Research and Test on the Stimulated Reservoir Volume Technology of Hot Dry Rock

-

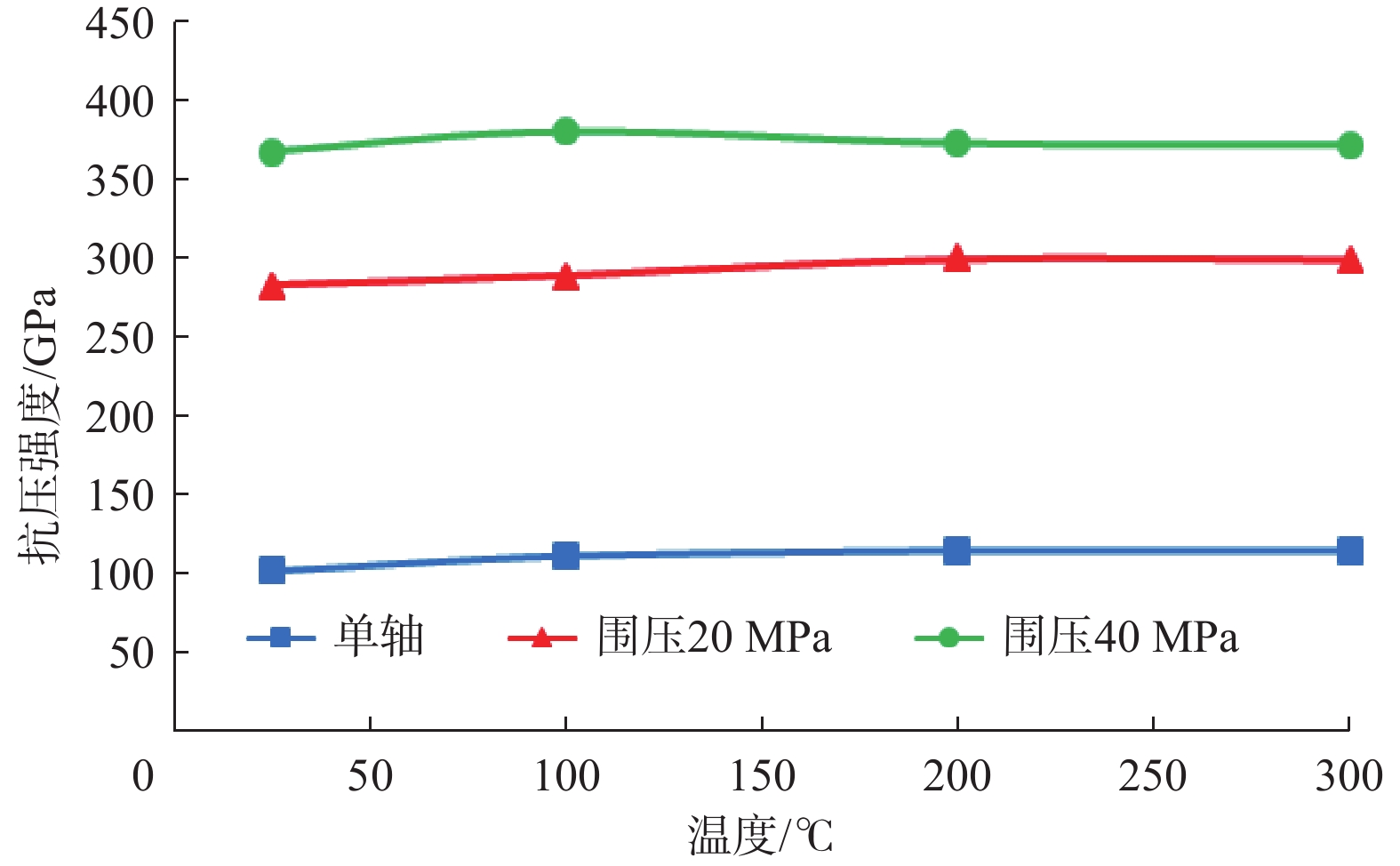

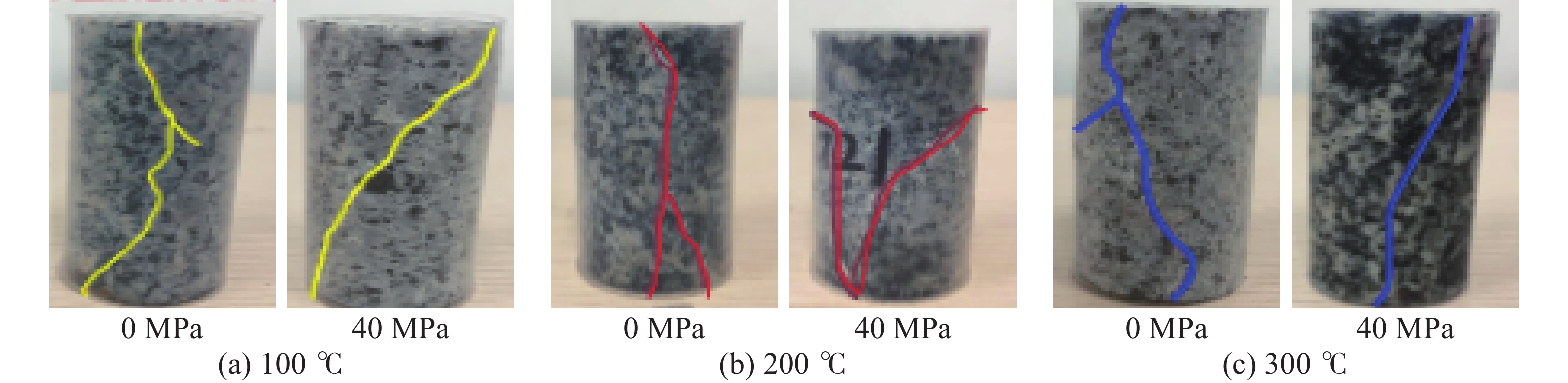

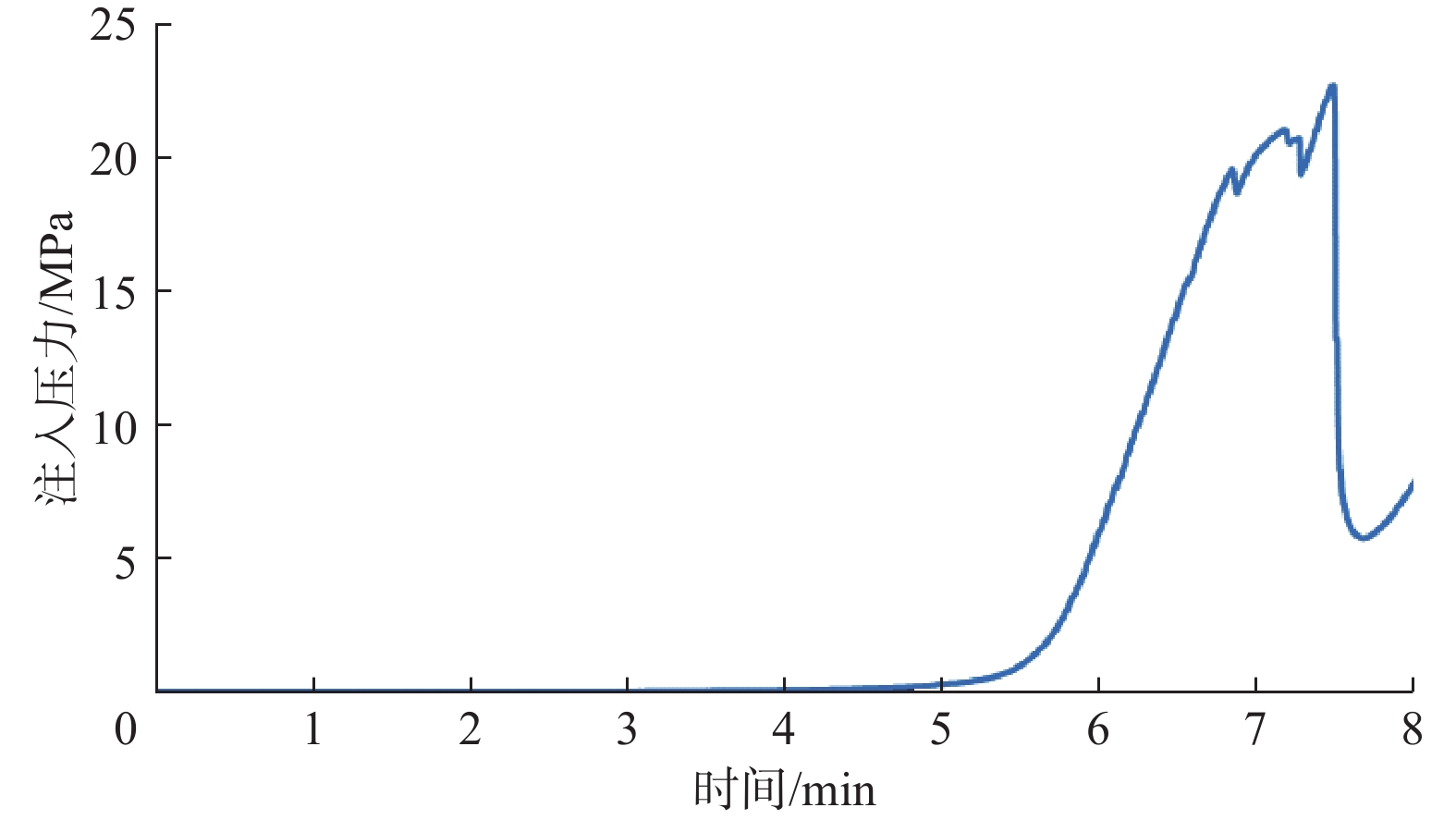

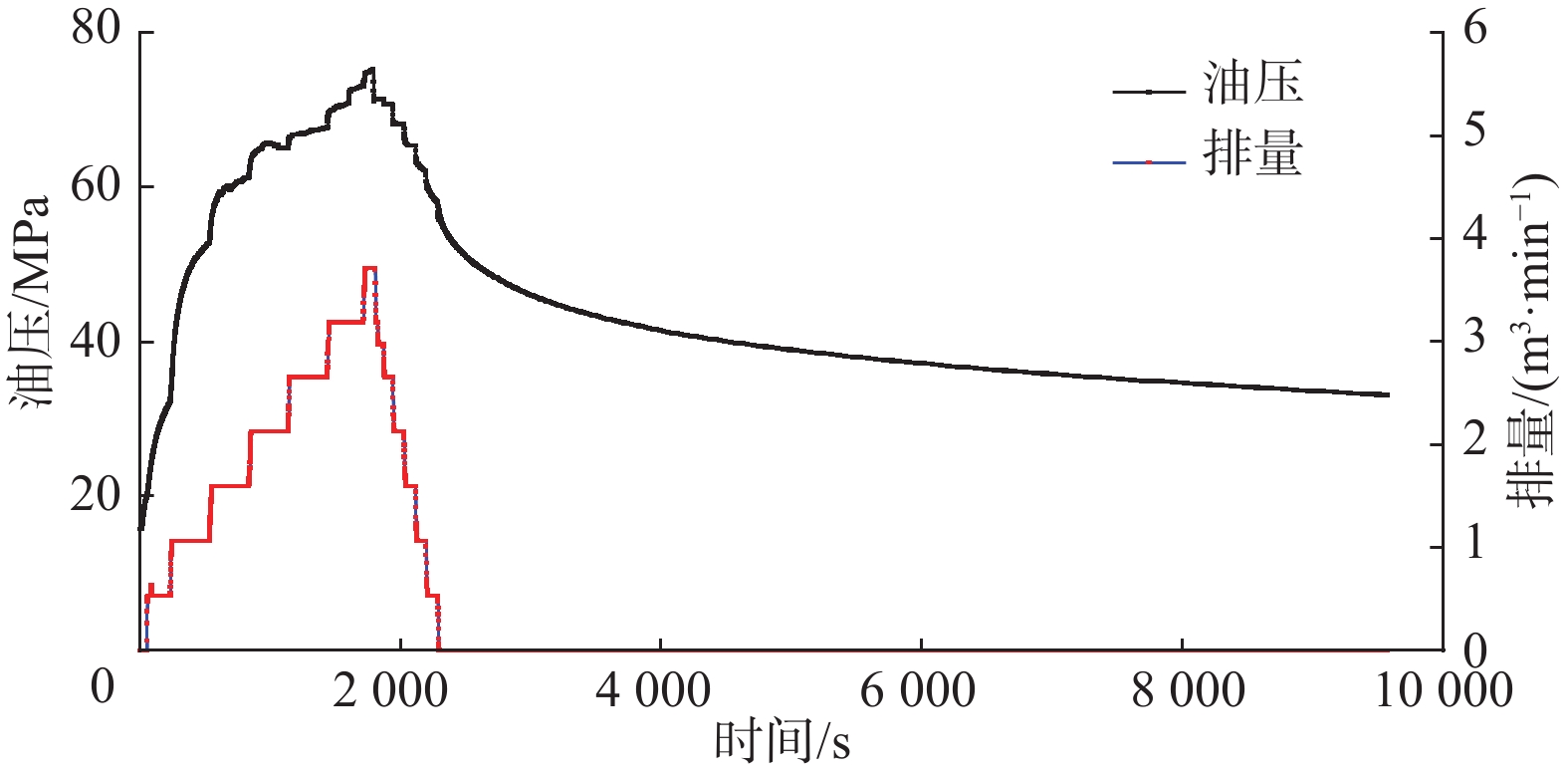

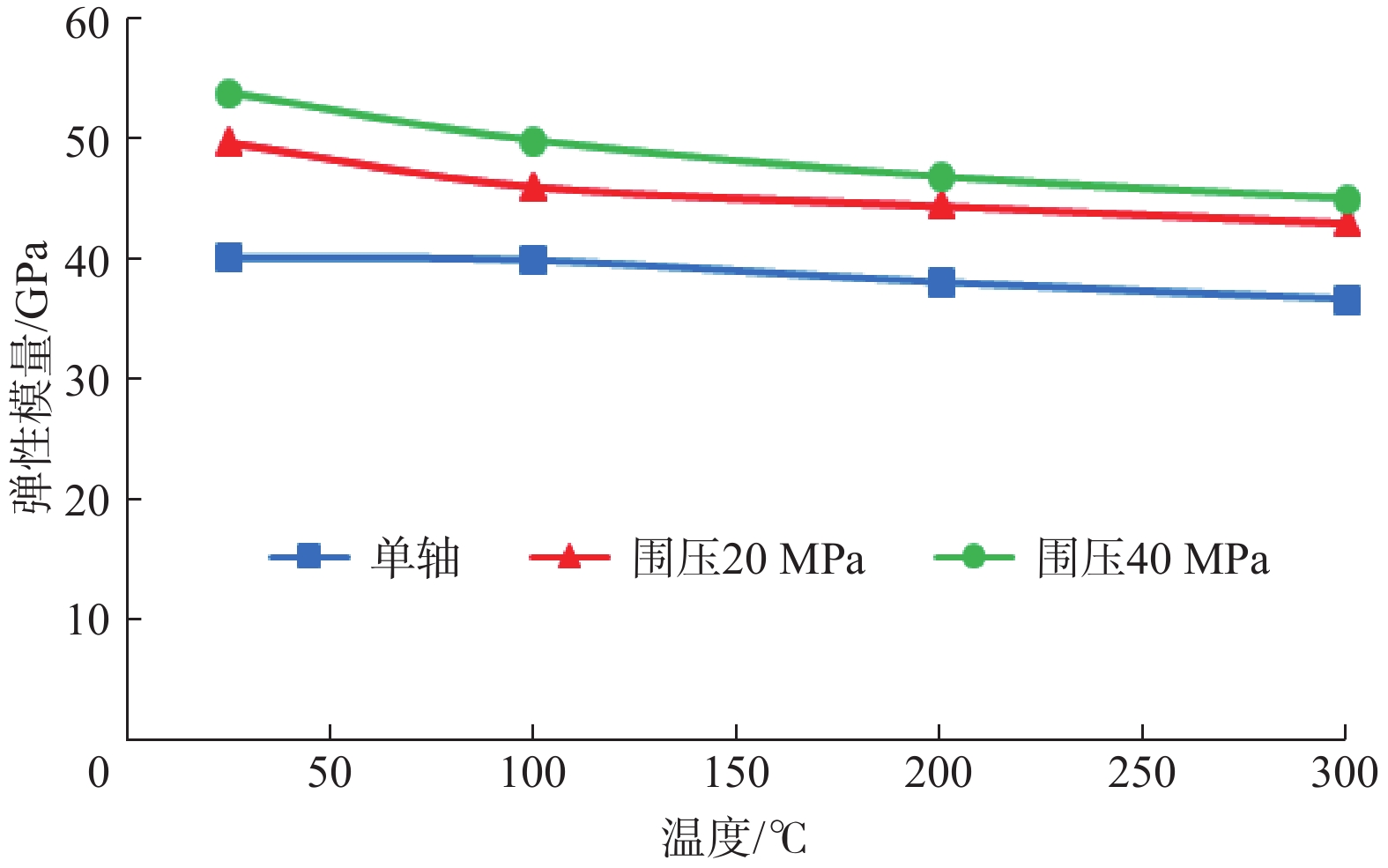

摘要: 干热岩的岩性、力学特性和开发利用方式与常规油气资源相比差异较大,其储层改造不能直接采用页岩油气与致密砂岩油气压裂技术,需要研究适用于干热岩的改造技术。为此,利用井下花岗岩岩心和大尺寸露头岩样,采用高温测试和真三轴物理模拟系统,测试分析了高温岩石力学特性,模拟研究了裂缝起裂与扩展形态特征,分析了高温下花岗岩的脆塑性、岩石破坏特性以及天然裂缝对裂缝破裂压力、扩展路径和形态的影响特征,提出了“低排量热破裂+胶液扩缝+变排量循环注入”体积改造技术,并进行了现场试验,验证了室内研究结果。研究表明,花岗岩在高温下塑性强、脆性差、水平应力差大,岩石以张性和剪切混合破坏为主,天然裂缝和温差效应可显著降低破裂压力、提高裂缝复杂性与改造体积。研究结果对于干热岩热储高效开发具有较好的指导作用。Abstract: Compared with conventional oil and gas resources, the lithology, mechanical properties, development and utilization methods for simulating reservoir volume in hot dry rock are quite different. The fracturing technologies for shale and tight sandstone cannot be directly used in hot dry rocks, and it is necessary to study a fracturing technology that is suitable for the stimulation of hot dry rock. To this end, the mechanical properties of rocks under high-temperature conditions were tested and analyzed by using downhole granite cores and large-size outcrop samples. By adopting high-temperature testing and true tri-axial physical simulation systems, it was possible to simulate and study the morphological characteristics of crack initiation and propagation. The characteristics of brittle-plastic granite at high temperature, rock failure features and the effect of natural fractures on the fracture pressure, propagation path and morphology were analyzed. On this basis, a stimulated reservoir volume technology of low flowrate thermal fracture + gel expanding of cracks + variable flowrate cyclic injection was proposed. A pilot fracturing program at well site was conducted to verify the results of indoor research. Studies suggested that granite had a strong plasticity, poor brittleness, and a large horizontal stress difference at high temperatures. The rock is mainly damaged by tension-shear failure, and natural fractures and temperature difference effect can significantly reduce the fracture pressure, increase the complexity of fractures and achieve a stimulated reservoir volume. The research results can provide a good guidance and best practices for the efficient development of hot dry rock reservoirs.

-

-

表 1 巴西圆盘劈裂拉伸强度试验结果

Table 1 The experimental results of splitting tensile strength with Brazilian disc

编号 直径/mm 厚度/mm 温度/℃ 最大载荷/kN 抗拉强度/MPa 1 58.33 24.92 25 29.4 12.88 2 58.26 24.91 28.4 12.46 3 58.31 25.18 27.9 12.10 4 58.27 25.15 200 28.6 12.42 5 58.25 24.96 28.0 12.26 6 58.23 24.98 24.5 10.72 表 2 地应力测试结果

Table 2 The test results of in-situ stress

井号 深度/

mKaiser点对应的应力/MPa 三向主应力/MPa 垂直 0º 45º 90º 垂向 水平最大 水平最小 X1 2 205 33.32 32.91 20.93 26.23 54.47 54.70 46.74 3 236 51.80 47.89 29.04 40.65 80.83 77.67 68.94 X2 2 642 41.50 39.01 27.23 32.97 65.35 63.40 56.28 表 3 不同施工排量下的井口压力预测结果

Table 3 The predicted wellhead pressure under different pumping flowrate

压裂液 不同施工排量下的井口压力/MPa 0.5 m3/min 1.0 m3/min 1.5 m3/min 2.0 m3/min 3.0 m3/min 3.5 m3/min 4.0 m3/min 5.0 m3/min 滑溜水 65.35 65.73 66.31 67.07 69.09 70.33 71.74 74.99 清水 65.63 66.69 68.30 70.41 76.02 79.49 83.38 92.36 -

[1] 陈作, 许国庆, 蒋漫旗. 国内外干热岩压裂技术现状及发展建议[J]. 石油钻探技术, 2019, 47(6): 1–8. doi: 10.11911/syztjs.2019110 CHEN Zuo, XU Guoqing, JIANG Manqi. The current status and development recommendations for dry hot rock fracturing technologies at home and abroad[J]. Petroleum Drilling Techniques, 2019, 47(6): 1–8. doi: 10.11911/syztjs.2019110

[2] 曾义金. 干热岩热能开发技术进展与思考[J]. 石油钻探技术, 2015, 43(2): 1–7. ZENG Yijin. Technical progress and thinking for development of hot dry rock (HDR) geothermal resources[J]. Petroleum Drilling Techniques, 2015, 43(2): 1–7.

[3] 廖志杰, 万天丰, 张振国. 增强型地热系统:潜力大、开发难[J]. 地学前缘, 2015, 22(1): 335–344. LIAO Zhijie, WAN Tianfeng, ZHANG Zhenguo. The enhanced geothermal system(EGS):huge capacity and difficult exploitation[J]. Earth Science Frontiers, 2015, 22(1): 335–344.

[4] 翟海珍, 苏正, 吴能友. 苏尔士增强型地热系统的开发经验及对我国地热开发的启示[J]. 新能源进展, 2014, 2(4): 286–294. doi: 10.3969/j.issn.2095-560X.2014.04.008 ZHAI Haizhen, SU Zheng, WU Nengyou. Development experiences of the Soultz enhanced geothermal systems and inspirations for geothermal development of China[J]. Advances in New and Renewable Energy, 2014, 2(4): 286–294. doi: 10.3969/j.issn.2095-560X.2014.04.008

[5] 付亚荣, 李明磊, 王树义, 等. 干热岩勘探开发现状及前景[J]. 石油钻采工艺, 2018, 40(4): 526–540. FU Yarong, LI Minglei, WANG Shuyi, et al. Present situation and prospect of hot dry rock exploration and development[J]. Oil Drilling & Production Technology, 2018, 40(4): 526–540.

[6] FRASH L, GUTIERREZ M, HAMPTON J. Scale model simulation of hydraulic fracturing for EGS reservoir creation using a heated true-triaxial apparatus[R]. ISRM-ICHF-2013-013, 2013.

[7] 赵阳升. 高温岩体地热开发的岩石力学问题: 21世纪新兴岩石力学与工程发展展望: 中国岩石力学与工程学会第六次学术大会论文集[C]. 北京: 中国科学技术出版社, 2000: 71–74. ZHAO Yangsheng. The problem of rock mechanics in heat extraction in hot dry rock: 21st advancing of rock mechanics & rock engineering: Proceedings of the 6th academic conference of the Chinese Society of Rock Mechanics and Engineering[C]. Beijing: China Science and Technology Press, 2000: 71–74.

[8] 万志军, 赵阳升, 董付科, 等. 高温及三轴应力下花岗岩体力学特性的实验研究[J]. 岩石力学与工程学报, 2008, 27(1): 72–77. doi: 10.3321/j.issn:1000-6915.2008.01.011 WAN Zhijun, ZHAO Yangsheng, DONG Fuke, et al. Experimental study on mechanical characteristics of granite under high temperatures and triaxial stresses[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(1): 72–77. doi: 10.3321/j.issn:1000-6915.2008.01.011

[9] 杜守继, 刘华, 职洪涛, 等. 高温后花岗岩力学性能的试验研究[J]. 岩石力学与工程学报, 2004, 23(14): 2359–2364. doi: 10.3321/j.issn:1000-6915.2004.14.010 DU Shouji, LIU Hua, ZHI Hongtao, et al. Testing study on mechanical properties of post-high-temperature granite[J]. Chinese Journal of Rock Mechanics and Engineering, 2004, 23(14): 2359–2364. doi: 10.3321/j.issn:1000-6915.2004.14.010

[10] 郤保平, 赵阳升. 600 ℃内高温状态花岗岩遇水冷却后力学特性试验研究[J]. 岩石力学与工程学报, 2010, 29(5): 892–898. XI Baoping, ZHAO Yangsheng. Experimental research on mechanics properties of water-cooled granite under high temperatures within 600 ℃[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(5): 892–898.

[11] TOMAC I, GUTIERREZ M. Micro-mechanical of hydro-thermo-mechanical fracture propagation in granite[R]. ARMA-2014-7148, 2014.

[12] RIAHI A, DAMJANAC B, FURTNEY J. Thermo-hydro-mechanical numerical modeling of stimulation and heat production of EGS reservoirs[R]. ARMA-2014-7741, 2014.

[13] RUTQVIST J, DOBSON P F, JEANNE P, et al. Modeling and monitoring of deep injection at the Northwest Geysers EGS Demonstration, California[R]. ARMA-2013-307, 2013.

[14] CLADOUHOS T T, PETTY S, NORDIN Y, et al. Improving geothermal project economics with multi-zone stimulation: results from the Newberry Volcano EGS Demonstration[R]. ARMA-2013-484, 2013.

[15] 谢文苹, 路睿, 张盛生, 等. 青海共和盆地干热岩勘查进展及开发技术探讨[J]. 石油钻探技术, 2020, 48(3): 77–84. doi: 10.11911/syztjs.2020042 XIE Wenping, LU Rui, ZHANG Shengsheng, et al. Progress in hot dry rock exploration and a discussion on development technology in the Gonghe Basin of Qinghai[J]. Petroleum Drilling Techniques, 2020, 48(3): 77–84. doi: 10.11911/syztjs.2020042

[16] 陈作, 薛承瑾, 蒋廷学, 等. 页岩气井体积压裂技术在我国的应用建议[J]. 天然气工业, 2010, 30(10): 30–32. doi: 10.3787/j.issn.1000-0976.2010.10.007 CHEN Zuo, XUE Chengjin, JIANG Tingxue, et al. Proposals for the application of fracturing by stimulated reservoir volume (SRV) in shale gas wells in China[J]. Natural Gas Industry, 2010, 30(10): 30–32. doi: 10.3787/j.issn.1000-0976.2010.10.007

[17] 陶亮, 郭建春, 李凌铎, 等. 致密油藏体积压裂水平井产能评价新方法[J]. 特种油气藏, 2019, 26(3): 89–93. doi: 10.3969/j.issn.1006-6535.2019.03.016 TAO Liang, GUO Jianchun, LI Lingduo, et al. New productivity evaluation of horizontal well with volume-fracturing in tight oil reservoir[J]. Special Oil & Gas Reservoirs, 2019, 26(3): 89–93. doi: 10.3969/j.issn.1006-6535.2019.03.016

-

期刊类型引用(17)

1. 王大勇,马红滨,李欣龙,熊超,史怀忠,黄中伟,赫文豪. 高压水射流辅助锥形PDC齿破碎花岗岩试验研究. 石油机械. 2024(07): 36-44 .  百度学术

百度学术

2. 王鸿远. 锥形与常规PDC齿混合布齿破岩机理研究及钻头研制. 石化技术. 2024(08): 389-391 .  百度学术

百度学术

3. 张文波,史怀忠,席传明,张楠,熊超,陈振良. 锥形PDC齿和常规PDC齿混合切削破岩试验研究. 石油机械. 2023(03): 33-39 .  百度学术

百度学术

4. 鲍伟伟,赵国辉,徐杨. 大港页岩油水平井优快钻井技术. 中国石油和化工标准与质量. 2023(12): 159-161 .  百度学术

百度学术

5. 傅新康,黄中伟,史怀忠,吴洪志,何森林,熊超,赫文豪. 锥形齿与平面齿切削碳酸盐岩特征对比分析. 石油机械. 2023(07): 59-67 .  百度学术

百度学术

6. 熊超,黄中伟,王立超,史怀忠,赫文豪,陈振良,李根生. 锥形聚晶金刚石复合片齿破岩特征与机制研究. 岩土力学. 2023(08): 2432-2444 .  百度学术

百度学术

7. 徐建飞,陈晖,邹德永,黄勇. 高造斜率定向CDE钻头设计与应用. 机械设计与制造工程. 2023(09): 117-120 .  百度学术

百度学术

8. 李彦操. PDC钻头齿的破岩机理和性能测试方法研究现状. 金刚石与磨料磨具工程. 2023(05): 553-567 .  百度学术

百度学术

9. 吴泽兵,席凯凯,赵海超,黄海,张文超,杨晨娟. 仿生PDC齿旋转破岩时的温度场和破岩特性模拟研究. 石油钻探技术. 2022(02): 71-77 .  本站查看

本站查看

10. 刘伟吉,阳飞龙,祝效华,罗云旭,何灵. 异形PDC齿切削破岩提速机理研究. 中国机械工程. 2022(17): 2133-2141 .  百度学术

百度学术

11. 胡思成,管志川,路保平,梁德阳,呼怀刚,闫炎,陶兴华. 锥形齿旋冲及扭冲的破岩过程与破岩效率分析. 石油钻探技术. 2021(03): 87-93 .  本站查看

本站查看

12. 徐卫强,史怀忠,曹权,史杏杏,胡锡辉,熊超,陈晗. 锥形PDC齿破碎砾岩特性试验研究. 石油机械. 2021(09): 9-16 .  百度学术

百度学术

13. 麻地辉,薛娟,李毅锐. 水力结构增强型PDC钻头应用分析. 西部探矿工程. 2019(12): 64-65+74 .  百度学术

百度学术

14. 汪为涛. 非均质地层锥形辅助切削齿PDC钻头设计与试验. 石油钻探技术. 2018(02): 58-62 .  本站查看

本站查看

15. 杨顺辉. 新型多重复合切削钻头的研制. 石油机械. 2016(10): 21-24 .  百度学术

百度学术

16. 孙源秀,邹德永,郭玉龙,陈修平,易杨. 切削-犁削混合钻头设计及现场应用. 石油钻采工艺. 2016(01): 53-56 .  百度学术

百度学术

17. 孙源秀,邹德永,徐城凯,郭玉龙. 锥形聚晶金刚石复合片钻头(PDC)齿与常规PDC齿破岩效果对比试验. 科学技术与工程. 2015(36): 159-162 .  百度学术

百度学术

其他类型引用(15)

下载:

下载: