Research Progress and Development Recommendations Covering Damage Mechanisms and Protection Technologies for Tight/Shale Oil and Gas Reservoirs

-

摘要:

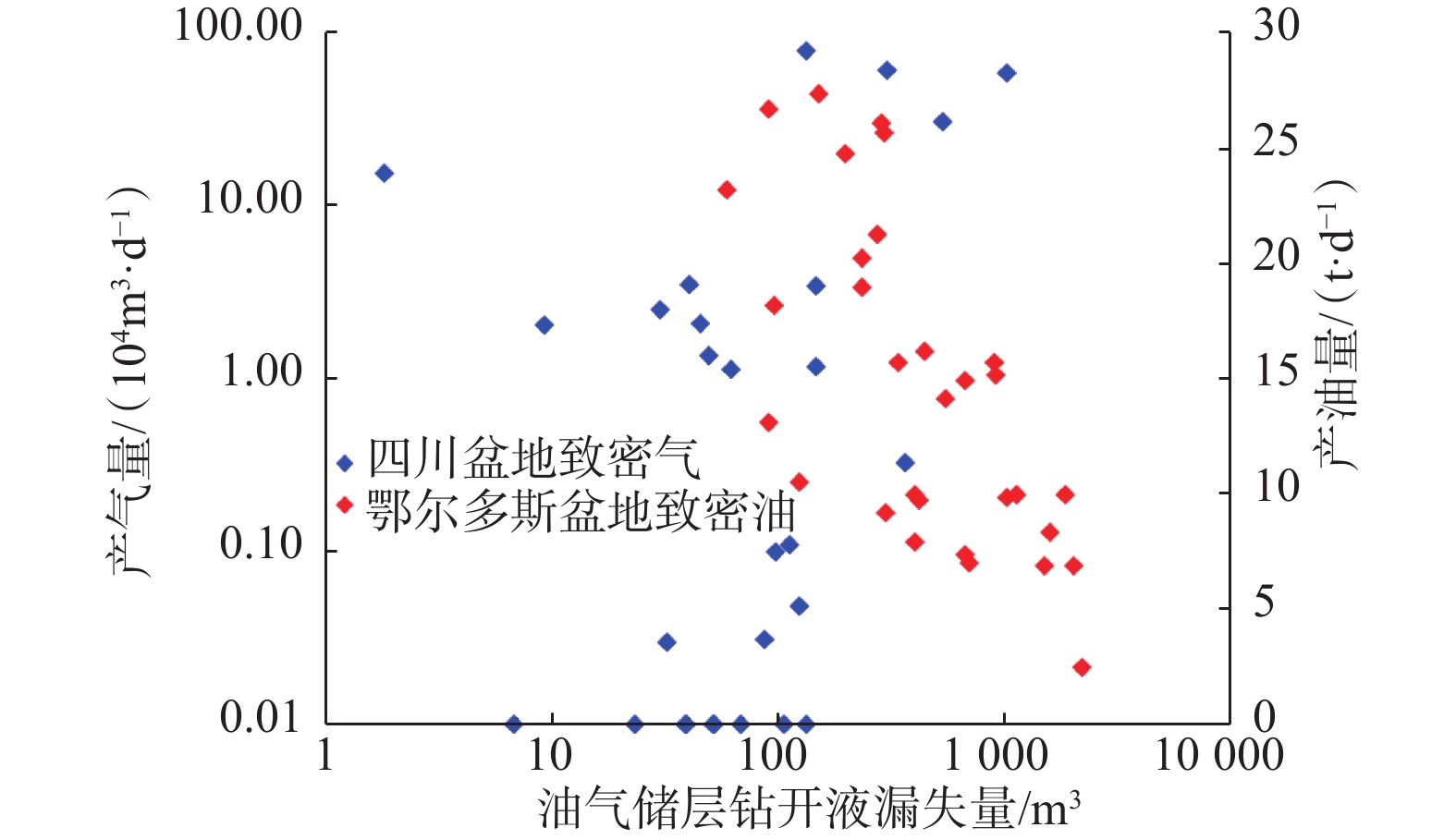

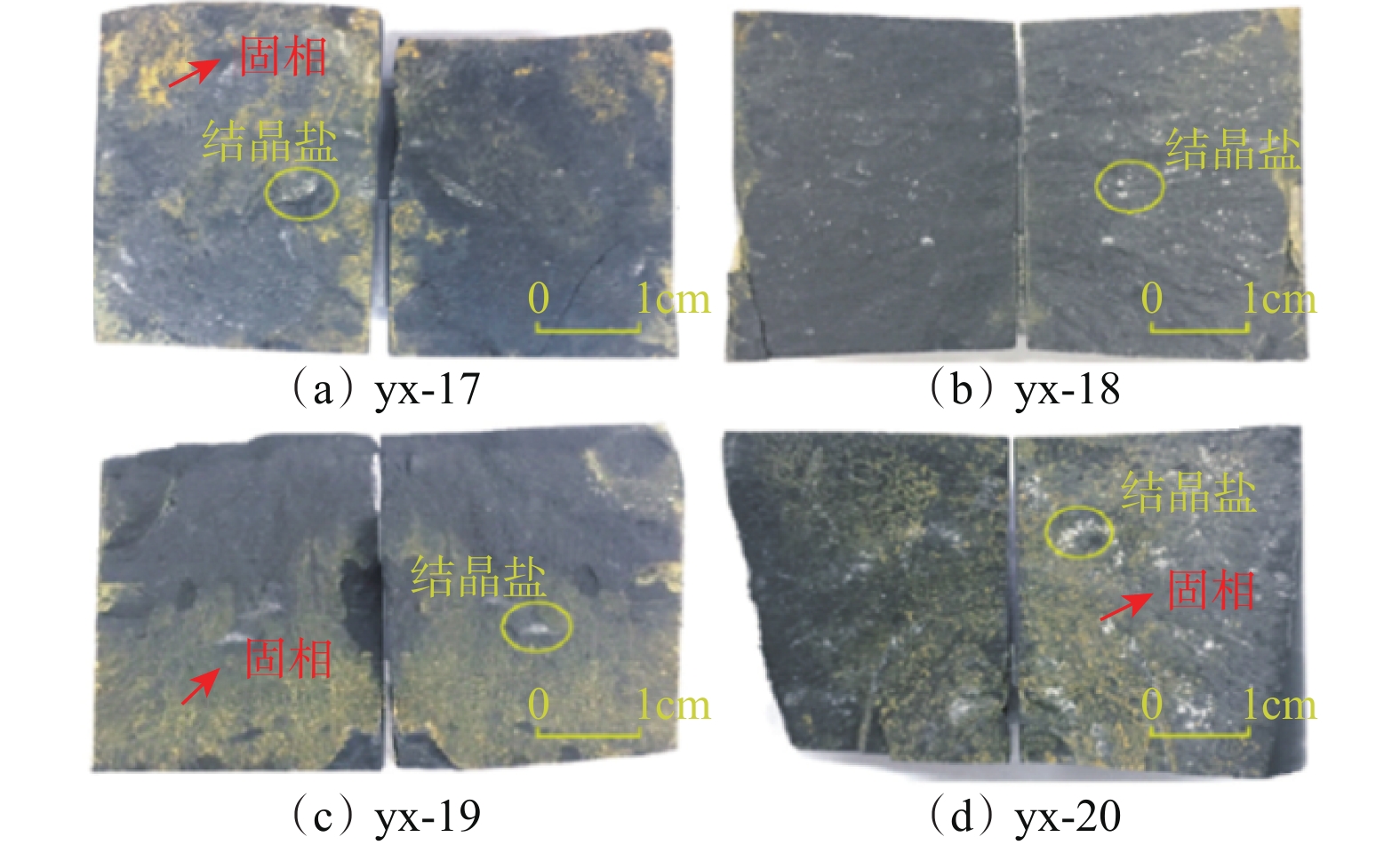

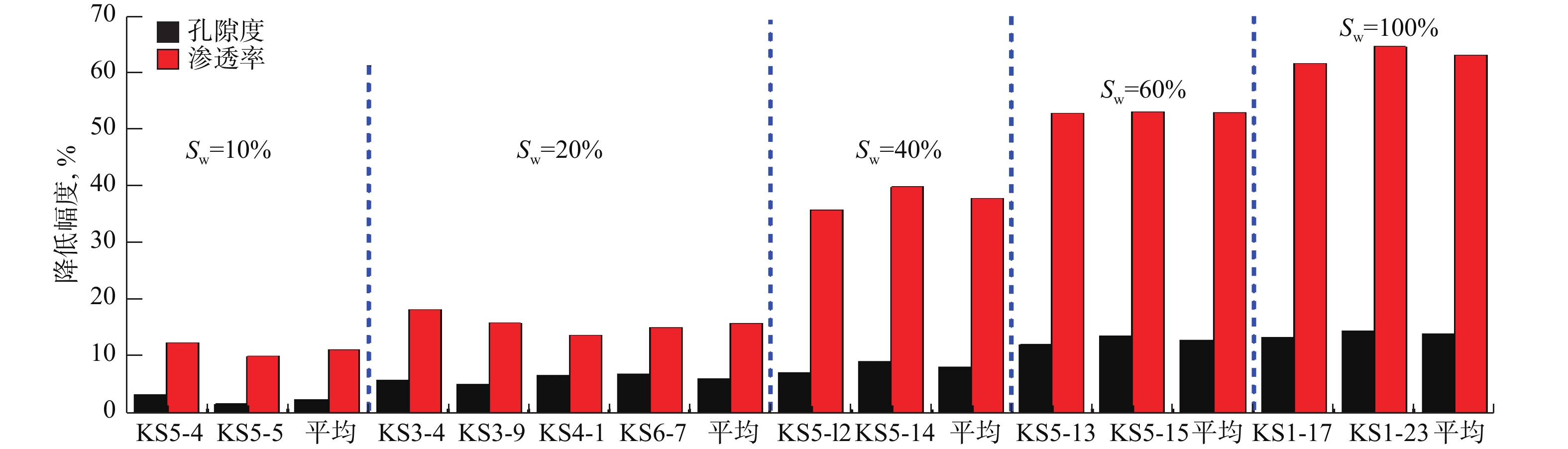

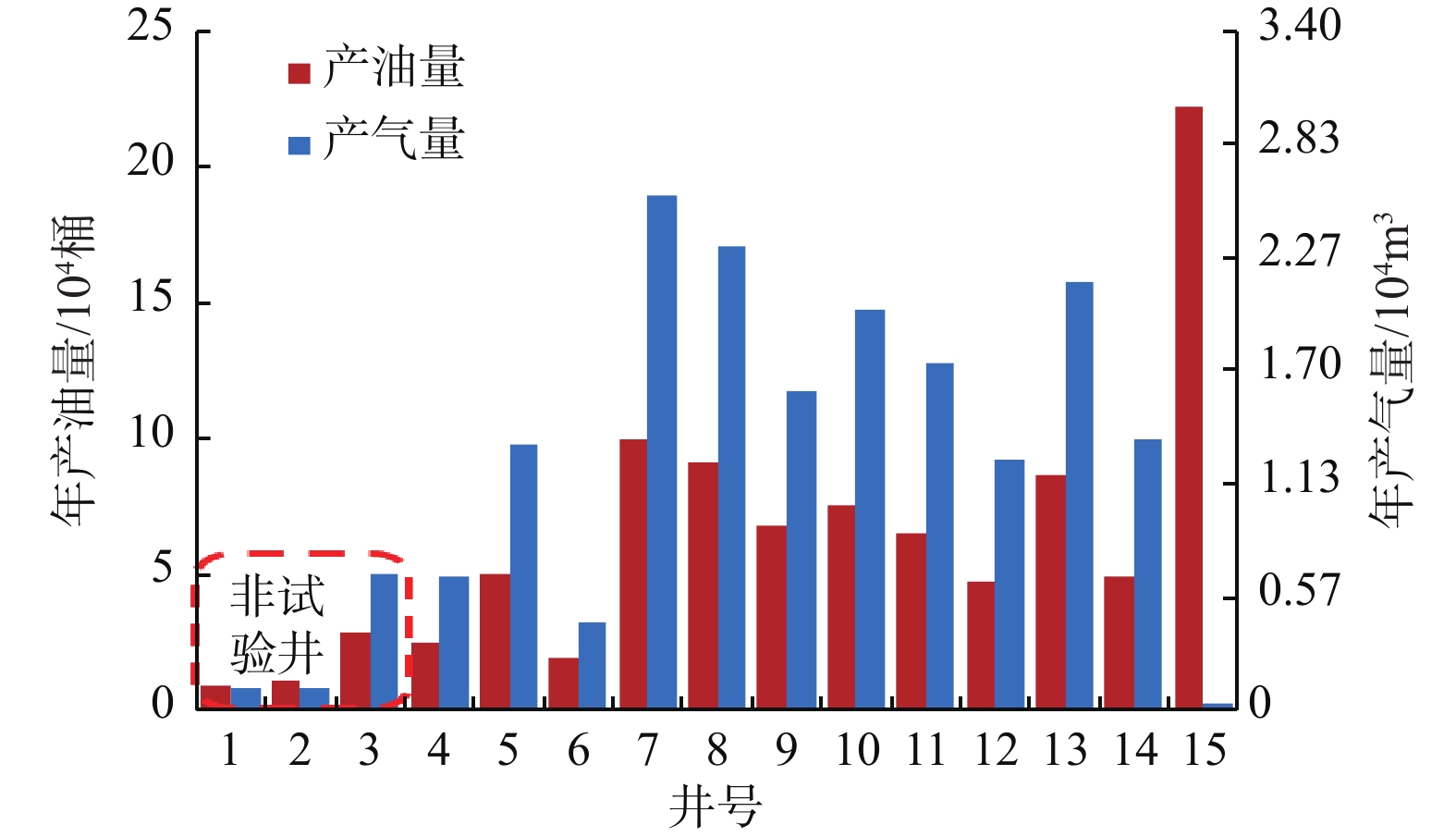

致密/页岩油气藏赋存地质条件独特,通常采用水平井加分段压裂技术进行开发,但油气井初期产量差异大且递减快,而钻井完井及增产改造中的储层损害是重要原因。如何降低致密/页岩油气藏勘探开发各环节的储层损害,提高单井产量与稳产周期,实现经济高效开发,是目前亟待解决的重大科学问题。为此,在分析致密/页岩油气储层损害特点的基础上,总结了钻井完井、增产改造与开发生产过程中致密/页岩油气储层损害的主要机理,介绍了物理颗粒暂堵、化学成膜暂堵、欠平衡钻井完井和界面修饰等储层保护技术的基本原理及研究进展,以典型案例阐述了储层保护技术对及时发现、准确评价和高效开发致密/页岩油气资源的重要作用,并指出储层损害预测与诊断系统、储层多尺度损害评价方法、智能型储层保护材料、液相圈闭损害防治措施和储层保护–漏失控制–增渗改造一体化技术是致密/页岩油气储层保护的重要发展方向。

Abstract:Tight and shale oil and gas reservoirs demonstrate unique geological characteristics such as extremely poor storage-flow quality, and multi-scale structure of storage and flow space. Those reservoirs are normally developed with staged fracturing of horizontal wells, which is made quite challenging by obviously different initial production rates and rapid declines. Further, uncertainty over the technical effects of drilling/completion and stimulation are significantly different. Currently, the major scientific issues that urgently need to be resolved include the requirement to reduce reservoir damage at all the exploration and development stages, to increase well production and stable production cycle, and to achieve economic and efficient development. Through the damage characteristics analysis of such reservoirs, and the main damage mechanisms summary during drilling/completion, stimulation and production, this paper introduces the basic principles and research progress of reservoir protection technologies such as the temporary plugging of physical particles and chemical filming, underbalanced drilling and completion, and interface modification, etc. The importance of damage prevention technologies in the timely discovery of tight/shale oil and gas reservoirs, correct evaluation and efficient development is elaborated with case studies. This paper also points out that integrated techniques in reservoir damage prediction and diagnosis system, multi-scale damage evaluation method, intelligent reservoir protection materials, liquid trap damage prevention measures, and reservoir protection-leakage control-permeability enhancement will be the important development trends in tight/shale oil and gas reservoir protection in the future.

-

长庆油田陇东地区长7段页岩油储层埋深一般为1 600~2 200 m,渗透率0.07~0.22 mD,压力系数0.77~0.85,脆性指数 0.34~0.45[1]。长7段页岩油藏与北美页岩油藏具有相似性,但开发更具挑战,主要表现为:沉积环境是湖相沉积,非均质性更强,地层压力系数低,脆性指数低,天然裂缝相对不发育。前期该页岩油藏的水平井主体采用水力泵送桥塞分段体积压裂工艺,初期单井日产油量 10 t 左右,未达到预期效果。分析认为,水平井分段多簇压裂改造过程中,受储层物性、地应力、各向异性及水力裂缝簇间干扰等因素影响[2-5],各簇不能均匀开启,簇间进液不均,达不到均匀改造储层的目的。因此,需要开展精细化分段压裂技术研究,以实现精细分层、规模可控,从而解决水平井分段多簇压裂部分射孔簇压不开,或虽已压开但并未建立起有效驱替压差,导致有效期短、无法实现长期有效动用的问题。为此,长庆油田开展了单段单簇细分切割压裂技术研究,形成了页岩油水平井细分切割压裂技术,实现了储层均匀改造、缝控储量的目的。目前,该技术已在陇东地区10口页岩油水平井进行了现场应用,取得了显著的增产效果。

1. 单段单簇细分切割压裂模拟研究

1.1 多簇压裂和细分切割单段单簇压裂模拟

利用软件模拟分析了多簇压裂和细分切割单段单簇压裂时的裂缝扩展情况,结果见图1(缝高、缝长固定,缝宽变化)。

多簇压裂方式下,2簇压开缝长260.00 m,缝高92.00 m;3簇压开缝长210.00 m,缝高67.00 m。模拟可知,并非所有簇都能均匀开启,压窜邻井(井距400.00 m)的风险很高,压穿相邻含水层的风险也升高。现场常出现某井压裂造成邻井含水率迅速升至100%的情况,证实了普遍存在压窜。

细分切割单段单簇压裂方式下,各裂缝长度为180.00 m,缝高52.00 m。模拟可知,该压裂方式可以确保储层各射孔位置均匀分布,能够保证每段均匀开启、充分改造,避免了压窜邻井的风险。

1.2 多簇合压和单簇单压下的产量预测

模拟了长7段页岩油藏1口页岩油水平井在多簇合压和单簇单压下的裂缝形态,并采用软件预测了2种工艺下的采油指数、无阻流量(见表1)和产能(见图2)。

表 1 多簇合压和单簇单压下的采油指数和无阻流量Table 1. Productivity index and open flow capacity under multi-cluster fracturing and single-cluster fracturing序号 压裂工艺 采油指数/(m3·d–1·MPa–1) 无阻流量/(m3·d–1) 1 多簇合压 2.058 46 32.93 2 单簇单压 2.241 65 35.86 由表1和图2可知,单簇单压下的采油指数和无阻流量明显高于多簇合压,且单簇单压较多簇合压的稳产时间更长。

2. 细分切割压裂优化设计

以实现“缝控储量最大化”为原则,利用压裂地质一体化设计方法,进行压裂改造方案优化,确定合理的储层改造工艺参数。

2.1 压裂段数优化

以华HXX-X井为例进行压裂优化设计。该井的基本参数:储层有效厚度16.00 m,储层压力16 MPa,孔隙度10.1%,渗透率0.18 mD,含水饱和度40%,采用页岩油水平井细分切割压裂工艺,每段1簇。

根据不同压裂段数下压裂后的累计产量、压裂成本及压裂净现值模拟计算结果(见图3),建议该井采用细分切割压裂的最优段数为38~42段。

2.2 射孔位置优化

2.2.1 非均质地质模型的建立

以陇东地区华H34平台为例,根据测井解释的水平段储层物性参数,利用克里金空间插值方法,建立了华 H34 平台的非均匀地质模型[6](见图4)。

2.2.2 综合甜点指数计算

首先,分别计算页岩油储层的工程甜点指数(可压性)和地质甜点指数(含油性);然后,将二者结合得到综合甜点指数[7-8]。其中,工程甜点指数由岩性和岩石力学参数2部分构成,岩性参数为脆性矿物含量与全岩矿物含量的比值,岩石力学参数为归一化的弹性模量和泊松比的平均值;地质甜点指数为归一化的孔隙度、渗透率、含油饱和度及全烃值乘以权重系数之和;综合甜点指数为工程甜点指数和地质甜点指数乘以权重系数之和。

2.2.3 华H34平台综合甜点分布

根据华H34平台各井的测井数据,计算得到了井筒综合甜点指数,再利用空间插值获得了区域甜点分布情况,如图5所示(图例中的数据为该平台综合甜点指数)。

2.2.4 射孔位置优选

基于综合甜点指数分布,设置最小缝间距,以压裂射孔位置总甜点指数最高为目标,避开套管接箍,优选射孔位置,结果见表2。

表 2 射孔位置优选结果Table 2. Optimized perforating positions压裂

段次射孔

位置/

m段间

距/m综合

甜点

指数,%压裂

段次射孔

位置/

m段间

距/m综合

甜点

指数,%1 3 221.50 55.9 13 2 741.90 25.00 66.2 2 3 169.60 51.90 59.2 14 2 711.10 30.80 79.1 3 3 133.80 35.80 82.9 15 2 670.40 40.70 77.5 4 3 106.30 27.50 60.0 16 2 643.30 27.10 72.0 5 3 079.80 26.50 73.9 17 2 598.10 45.20 64.1 6 3 053.40 26.40 60.5 18 2 568.60 29.50 73.0 7 3 028.10 25.30 71.4 19 2 540.60 28.00 64.5 8 3 002.80 25.30 54.7 20 2 510.90 29.70 70.0 9 2 962.00 40.80 62.1 21 2 480.90 30.00 87.7 10 2 928.10 33.90 56.0 22 2 455.10 25.80 66.5 11 2 792.10 136.00 63.1 23 2 393.60 61.50 52.5 12 2 766.90 25.20 80.8 24 2 354.00 39.60 87.5 由表2可知,24段平均段间距37.70 m,平均综合甜点指数68.4%。

2.3 裂缝半长优化

陇东地区页岩油华H34平台平均井距308 m。在此条件下,模拟不同裂缝半长下的累计产油量,结果如图6所示。从图6可以看出,裂缝半长大于135 m之后产油量增幅明显减小。因此,将平均裂缝半长优化为135 m。至于具体每一段的裂缝半长的设计值,可根据实际井距进行调整。

3. 压裂施工参数优化

3.1 加砂量、砂比的优化

采用压裂地质一体化软件,模拟了相同液量、不同砂比(加砂量)下的裂缝参数及压后的产量,结果见表3。模拟采用的基本参数:储层压力16 MPa,渗透率0.10 mD,含水饱和度45%,井距300 m,水平段长度1 750 m,储层钻遇率80%,压裂43段,前置液占比40%。

表 3 相同液量、不同砂比(加砂量)下的裂缝参数及压后的产量Table 3. Fracture parameters and post-fracturing production with the same fluid rates but different proppant concentration (sand content)序号 砂比,

%每段液量/m3 每段加砂量/m3 支撑缝长/m 导流能力/

(mD·m)无因次

导流能力第1年

产量/t1 21 620 78.0 131.30 740.3 56.4 4 083.2 2 18 620 66.8 130.40 644.5 49.4 4 053.0 3 15 620 55.7 129.50 538.8 41.6 4 023.5 4 12 620 44.6 121.50 454.3 37.4 3 773.6 5 9 620 33.4 108.70 381.8 35.1 3 226.3 从表3可以看出,砂比降低,裂缝导流能力下降,但导流能力对产量的影响较小,主要是因为基质渗透率很低、压裂段数很多,且产量不高,裂缝的导流能力能满足生产;但砂比降低到一定程度后,支撑缝长明显缩短,产量大幅度降低。经过综合对比确定最佳砂比为15%,每段最佳加砂量为55.7 m3。

3.2 压裂支撑剂组合的优化

模拟计算了40/70目和20/40目支撑剂(石英砂)以不同比例组合后的裂缝导流能力与压后的产量,结果见表4。

表 4 两种粒径支撑剂以不同比例组合后的裂缝导流能力与压后产量Table 4. Fracture conductivity and post-fracturing production after the proppant with two particle sizes were combined in different proportions序号 40/70目和20/40目

支撑剂配比导流能力/

(mD·m)无因次导流

能力第1年

产量/t1 1∶3 533.4 25.8 5 263.1 2 1∶2 481.7 23.3 5 253.6 3 1∶1 405.9 19.6 5 243.4 4 2∶1 327.5 15.8 5 233.8 5 3∶1 276.5 13.4 5 179.2 由表4可知,40/70目和20/40目支撑剂组合中,随着40/70目支撑剂所占比例增大,裂缝导流能力降低,压后第1年的产量虽然有所降低但降低幅度非常小,这主要是因为导流能力已经可以满足流体流动的需求。不过,小粒径支撑剂沉降速度更小,液体能携带更远,支撑剂铺置剖面更均匀,有利于形成更长的支撑裂缝[9-11]。因此,综合考虑40/70目与20/40目支撑剂的最优组合比例为2∶1。

3.3 施工排量的优化

模拟计算了不同尺寸连续油管在不同排量下的环空流速,结果见表5。

表 5 不同尺寸连续油管在不同排量下的环空流速Table 5. Annular flow velocity of coiled tubings in different sizes under different flow rates排量/

(m3·min–1)不同尺寸连续油管对应环空流速/(m·s–1) ϕ58.4 mm ϕ50.8 mm ϕ43.2 mm 6.4 11.5 10.6 10.1 6.6 11.9 10.9 10.4 6.8 12.2 11.2 10.7 7.0 12.6 11.6 11.0 7.2 12.9 11.9 11.3 7.4 13.3 12.2 11.7 7.6 13.7 12.5 12.0 7.8 14.0 12.9 12.3 8.0 14.4 13.2 12.6 8.2 14.7 13.5 12.9 8.4 15.1 13.9 13.2 根据表5中数据,参考石油天然气行业标准《石油钻采高压管汇的使用、维护、维修与检测》(SY/T 6270—2012)高压管汇液体流速不大于12.2 m/s的要求,并考虑连续油管在水平段会发生螺旋屈曲、增大冲蚀等情况,设计安全系数为1.20,将ϕ58.4 mm连续油管最大施工排量优化为5.6 m3/min。

4. 现场应用

页岩油水平井细分切割压裂技术在长庆油田陇东地区10口井的长7段进行了应用,通过“精细分段、定点布缝”,达到了精准压裂、有效改造的效果,施工成功率100%,改造后增加了缝控储量,提高了单井产量。

其中,XP237井组投产时间最长,生产31个月,应用井XP237-72井有效储层长度和改造强度均比同平台邻井略低。但从XP237平台改造和投产数据对比数据(见表6)及XP237平台产油量曲线(见图7)可以看出:目前XP237-72井日产油量14.4 t,比邻井平均日产油量高15.6%;累计产油量17 633.6 t,比邻井平均累计产油量高39.5%。而从XP237平台含水曲线(见图8)可以看出,XP237-72井的含水率明显低于同平台邻井。

表 6 XP237平台各井改造和投产数据对比Table 6. Comparison of stimulation and production data of the wells on the Platform XP237井别 井号 投产时间 目前情况 改造工艺 段数 簇数 入地液量/

m3加砂量/

m3水平段

长度/m油层钻遇

率,%加砂强度/

(m3·m–1)进液强度/

(m3·m–1)油量/

t含水率,% 对比井 XP 237-71 2018/02/18 8.85 16.3 桥塞分段 31 67 29 660.6 3 261.3 2 237.0 79.8 1.8 16.6 XP 237-74 2018/08/03 17.53 25.8 22 62 26 418.5 3 321.4 1 876.0 85.3 2.1 16.5 XP 237-75 2018/08/19 8.62 33.7 26 67 28 779.0 3 102.7 1 682.3 79.3 2.3 21.6 XP 237-76 2018/08/19 14.78 18.5 18 58 22 676.4 2 842.8 1 934.6 87.1 1.7 13.4 应用井 XP 237-72 2018/05/21 14.39 19.2 细分切割 40 40 23 467.7 2 610.0 1 535.0 99.7 1.7 15.3 5. 结 论

1)针对长庆油田陇东地区页岩油储层脆性指数低、天然裂缝不发育、不易形成复杂缝网,以及采用分段多簇体积压裂时因受储层物性、地应力、各向异性及水力裂缝簇间干扰等因素影响导致簇间进液不均、达不到储层均匀改造目的的问题,研究了更具针对性的单段单簇细分切割压裂技术。

2)利用压裂优化设计及监测评价技术一体化平台,建立了页岩油水平井非均质地质模型;基于甜点空间分布优化压裂段数,形成了细分切割压裂设计方法。同时,优化了加砂量、砂比和排量等压裂施工参数,实现了细分切割压裂的充分改造。

3)长庆油田陇东地区页岩油水平井细分切割压裂技术已在现场应用10口井,采用“精细分段、定点布缝”压裂设计,借助连续油管底封拖动压裂工艺,对长7段储层进行了充分改造,改造效果明显优于邻井采用的常规压裂技术。

-

井号 测试层位 测试产量/(104m3·d–1) 备注 D7 石盒子组3段 3.17 非试验井 D10 4.04 非试验井 D15 21.08 试验井 DK2 38.87 试验井 D8 山西组2段 1.54 非试验井 D9 0.24 非试验井 D12 2.31 试验井 D13 7.03 试验井 注:气井均采用水平井加砂压裂+液氮伴注的投产方式。 表 2 塔里木盆地克深区块超深致密砂岩气藏储层保护效果[55]

Table 2 Protection effect of ultra-deep tight sandstone gas reservoirs in Keshen Block, Tarim Basin[55]

井号 测试井段/m 钻井液漏

失量/m3测试产气量/

(104m3·d–1)备注 KS907 7 509.00~7 635.00 3.40 94.87 试验井 KS905 7 540.00~7 720.00 13.90 96.64 试验井 KS901 7 910.00~7 930.00 242.40 0.74 非试验井 KS902 7 810.00~7 812.00 55.00 45.66 非试验井 KS903 7 559.00~7 641.20 222.41 63.44 非试验井 KS904 7 710.00~7 780.00 309.80 11.96 非试验井 表 3 化学成膜与物理暂堵技术协同保护储层效果[65]

Table 3 The reservoir protection effects of chemical filming and physical temporary plugging technologies[65]

井号 油气层

厚度/m油气井米采油指数/

(m3·m−1·MPa−1)增产

倍数备注 中30-斜更533 10.5 0.0952 2.11 试验井 中31-更533 7.3 0.4520 非试验井 中32-斜533 15.0 0.5800 1.28 试验井 中31-斜533 7.3 0.4520 非试验井 中30-斜更528 19.1 0.7330 8.63 试验井 中31-斜529 15.3 0.0850 非试验井 表 4 四川盆地邛西构造须2段致密砂岩气藏储层保护效果

Table 4 Protection effect of Xu 2 tight sandstone gas reservoir in Qiongxi structure, Sichuan Basin

井号 井深/m 完井方式 测试产量/(104m3·d–1) 钻井方法 邛西1 4 450 射孔完井 0.07 常规过平衡 邛西2 3 900 加砂压裂 0.52 邛西3 3 572 先期裸眼 45.67 全过程欠平衡 邛西4 3 852 衬管完井 89.34 -

[1] 邹才能,潘松圻,荆振华,等. 页岩油气革命及影响[J]. 石油学报, 2020, 41(1): 1–12. doi: 10.1038/s41401-019-0299-4 ZOU Caineng, PAN Songqi, JING Zhenhua, et al. Shale oil and gas revolution and its impact[J]. Acta Petrolei Sinica, 2020, 41(1): 1–12. doi: 10.1038/s41401-019-0299-4

[2] 邹才能,潘松圻,赵群. 论中国“能源独立”战略的内涵、挑战及意义[J]. 石油勘探与开发, 2020, 47(2): 416–426. ZOU Caineng, PAN Songqi, ZHAO Qun. On the connotation, challen-ges and significance of China’s“energy independence”strategy[J]. Petroleum Exploration and Development, 2020, 47(2): 416–426.

[3] 罗平亚,康毅力,孟英峰. 我国储层保护技术实现跨越式发展[J]. 天然气工业, 2006, 26(1): 84–87. LUO Pingya, KANG Yili, MENG Yingfeng. China’s reservoir protection technologies develop in leaps[J]. Natural Gas Industry, 2006, 26(1): 84–87.

[4] ZHANG Dujie, KANG Yili, YOU Lijun, et al. Investigation of formation damage induced during drill-in process of ultra-deep fractured tight sandstone gas reservoirs[J]. Journal of Energy Resources Technology, 2018, 141(7): 1–11.

[5] 康毅力,罗平亚. 中国致密砂岩气藏勘探开发关键工程技术现状与展望[J]. 石油勘探与开发, 2007, 34(2): 239–245. KANG Yili, LUO Pingya. Current status and prospect of key techniques for exploration and production of tight sandstone gas reservoirs in China[J]. Petroleum Exploration and Development, 2007, 34(2): 239–245.

[6] BENNION D B. An overview of formation damage mechanisms causing a reduction in the productivity and injectivity of oil and gas producing formations[J]. Journal of Canadian Petroleum Technology, 2002, 44(11): 29–36.

[7] XU Chengyuan, KANG Yili, YOU Zhenjiang, et al. Review on formation damage mechanisms and processes in shale gas reservoir: known and to be known[J]. Journal of Natural Gas Science and Engineering, 2016, 36: 1208–1219. doi: 10.1016/j.jngse.2016.03.096

[8] 徐同台, 熊友明, 康毅力.保护油气层技术[M].3版.北京: 石油工业出版社, 2010. XU Tongtai, XIONG Youming, KANG Yili. Technology for protecting oil and gas layers[M]. 3rd ed. Beijing: Petroleum Industry Press, 2010.

[9] CIVAN F. Reservoir formation damage[M]. 2nd ed. London: Gulf Professional Publishing, 2015.

[10] 康毅力,罗平亚. 储层保护系统工程:实践与认识[J]. 钻井液与完井液, 2007, 24(1): 1–7. KANG Yili, LUO Pingya. System engineering of reservoir preservation: practice and theory[J]. Drilling Fluid & Completion Fluid, 2007, 24(1): 1–7.

[11] KANG Yili, XU Chengyuan, YOU Lijun, et al. Comprehensive evaluation of formation damage induced by working fluid loss in fractured tight gas reservoir[J]. Journal of Natural Gas Science and Engineering, 2014, 18: 353–359. doi: 10.1016/j.jngse.2014.03.016

[12] WANG Hanyi. What factors control shale-gas production and production-decline trend in fractured systems: a comprehensive analysis and investigation[J]. SPE Journal, 2017, 22(2): 562–581. doi: 10.2118/179967-PA

[13] CUI Q, ABASS H H. Experimental study of permeability decline in tight formations during long-term depletion[R]. SPE 180257, 2016.

[14] LIANG Tianbo, GU Fuyang, YAO Erdong, et al. Formation damage due to drilling and fracturing fluids and its solution for tight naturally fractured sandstone reservoirs[J/OL]. Geofluids, 2017[2020-03-20]. https://doi.org/10.1155/2017/9350967.

[15] 黄维安,邱正松,岳星辰,等. 页岩气储层损害机制及保护水基钻完井液技术[J]. 中国石油大学学报(自然科学版), 2014, 38(3): 99–105. HUANG Weian, QIU Zhengsong, YUE Xingchen, et al. Damage mechanism and water-based drilling fluid protection technology for shale gas reservoir[J]. Journal of China University of Petroleum (Edition of Natural Science), 2014, 38(3): 99–105.

[16] RAHMAN M K, SUAREZ Y A, CHEN Z, et al. Unsuccessful hydraulic fracturing cases in Australia: investigation into causes of failures and their remedies[J]. Journal of Petroleum Science and Engineering, 2007, 57(1/2): 70–81. doi: 10.1016/j.petrol.2005.07.009

[17] 康毅力,杨斌,游利军,等. 油基钻井完井液对页岩储层保护能力评价[J]. 天然气工业, 2013, 33(12): 99–104. KANG Yili, YANG Bin, YOU Lijun, et al. Damage evaluation of oil-based drill-in fluids to shale reservoirs[J]. Natural Gas Industry, 2013, 33(12): 99–104.

[18] XU Chengyuan, KANG Yili, YOU Lijun, et al. Lost-circulation control for formation-damage prevention in naturally fractured reservoir: mathematical model and experimental study[J]. SPE Journal, 2017, 22(5): 1654–1670. doi: 10.2118/182266-PA

[19] 许成元,闫霄鹏,康毅力,等. 深层裂缝性储集层封堵层结构失稳机理与强化方法[J]. 石油勘探与开发, 2020, 47(2): 399–408. XU Chengyuan, YAN Xiaopeng, KANG Yili, et al. Structural failure mechanism and strengthening method of plugging zone in deep naturally fractured reservoirs[J]. Petroleum Exploration and Development, 2020, 47(2): 399–408.

[20] XU Chengyuan, YOU Zhenjiang, KANG Yili, et al. Stochastic modelling of particulate suspension transport for formation damage prediction in fractured tight reservoir[J]. Fuel, 2018, 221: 476–490. doi: 10.1016/j.fuel.2018.02.056

[21] 许成元,康毅力,游利军,等. 裂缝性储层渗透率返排恢复率的影响因素[J]. 石油钻探技术, 2012, 40(6): 17–21. XU Chengyuan, KANG Yili, YOU Lijun, et al. Influential factors on permeability recovery during flowback of fractured reservoirs[J]. Petroleum Drilling Techniques, 2012, 40(6): 17–21.

[22] ZHANG Dujie, KANG Yili, SELVADURAI A P S, et al. The role of phase trapping on permeability reduction in an ultra-deep tight sandstone gas reservoirs[J]. Journal of Petroleum Science and Engineering, 2019, 178: 311–323. doi: 10.1016/j.petrol.2019.03.045

[23] ZHANG Hao, ZHONG Ying, KURU E, et al. Impacts of permeability stress sensitivity and aqueous phase trapping on the tight sandstone gas well productivity: a case study of the Daniudi Gas Field[J]. Journal of Petroleum Science and Engineering, 2019, 177: 261–269. doi: 10.1016/j.petrol.2019.02.044

[24] 张涛,李相方,王永辉,等. 页岩储层特殊性质对压裂液返排率和产能的影响[J]. 天然气地球科学, 2017, 28(6): 828–838. ZHANG Tao, LI Xiangfang, WANG Yonghui, et al. Study on the effect of gas-shale reservoir special properties on the fracturing fluidrecovery efficiency and production performance[J]. Natural Gas Geoscience, 2017, 28(6): 828–838.

[25] 刘乃震,柳明,张士诚. 页岩气井压后返排规律[J]. 天然气工业, 2015, 35(3): 50–54. LIU Naizhen, LIU Ming, ZHANG Shicheng. Flowback patterns of fractured shale gas wells[J]. Natural Gas Industry, 2015, 35(3): 50–54.

[26] GHANBARI E, ABBASI M A, DEHGHANPOUR H, et al. Flowback volumetric and chemical analysis for evaluating load recovery and its impact on early-time production[R]. SPE 167165, 2013.

[27] MIRZAEI-PAIAMAN A, MASIHI M, MOGHADASI J. Formation damage through aqueous phase trapping: a review of the evaluating methods[J]. Petroleum Science and Technology, 2011, 29(11): 1187–1196. doi: 10.1080/10916460903551073

[28] PHAN T, KAZEMPOUR M, NGUYEN D, et al. Treating liquid banking problem to increase shale gas wells productivity[R]. SPE 189523, 2018.

[29] PENG Yan, QU Hongyan, LIU Jishan, et al. Impact of fluid adsorption on geomechanical properties of shale gas reservoir and shale gas recovery rate[R]. ARMA-2018-342, 2018.

[30] ZHANG Junjing, OUYANG Liangchen, ZHU Ding, et al. Experimental and numerical studies of reduced fracture conductivity due to proppant embedment in the shale reservoirs[J]. Journal of Petroleum Science and Engineering, 2015, 130: 37–45. doi: 10.1016/j.petrol.2015.04.004

[31] ZHANG Junjing, ZHU Ding, HILL A D. Water-induced damage to propped-fracture conductivity in shale formations[J]. SPE Production & Operations, 2016, 31(2): 334–343.

[32] SABOORIAN-JOOYBARI H, POURAFSHARY P. Potential severity of phase trapping in petroleum reservoirs: an analytical approach to prediction[J]. SPE Journal, 2017, 22(3): 863–874. doi: 10.2118/183631-PA

[33] BAHRAMI H, REZAEE R, CLENNELL B. Water blocking damage in hydraulically fractured tight sand gas reservoirs: an example from Perth Basin, Western Australia[J]. Journal of Petroleum Science and Engineering, 2012, 88/89: 100–106. doi: 10.1016/j.petrol.2012.04.002

[34] YOU Lijun, KANG Yili. Integrated evaluation of water phase trapping damage potential in tight gas reservoirs[R]. SPE 122034, 2009.

[35] PAGELS M, WILLBERG D M, EDELMAN E, et al. Quantifying fracturing fluid damage on reservoir rock to optimize production[R]. SPE 1578948, 2013.

[36] DING D Y, LANGOUËT H, JEANNIN L. Simulation of fracturing-induced formation damage and gas production from fractured wells in tight gas reservoirs[R]. SPE Production & Operations, 2013, 28(3): 13-22.

[37] ZOLFAGHARI A, DEHGHANPOUR H, NOEL M, et al. Laboratory and field analysis of flowback water from gas shales[J]. Journal of Unconventional Oil and Gas Resources, 2016, 14: 113–127. doi: 10.1016/j.juogr.2016.03.004

[38] NICOT J P, SCANLON B R, REEDY R C, et al. Source and fate of hydraulic fracturing water in the Barnett shale: a historical perspective[J]. Environmental Science & Technology, 2014, 48(4): 2464–2471.

[39] 游利军,谢本彬,杨建,等. 页岩气井压裂液返排对储层裂缝的损害机理[J]. 天然气工业, 2018, 38(12): 61–69. YOU Lijun, XIE Benbin, YANG Jian, et al. Mechanism of fracture damage induced by fracturing fluid flowback in shale gas reservoirs[J]. Natural Gas Industry, 2018, 38(12): 61–69.

[40] YANG Bin, ZHANG Hao, KANG Yili. In situ sequestration of a hydraulic fracturing fluid in Longmaxi shale gas formation in the Sichuan Basin[R]. Energy & Fuels, 2019, 33(8): 6983–6994.

[41] XU Chengyuan, LIN Chong, KANG Yili, et al. An experimental study on porosity and permeability stress-sensitive behavior of sandstone under hydrostatic compression: characteristics, mechanisms and controlling factors[J]. Rock Mechanics and Rock Engineering, 2018, 51: 2321–2338. doi: 10.1007/s00603-018-1481-6

[42] BAI Jiajia, KANG Yili, CHEN Zhangxin, et al. Changes in retained fracturing fluid properties and their effect on shale mechanical properties[J]. Journal of Natural Gas Science and Engineering, 2020, 75: 1–12.

[43] 唐建新, 腾俊洋, 张闯, 等. 层状含水页岩蠕变特性试验研究[J].岩土力学, 2018, 39(增刊1):33–41. TANG Jianxin, TENG Junyang, ZHANG Chuang, et al. Experimental study on creep characteristics of layered water bearing shale[J]. Rock and Soil Mechanics, 2018, 39(supplement 1): 33–41.

[44] CHEN Tianyu, FENG Xiating, CUI Guanglei, et al. Experimental study of permeability change of organic-rich gas shales under high effective stress[J]. Journal of Natural Gas Science and Engineering, 2019, 64: 1–14. doi: 10.1016/j.jngse.2019.01.014

[45] SLIM M, HOFMANN R, SAXENA N, et al. Impact of mineralogy on creep properties and production decline rates[R].ARMA-2019-2065, 2019.

[46] ZHANG Dujie, KANG Yili, YOU Lijun, et al. Investigation of multi-scale approach for damage control in ultra-deep tight sandstone gas reservoirs based on the multi-scale formation damage mechanisms[R]. IPTC 19254, 2019.

[47] 罗向东,罗平亚. 屏蔽式暂堵技术在储层保护中的应用研究[J]. 钻井液与完井液, 1992, 9(2): 19–27. LUO Xiangdong, LUO Pingya. Protecting oil reservoir with temporary shielding method[J]. Drilling Fluid & Completion Fluid, 1992, 9(2): 19–27.

[48] 蒋官澄,鄢捷年,王富华,等. 新型屏蔽暂堵技术在大宛齐地区的应用[J]. 石油钻探技术, 1999, 27(6): 21–23. JIANG Guancheng, YAN Jienian, WANG Fuhua, et al. Applications of temporary plugging techniques in Dawanqi Area[J]. Petroleum Drilling Techniques, 1999, 27(6): 21–23.

[49] 蒋官澄,胡成亮,熊英,等. 广谱“油膜”暂堵钻井液体系研究[J]. 中国石油大学学报(自然科学版), 2006, 30(4): 53–57. JIANG Guancheng, HU Chengliang, XIONG Ying, et al. Study on system of broad-spectrum oil-film temporary plugging drilling fluid[J]. Journal of China University of Petroleum(Edition of Natural Science), 2006, 30(4): 53–57.

[50] 李志勇,鄢捷年,王友兵,等. 保护储层钻井液优化设计新方法及其应用[J]. 钻采工艺, 2006, 29(2): 85–87. LI Zhiyong, YAN Jienian, WANG Youbing, et al. New optimized design method and application of drilling fluid used for formation damage control[J]. Drilling & Production Technology, 2006, 29(2): 85–87.

[51] 鄢捷年,赵胜英,王兆霖,等. 理想充填油气层保护技术在青海油田深探井中的应用[J]. 石油钻探技术, 2007, 35(4): 53–55. YAN Jienian, ZHAO Shengying, WANG Zhaolin, et al. Application of formation damage control technology based on ideal packingtheory to deep exploration wells in Qinghai Oilfield[J]. Petroleum Drilling Techniques, 2007, 35(4): 53–55.

[52] 吕开河,邱正松,王在明. 自适应屏蔽暂堵钻井液技术[J]. 中国石油大学学报(自然科学版), 2008, 32(2): 68–71. LV Kaihe, QIU Zhengsong, WANG Zaiming. Techniques of auto-adapting shielding and temporary plugging drilling fluid[J]. Journal of China University of Petroleum(Edition of Natural Science), 2008, 32(2): 68–71.

[53] KANG Yili, XU Chengyuan, YOU Lijun, et al. Temporary sealing technology to control formation damage induced by drill-in fluid loss in fractured tight gas reservoir[J]. Journal of Natural GasScience and Engineering, 2014, 20: 67–73. doi: 10.1016/j.jngse.2014.06.016

[54] 闫丰明,康毅力,孙凯,等. 裂缝–孔洞型碳酸盐岩储层暂堵性堵漏机理研究[J]. 石油钻探技术, 2011, 39(2): 81–85. YAN Fengming, KANG Yili, SUN Kai, et al. Mechanism oftemporary sealing for fractured-vuggy carbonate reservoir[J]. Petroleum Drilling Techniques, 2011, 39(2): 81–85.

[55] SELVADURAI A P S, ZHANG Dujie, KANG Yili. Permeability evolution in natural fractures and their potential influence on loss of productivity in ultra-deep gas reservoirs of the Tarim Basin, China[J]. Journal of Natural Gas Science and Engineering, 2018, 58: 162–177. doi: 10.1016/j.jngse.2018.07.026

[56] 朱金智,游利军,李家学,等. 油基钻井液对超深裂缝性致密砂岩气藏的保护能力评价[J]. 天然气工业, 2017, 37(2): 62–68. ZHU Jinzhi, YOU Lijun, LI Jiaxue, et al. Damage evaluation on oil-based drill-in fluids for ultra-deep fractured tight sandstone gas reservoirs[J]. Natural Gas Industry, 2017, 37(2): 62–68.

[57] 蒋官澄,马先平,纪朝凤,等. 广谱“油膜”暂堵剂在油层保护技术中的应用[J]. 应用化学, 2007, 24(6): 665–669. JIANG Guancheng, MA Xianping, JI Chaofeng, et al. Application of a broad-spectrum oil-film temporary plugging agent to reservoir protection[J]. Chinese Journal of Applied Chemistry, 2007, 24(6): 665–669.

[58] 孙金生.水基钻井液成膜技术研究[D].成都: 西南石油大学, 2006. SUN Jinsheng. Research on film-forming technology of water-based drilling fluid[D]. Chengdu: Southwest Petroleum University, 2006.

[59] 王伟吉,邱正松,暴丹,等. 温压成膜封堵技术研究及应用[J]. 特种油气藏, 2015, 22(1): 144–147. WANG Weiji, QIU Zhengsong, BAO Dan, et al. Warm-compaction film-forming plugging and its application[J]. Special Oil & Gas Reservoirs, 2015, 22(1): 144–147.

[60] 袁春,孙金声,王平全,等. 抗高温成膜降滤失剂CMJ-1的研制及其性能[J]. 石油钻探技术, 2004, 32(2): 30–32. YUAN Chun, SUN Jinsheng, WANG Pingquan, et al. Development of CMJ-1: a high temperature film-forming fluid loss additive and the properties[J]. Petroleum Drilling Techniques, 2004, 32(2): 30–32.

[61] 蒋官澄,毛蕴才,周宝义,等. 暂堵型保护油气层钻井液技术研究进展与发展趋势[J]. 钻井液与完井液, 2018, 35(2): 1–16. JIANG Guancheng, MAO Yuncai, ZHOU Baoyi, et al. Progress made and trend of development in studying on temporarily type plugging reservoir protection drilling fluids[J]. Drilling Fluid & Completion Fluid, 2018, 35(2): 1–16.

[62] MOHAMMADI M K, NOWTARKI K T, GHALAMBOR A. Successful application of non-damaging drill-in-fluids proves oil production improvement in heavy oil reservoirs[R]. SPE 199326, 2020.

[63] 孙金声,苏义脑,罗平亚,等. 超低渗透钻井液提高地层承压能力机理研究[J]. 钻井液与完井液, 2005, 22(5): 1–3. SUN Jinsheng, SU Yinao, LUO Pingya, et al. Mechanism study on ultra-low invasion drilling fluid for improvement of formation pressure-bearing ability[J]. Drilling Fluid & Completion Fluid, 2005, 22(5): 1–3.

[64] 孙金声,唐继平,张斌,等. 几种超低渗透钻井液性能测试方法[J]. 石油钻探技术, 2005, 33(6): 25–27. SUN Jinsheng, TANG Jiping, ZHANG Bin, et al. Methods for testing properties of ultra-low permeable drilling fluid[J]. Petroleum Drilling Techniques, 2005, 33(6): 25–27.

[65] JIANG Guancheng, XUAN Yang, WU Xianzhu, et al. Method for preparation of biomimetic polymer for stabilizing wellbore and drilling fluid: US9410068[P]. 2016-08-09.

[66] 谢晓永,孟英峰,唐洪明,等. 裂缝性低渗砂岩气藏水基钻井液欠平衡钻井储层保护[J]. 石油钻探技术, 2008, 36(5): 51–53. XIE Xiaoyong, MENG Yingfeng, TANG Hongming, et al. Underbalanced water based mud to protect fractured tight sandstone gas reservoirs[J]. Petroleum Drilling Techniques, 2008, 36(5): 51–53.

[67] 胡进科,李皋,孟英峰. 页岩气钻井过程中的储层保护[J]. 天然气工业, 2012, 32(12): 66–70. HU Jinke, LI Gao, MENG Yingfeng. Reservoir protection in the process of shale gas drilling[J]. Natural Gas Industry, 2012, 32(12): 66–70.

[68] 李皋,孟英峰,钟水清,等. MRC井与UBD相结合的技术潜力研究[J]. 钻采工艺, 2010, 33(1): 28–30. LI Gao, MENG Yingfeng, ZHONG Shuiqing, et al. Technical research on combination of MRC well and UBD technology[J]. Drilling & Production Technology, 2010, 33(1): 28–30.

[69] 刘雪芬,康毅力,罗平亚,等. 界面修饰对致密砂岩气藏微孔系统渗流的调控[J]. 油田化学, 2015, 32(1): 137–140. LIU Xuefen, KANG Yili, LUO Pingya, et al. Seepage regulation of micro-pore system in tight sandstone gas reservoirs by interfacial modification[J]. Oilfield Chemistry, 2015, 32(1): 137–140.

[70] 刘雪芬,康毅力,罗平亚,等. 氟化物对致密砂岩气体渗流能力的影响[J]. 石油学报, 2015, 36(8): 995–1003. LIU Xuefen, KANG Yili, LUO Pingya, et al. Impact of fluoride on seepage ability of tight sandstone[J]. Acta Petrolei Sinica, 2015, 36(8): 995–1003.

[71] 蒋官澄, 张县民, 王乐, 等.双阳离子氟碳表面活性剂及其制备方法和作为双疏型润湿反转剂的应用和钻井液及其应用: CN201710038133.1[P].2018-02-06. JIANG Guancheng, ZHANG Xianmin, WANG Le, et al. Double cation fluorocarbon surfactant and its preparation method and application as a double-phobic wetting inversion agent and drilling fluid and its application: CN201710038133.1[P]. 2018-02-06.

-

期刊类型引用(8)

1. 党永潮,梁晓伟,罗锦昌,张玉良,柴小勇,高赵伟,蒋勇鹏,焦众鑫. 国家示范工程陆相湖盆夹层型页岩油高效开发技术. 石油钻采工艺. 2024(02): 208-219 .  百度学术

百度学术

2. 寇园园,陈军斌,聂向荣,成程. 基于离散元方法的拉链式压裂效果影响因素分析. 石油钻采工艺. 2023(02): 211-222 .  百度学术

百度学术

3. 蒋廷学. 非常规油气藏新一代体积压裂技术的几个关键问题探讨. 石油钻探技术. 2023(04): 184-191 .  本站查看

本站查看

4. 胡文瑞,魏漪,鲍敬伟. 鄂尔多斯盆地非常规油气开发技术与管理模式. 工程管理科技前沿. 2023(03): 1-10 .  百度学术

百度学术

5. 张冕,陶长州,左挺. 页岩油华H100平台储层改造关键技术及实践. 钻采工艺. 2023(06): 53-58 .  百度学术

百度学术

6. 刘尧文,卞晓冰,李双明,蒋廷学,张驰. 基于应力反演的页岩可压性评价方法. 石油钻探技术. 2022(01): 82-88 .  本站查看

本站查看

7. 张矿生,唐梅荣,陶亮,杜现飞. 庆城油田页岩油水平井压增渗一体化体积压裂技术. 石油钻探技术. 2022(02): 9-15 .  本站查看

本站查看

8. 蒋廷学,周珺,廖璐璐. 国内外智能压裂技术现状及发展趋势. 石油钻探技术. 2022(03): 1-9 .  本站查看

本站查看

其他类型引用(3)

下载:

下载: