Development and Testing of a Graphene-Modified Sponge Coring Tool

-

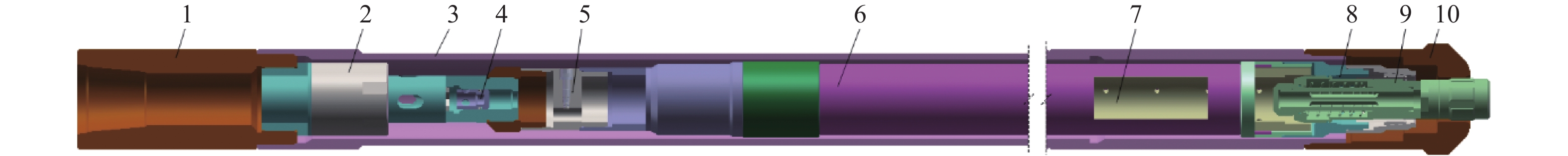

摘要: 为了直接测量、准确获取岩心的含油饱和度,进行了石墨烯改性海绵取心工具的研制与试验研究。对常规海绵经石墨烯溶胶进行了浸渍、老化、超临界干燥等工艺改性处理,得到了石墨烯海绵材料。该海绵内部孔隙直径可调,常温下原油吸附量可达自身质量的80.5倍。在此基础上,设计开发了石墨烯改性海绵取心工具。采取预充海绵保护液和设置密封活塞方式对海绵材料进行防污染保护,通过室内试验确定海绵衬筒直径小于岩心直径0.6~1.0 mm,采用长条薄片压紧方式保护海绵内衬,使之同时满足了吸油和岩心进筒要求。通过与含油饱和度常规计算方法进行比较,确定了岩心含油饱和度的测量、计算方法。石墨烯改性海绵取心工具可在不影响取心收获率的前提下收集岩心逸出的原油,具有较好的推广应用前景。Abstract: In order to directly measure and accurately obtain the oil saturation of cores, processes such as graphene gel impregnation, aging and supercritical drying were used in conjunction with a conventional sponge to obtain the graphene sponge material with an adjustable pore diameter. At room temperature, crude oil absorption of graphene sponge material is as high as 80.5 times its own mass, and the graphene modified sponge coring tool is designed and developed. The grapheme modified sponge coring tool adopts pre-filled sponge protection fluid and a sealed piston to protect the sponge material from being polluted. Through indoor laboratory experiments, the diameter of sponge liner is determined to be 0.6–1.0 mm less than that of the core, and a strip sheet is used to press and protect the sponge liner while satisfying the requirement of oil absorption and core feeding. Based on the comparison with conventional methods, the measurement and calculation methods of the oil saturation of cores are determined. This new sponge coring tool can effectively collect the crude oil escaping from the core without compromising the core recovery. Therefore, it demonstrates a high potential for application.

-

Keywords:

- graphene /

- modified sponge /

- coring tool /

- oil saturation /

- calculation method

-

-

表 1 部分石墨烯改性海绵样品的基本性能参数

Table 1 Basic performance parameters of partial graphene modified sponge samples

样品

编号密度/

(mg·cm−3)热导率/

(W·m−1·K−1)水接触角/

(°)孔径/

μm吸油倍率/(g·g−1) 正己烷 原油 S0 9.0 0.025 137 67 14.7 21.5 S1 9.0 0.024 139 125 69.0 80.5 S2 9.0 0.027 140 172 62.0 71.6 S3 12.5 0.021 146 153 65.0 75.8 S4 98.0 0.057 144 91 4.8 9.5 S5 152.0 0.058 141 45 3.6 5.4 S6 217.0 0.068 145 16 1.5 2.9 -

[1] DURANDEAU M, EL-EMAM M, ANIS A-H, et al. Successful field evaluation of the efficiency of a gas gravity drainage process by applying recent developments in sponge coring technique in a major oil field[R]. SPE 29809, 1995.

[2] 曹华庆,龙志平. 苏北盆地戴南组和阜宁组地层取心关键技术[J]. 石油钻探技术, 2019, 47(2): 28–33. CAO Huaqing, LONG Zhiping. Key coring technologies for the Dainan Formation and Funing Formation in North Jiangsu Basin[J]. Petroleum Drilling Techniques, 2019, 47(2): 28–33.

[3] 王丽忱,甄鉴,张露. 钻井取心技术现状及进展[J]. 石油科技论坛, 2015, 34(2): 44–50. WANG Lichen, ZHEN Jian, ZHANG Lu. Present conditions and progress of coring technology[J]. Oil Forum, 2015, 34(2): 44–50.

[4] 苏洋. 松散地层密闭环保取心技术[J]. 石油钻采工艺, 2019, 41(5): 592–596. SU Yang. Environmentally-friendly sealed coring technology for unconsolidated formations[J]. Oil Drilling & Production Technology, 2019, 41(5): 592–596.

[5] 芦凤明,马文华,白晶,等. 大港油田储层岩心饱和度校正方法优选[J]. 长江大学学报(自然科学版), 2019, 16(12): 50–53. LU Fengming, MA Wenhua, BAI Jing, et al. Optimization of reservoir core saturation correction method in Dagang Oilfield[J]. Journal of Yangtze University(Natural Science Edition), 2019, 16(12): 50–53.

[6] 袭杰,王晓舟,杨永祥,等. 保压取心技术在吐哈油田陵检14-241井的应用[J]. 石油钻探技术, 2003, 31(3): 19–21. XI Jie, WANG Xiaozhou, YANG Yongxiang, et al. Application of coring technology with keeping pressure in Lingjian 14-241 Well in Tuha Oilfield[J]. Petroleum Drilling Techniques, 2003, 31(3): 19–21.

[7] van LINGEN P P, SCHERMER P J C, BARZANDJI O H M, et al. Analysis and modeling of flow processes during sponge coring[R]. SPE 38690, 1997.

[8] 姜伟. 海绵取心工艺在SZ36-1油田的应用及其评价[J]. 石油钻采工艺, 1994, 16(6): 43–47. JIANG Wei. Application and evaluation of sponge coring in SZ36-1 Oilfield[J]. Oil Drilling & Production Technology, 1994, 16(6): 43–47.

[9] 付常春,杨保健,刘宝生,等. 渤海油田特殊地层取心技术优化及应用[J]. 钻采工艺, 2019, 42(2): 118–120. FU Changchun, YANG Baojian, LIU Baosheng, et al. Coring optimization for complex formations at Bohai Oilfield[J]. Drilling & Production Technology, 2019, 42(2): 118–120.

[10] 李让. ZY-B型大斜度井密闭取心工具研究与应用[J]. 石油矿场机械, 2018, 47(3): 57–60. LI Rang. Research and application of ZY-B type sealed coring tool in highly deviated wells[J]. Oil Field Equipment, 2018, 47(3): 57–60.

[11] 陈德坡,薛亮,王宁,等. 密闭取心三相流体饱和度半解析校正方法[J]. 特种油气藏, 2019, 26(2): 82–86. CHEN Depo, XUE Liang, WANG Ning, et al. Semi-analytical correction of three-phase fluid saturation for pressure coring[J]. Special Oil & Gas Reservoirs, 2019, 26(2): 82–86.

[12] 涂彬,李杰. 密闭取心饱和度校正动态模型及影响因素分析[J]. 石油钻采工艺, 2018, 40(4): 460–467. TU Bin, LI Jie. A dynamic model for correcting sealing core saturation and its influencing factors[J]. Oil Drilling & Production Technology, 2018, 40(4): 460–467.

[13] 陈良晓,姚大虎,汤慧慧,等. 超疏水亲油海绵的制备与表征[J]. 化工新型材料, 2018, 46(12): 218–221. CHEN Liangxiao, YAO Dahu, TANG Huihui, et al. Preparation and characterization of superhydrophobic-lipophilic sponge[J]. New Chemical Materials, 2018, 46(12): 218–221.

[14] 厉旭,裴学良. 基于聚硅氧烷疏水改性聚酰亚胺气凝胶[J]. 功能材料, 2019, 50(10): 10018–10022, 10026. LI Xu, PEI Xueliang. Improving the hydrophobicity of polyimide aerogel via polysiloxane[J]. Journal of Functional Materials, 2019, 50(10): 10018–10022, 10026.

[15] 吴艳杰,肖长发. 聚氨酯/部分还原氧化石墨烯海绵的制备及性能[J]. 高分子材料科学与工程, 2020, 36(2): 133–139. WU Yanjie, XIAO Changfa. Preparation and performance of polyurethane/portion reduced graphene oxide sponges[J]. Polymer Materials Science & Engineering, 2020, 36(2): 133–139.

[16] SHALE L, RADFORD S, UHLENBERG T, et al. New sponge liner coring system records step-change improvement in core acquisition and accurate fluid recovery[R]. SPE 167705, 2014.

[17] AL-HARBI A A, SCHMITT D P, MA S M. Toward quantitative remaining oil saturation (ROS): determination challenges and techniques[R]. SPE 147651, 2011.

-

期刊类型引用(3)

1. 苏超, 吴亮, 张卓, 陈洪地. 页岩气返排测试过程中防砂控砂技术浅析. 非常规油气. 2018(01): 76-79 .  百度学术

百度学术

2. 苏超, 吴亮, 张卓, 陈洪地. 页岩气返排测试过程中防砂控砂技术浅析. 非常规油气. 2018(02): 94-97 .  百度学术

百度学术

3. 李川, 张翔, 杜现飞, 唐梅荣, 王广涛, 李昌恒. 鄂尔多斯盆地致密油应力循环压裂技术. 石油钻采工艺. 2018(04): 494-498 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: