Fracturing Parameters Optimization of Horizontal Wells in Shale Reservoirsduring "Well Fracturing-Soaking-Producing"

-

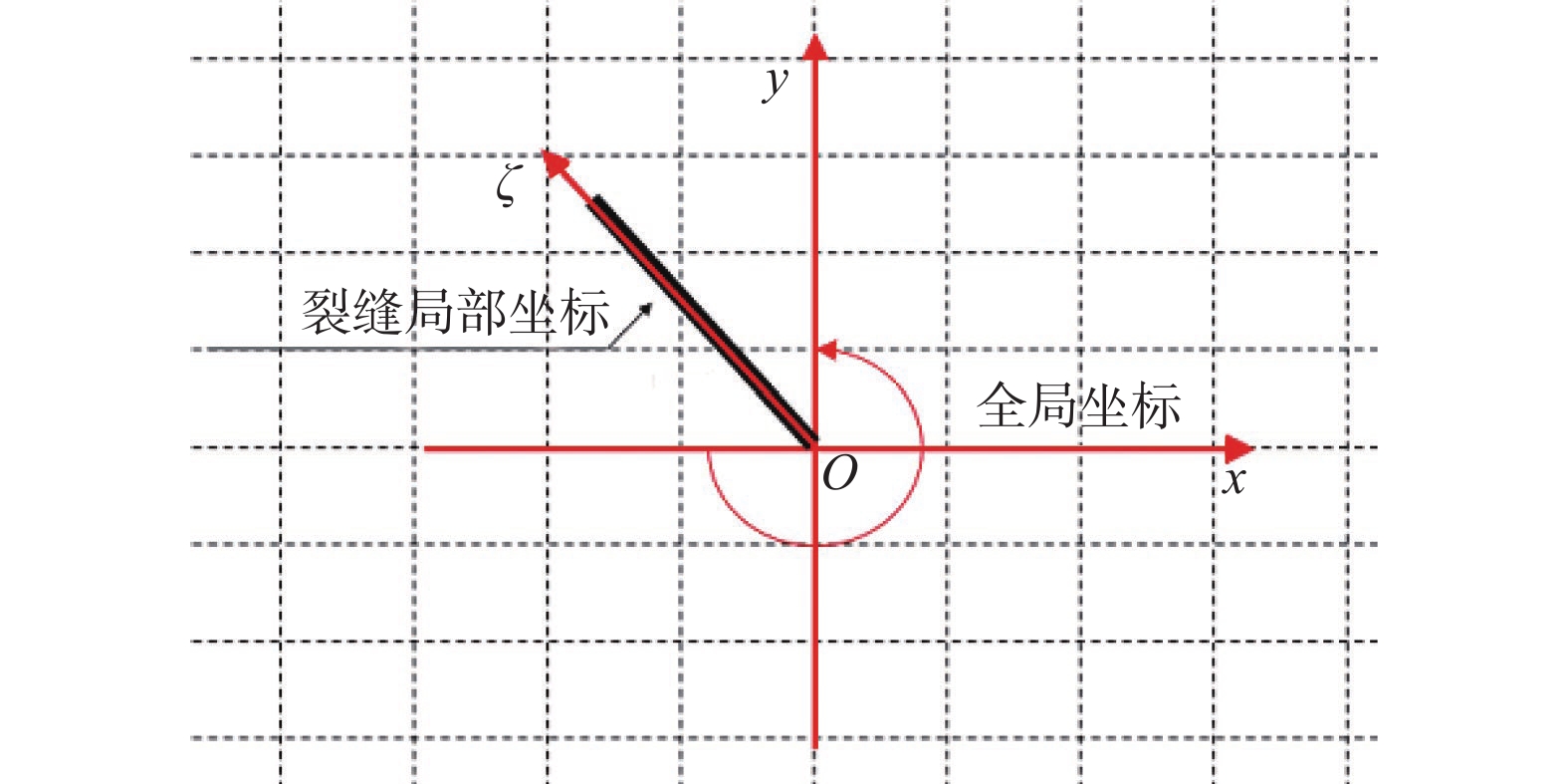

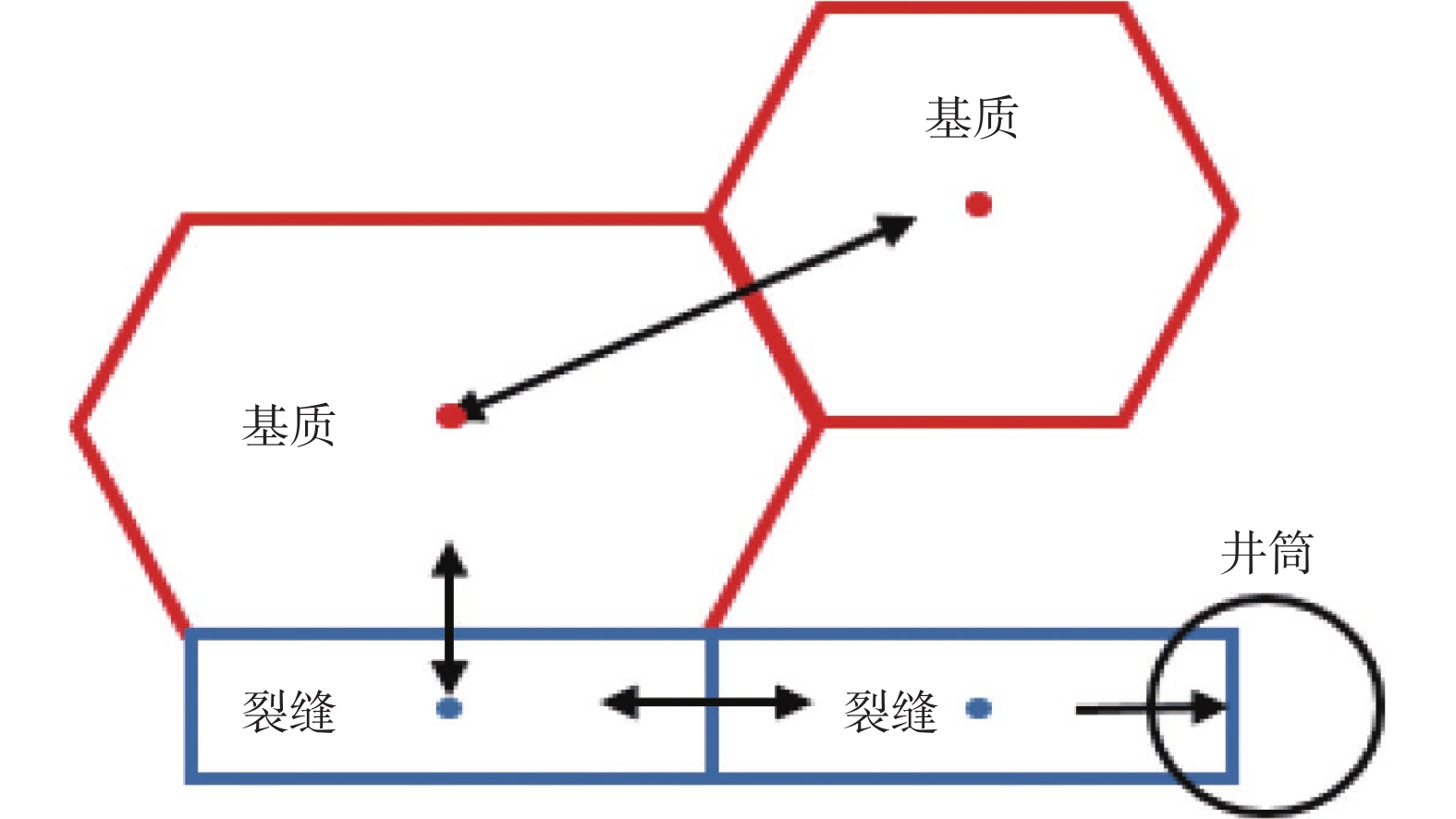

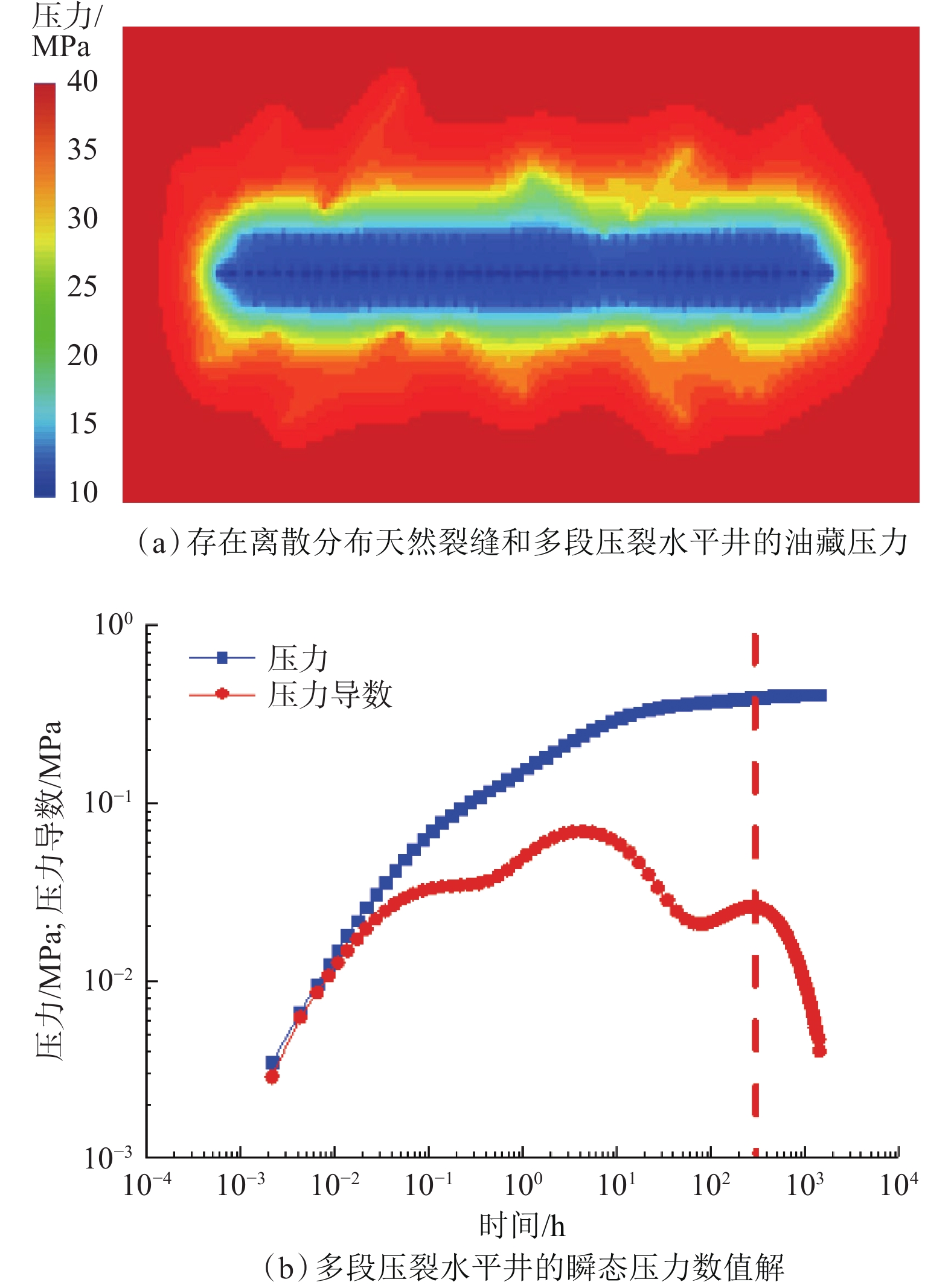

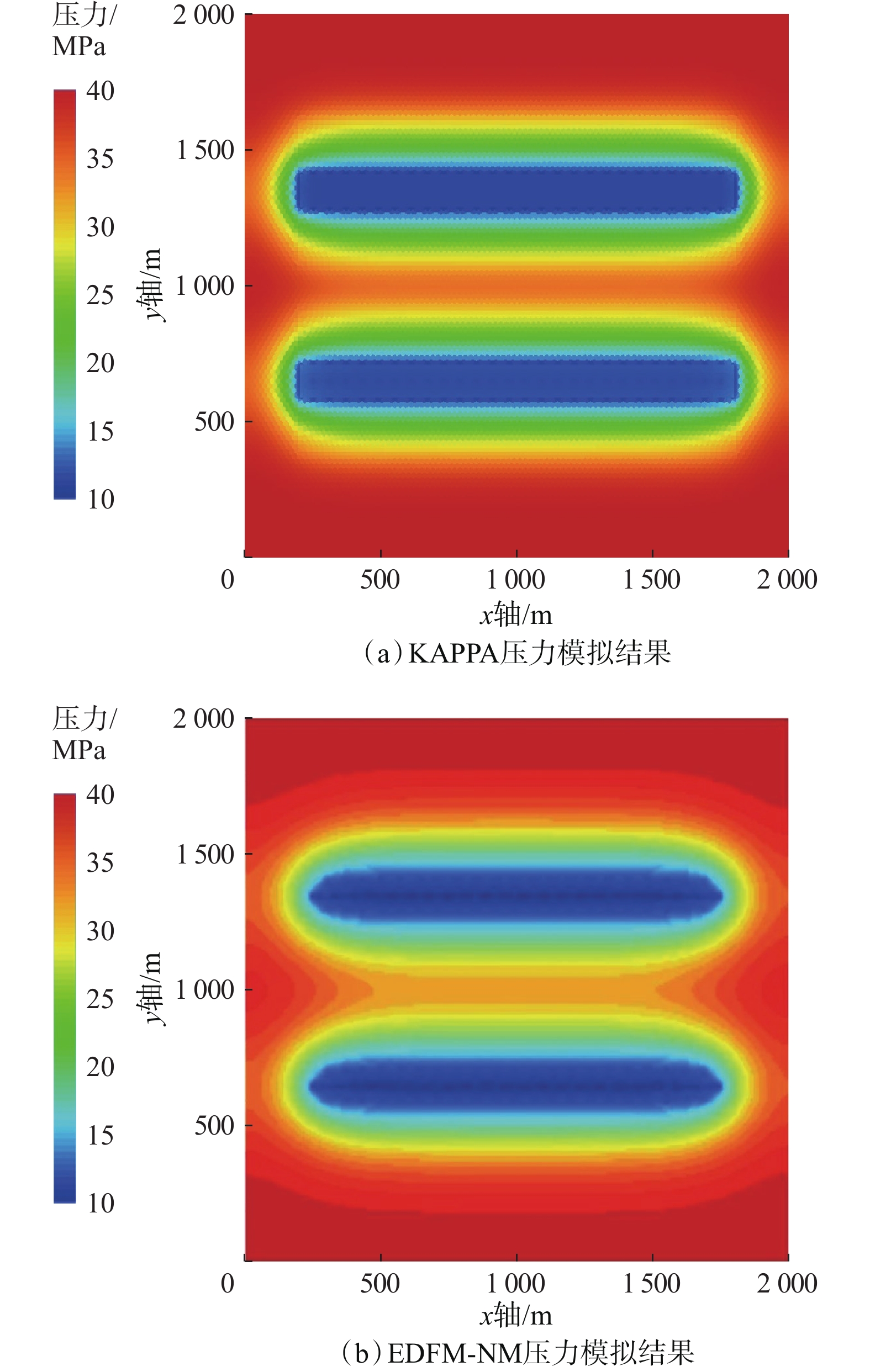

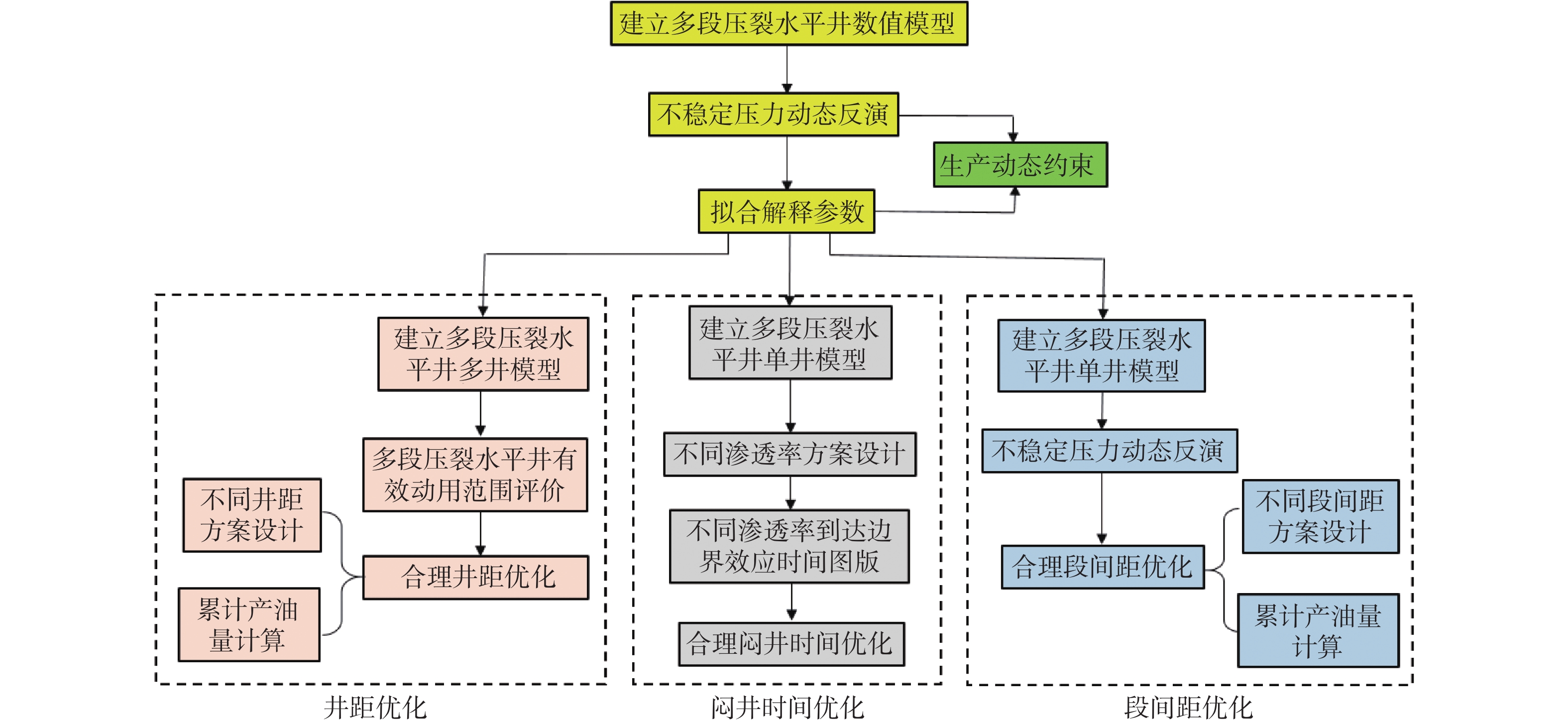

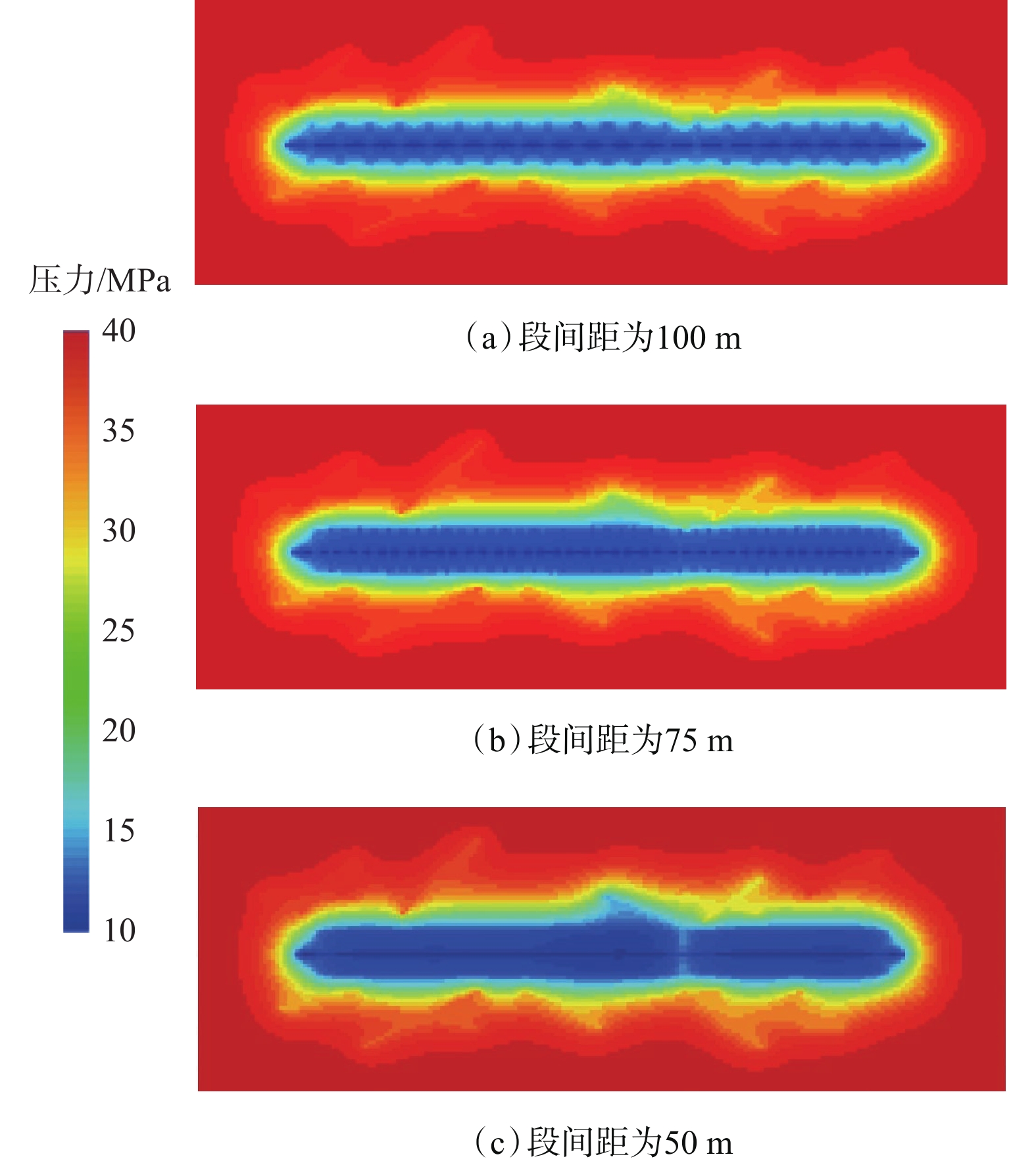

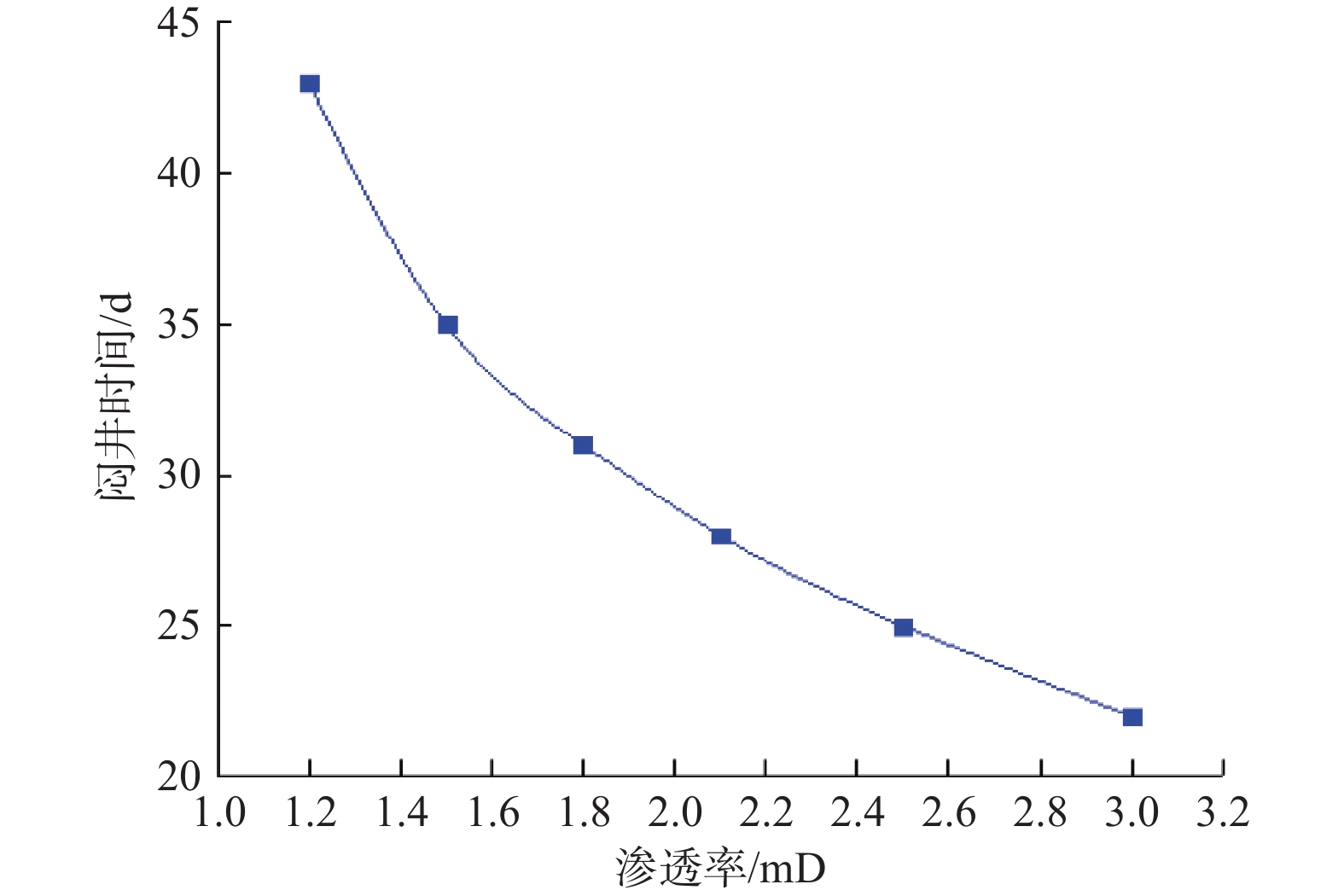

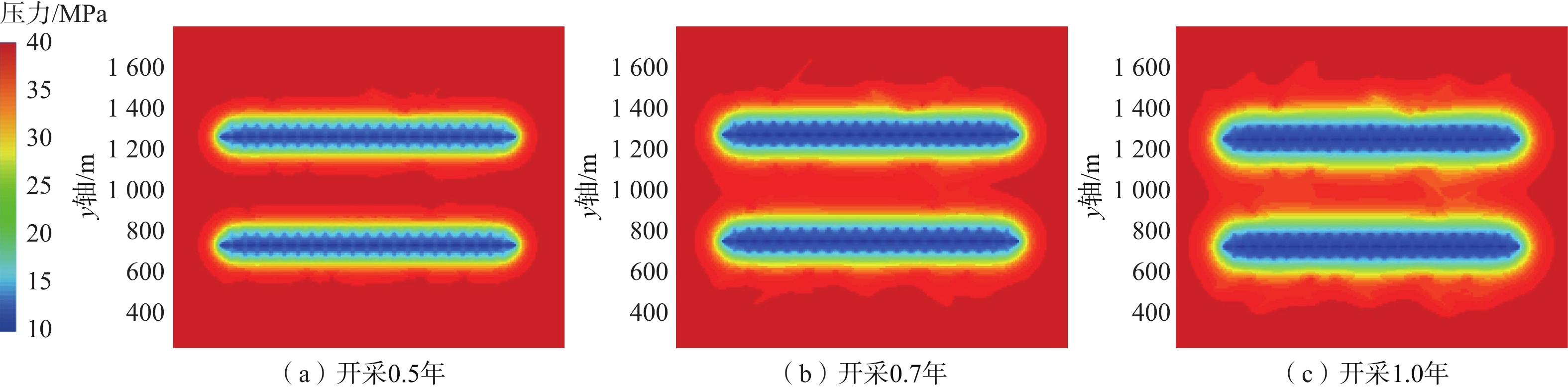

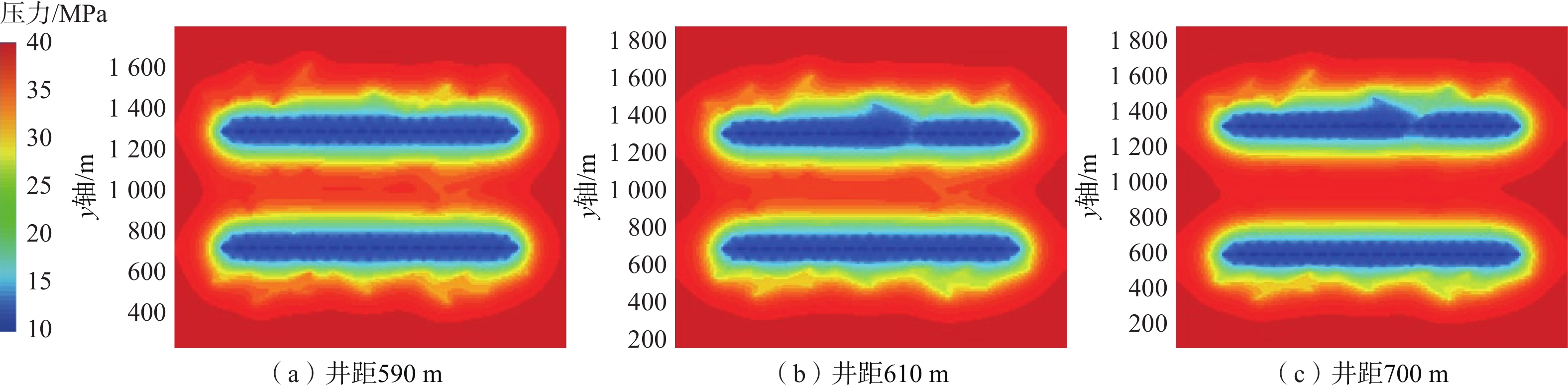

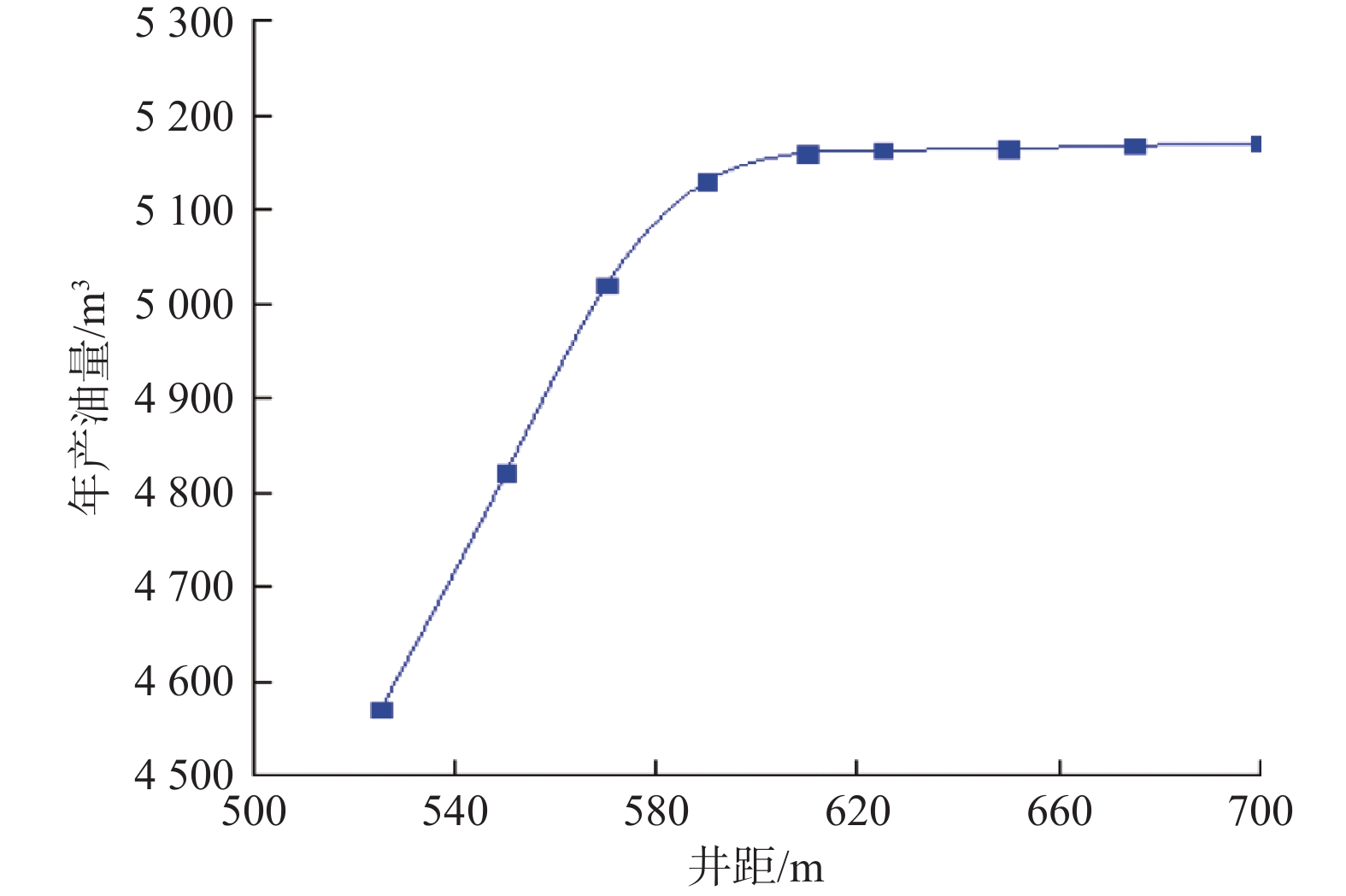

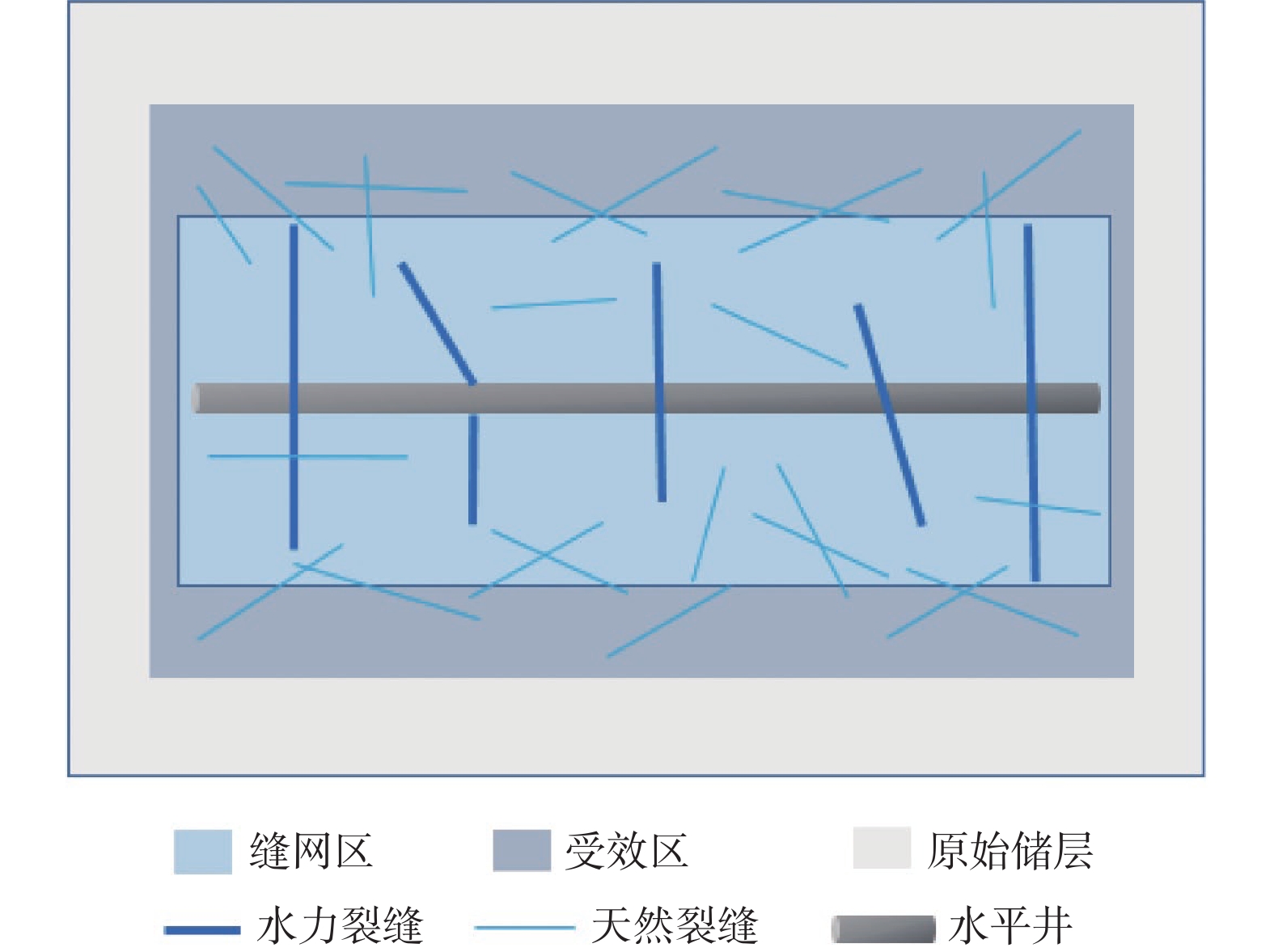

摘要: 目前在页岩油藏的多段压裂水平井压–闷–采过程中,缺乏系统完善的水平井压裂参数优化方法,为此,基于动态反演理论,建立了压裂参数优化方法。首先,根据页岩油藏压裂后形成的复杂缝网,采用数值理论和离散裂缝方法,建立了考虑页岩油储层特征和复杂天然裂缝的多段压裂水平井数值模型(EDFM-NM),得到了含离散天然裂缝的油藏压力解及多段压裂水平井的井底压力数值解;然后,应用动态分析方法,建立了包括段间距、闷井时间和井距的优化方法。应用建立的优化方法对长庆页岩油XC井进行实例分析,结果表明,实例井合理段间距为100~125 m,合理闷井时间为25~35 d,合理井距为590~610 m。研究结果为长庆油田页岩油藏压–闷–采参数优化提供了理论基础。Abstract: Regarding the absence of a systemic and complete method for optimizing the multi-stage fracturing parameters of horizontal wells in shale reservoirs during well fracturing-soaking-producing, a fracturing parameter optimization method was developed based on the dynamic inversion theory. First, a numerical model (EDFM-NM) for horizontal wells was established depending on the complex induced fracture networks formed in hydraulic fracturing of shale oil reservoirs, which takes into consideration the characteristics of the reservoirs as well as complex natural fractures. With the model, solution for the pressure of reservoirs with discrete natural fractures and numerical solution of bottom hole pressure of horizontal wells after multi-stage fracturing were obtained. Second, approaches for optimization of stage spacing, soaking time, and well spacing were proposed utilizing the dynamic analysis. Finally, the optimization method was applied to shale oil Well XC in Changqing Oilfield. Reasonable stage spacing, soaking time, and well spacing were found to be 100−125 m, 25−35 d, and 590−610 m, respectively. The research results can provide a theoretical basis for the optimization of fracturing parameters during “well fracturing–soaking–producing” of shale reservoirs in Changqing Oilfield.

-

Keywords:

- shale oil /

- horizontal well /

- dynamic inversion /

- parameter optimization /

- stage spacing /

- soaking time /

- well spacing /

- Changqing Oilfield

-

-

表 1 长庆油田长7页岩油XC井基础参数

Table 1 Basic model parameters of the Chang 7 shale oil well XC in Changqing Oilfield

区域 参数 数值 缝网区 裂缝半长/m 60 裂缝导流能力/(mD·m) 30 渗透率/mD 2.0 导压系数/(cm2·s–1) 0.056 1 缝网体积比 0.05 基质窜流系数 1.0×10–6 受效区 半径/m 260 渗透率/mD 0.1 导压系数/(cm2·s–1) 0.013 7 未改造区 渗透率/mD 0.01 导压系数/(cm2·s–1) 0.000 6 井筒 水平段长/m 1 500 储集系数/(m3·MPa–1) 0.23 井筒半径/m 0.108 储层 有效厚度/m 14 储层中深/m 2 100 体积系数/(m3·m–3) 1.192 流体黏度/(mPa·s) 1.27 综合压缩系数/MPa–1 1.042×10–3 -

[1] MUSKAT M. The flow of homogeneous fluids through porous[J]. SPE Journal, 1946, 103(1): 219–249.

[2] 翟云芳. 渗流力学[M]. 3版. 北京: 石油工业出版社, 2009: 54-73. ZHAI Yunfang. Seepage mechanics[M]. 3rd ed. Beijing: Petroleum Industry Press, 2009: 54-73.

[3] 齐与峰. 砂岩油田注水开发合理井网研究中的几个理论问题[J]. 石油学报,1990,11(4):51–60. doi: 10.3321/j.issn:0253-2697.1990.04.005 QI Yufeng. Some theoretical considerations on optimal well pattern analysis in a water flooding sandy oil reservoir[J]. Acta Petrolei Sinica, 1990, 11(4): 51–60. doi: 10.3321/j.issn:0253-2697.1990.04.005

[4] 尹建,郭建春,曾凡辉. 水平井分段压裂射孔间距优化方法[J]. 石油钻探技术,2012,40(5):67–71. doi: 10.3969/j.issn.1001-0890.2012.05.015 YIN Jian, GUO Jianchun, ZENG Fanhui. Perforation spacing optimization for staged fracturing of horizontal well[J]. Petroleum Drilling Techniques, 2012, 40(5): 67–71. doi: 10.3969/j.issn.1001-0890.2012.05.015

[5] 蒲春生,陈庆栋,吴飞鹏,等. 致密砂岩油藏水平井分段压裂布缝与参数优化[J]. 石油钻探技术,2014,42(6):73–79. PU Chunsheng, CHEN Qingdong, WU Feipeng, et al. Staged fracturing pattern and parameter optimization of horizontal wells in tight sandstone oil reservoir[J]. Petroleum Drilling Techniques, 2014, 42(6): 73–79.

[6] 蒋廷学,卞晓冰,袁凯,等. 页岩气水平井分段压裂优化设计新方法[J]. 石油钻探技术,2014,42(2):1–6. JIANG Tingxue, BIAN Xiaobing, YUAN Kai, et al. A new method in staged fracturing design optimization for shale gas horizontal wells[J]. Petroleum Drilling Techniques, 2014, 42(2): 1–6.

[7] 刘闯. 水平井水力压裂数值模拟与施工参数优化研究[D]. 合肥: 中国科学技术大学, 2017. LIU Chuang. Numerical investigating the hydraulic fracturing of horizontal well and the optimization of stimulation parameters[D]. Hefei: University of Science and Technology of China, 2017.

[8] 王天驹,陈赞,王蕊,等. 致密砂岩油藏体积压裂簇间距优化新方法[J]. 新疆石油地质,2019,40(3):351–356. WANG Tianju, CHEN Zan, WANG Rui, et al. A new method for cluster spacing optimization during volumetric fracturing in tight sandstone oil reservoirs[J]. Xinjiang Petroleum Geology, 2019, 40(3): 351–356.

[9] 林旺,范洪富,闫林,等. 致密油藏注水吞吐参数优化模拟:以吉林扶余油层为例[J]. 中国科技论文,2019,14(9):937–942. doi: 10.3969/j.issn.2095-2783.2019.09.001 LIN Wang, FAN Hongfu, YAN Lin, et al. Optimization of engineering parameters for horizontal huff and puff development of tight reservoir: taking Fuyu oil layer in Jilin as an example[J]. China Sciencepaper, 2019, 14(9): 937–942. doi: 10.3969/j.issn.2095-2783.2019.09.001

[10] 王继坤. 致密砂岩油藏压后关井时间优化模型研究[D]. 北京: 中国地质大学(北京), 2020. WANG Jikun. Study on optimization model of shut-in time after fracturing in tight sandstone reservoir[D]. Beijing: China University of Geosciences(Beijing), 2020.

[11] 张矿生,唐梅荣,陈文斌,等. 压裂裂缝间距优化设计[J]. 科学技术与工程,2021,21(4):1367–1374. doi: 10.3969/j.issn.1671-1815.2021.04.017 ZHANG Kuangsheng, TANG Meirong, CHEN Wenbin, et al. Optimization of fracture spacing for hydraulic fracturing[J]. Science Technology and Engineering, 2021, 21(4): 1367–1374. doi: 10.3969/j.issn.1671-1815.2021.04.017

[12] 付金华,牛小兵,淡卫东,等. 鄂尔多斯盆地中生界延长组长7段页岩油地质特征及勘探开发进展[J]. 中国石油勘探,2019,24(5):601–614. doi: 10.3969/j.issn.1672-7703.2019.05.007 FU Jinhua, NIU Xiaobing, DAN Weidong, et al. The geological characteristics and the progress on exploration and development of shale oil in Chang7 Member of Mesozoic Yanchang Formation, Ordos Basin[J]. China Petroleum Exploration, 2019, 24(5): 601–614. doi: 10.3969/j.issn.1672-7703.2019.05.007

[13] 董姜畅,王爱国,樊志强,等. 鄂尔多斯盆地中部延长组长7段致密储层成因及控制因素[J]. 断块油气田,2021,28(4):446–451. DONG Jiangchang,WANG Aiguo,FAN Zhiqiang, et al. Origin and dominated factors of Chang 7 Member tight reservoirs in Yanchang formation, central Ordos Basin[J]. Fault-Block Oil & Gas Field, 2021, 28(4): 446–451.

[14] 杨华,梁晓伟,牛小兵,等. 陆相致密油形成地质条件及富集主控因素:以鄂尔多斯盆地三叠系延长组7段为例[J]. 石油勘探与开发,2017,44(1):12–20. YANG Hua, LIANG Xiaowei, NIU Xiaobing, et al. Geological conditions for continental tight oil formation and the main controlling factors for the enrichment: A case of Chang 7 Member, Triassic Yanchang Formation, Ordos Basin, NW China[J]. Petroleum Exploration and Development, 2017, 44(1): 12–20.

[15] 付金华,喻建,徐黎明,等. 鄂尔多斯盆地致密油勘探开发新进展及规模富集可开发主控因素[J]. 中国石油勘探,2015,20(5):9–19. doi: 10.3969/j.issn.1672-7703.2015.05.002 FU Jinhua, YU Jian, XU Liming, et al. New progress in exploration and development of tight oil in Ordos Basin and main controlling factors of large-scale enrichment and exploitable capacity[J]. China Petroleum Exploration, 2015, 20(5): 9–19. doi: 10.3969/j.issn.1672-7703.2015.05.002

[16] 赵国翔,姚约东,王链,等. 页岩油藏微尺度流动特征及应力敏感性分析[J]. 断块油气田,2021,28(2):247–252. ZHAO Guoxiang, YAO Yuedong, WANG Lian, et al. Microscale transport behaviors of shale oil and stress sensitivity analysis[J]. Fault-Block Oil & Gas Field, 2021, 28(2): 247–252.

[17] 雷浩,何建华,胡振国. 潜江凹陷页岩油藏渗流特征物理模拟及影响因素分析[J]. 特种油气藏,2019,26(3):94–98. doi: 10.3969/j.issn.1006-6535.2019.03.017 LEI Hao, HE Jianhua, HU Zhenguo. Physical simulation and influencing factor analysis of the flow characteristics in the shale oil reservoir of Qianjiang Depression[J]. Special Oil & Gas Reservoirs, 2019, 26(3): 94–98. doi: 10.3969/j.issn.1006-6535.2019.03.017

[18] 王秀影,吴通,蔡军,等. 饶阳凹陷页岩油储层应力敏感规律[J]. 钻井液与完井液,2020,37(2):185–191. doi: 10.3969/j.issn.1001-5620.2020.02.009 WANG Xiuying, WU Tong, CAI Jun, et al. Patterns of stress sensitivity of the shale oil reservoirs in Raoyang Depression[J]. Drilling Fluid & Completion Fluid, 2020, 37(2): 185–191. doi: 10.3969/j.issn.1001-5620.2020.02.009

[19] 慕立俊,吴顺林,徐创朝,等. 基于缝网扩展模拟的致密储层体积压裂水平井产能贡献分析[J]. 特种油气藏,2021,28(2):126–132. doi: 10.3969/j.issn.1006-6535.2021.02.019 MU Lijun, WU Shunlin, XU Chuangchao, et al. Analysis on contribution to productivity of SRV-fractured horizontal wells in tight reservoirs based on simulation of fracture network propagation[J]. Special Oil & Gas Reservoirs, 2021, 28(2): 126–132. doi: 10.3969/j.issn.1006-6535.2021.02.019

[20] 赵振峰,李楷,赵鹏云,等. 鄂尔多斯盆地页岩油体积压裂技术实践与发展建议[J]. 石油钻探技术,2021,49(4):85–91. doi: 10.11911/syztjs.2021075 ZHAO Zhenfeng, LI Kai, ZHAO Pengyun, et al. Practice and development suggestions for volumetric fracturing technology for shale oil in the Ordos Basin[J]. Petroleum Drilling Techniques, 2021, 49(4): 85–91. doi: 10.11911/syztjs.2021075

[21] 管保山,刘玉婷,梁利,等. 页岩油储层改造和高效开发技术[J]. 石油钻采工艺,2019,41(2):212–223. GUAN Baoshan, LIU Yuting, LIANG Li, et al. Shale oil reservoir reconstruction and efficient development technology[J]. Oil Drilling & Production Technology, 2019, 41(2): 212–223.

[22] 闫林,陈福利,王志平,等. 我国页岩油有效开发面临的挑战及关键技术研究[J]. 石油钻探技术,2020,48(3):63–69. doi: 10.11911/syztjs.2020058 YAN Lin, CHEN Fuli, WANG Zhiping, et al. Challenges and technical countermeasures for effective development of shale oil in China[J]. Petroleum Drilling Techniques, 2020, 48(3): 63–69. doi: 10.11911/syztjs.2020058

[23] 王磊,盛志民,赵忠祥,等. 吉木萨尔页岩油水平井大段多簇压裂技术[J]. 石油钻探技术,2021,49(4):106–111. doi: 10.11911/syztjs.2021091 WANG Lei, SHENG Zhimin, ZHAO Zhongxiang, et al. Large-section and multi-cluster fracturing technology for horizontal wells in the Jimsar shale oil reservoir[J]. Petroleum Drilling Techniques, 2021, 49(4): 106–111. doi: 10.11911/syztjs.2021091

[24] 沈产量,张景皓,张璐,等. 基于离散裂缝方法的多段压裂水平井数值试井模型[J]. 油气井测试,2021,30(1):1–8. SHEN Chanliang, ZHANG Jinghao, ZHANG Lu, et al. Numerical well test model of multi-stage fractured horizontal well based on discrete fracture method[J]. Well Testing, 2021, 30(1): 1–8.

[25] LIU Hui, LIAO Xinwei, TANG Xuefeng, et al. A well test model based on embedded discrete-fracture method for pressure-transient analysis of fractured wells with complex fracture networks[J]. Journal of Petroleum Science and Engineering, 2021, 196: 108042. doi: 10.1016/j.petrol.2020.108042

[26] LIE K A. An introduction to reservoir simulation using MATLAB/GNU octave: user guide for the MATLAB Reservoir Simulation Toolbox (MRST)[M]. Cambridge: Cambridge University Press, 2019: 19–110.

-

期刊类型引用(7)

1. 白财远,王虎,杨行蔚. 安全生产责任落实背景下石油钻探设备安全故障检测研究. 现代职业安全. 2024(02): 66-70 .  百度学术

百度学术

2. 方昕,沈澜,李飞,吕方兴. 基于压缩感知的井下振动高频测量方法研究. 电子测量技术. 2024(06): 20-27 .  百度学术

百度学术

3. 高德利,鲜保安,毕延森. 水平井尾管完井与钻井一体化设计控制技术. 石油勘探与开发. 2024(04): 878-888 .  百度学术

百度学术

4. GAO Deli,XIAN Baoan,BI Yansen. Integrated design and control technology of liner completion and drilling for horizontal wells. Petroleum Exploration and Development. 2024(04): 1009-1021 .  必应学术

必应学术

5. 肖新磊,席境阳,杜旭,王迎春. 胜利油田页岩油大井眼高效钻进技术研究与应用. 钻探工程. 2023(06): 122-128 .  百度学术

百度学术

6. 贾建伟. 钻具标准在生产检修中的作用. 现代制造技术与装备. 2022(03): 144-146 .  百度学术

百度学术

7. 蒲文学,范光第,朱建建,赵国山. 磁性随钻测斜仪所需无磁钻具长度及影响因素研究. 石油钻探技术. 2022(04): 129-134 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: