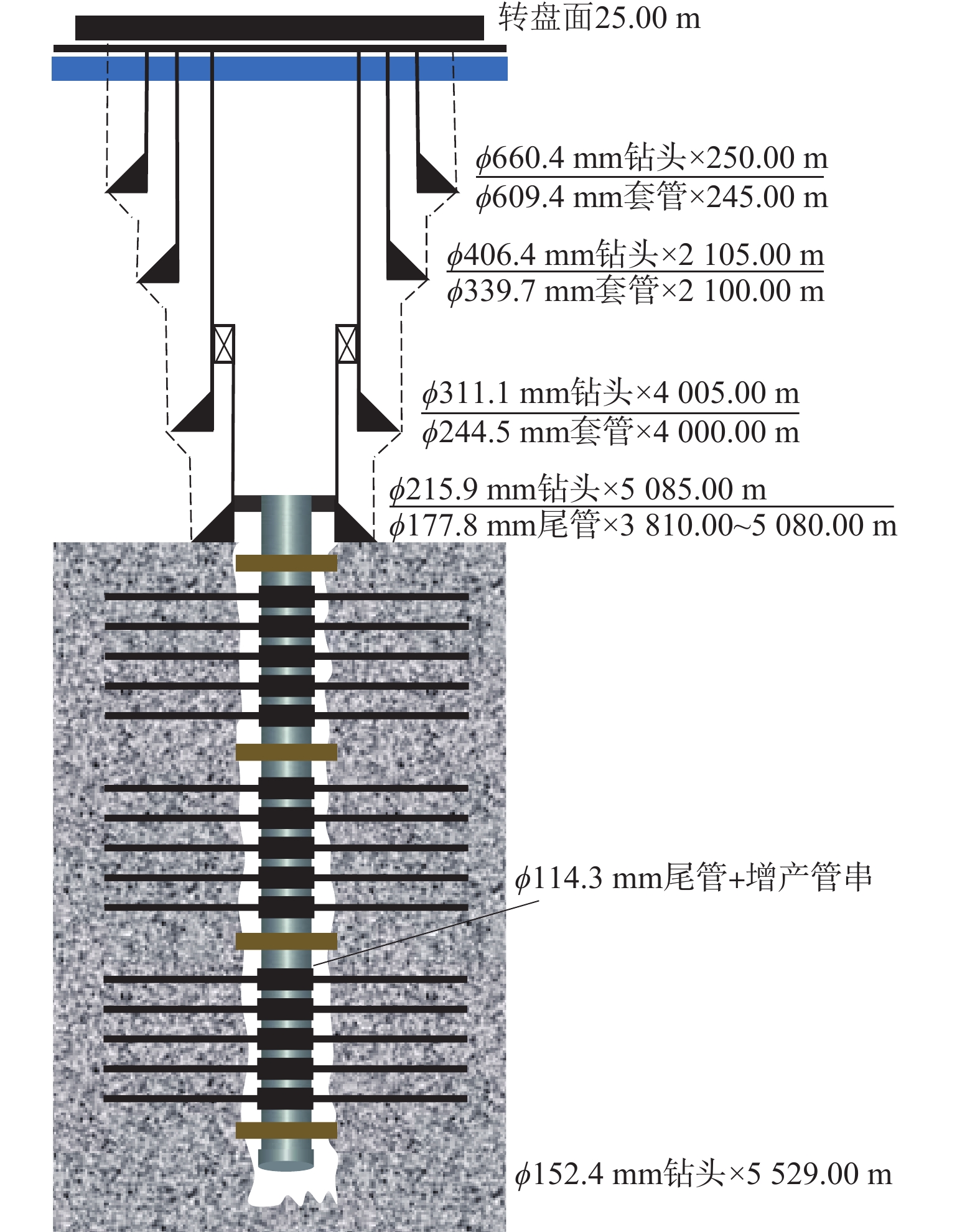

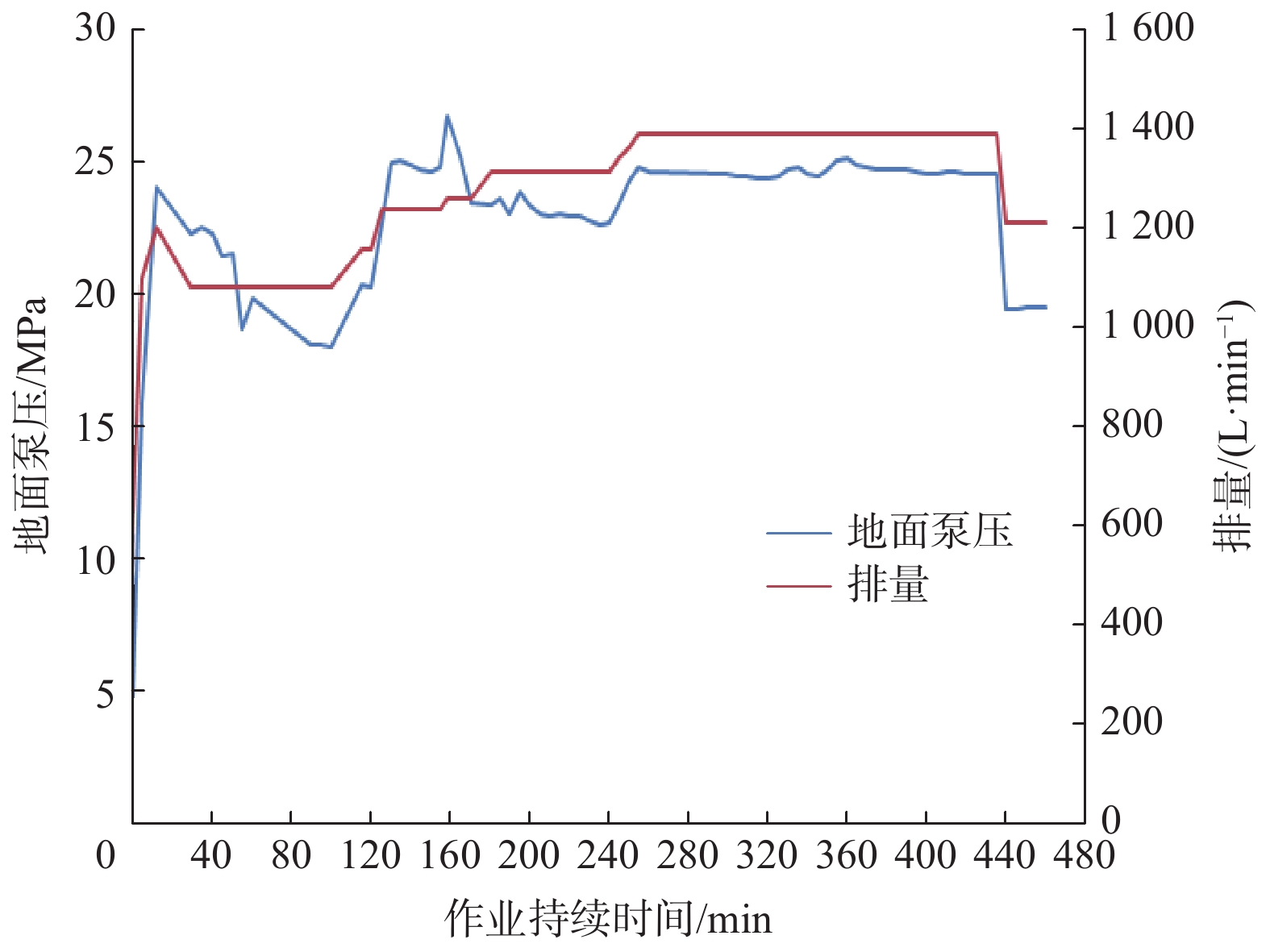

为了提高渤海油田渤中区块裂缝性储层的单井产能,降低开发成本,进行了鱼骨刺形多分支孔增产技术试验。鱼骨刺形多分支孔增产技术具有增产工具结构简单、施工便捷、平台负担小的特点,适合于海上平台作业,实施后可从主井筒向储层一次性钻成多组长12 m的分支孔,能够穿透近井污染带,沟通近井地带的油气流动通道,提高单井产量,在裂缝性储层增产方面具有巨大的应用潜力。首先,通过地面试验分析了裂缝性硬地层岩石的可钻性和分支孔眼轨迹的可控性;在此基础上,优化了水力参数和施工方案,并在渤中区块某探井进行了井下试验。该探井实施鱼骨刺形多分支孔增产措施后,比采气指数提高29%以上,日产气量提高20%以上。试验结果表明,鱼骨刺形多分支孔增产技术可以提高渤海油田渤中区块裂缝性储层的单井产能,且该技术成本低,为渤海油田渤中区块效益开发提供了技术支持。

Abstract:In order to increase the single well production and reduce development costs of fractured reservoirs in the Bozhong Block of Bohai Oilfield, a field test of fishbone multi-branch hole stimulation technology was carried out. The technology is characterized by simple tool structure, convenient construction, and low platform burden which make it suitable for offshore platform operation. As the technology is implemented, multi-branch holes with a length of 12 m can be drilled from the main wellbore to the reservoir at one time, and they can penetrate near-well pollution zones, connect the oil and gas flow channels in near-well zones, and improve the single well production, which has great application potential in increasing the production of fractured reservoirs. To ensure the field test could be carried out smoothly, the first step involved a ground test to analyze the drillability of the rock in fractured reservoirs and the trajectory controllability of multi-branch holes. The hydraulic parameters and construction scheme for the fishbone multi-branch hole stimulation technology were optimized accordingly. Furthermore, the field test was carried out in an exploratory well in the Bozhong block. After the application of fishbone multi-branch hole stimulation technology, the well’s gas productivity index and daily gas production were increased by more than 29% and 20%, respectively. The test results showed that the fishbone multi-branch hole technology can improve the single well production of fractured reservoirs in the Bozhong Block of Bohai Oilfield, and provide technical support for the efficient development in the block with low implementation cost.

-

-

表 1 岩石可钻性试验结果

Table 1 Rock drillability test results

岩心编号 钻头型号 钻头直径/

mm钻头长度/

mm钻压/

N转速/

(r·min−1)平均机械钻速/

(m·h−1)钻后孔径/

mm1 DT-CG 11.6 8.0 400 1 450 8.5 11.9 2 DT-CG 11.6 8.0 400 1 450 6.2 11.9 3 DT-CG 11.6 8.0 400 1 450 5.3 11.9 4 DT-CG 11.6 8.0 400 1 450 2.9 11.9 表 2 钻鱼骨刺多分支孔前后试验井的测试结果

Table 2 Test results of a well before and after fishbone multi-branch hole technology implemented

测试时间 测试井段/m 厚度/m 求产方式 井底压差/MPa 压力系数 比采气指数/(m3·MPa−1·d−1·m−1) 日产气量/m3 钻分支孔前 5 076~5 529 453 敞放 46.43 1.10 0.68 14 235 钻分支孔后 5 076~5 529 453 敞放 44.60~48.80 1.10 0.80~0.88 16 289~17 732 -

[1] 薛永安. 渤海海域深层天然气勘探的突破与启示[J]. 天然气工业,2019,39(1):11–20. doi: 10.3787/j.issn.1000-0976.2019.01.002 XUE Yong’an. The breakthrough of the deep-buried gas exploration in the Bohai Sea area and its enlightenment[J]. Natural Gas Industry, 2019, 39(1): 11–20. doi: 10.3787/j.issn.1000-0976.2019.01.002

[2] 李根生,夏强,黄中伟,等. 深井水力喷射压裂可行性分析及设计计算[J]. 石油钻探技术,2011,39(5):58–62. doi: 10.3969/j.issn.1001-0890.2011.05.013 LI Gensheng, XIA Qiang, HUANG Zhongwei, et al. Feasibility study and treatment design of hydrojet-fracturing in deep wells[J]. Petroleum Drilling Techniques, 2011, 39(5): 58–62. doi: 10.3969/j.issn.1001-0890.2011.05.013

[3] 刘平礼,黄晶,幸雪松,等. 超高温裂缝性变质片麻岩凝析油气藏缝网酸压改造技术:以海上A气田太古界潜山储层为例[J]. 天然气工业,2021,41(12):73–80. doi: 10.3787/j.issn.1000-0976.2021.12.008 LIU Pingli, HUANG Jing, XING Xuesong, et al. Fracture-network acid fracturing technology for ultra-high temperature fractured metamorphic gneiss condensate reservoirs: a case study of the Archean buried-hill reservoirs of the offshore A Gas Field[J]. Natural Gas Industry, 2021, 41(12): 73–80. doi: 10.3787/j.issn.1000-0976.2021.12.008

[4] FREYER R, KRISTIANSEN T, MADLAND M V, et al. Multilateral system allowing 100 level 5 laterals drilled simultaneously[R]. SPE 121814, 2009.

[5] RICE K, JORGENSENT T, WATERS J W. First installation of efficient and accurate multilaterals stimulation technology in carbonate oil application[R]. SPE 171021, 2014.

[6] RICE K, JØRGENSEN T, SOLHAUG K. Technology qualification and installation plan of efficient and accurate multilaterals drilling stimulation technology for sandstone oil application[R]. SPE 174035, 2015.

[7] FREYER R. Method and a device for solvent injection in a subsurface well: US08037937B2[P]. 2011-10-18.

[8] FREYER R. Method and device for making lateral openings out of a wellbore: US20110017445[P]. 2011-01-27.

[9] FREYER R. Method and jetting head for making a long and narrow penetration in the ground: US20120273276A1[P]. 2012-11-01.

[10] 程光明,何同,曹海涛. 柔性分支管增产工具关键技术研究[J]. 石油机械,2020,48(2):85–89. CHENG Guangming, HE Tong, CAO Haitao. Research on key techniques of reservoir stimulation using fishbone flexible pipes[J]. China Petroleum Machinery, 2020, 48(2): 85–89.

[11] 邓建明,马英文. 渤海中深层天然气田钻完井关键技术现状及展望[J]. 石油钻采工艺,2018,40(6):677–683. DENG Jianming, MA Yingwen. Status and prospect of key drilling and completion technologies used in middle-deep natural gas fields of the Bohai Sea[J]. Oil Drilling & Production Technology, 2018, 40(6): 677–683.

[12] 王达,卢岩,周福建,等. 低、无污染基质孔隙型灰岩储层基质酸化增产可行性探索[J]. 科学技术与工程,2020,20(14):5603–5609. doi: 10.3969/j.issn.1671-1815.2020.14.021 WANG Da, LU Yan, ZHOU Fujian, et al. Feasibility study of matrix acidizing technology to stimulate low damaged or undamaged porous carbonate reservoirs[J]. Science Technology and Engineering, 2020, 20(14): 5603–5609. doi: 10.3969/j.issn.1671-1815.2020.14.021

[13] 张明,刘光泽,程飞,等. SZ36-1油田稠油储层解堵酸化技术研究[J]. 非常规油气,2017,4(2):85–90. doi: 10.3969/j.issn.2095-8471.2017.02.013 ZHANG Ming, LIU Guangze, CHENG Fei, et al. The heavy oil reservoir of SZ36-1 Oilfield acidification technology research and appli-cation[J]. Unconventional Oil & Gas, 2017, 4(2): 85–90. doi: 10.3969/j.issn.2095-8471.2017.02.013

[14] 杨子,冯卫华,施洋,等. 多氢酸酸化技术在海上油田中的应用与研究[J]. 石油化工应用,2014,33(2):59–62. doi: 10.3969/j.issn.1673-5285.2014.02.016 YANG Zi, FENG Weihua, SHI Yang, et al. The application and research of reservoir acidification reconstruction technology in offshore field[J]. Petrochemical Industry Application, 2014, 33(2): 59–62. doi: 10.3969/j.issn.1673-5285.2014.02.016

[15] 穆笛. 储层改造中人工裂缝穿过天然裂缝的判别机理[J]. 石油机械,2018,46(7):80–83. MU Di. Identification mechanism of artificial fracture crossing natural fracture in reservoir stimulation[J]. China Petroleum Machinery, 2018, 46(7): 80–83.

[16] 张宏友. 渤海油田某奥陶系潜山碳酸盐岩油藏酸化后试井曲线特征分析[J]. 重庆科技学院学报(自然科学版),2019,21(2):49–51. ZHANG Hongyou. Analysis of well test curve characteristics of ordovician buried carbonate reservoir after acidizing in Bohai Oilfield[J]. Journal of Chongqing University of Science and Technology(Natural Sciences Edition), 2019, 21(2): 49–51.

[17] 孙林,李旭光,黄利平,等. 渤海油田注水井延效酸化技术研究与应用[J]. 石油钻探技术,2021,49(2):90–95. doi: 10.11911/syztjs.2021029 SUN Lin, LI Xuguang, HUANG Liping, et al. Research and application of prolonged-effect acidizing technology for water injection wells in the Bohai Oilfield[J]. Petroleum Drilling Techniques, 2021, 49(2): 90–95. doi: 10.11911/syztjs.2021029

[18] 孙恩慧,杨东东,杨威,等. 鱼骨型多分支井产能预测公式推导及影响因素分析[J]. 重庆科技学院学报(自然科学版),2020,22(3):32–35. SUN Enhui, YANG Dongdong, YANG Wei, et al. Productivity prediction and its influencing factors for herring bone-like laterals well[J]. Journal of Chongqing University of Science and Technology(Natural Sciences Edition), 2020, 22(3): 32–35.

[19] 李晓益,艾爽,程光明,等. 鱼骨刺柔性管在碳酸盐岩缝洞型油藏应用的数值模拟研究[J]. 石油钻探技术,2017,45(3):102–106. LI Xiaoyi, AI Shuang, CHENG Guangming, et al. Numerical simulation of fishbone flexible pipes in fractured vuggy carbonate reservoirs[J]. Petroleum Drilling Techniques, 2017, 45(3): 102–106.

[20] 王敏生,光新军,赵阳,等. 6级分支井系统及国内研究进展[J]. 石油机械,2015,43(3):21–25. WANG Minsheng, GUANG Xinjun, ZHAO Yang, et al. Six-lateral well system and progress of researches in China[J]. China Petroleum Machinery, 2015, 43(3): 21–25.

[21] 白殿刚,陈秋睿,安鹏,等. 张海39-39Z分支井钻井液技术[J]. 钻井液与完井液,2020,37(4):494–497. BAI Diangang, CHEN Qiurui, AN Peng, et al. Drilling fluid technology of Zhanghai 39-39Z multilateral well[J]. Drilling Fluid & Completion Fluid, 2020, 37(4): 494–497.

[22] 豆志远,王昆剑,李进,等. 渤海油田水平分支井钻完井关键技术[J]. 特种油气藏,2020,27(2):157–163. doi: 10.3969/j.issn.1006-6535.2020.02.025 DOU Zhiyuan, WANG Kunjian, LI Jin, et al. Key technologies for horizontal branch well drilling and completion in Bohai Oilfield[J]. Special Oil & Gas Reservoirs, 2020, 27(2): 157–163. doi: 10.3969/j.issn.1006-6535.2020.02.025

[23] 谭忠健,项华,刘富奎,等. 渤海复杂油气藏测试技术研究及应用效果[J]. 中国海上油气,2006,18(4):223–228. doi: 10.3969/j.issn.1673-1506.2006.04.002 TAN Zhongjian, XIANG Hua, LIU Fukui, et al. Testing techniques for complex reservoirs and their application in Bohai Sea[J]. China Offshore Oil and Gas, 2006, 18(4): 223–228. doi: 10.3969/j.issn.1673-1506.2006.04.002

-

期刊类型引用(13)

1. 蔡润峰,陈卓,张磊,赵佳彬. 渤中构造储层保护技术体系及应用. 中国石油和化工标准与质量. 2024(05): 196-198 .  百度学术

百度学术

2. 刘明,许鹏,陈述,夏林,边建杰,张华. 四川盆地致密气水平井钻井关键技术. 非常规油气. 2024(04): 152-159 .  百度学术

百度学术

3. 周英操,郭庆丰,蔡骁,王正旭. 精细控压钻井技术及装备研究进展. 钻采工艺. 2024(04): 94-104 .  百度学术

百度学术

4. 赵凌霄,王春才,叶素桃,邹双,王健栋,王彪. 东秋X井高压气层窄密度窗口固井技术. 钻井液与完井液. 2024(05): 661-667 .  百度学术

百度学术

5. 葛磊,杨春旭,郭兵,王志远,王子毓. 气侵后井底初始气泡平均直径预测模型实验研究. 石油钻探技术. 2023(02): 46-53 .  本站查看

本站查看

6. 刘德平,付焘,杨璨,刘风云,赵任飞,李秋茂,蔡刚. 漏失地层圈闭压力的形成与处置技术. 钻采工艺. 2021(06): 40-44 .  百度学术

百度学术

7. 王文彬,郭军,苑坤,董旭,韩菲. 桂中-南盘江地区黔水地1井卡钻事故处理及原因分析. 石油工业技术监督. 2020(12): 59-62 .  百度学术

百度学术

8. 黎凌,卫俊佚,张谦. 用于精细控压钻井的无机凝胶隔离塞的研制及现场试验. 石油钻探技术. 2019(01): 45-51 .  本站查看

本站查看

9. 李维,代锋,左星. 存在井间干扰的页岩气井精细控压技术应用. 钻采工艺. 2019(05): 103-105 .  百度学术

百度学术

10. 左星,张军,贺明敏,舒挺,蒋林,何嵬. “控压起钻+重浆帽”技术在裂缝储层中的应用与认识. 钻采工艺. 2019(06): 21-24+2 .  百度学术

百度学术

11. 黎凌. 水乳环氧树脂对水硬性凝胶隔段综合性能的影响. 油田化学. 2018(04): 597-602 .  百度学术

百度学术

12. 郗凤亮,徐朝阳,马金山,齐金涛,徐海潮. 控压钻井自动分流管汇系统设计与数值模拟研究. 石油钻探技术. 2017(05): 23-29 .  本站查看

本站查看

13. 李军,何淼,柳贡慧,段永贤,陈军. 控压钻井起下钻钻井液帽优化设计. 石油机械. 2016(12): 21-24 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: