Post-Frac Evaluation of Multi-Stage Fracturing on Horizontal Wells Based on Early Flowback History

-

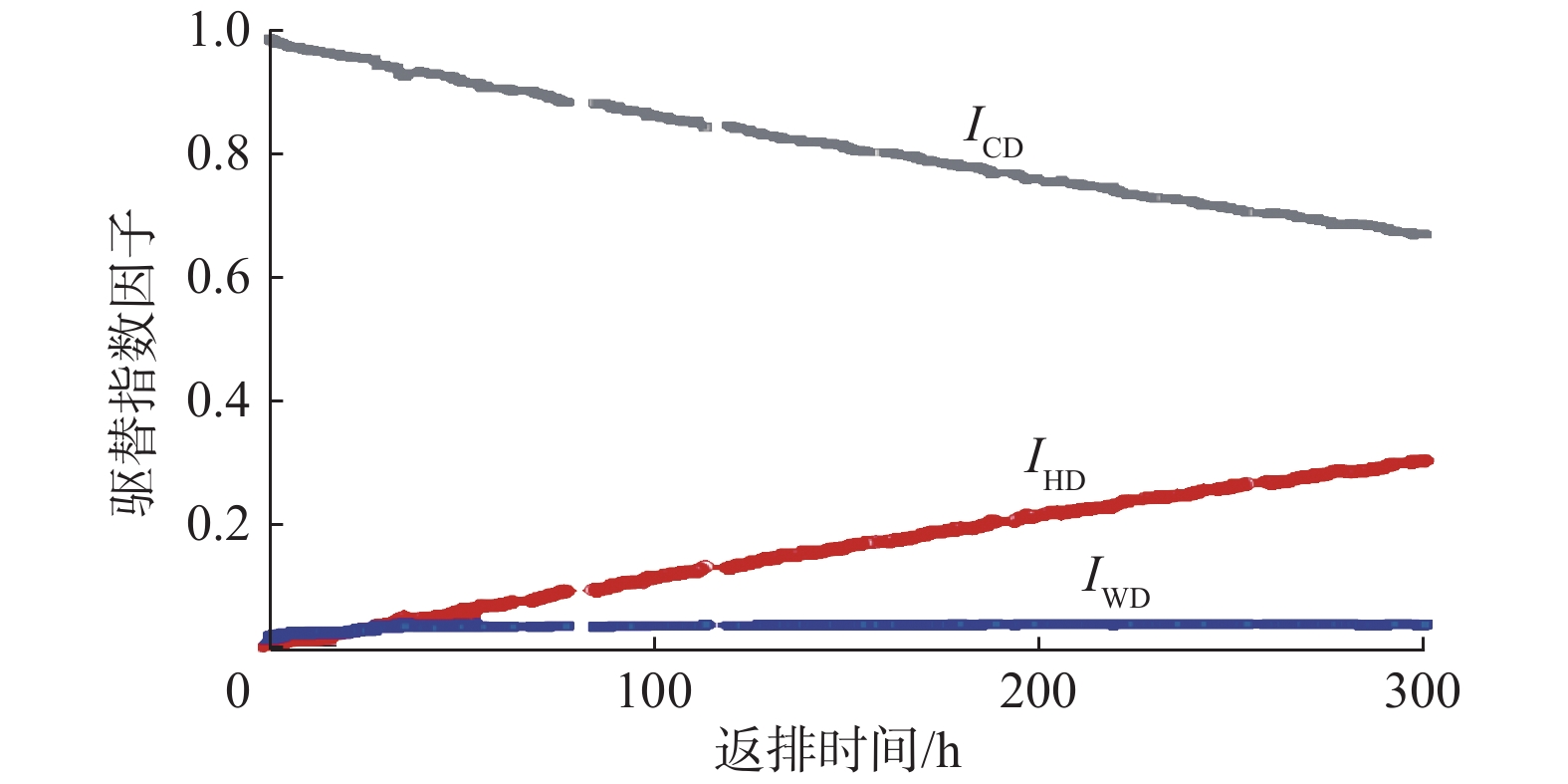

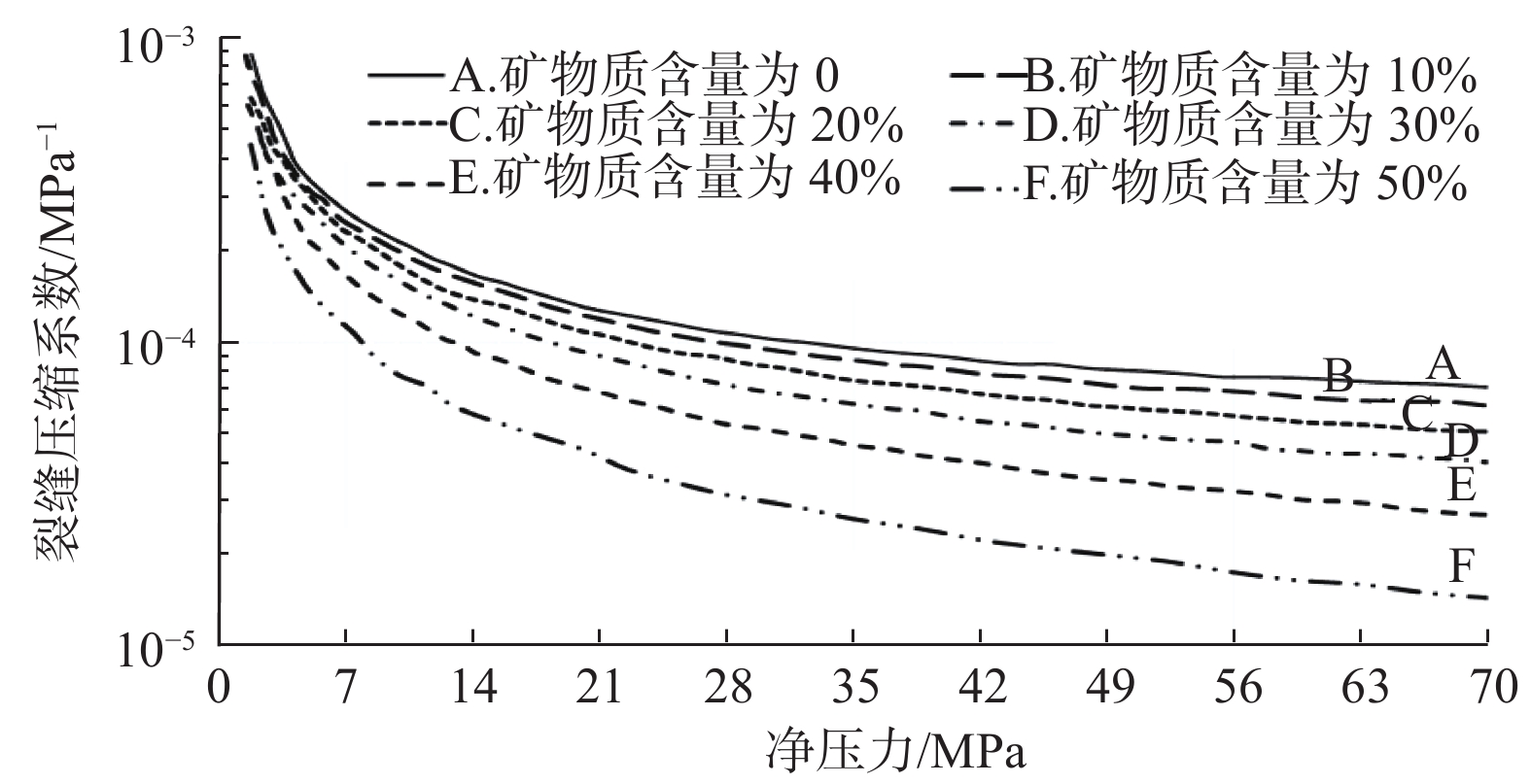

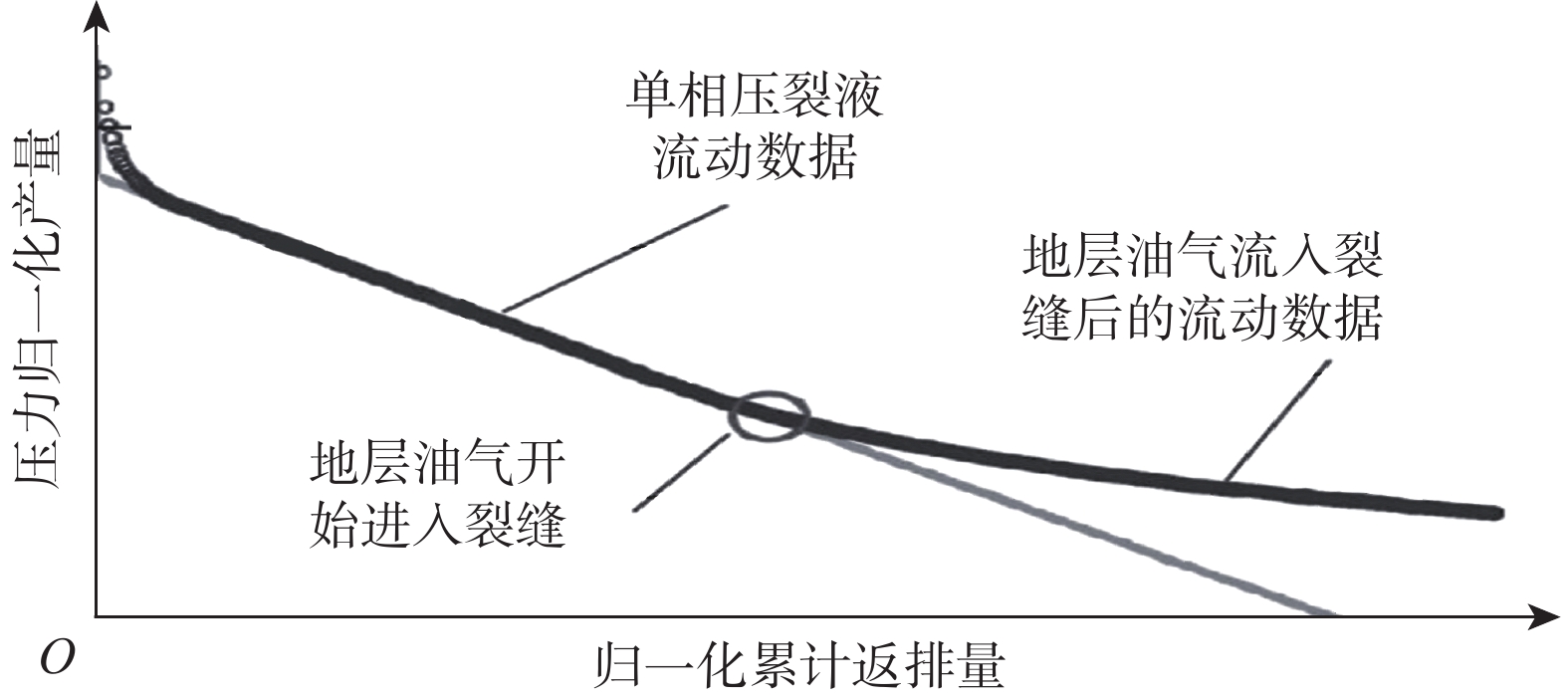

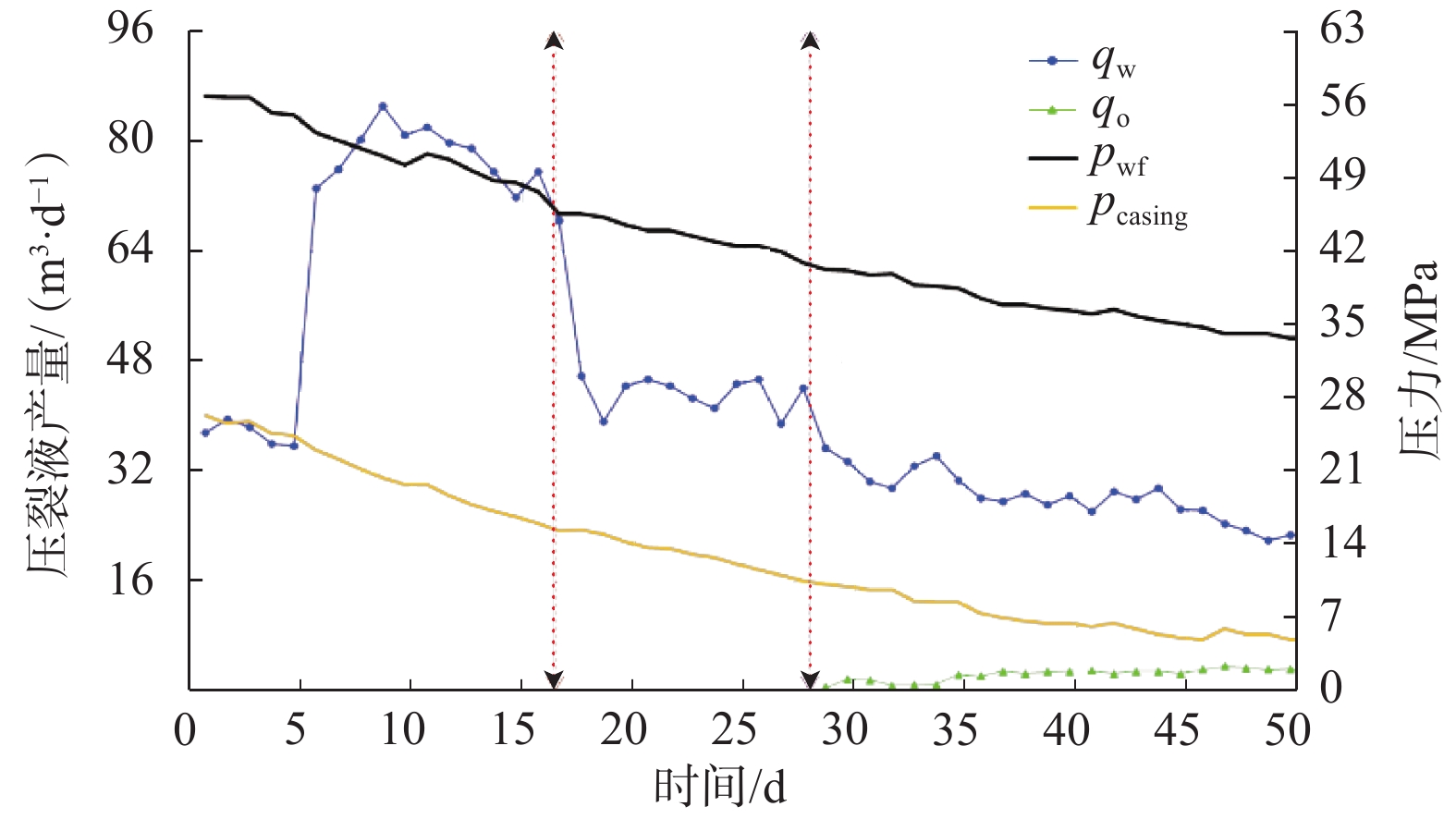

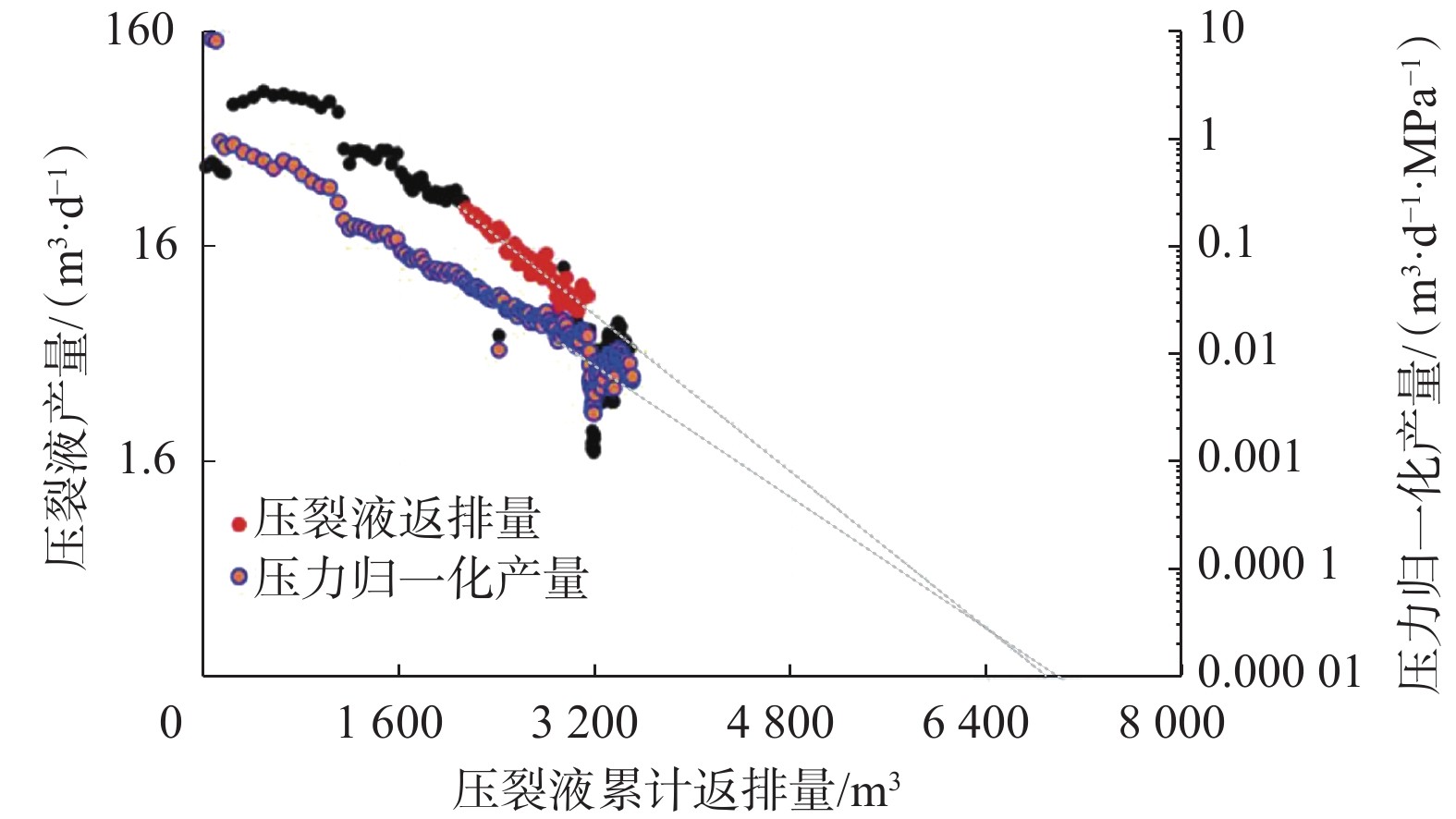

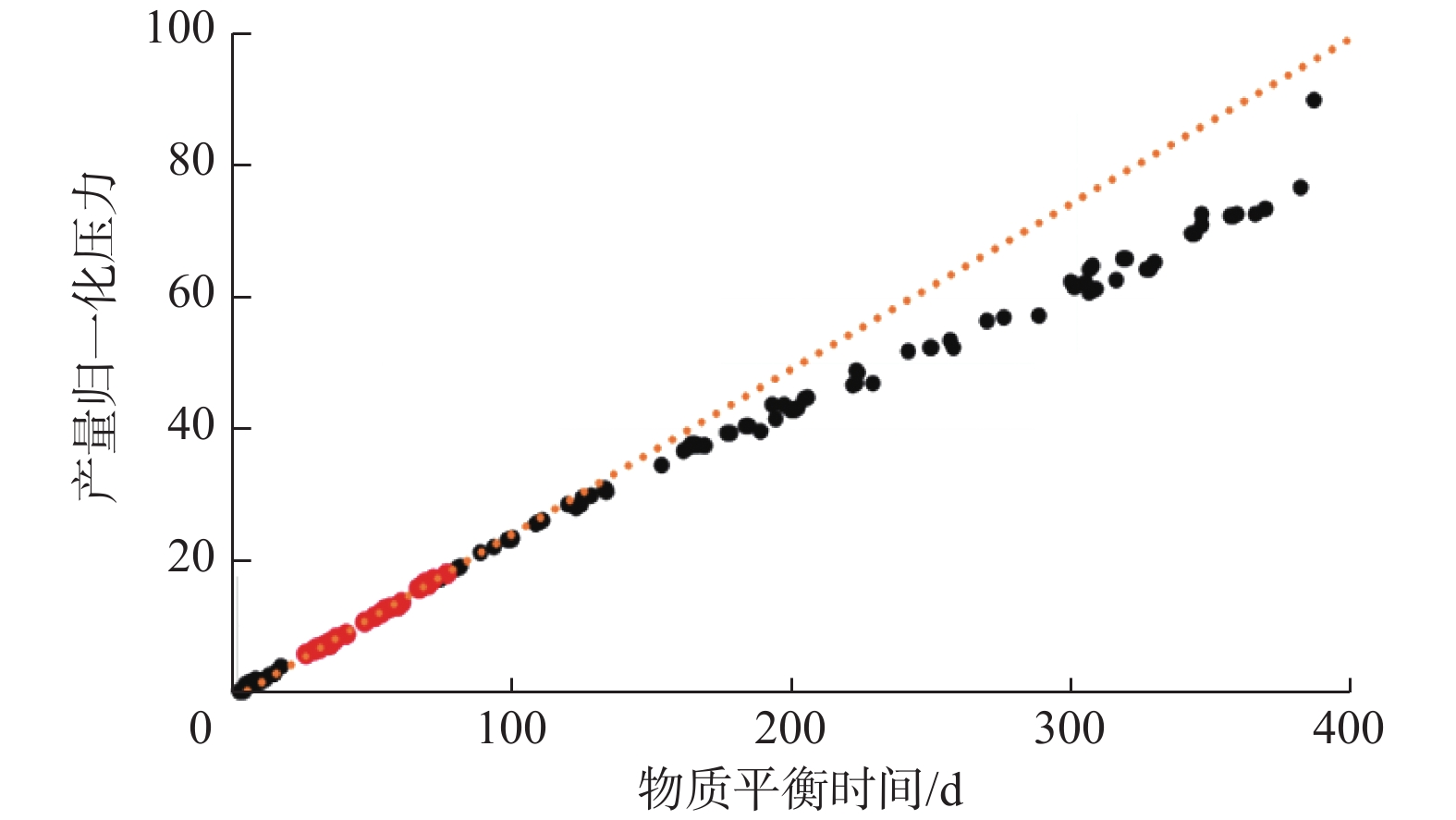

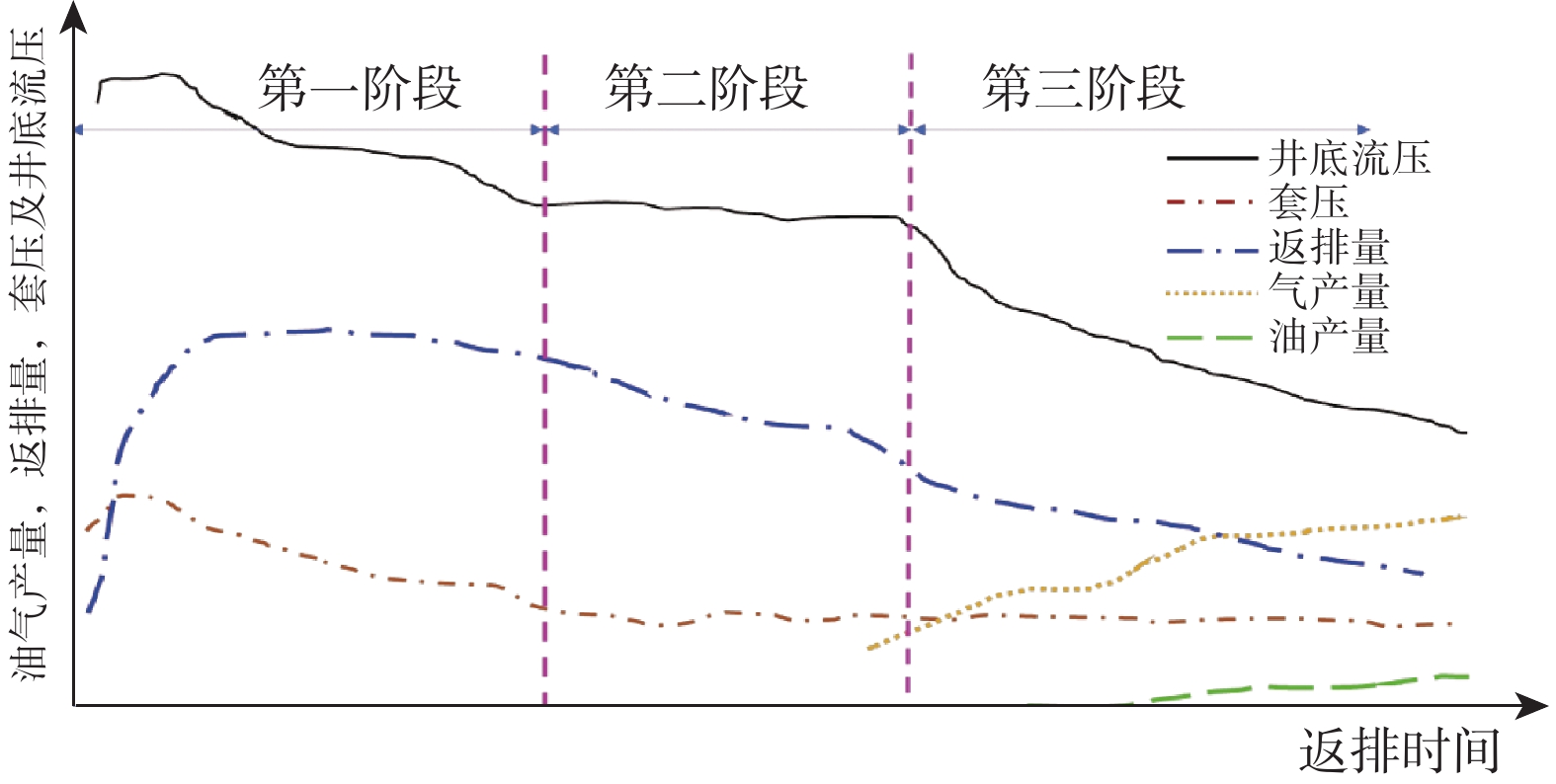

摘要: 压裂液早期返排历史数据可用于评价水平井分段压裂效果,而有效裂缝孔隙体积是反映压裂效果的重要参数,但目前基于压裂液返排历史数据的有效裂缝孔隙体积计算方法存在准确性不高的问题。为此,基于北美最新的基于返排历史数据计算初始有效裂缝孔隙体积的研究成果,应用产量不稳定试井中的流动物质平衡方法,结合传统的产量递减方法,提出了一种利用返排历史数据定量求取有效裂缝孔隙体积的方法,并以国内某口分段压裂的致密油水平井为例,详细介绍了该方法的计算分析过程,计算发现,仅有21%的注入压裂液对裂缝导流能力有贡献。研究结果表明,该方法能有效提高有效裂缝孔隙体积计算结果的准确性,可以对水平井分段压裂效果进行正确评价。Abstract: The early flowback history data of fracturing fluid can be used to evaluate multi-stage fracturing effect for horizontal wells, and the effective fracture pore volume is a critical parameter to reflect the fracturing effectiveness. However, current calculation methods of effective fracture pore volume based on the fracturing fluid flowback history shows low accuracy. This paper presents a new method for quantitatively calculating the effective fracture pore volume based on flowback history. On the bases of the latest methodology in North America, the method uses the flowing material balance method of rate transient analysis (RTA) and is combined with a traditional production decline method. Its calculation and analysis process is introduced in detail based on a domestic multi-stage fracturing horizontal tight oil well. The calculation results show that only 21% of the injected fracturing fluid contributes to the fracture conductivity. The results show that the new method can effectively improve the calculation accuracy of the effective fracture pore volume and implement correct evaluation of multi-stage fracturing effect for horizontal wells.

-

-

-

[1] MATTAR L, ANDERSON D, STOTTS G. Dynamic material balance: oil or gas-in-place without shut-ins[R]. PETSOC-06-11-TN, 2006.

[2] ARPS J J. Analysis of decline curves[J]. Transactions of the AIME, 1945, 160(1): 228–247.

[3] MAJID Ali Abbasi, DEHGHANPOUR H, HAWKES R V. Flowback analysis for fracture characterization[R]. SPE 162661, 2012.

[4] MAJID Ali Abbasi, EZULIKE D O, DEHGHANPOUR H, et al. A comparative study of flowback rate and pressure transient behavior in multifractured horizontal wells completed in tight gas and oil reservoirs[J]. Journal of Natural Gas Science and Engineering, 2014, 17: 82–93. doi: 10.1016/j.jngse.2013.12.007

[5] EZULIKE D O, DEHGHANPOUR H. Modelling flowback as a transient two-phase depletion process[J]. Journal of Natural Gas Science and Engineering, 2014, 19: 258–278. doi: 10.1016/j.jngse.2014.05.004

[6] EZULIKE D O, DEHGHANPOUR H, VIRUES C, et al. Flowback fracture closure: a key factor for estimating effective pore volume[J]. SPE Reservoir Evaluation & Engineering, 2016, 19(4): 567–582.

[7] FU Y, DEHGHANPOUR H, EZULIKE D O, et al. Estimating effective fracture pore volume from flowback data and evaluating its relationship to design parameters of multistage-fracture completion[J]. SPE Production & Operations, 2017, 32(4): 423–439.

[8] XU Y, ADEFIDIPE O A, DEHGHANPOUR H. Estimating fracture volume using flowback data from the Horn River Basin: a material balance approach[J]. Journal of Natural Gas Science and Engineering, 2015, 25: 253–270. doi: 10.1016/j.jngse.2015.04.036

[9] XU Y, ADEFIDIPE O A, DEHGHANPOUR H. A flowing material balance equation for two-phase flowback analysis[J]. Journal of Petroleum Science and Engineering, 2016, 142: 170–185. doi: 10.1016/j.petrol.2016.01.018

[10] XU Y, DEHGHANPOUR H, EZULIKE O, et al. Effectiveness and time variation of induced fracture volume: lessons from water flowback analysis[J]. Fuel, 210: 844–858.

[11] FU Y, DEHGHANPOUR H, MOTEALLEH S, et al. Evaluating fracture volume loss during flowback and its relationship to choke size: fastback vs. slowback[J]. SPE Production & Operations, 2018, 34(3): 615–624.

[12] BAI B, GOODWIN S, CARLSON K. Modeling of frac flowback and produced water volume from Wattenberg oil and gas field[J]. Journal of Petroleum Science and Engineering, 2013, 108: 383–392. doi: 10.1016/j.petrol.2013.05.003

[13] SABBIR H, EZULIKE O, FU Y, et al. Average fracture compressibility from flowback data[J]. SPE Production & Operations, 2021, 36(3): 516–529.

[14] 虞绍永. 页岩及致密油气藏工程方法[M]. 北京: 石油工业出版社, 2018. YU Shaoyong. Shale and tight reservoirs engineering[M]. Beijing: Petroleum Industry Press, 2018.

[15] CLARKSON C R, WILLIAMS-KOVACS J D. A new method for modeling multi-phase flowback of multi-fractured horizontal tight oil wells to determine hydraulic fracture properties[R]. SPE 166214, 2013.

[16] AGUILERA R. Recovery factors and reserves in naturally fractured reservoirs[R]. PETSOC-99-07-DA, 1999.

[17] WILLIAMS-KOVACS J D, CLARKSON C R. Stochastic modeling of multi-phase flowback from multi-fractured horizontal tight oil wells[R]. SPE 167232, 2013.

[18] WILLIAMS-KOVACS J D, CLARKSON C R, ZANGANEH B. Case studies in quantitative flowback analysis[R]. SPE 175983, 2015.

下载:

下载: