Key Drilling Technologies for the Ultra-Deep Well Manshen 1 in the Tarim Basin

-

摘要:

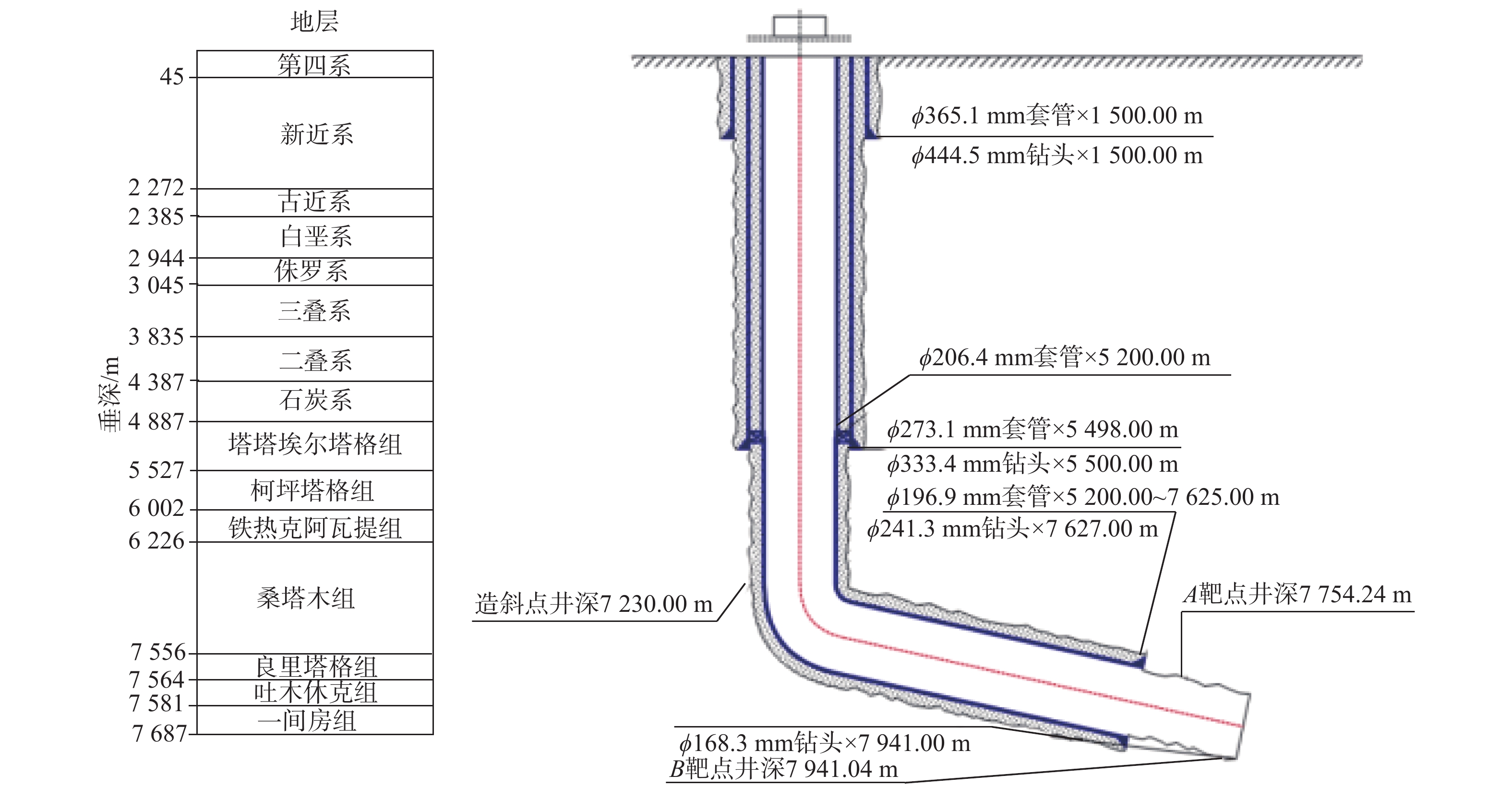

满深1井是位于塔里木盆地塔北隆起满深1号断裂带上的一口预探井,钻井过程中存在二叠系玄武岩漏失与垮塌同存,志留系塔塔埃尔塔格组可钻性差、钻头磨损快,奥陶系桑塔木组易井斜与井壁失稳垮塌等技术难点。为此,研究应用了二叠系优快钻井技术、志留系减振提速技术和奥陶系防斜防塌技术,有效解决了该井面临的钻井技术难点:应用混合钻头+螺杆钻具提速技术一趟钻钻穿二叠系玄武岩地层,应用聚磺钻井液体系确保了二叠系地层的安全钻进,未发生漏失及垮塌等井下故障,与邻井相比机械钻速提高了265.96%;应用个性化PDC钻头+TorkBuster扭力冲击器一趟钻钻穿志留系地层,且钻进期间扭矩稳定、粘滑振动弱,减振提速效果明显;应用预弯曲动力学防斜钻具组合钻进奥陶系高陡地层,防斜打直效果明显;应用高性能防塌水基钻井液安全钻穿奥陶系硬脆性泥岩,井壁稳定效果显著。该井试油获得高产工业油流,实现了塔里木盆地超深层油气勘探的重大突破,形成的超深层碳酸盐岩钻井完井技术为塔里木油田深层油气勘探开发提供了技术支撑。

Abstract:Well Manshen 1 is a pre-exploration well deployed on the Manshen No. 1 fault zone of the Tabei uplift in the Tarim Basin. During the drilling process, this well suffered from both lost circulation and the collapse of Permian basalt. Further, the development of the well was challenged by poor drillability and rapid bit wear in Silurian Tataaiertage Formation, and the slanting and wellbore instability/collapse in Ordovician Santamu Formation. Through technical research, a series of technologies and interventions strategies such as Permian “2X Excellence” drilling, the Silurian vibration reduction and accelerated drilling, and the Ordovician anti-slanting/ collapse drilling were developed, which effectively solved those challenges. The application of hybrid drilling bit+ PDM fast drilling technology successfully penetrating Permian basalt in one trip; the application of polysulfonate drilling fluid system ensuring the safe drilling in Permian strata, and eliminating the downhole failures such as leakage and collapse. Compared with the adjacent wells, the ROP was increased by 265.96%; the customized PDC bit + TorkBuster torque impactor successfully penetrating Silurian strata in one trip, the torque was stable and the stick-slip vibration was weak during the drilling, and the effects of vibration reduction and speed up were clear. The application of pre-bending downhole motor BHA successfully allowed the drillbit to penetrae the Ordovician large dip-angle strata. In this, the anti-slanting effect was obvious; the application of high-performance anti-collapse water-based drilling fluid system safely drilling through the Ordovician hard and brittle mudstone, which achieved a remarkable borehole stabilization effect. This well achieved high-production industrial oil flow drilling oil testing, brought about a major breakthrough in ultra-deep oil and gas exploration of the Tarim Basin, and initially formed the ultra-deep carbonate drilling/completion technologies, which provided technical supports and best practice for the deep oil and gas exploration & development the of Tarim Oilfield.

-

随着陆地油田开发进入中后期,海洋油气田开发逐渐成为主要增长点,大位移水平井及丛式井技术能够高效开发远距离油气储层,但面临着水平段延伸极限与复杂地质条件带来的技术挑战[1]。其中,钻速优化是制约钻井效率的核心问题之一,高钻速不仅可以缩短钻井周期,还能显著降低整体的钻井成本[2]。然而,大位移井由于其长的水平段和复杂的地质条件,导致摩擦力和扭矩较大,使得提高钻速的任务变得更加艰巨[3]。传统钻速提升的方法涉及机械[4–5]、流体动力学[6]、地质分析[7]等方面。然而大位移井因摩擦力、扭矩剧增及地质不确定性,导致传统钻速提升手段在复杂工况下效果受限,亟需进行技术攻关研究。

近年来,机器学习技术在石油开发领域的应用给这一问题的解决提供了新的思路。2018年,G. Hegde等人[8]详细介绍了使用机器学习方法来预测和提高机械钻速的过程,将钻速预测模型划分为基于物理经验的模型、基于数据驱动的模型和混合模型三大类。郑双进等人[9]以井深、钻压、转速、流量等参数作为模型的输入参数,采用长短期记忆网络与改进的蜣螂优化算法相结合来预测钻速。伊鹏等人[10]将改进的自适应遗传算法应用于钻井参数的优化设计,根据实时钻井工程的需求,降低了钻井成本;刘星光等人[11]建立了一定约束条件下的多目标数学模型,采用改进蚁群算法进行钻井参数优化;刘兆年等人[12]利用反向传播神经网络结合遗传算法,得到了适用于渤海地区不同地层段的机器学习模型,实现了钻井速度的提升。

随着人工智能技术的快速发展,机器学习等智能方法在钻速预测和钻井参数优化中展现出了巨大的潜力[13–16]。其中,BP神经网络具有强大的非线性映射能力,可以用于处理复杂的预测问题[17–20]。同时,贝叶斯优化作为一种高效的全局优化算法,在处理复杂优化问题中的效率和稳定性,被广泛应用于各种工程优化场景[21–22]。然而,现有的钻井参数优化方法存在以下技术挑战:其一,传统模型对井眼轨迹动态特征的表征能力不足,难以适配大位移井的复杂井身结构;其二,优化算法在处理高维参数空间时易陷入局部最优,导致全局寻优效率受限。针对上述问题,笔者融合钻井参数与井眼轨迹参数,提出了一种集成机器学习模型与贝叶斯优化的钻速提升方法,不仅拓展了传统机器学习模型的输入维度,还为大位移井的智能化钻井提供了理论支撑,对降低海洋油气开发成本、提高作业效率具有工程实用价值。

1. 机器学习模型与贝叶斯优化算法原理

1.1 BP神经网络

BP 神经网络是一种根据误差反向传播训练的多层前馈网络,其主要特点是能够通过反向传播算法来调整网络的权重和偏置,从而使得网络能够逐渐逼近目标函数的最小值。BP 神经网络一般由输入层、隐藏层和输出层等3层组成,输入层接收输入数据,隐藏层处理输入数据并将结果传递给输出层,输出层生成网络的输出结果。

BP 神经网络的训练分为前向传播和反向传播2个阶段。假设BP神经网络的输入为X=(x1, x2, ..., xn),输出为Y=(y1, y2, ..., ym),其中n和m分别为输入和输出的神经元数,采用Sigmoid函数作为激活函数。BP神经网络隐藏层神经元j的输出Hj可表示为[23]:

Hj=Sigmoid(n∑l=1wljxlj+aj) (1) 式中:Hj为隐藏层神经元j的输出;wlj为输入层神经元l到隐藏层神经元j的权重;xlj为输入层神经元l到隐藏层神经元j的输入值;aj为隐藏层神经元j的偏置。

BP神经网络输出层神经元k的表达Gk为:

Gk=m∑j=1Hjwjk+bk (2) 式中:Gk为输出层神经元k的输出; wjk为隐藏层神经元j到输出层神经元k的权重;bk为输出层神经元k的偏置。

BP神经网络的总误差可表示为:

E=1mm∑k=1(Yk−Gk)2 (3) 式中:E为神经网络的总误差;Yk为期望输出。

BP神经网络的权重更新公式为:

{w∗lj=wlj+ηHj(1−Hj)xlm∑k=1wjk(Yk−Gk)w∗jk=wjk+ηHj(Yk−Gk) (4) 式中:

w∗lj 和w∗jk 分别为更新后的权重;η为学习率。BP神经网络中,前向传播通过逐层传递输入数据并计算神经元输出,最终生成预测结果;反向传播则基于预测与期望值的误差通过链式法则逐层反向传播误差信号,依据各神经元对误差的贡献动态调整网络权重和偏置。该过程通过反复迭代前向计算与误差反馈,使网络参数沿损失函数梯度方向持续优化,最终使预测输出逼近目标值,实现对输入数据的精准建模。

1.2 随机森林模型

随机森林算法以集成学习为核心框架,它通过构建多棵决策树来进行决策,最终将多个模型的输出结果进行投票或平均,从而得到一个更加稳定和准确的预测结果。随机森林通过以下步骤进行构建[24–25]:

1)随机采样。在训练阶段,将不同钻井参数和井眼轨迹参数作为输入变量,将钻速作为输出变量。随机森林采用自助采样法,从原始训练数据集中有放回地随机抽取多个子集。每个子集包含与原始数据集相同数量的样本,且允许单个样本在子集中重复出现,用于独立训练一棵决策树。

2)特征随机选择。每棵决策树的构建过程中,随机森林不仅在样本上进行随机抽样,还在每个节点分裂时随机选择一部分特征进行分裂,而不是使用所有的特征,这降低了树与树之间的相关性,提高了模型的泛化能力。

3)构建多棵决策树。对于每个从数据中抽取的子集,随机森林都会训练一棵决策树。每棵树的训练过程中,树的深度可以控制,通过递归分裂节点,直到节点纯度达到某个阈值或树的最大深度。

4)集成预测。在预测阶段,随机森林对每棵树的预测结果进行集成,将所有决策树的输出结果求得平均值,作为最终预测结果。

1.3 支持向量回归

支持向量回归(Support Vector Regression,SVR)核心思想是利用支持向量机的理论框架将数据映射到高维空间,并通过一个最优的超平面来进行回归预测[26]。支持向量回归的目标是找到一个函数

f(x) 来近似样本数据(xi,yi) ,使得该函数的预测误差尽可能小,并且模型的复杂度尽量低。SVR的目标是最小化以下目标函数:min (5) 式中:w为回归函数的权重;

{\xi _i} 和\xi _i^ * 为松弛变量,表示误差的大小;C为正则化参数,用于控制误差的惩罚;s为训练样本的数量。为了限制误差,SVR需要满足以下约束条件:

\left\{\begin{array}{*{20}{l}} {{y_i} - f\left( {{x_i}} \right)}&{ \leqslant \varepsilon + {\xi _i}} \\ {f\left( {{x_i}} \right) - {y_i}}&{ \leqslant \varepsilon + \xi _i^ * } \\ {\xi _i},\xi _i^ * &{{ \geqslant 0}} \end{array} \right. (6) 式中:

\varepsilon 为容忍度。为了处理非线性回归问题,SVR通过核函数将数据从低维空间映射到高维空间。常用的核函数包括线性核、径向基函数核和多项式核等。训练完成后,SVR的回归函数为:

f(x) = \mathop \sum \limits_{i = 1}^s {\alpha _i}K\left( {x,{x_i}} \right) + b (7) 式中:

{\alpha _i} 为拉格朗日乘子,通过对偶问题求解得到;K\left( {x,{x_i}} \right) 为核函数;b为偏置项。1.4 贝叶斯优化

贝叶斯优化算法(Bayesian Optimization)是一种基于概率模型的全局优化策略,主要用于优化高度非线性、非凸及没有解析梯度信息的目标函数[27]。贝叶斯算法结合贝叶斯推理和概率模型,构建目标函数的后验概率分布,并利用后验概率分布来指导搜索过程,从而获得问题的近似最优解。贝叶斯优化通常采用高斯过程作为其概率代理模型,可以预测函数在未探索区域的值及其不确定性。模型可表示为:

f(x) \sim GP\left( {m(x),k\left( {x,x'} \right)} \right) (8) 式中:

f(x) 为目标函数;m(x)为均值函数,通常可以假设为0;k\left( {x,x'} \right) 为协方差函数,描述了输入空间中点与点之间的相关性。采集函数用于基于当前代理模型的预测来决定下一个探索点,以优化目标函数。贝叶斯算法采集函数的迭代过程如图1所示。常用的采集函数包括期望改进、概率改进和贪婪下降。

基于期望改进的采集函数可以表示为:

EI(x)=\left(f\left(x^+\right)-\mu(x)\right)\text{ } \mathit{\Phi \text{ }}(Z)+\sigma(x)\phi(Z) (9) 其中\quad\qquad\quad Z = \frac{{f\left( {{x^ + }} \right) - \mu (x)}}{{\sigma (x)}} (10) 式中:EI (x)为期望采集函数;x+为当前已知的最佳输入;f (x+)为当前观测到的最佳目标函数值;μ(x)和σ(x)分别为代理模型在点x的预测均值和标准差;Φ和ϕ分别为标准正态分布的累计分布函数和概率密度函数;Z为归一化得分,表示相对于目前最佳观测的改进幅度,当Z值为正时,意味着预测的改进大于0,即模型预测该点的性能优于目前已知最佳性能。

贝叶斯优化时需要先选定一组初始参数对其进行评估,并建立初始的高斯过程模型。每次迭代时采集函数分析当前模型,并确定新的参数点,以进行测试,这些点预计会带来最大的目标函数改进。通过这种方式,模型逐渐聚焦于那些能显著提高钻速的参数区域,从而在较少的迭代次数内找到近似最优解。

2. 数据集预处理

海上大位移井钻进过程中,大位移井的井眼轨迹通常包括较长的水平钻进段,并且在不同井深和水平距离处的钻井参数也不同,这些因素共同作用,使得井下摩擦力大大增加,限制了钻井效率[28]。大位移井的水平位移、井深、井斜角和方位角等参数通常比常规井更为极端,因此,大位移井的特点在很大程度上体现在其井眼轨迹参数之中。因此,采用A区块5口井的钻井数据和井眼轨迹数据,包括井深、井斜角、方位角、狗腿度、水平位移、大钩载荷、钻压、转盘转速、排量等参数。

建立钻速预测模型前,为了确保数据质量,提高分析结果的可靠性和精确性,需要进行适当的数据预处理。数据预处理包括缺失值处理、数据滤波、数据归一化和相关性分析等。

2.1 缺失值处理和归一化

数据集中的缺失值会严重影响模型的性能和预测的准确性,因此,需要进行缺失值处理来保证数据的质量。采用两级处理策略:首先,对缺失比例超过30%的特征或存在多数特征值缺失的样本直接执行删除操作,以避免因信息残缺导致的建模偏差;其次,针对低缺失率特征,通过相邻数据点的分布规律运用插值法推断缺失值,该方法基于局部数据关联性构建估算模型,在保留数据完整性的同时,提升了特征可用性。该组合策略通过阈值判断与关系建模的平衡,可以解决缺失值引发的噪声干扰与样本偏态问题。

由于钻井数据集中存在不同的度量单位或量纲,导致特征之间的数值差异较大。在这种情况下,某些特征的数值范围较大,可能会主导模型的结果,而其他特征的影响可能会被弱化甚至忽略。为了解决数据量纲问题,常见的方法是进行特征缩放或标准化。特征缩放的目的是将不同量纲的特征转化为相似的数值范围,以消除量纲之间的差异。本文采用最小−最大缩放的方法对数据进行归一化,同时对数据进行 Z-score 标准化,计算公式为:

{X_{\mathrm{N}}} = \frac{{x - {x_{\min }}}}{{{x_{\max }} - {x_{\min }}}} (11) {X_{\mathrm{S}}} = \frac{{x - \mu }}{\sigma } (12) 式中:x为初始值;XN为归一化后的值;XS为标准化后的值;xmin为数据中的最小值;xmax为数据中的最大值;μ为数据平均值;σ为数据标准差。

2.2 数据降噪

针对钻井数据在数字电路传输过程中因高频信号干扰产生的异常噪声问题[29],本研究采用加权移动平均滤波算法进行信号优化。该方法通过动态权重分配机制改进传统移动平均算法,基于局部窗口内数据点的最小二乘多项式拟合实现平滑处理。与传统算法采用均匀权重计算均值不同,加权移动平均滤波依据数据时序特性赋予近期采样点更高权重,通过非线性权重衰减函数更精准地捕捉信号变化趋势,在抑制高频噪声的同时保留了数据动态特征,从而显著提升了现场监测数据的信噪比和可用性。该滤波器的信号处理原理为:

y(t)=\frac{\displaystyle\sum\limits_{a=0}^{c-1}w_a\cdot x(t-a)}{\displaystyle\sum\limits_{a=0}^{n-1}w_a} (13) 式中:x(t)为原始数据值;y(t) 为降噪后的信号;c为窗口大小;wa为分配给每个数据点的权重,常见的权重分配方式包括线性权重和指数权重等。

加权移动平均滤波的效果高度依赖窗口尺寸选择,该参数直接决定参与均值计算的连续数据点范围。采用滤波窗口大小为5的线性加权移动平均滤波器进行数据的去噪。钻压数据的降噪效果对比如图2所示。

2.3 相关性分析

为量化不同参数与机械钻速间的关联强度,采用皮尔森相关系数进行相关性分析,通过协方差与标准差比值衡量变量间线性相关程度,取值区间为[−1, 1],绝对值越接近1,相关性越强,0表示无线性相关性。其数学表达式为:

r = \frac{{ \displaystyle\sum \nolimits_{h = 1}^N \left( {{X_h} - \bar X} \right)\left( {{Y_h} - \bar Y} \right)}}{{\sqrt { \displaystyle\sum \nolimits_{h = 1}^N {{\left( {{X_h} - \bar X} \right)}^2} \displaystyle\sum \nolimits_{h = 1}^n {{\left( {{Y_h} - \bar Y} \right)}^2}} }} (14) 式中:r为皮尔森相关系数;Xh和Yh为样本值;

\bar X 和\bar Y 是变量X和Y的均值;N为样本数量。对模型输入参数进行相关性分析,分析结果如图3所示。由图3可知,各类参数与机械钻速之间大多呈负相关关系,特别是井深、垂深、井斜角、水平位移、纯钻时间、泵送时间和大钩载荷等参数对机械钻速有显著的负面影响。此外,钻压、转盘转速、扭矩、立管压力与机械钻速间也呈较高的相关性,反映了这些参数在钻井过程中的强关联作用。同时,狗腿度、排量等参数与钻速的相关性较小。但实际钻井过程中,钻速受到多种因素的综合影响,这些因素可能相互作用,单一因素的影响可能被其他因素的影响所掩盖,因此,低相关性并不一定意味着该特征不重要,这些因素可能在特定的条件组合或交互作用中才显现出重要性。因此,仍将其作为预测模型的输入参数,以增强模型预测能力。

3. 预测与优化结果

基于A区块5口井的实测数据构建预测模型,数据包含井深500~4 000 m范围的深度、钻压、转盘转速、泵压、井斜角及水平位移等多维度钻井参数。数据经标准化处理后,按比例7∶3划分为训练集与测试集,用于验证模型预测效果。通过对比3种模型的泛化性能,筛选最优钻速预测方法。

针对模型超参数优化问题,采用网格搜索法穷举遍历预设参数组合,系统评估不同配置对预测精度的影响,确保在全局参数空间内找到最优模型配置,从而提升预测可靠性。BP神经网络经网格搜索后,确定学习率为0.01,训练次数为1 000次,采用Sigmoid激活函数与Adam优化器;随机森林模型通过参数寻优选择100棵决策树,限制最大深度为10,设置节点最小分割样本数2,并采用基尼不纯度作为分裂标准;支持向量机经网格搜索后,确定RBF核函数配合正则化参数C=1.0,核参数γ=0.1,在模型复杂度与泛化能力间达到最优平衡。

3.1 预测结果对比

对于回归预测任务,评价指标主要用于量化模型的预测结果与真实值之间的偏离程度。采用决定系数(R2)、均方误差(MSE)、平均绝对误差(MAE)和均方根误差(RMSE)等4个核心性能指标综合评估预测效果,3种机器学习算法钻速预测的评价指标如表1所示。

表 1 预测模型评价指标Table 1. Evaluation Metrics for Prediction Models算法 决定系数 平均绝对误差 均方误差 均方根误差 BP神经网络 0.883 4.81 57.64 7.59 随机森林 0.838 5.59 69.95 8.36 支持向量机 0.680 8.79 215.25 14.67 从表1可以看出,BP神经网络优势显著,决定系数为0.883,且均方误差与平均绝对误差均低于随机森林和支持向量回归。由于支持向量回归对特征空间维度敏感,特征空间较大时容易产生过拟合或欠拟合;随机森林在处理高维复杂数据时,树结构与深度等参数的不当配置可能限制了其拟合能力。相比之下,BP神经网络有较强的非线性映射能力,能够有效捕捉各参数与钻速间的复杂关系。BP神经网络的钻速预测效果如图4所示。

由图4可知,大部分井深区间的BP神经网络预测值与实际值非常接近,显示出较好的拟合度;尤其是井深较大区段,预测结果误差更小。因此,选择BP神经网络作为核心预测模型,并结合优化算法进一步优化钻井参数。

3.2 优化模型建立

钻速直接关联钻井效率与经济性[30],因此以钻速最大化作为核心优化目标。钻压决定着钻头破碎岩石的接触效率,转速影响着钻进速率与钻头磨损平衡,排量影响井底清洁与冷却效果,三者均通过物理作用机制显著影响钻速,因此选取钻压、转速和排量作为关键决策变量。设定约束条件为:钻压需介于门限值与钻机最大提供值之间,转速需符合钻头型号设计范围,排量不得超过泵送系统最大容量,以确保参数组合在设备物理限制与地质条件约束下具备工程可行性。通过优化这3个可控参数,可在满足操作安全规范的前提下提升钻速。该优化模型可以表示为:

\begin{gathered}\max v_{\mathrm{ROP}}=\max f(W,n,Q) \\ ^{^{^{ }}}\mathrm{s.t.}\left\{\begin{array}{*{20}{l}}M < W\leqslant W_{\text{max }},M > 0 \\ 0 < W\leqslant W_{\text{max }},M < 0 \\ n_{\text{min}} < n\leqslant n_{\text{max }} \\ 0 < Q\leqslant Q_{\text{max }}\end{array}\right. \\ \end{gathered} (15) 式中:vROP为钻速,m/h;M为门限钻压,kN;W,Wmax 分别为钻压和钻压允许调节的最大值,kN;n, nmin和nmax为转盘转速和转速允许调节的最小值与最大值,r/min;Q,Qmax 分别为泵排量及最大泵排量,L/s。

3.3 优化效果展示

贝叶斯优化是一种基于概率模型的全局优化方法,特别适用于优化计算迭代复杂或无法直接导出的目标函数。在本研究中,采用贝叶斯优化来调整钻井参数,以最大化钻速。井深1 700~1 800 m处钻速偏低,且变化波动较大,因此选择该井段进行钻井参数优化。为明确优化效果,每间隔1 m井深选取一个实时点进行优化,该井段长100 m,共计101个点进行优化,优化结果如图5和图6所示。

由图5和图6可知,1 700~1 800 m井段的机械钻速提升较大,尤其在1 720 m以深的优化效果逐渐显著。其中,

1735 ~1800 m井段提升效果明显,多数情况下钻速提升了20%~40%,部分区域甚至超过50%。优化前后的钻速对比表明,该井段优化前平均机械钻速为 53.97 m/h,优化后平均机械钻速为64.15 m/h,平均提高 18.86%;钻速提升最大的点在1 769 m处,提升了106.96%,最小钻速提升点在1 715 m处,提升了2.64%。以上研究表明,通过调整优化钻压、转盘转速和排量等参数,钻速得到了显著提升,也验证了本文的优化措施在提高钻井效率和降低作业成本方面的有效性。4. 结论与建议

1)针对海上大位移井钻速提升问题,通过分析大位移井的钻井数据和井眼轨迹参数,揭示了钻压、转盘转速等关键参数与钻速之间的显著相关性,结合机器学习和贝叶斯优化算法,提出了一种钻速预测及钻井参数优化方法。

2)钻速预测模型对比研究中,BP神经网络相较于随机森林和支持向量机展现出更优的预测性能,其预测精度与稳定性均表现突出,尤其适用于大位移井复杂工况下机械钻速的精准预测。

3)求解钻井参数优化模型时,通过调整可控参数,机械钻速得到显著提升,优化后的钻速比优化前平均提高了18.86%。

4)受钻井数据获取条件限制(如传感器精度、传输稳定性等),实验数据集存在偏差与缺失,可能影响模型训练及预测精度,建议以后可通过扩大数据规模、引入多源优质数据等方式提升模型可靠性。

-

表 1 满深1井志留系塔塔埃尔塔格组钻头应用情况

Table 1 The application of bit in the Silurian Tataaiertage Formation of Well Manshen 1

PDC钻头型号 钻进井段/m 进尺/

m纯钻时间/

h机械钻速/

(m·h–1)DXS1654 4 885.00~4 918.00 33.00 11.0 3.00 DXS1654 4 918.00~4 975.00 57.00 19.0 3.00 KS1652DGRX 4 975.00~5 014.80 39.80 23.0 1.73 DXS1654 5 016.65~5 032.60 15.95 10.0 1.60 KS1652DGRX 5 032.60~5 124.59 91.99 17.0 5.40 KS1652DGRX 5 127.00~5 209.45 82.45 19.5 4.23 -

[1] 赵志国,白彬珍,何世明,等. 顺北油田超深井优快钻井技术[J]. 石油钻探技术, 2017, 45(6): 8–13. ZHAO Zhiguo, BAI Binzhen, HE Shiming, et al. Optimization of fast drilling technology for ultra-deep wells in the Shunbei Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(6): 8–13.

[2] 李大奇,康毅力,刘修善,等. 裂缝性地层钻井液漏失动力学模型研究进展[J]. 石油钻探技术, 2013, 41(4): 42–47. doi: 10.3969/j.issn.1001-0890.2013.04.010 LI Daqi, KANG Yili, LIU Xiushan, et al. Progress in drilling fluid loss dynamics model for fractured formations[J]. Petroleum Drilling Techniques, 2013, 41(4): 42–47. doi: 10.3969/j.issn.1001-0890.2013.04.010

[3] 胡大梁,严焱诚,李群生,等. 混合钻头在元坝须家河组高研磨性地层的应用[J]. 钻采工艺, 2013, 36(6): 8–12. doi: 10.3969/J.ISSN.1006-768X.2013.06.03 HU Daliang, YAN Yancheng, LI Qunsheng, et al. Application of hybrid drill bit in Xujiahe high abrasive formation of Yuanba Gas Field[J]. Drilling & Production Technology, 2013, 36(6): 8–12. doi: 10.3969/J.ISSN.1006-768X.2013.06.03

[4] 杨顺辉,武好杰,牛成成,等. 特种孕镶块加强PDC钻头的研制与试验[J]. 石油钻探技术, 2014, 42(6): 111–114. YANG Shunhui, WU Haojie, NIU Chengcheng, et al. Manufacture and application of PDC bit enhanced by special diamond-impregnatedsegment[J]. Petroleum Drilling Techniques, 2014, 42(6): 111–114.

[5] 陈星星. 混合钻头在涪陵页岩气田的应用[J]. 探矿工程(岩土钻掘工程), 2019, 46(10): 34–39. CHEN Xingxing. Application of hybrid drill bits in Fuling Shale Gas Field[J]. Exploration Engineering(Rock & Soil Drilling and Tunneling), 2019, 46(10): 34–39.

[6] 朱宽亮,周岩,胡中志. PDC-牙轮复合钻头在南堡油田大斜度井的应用[J]. 石油钻探技术, 2017, 45(6): 60–64. ZHU Kuanliang, ZHOU Yan, HU Zhongzhi. Application of a PDC-roller hybrid bit in highly-deviated wells of the Nanpu Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(6): 60–64.

[7] 孙源秀,邹德永,郭玉龙,等. 切削-犁削混合钻头设计及现场应用[J]. 石油钻采工艺, 2016, 38(1): 53–56. SUN Yuanxiu, ZOU Deyong, GUO Yulong, et al. Design and field application of plow-cutting PDC bit[J]. Oil Drilling & Production Technology, 2016, 38(1): 53–56.

[8] 林四元,李中,黄熠,等. 南海文昌区块深部地层旋转切削齿PDC钻头提速技术[J]. 石油钻探技术, 2017, 45(6): 65–69. LIN Siyuan, LI Zhong, HUANG Yi, et al. Technique for enhancing the rate of penetration through the application of a new PDC bit with rotary cutters in deep formations in the Wenchang Block[J]. Petroleum Drilling Techniques, 2017, 45(6): 65–69.

[9] 王滨,李军,邹德永,等. 适合强研磨性硬地层PDC-金刚石孕镶块混合钻头设计与应用[J]. 特种油气藏, 2018, 25(1): 169–176. doi: 10.3969/j.issn.1006-6535.2018.01.035 WANG Bin, LI Jun, ZOU Deyong, et al. Design and application of a PDC hybrid drill bit with impregnated diamond insert for the hard formation with strong abrasivity[J]. Special Oil & Gas Reservoirs, 2018, 25(1): 169–176. doi: 10.3969/j.issn.1006-6535.2018.01.035

[10] 张进双,张增宝,王学才. 刀翼式孕镶金刚石钻头设计及在哈山101井的应用[J]. 石油钻探技术, 2019, 47(5): 57–61. ZHANG Jinshuang, ZHANG Zengbao, WANG Xuecai. The design of blade type diamond-impregnated bit and it’s application in Well Hashan 101[J]. Petroleum Drilling Techniques, 2019, 47(5): 57–61.

[11] 彭齐,周英操,周波,等. 凸脊型非平面齿PDC钻头的研制与现场试验[J]. 石油钻探技术, 2020, 48(2): 49–55. doi: 10.11911/syztjs.2020035 PENG Qi, ZHOU Yingcao, ZHOU Bo, et al. Development and field test of a non-planar cutter PDC bit with convex ridges[J]. Petroleum Drilling Techniques, 2020, 48(2): 49–55. doi: 10.11911/syztjs.2020035

[12] 滕学清,白登相,杨成新,等. 塔北地区深井钻井提速配套技术及其应用效果[J]. 天然气工业, 2013, 33(7): 68–73. doi: 10.3787/j.issn.1000-0976.2013.07.012 TENG Xueqing, BAI Dengxiang, YANG Chengxin, et al. ROP enhancing technologies and their application in deep wells in the Northern Tarim Basin[J]. Natural Gas Industry, 2013, 33(7): 68–73. doi: 10.3787/j.issn.1000-0976.2013.07.012

[13] 李宁,周小君,周波,等. 塔里木油田HLHT区块超深井钻井提速配套技术[J]. 石油钻探技术, 2017, 45(2): 10–14. LI Ning, ZHOU Xiaojun, ZHOU Bo, et al. Technologies for fast drilling ultra-deep wells in the HLHT Block, Tarim Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(2): 10–14.

[14] 胡群爱,孙连忠,张进双,等. 硬地层稳压稳扭钻井提速技术[J]. 石油钻探技术, 2019, 47(3): 107–112. doi: 10.11911/syztjs.2019053 HU Qun’ai, SUN Lianzhong, ZHANG Jinshuang, et al. Technology for drilling speed increase using stable WOB/torque for hard formations[J]. Petroleum Drilling Techniques, 2019, 47(3): 107–112. doi: 10.11911/syztjs.2019053

[15] 汪为涛. 非均质地层锥形辅助切削齿PDC钻头设计与试验[J]. 石油钻探技术, 2018, 46(2): 58–62. WANG Weitao. Design and test of a new PDC bit with tapered auxiliary cutter for heterogeneous formations[J]. Petroleum Drilling Techniques, 2018, 46(2): 58–62.

[16] 王沫,杜欢,伊尔齐木,等. 顺南井区优快钻井技术[J]. 石油钻探技术, 2015, 43(3): 50–54. WANG Mo, DU Huan, Eerqm, et al. Optimal and fast drilling technology for Shunnan Block[J]. Petroleum Drilling Techniques, 2015, 43(3): 50–54.

[17] 吕晓平,李国兴,王震宇,等. 扭力冲击器在鸭深1井志留系地层的试验应用[J]. 石油钻采工艺, 2012, 34(2): 99–101. doi: 10.3969/j.issn.1000-7393.2012.02.027 LYU Xiaoping, LI Guoxing, WANG Zhenyu, et al. Experiment of Torkbuster on Well YS1 in Silurian Formation[J]. Oil Drilling & Production Technology, 2012, 34(2): 99–101. doi: 10.3969/j.issn.1000-7393.2012.02.027

[18] 孙起昱,张雨生,李少海,等. 钻头扭转冲击器在元坝10井的试验[J]. 石油钻探技术, 2010, 38(6): 84–87. doi: 10.3969/j.issn.1001-0890.2010.06.018 SUN Qiyu, ZHANG Yusheng, LI Shaohai, et al. Application of bit torsional impact generator in Well Yuanba 10[J]. Petroleum Drilling Techniques, 2010, 38(6): 84–87. doi: 10.3969/j.issn.1001-0890.2010.06.018

[19] 狄勤丰,朱卫平,姚建林,等. 预弯曲动力学防斜打快钻具组合动力学模型[J]. 石油学报, 2007, 28(6): 118–121. doi: 10.3321/j.issn:0253-2697.2007.06.024 DI Qinfeng, ZHU Weiping, YAO Jianlin, et al. Dynamic model of bottom hole assembly used in pre-bending dynamic vertical and fast drilling technology[J]. Acta Petrolei Sinica, 2007, 28(6): 118–121. doi: 10.3321/j.issn:0253-2697.2007.06.024

[20] 龙大清,樊相生,王昆,等. 应用于中国页岩气水平井的高性能水基钻井液[J]. 钻井液与完井液, 2016, 33(1): 17–21. LONG Daqing, FAN Xiangsheng, WANG Kun, et al. High performance water base drilling fluid for shale gas drilling[J]. Drilling Fluid & Completion Fluid, 2016, 33(1): 17–21.

下载:

下载: