Research and Field Test on Drilling Acceleration Technology with Hydraulic Torsional Impactor Combined with Hydraulic Boosters

-

摘要:

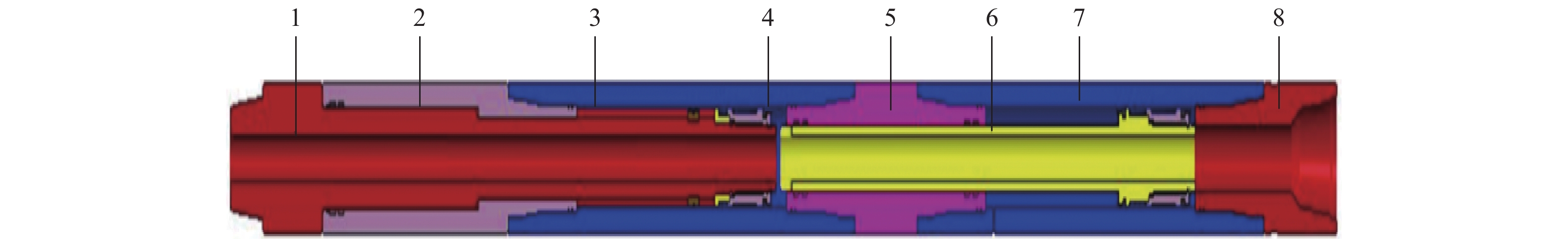

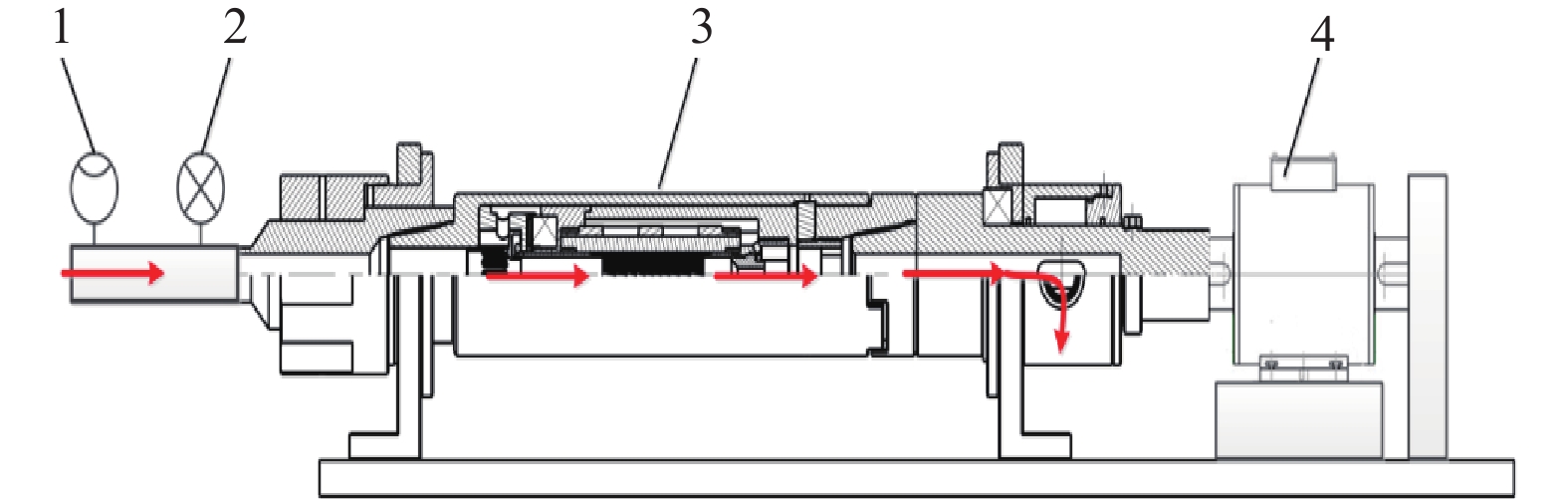

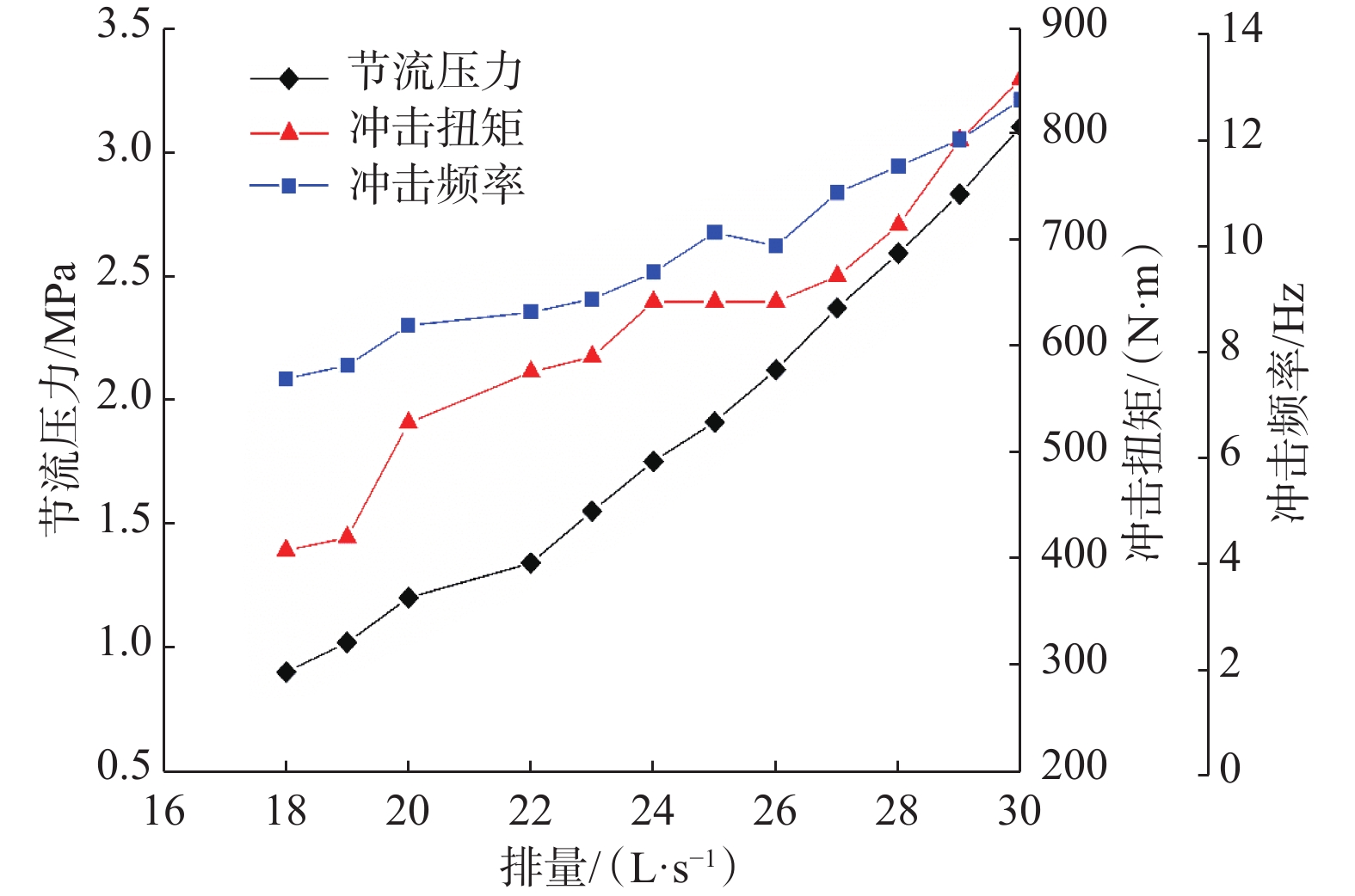

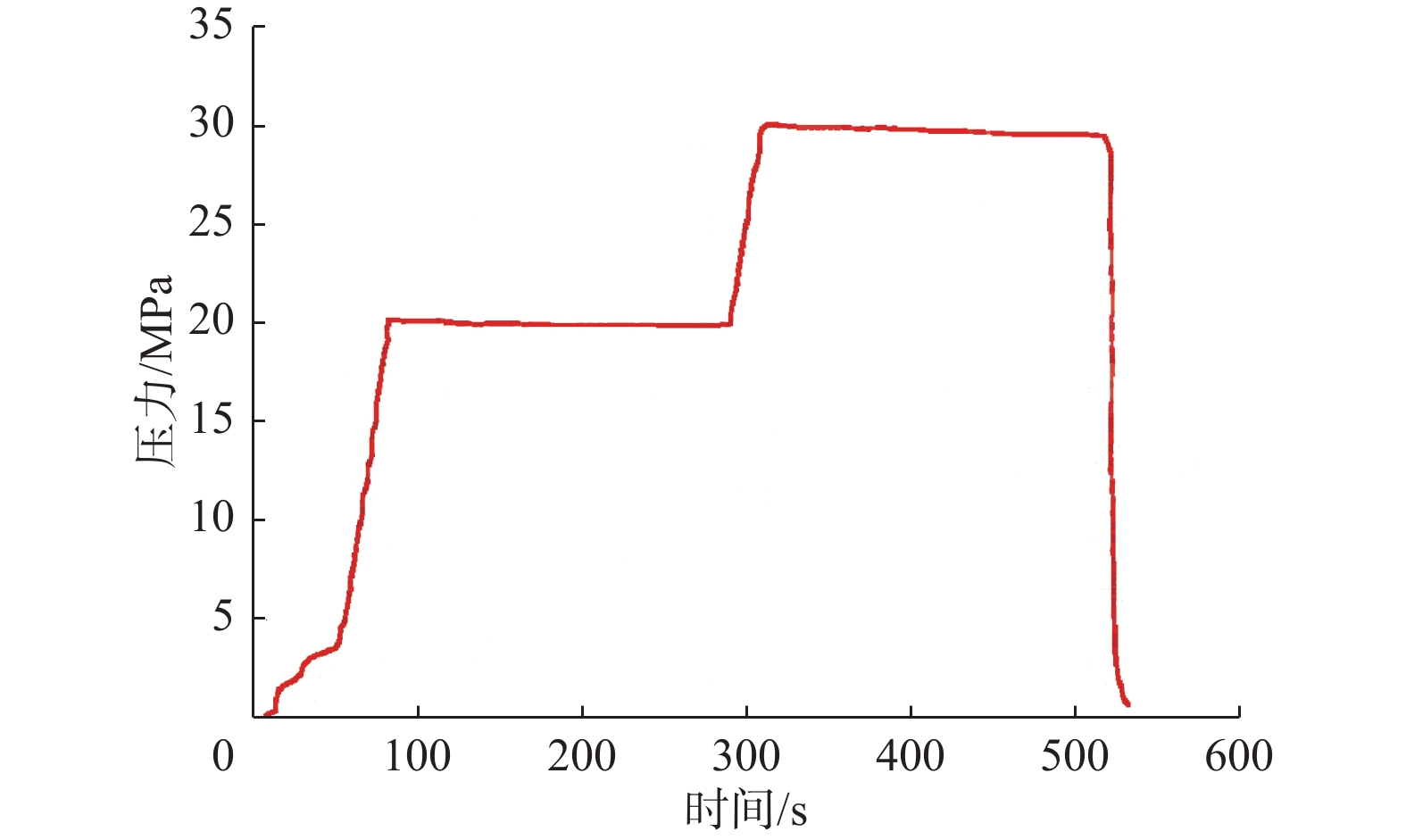

在应用PDC钻头钻进硬地层时易出现钻具粘滑振动、跳钻、钻具突然回转等问题,导致钻头崩齿、钻具扭转变形,从而影响钻井效率和钻头、钻具的使用寿命。为此,研制了液力扭转冲击器和液力加压器并组合应用,形成了液力扭转冲击器配合液力加压器的钻井提速技术。室内性能试验结果表明,液力扭转冲击器能够产生高频冲击扭矩,且随着排量的增加,冲击扭矩、冲击频率和节流压力均会增加;液力加压器可以降低钻头的剧烈振动,从而达到提高钻速、保护钻头的目的。该技术在3口井进行了现场试验,与邻井相比,机械钻速分别提高了50%,33%和68%,且单只钻头进尺显著增加。研究表明,液力扭转冲击器配合液力加压器的钻井提速技术,可以大幅度提高机械钻速,并解决定向钻井中存在的托压问题,为实现油气藏高效开发提供了一种新技术。

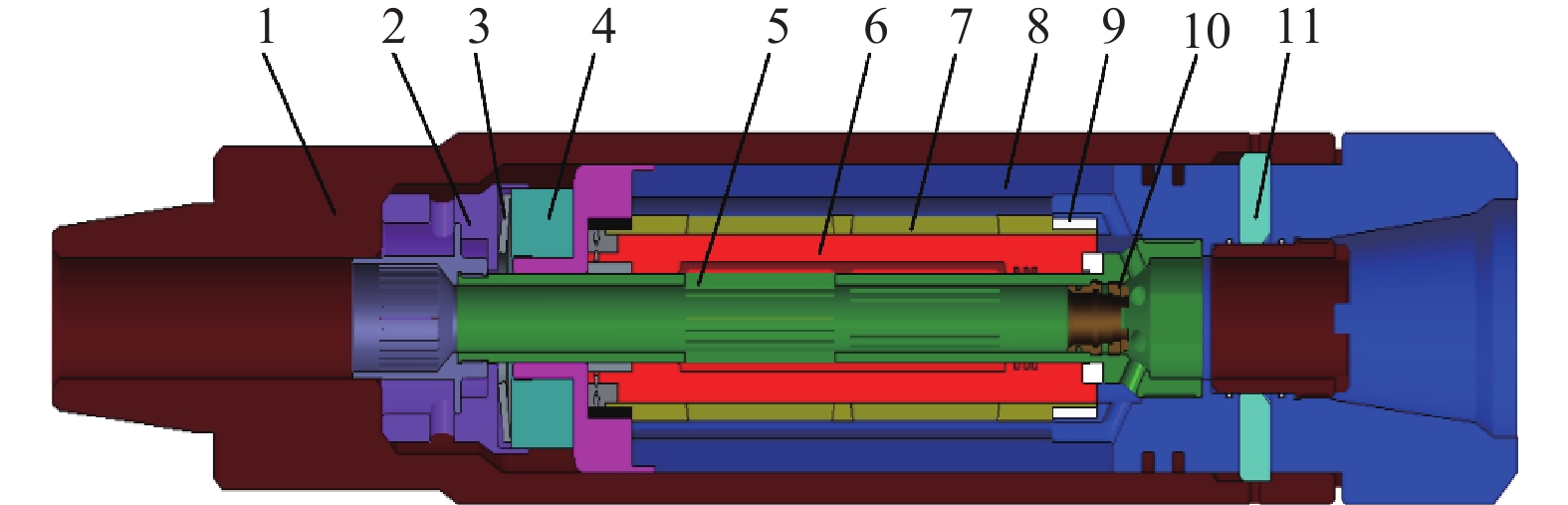

Abstract:When drilling into hard formations with a PDC bit, problems such as stick-slip vibration, bit bouncing and whirling of drilling string occur frequently, which causes the drill bit to collapse and the drilling string to twist and deform, hence compromising the drilling efficiency and the service life of the bit and the drill string. For this reason, based on the development of hydraulic torsional impactor and hydraulic booster as well as the combined application, a drilling acceleration technology was developed by jointly using hydraulic torsional impactor and hydraulic booster. The results of indoor performance test showed that the hydraulic torsional impactor could generate high-frequency impact torque, and the impact torque, impact frequency and choking pressure would increase with the flowrate. The hydraulic booster coudd effectively reduce the severe vibration in the drill bit, so as to achieve the purpose of improving ROP and protecting the drill bit. This technology was field tested in 3 wells. Compared with the adjacent wells, the ROPs were increased by 50%, 33% and 68%, respectively, and the footage of single bit was increased significantly. The research showed that the drilling speed-up technology of combining hydraulic torsional impactor with hydraulic booster could greatly increase ROP and solve the problem of WOB stacking in the directional drilling of this oilfield, which provided a technical measure to achieve an efficient development of reservoirs.

-

-

表 1 液力扭转冲击器配合液力加压器的钻井提速技术现场试验效果

Table 1 Field test results of the drilling speed-up technology of combining hydraulic torsional impactor with hydraulic boosterwith hydraulic booster

井号 钻进井段/

m入井时间/

h机械钻速/

(m·h–1)钻速提高

幅度,%2-4-18A 2 146~2 600 117 8.40 50 延491 3 194~3 438 76 6.39 39 盘2-斜125 260~1 317 69 26.44 68 -

[1] 闫光庆,张金成. 中国石化超深井钻井技术现状与发展建议[J]. 石油钻探技术, 2013, 41(2): 1–6. doi: 10.3969/j.issn.1001-0890.2013.02.001 YAN Guangqing, ZHANG Jincheng. Status and proposal of the Sinopec ultra-deep drilling technology[J]. Petroleum Drilling Techniques, 2013, 41(2): 1–6. doi: 10.3969/j.issn.1001-0890.2013.02.001

[2] 汪海阁,葛云华,石林. 深井超深井钻完井技术现状、挑战和“十三五”发展方向[J]. 天然气工业, 2017, 37(4): 1–8. doi: 10.3787/j.issn.1000-0976.2017.04.001 WANG Haige, GE Yunhua, SHI Lin. Technologies in deep andultra-deep well drilling: present status, challenges and future trend in the 13th Five-Year Plan period (2016-2020)[J]. Natural Gas Industry, 2017, 37(4): 1–8. doi: 10.3787/j.issn.1000-0976.2017.04.001

[3] 柳贡慧,李玉梅,李军,等. 复合冲击破岩钻井新技术[J]. 石油钻探技术, 2016, 44(5): 10–15. LIU Gonghui, LI Yumei, LI Jun, et al. New technology with composite percussion drilling and rock breaking[J]. Petroleum Drilling Techniques, 2016, 44(5): 10–15.

[4] 陈志学,冯晓炜,樊洪海,等. 扭力缓冲器在新疆火山岩地层的应用研究[J]. 石油机械, 2013, 41(11): 11–13. doi: 10.3969/j.issn.1001-4578.2013.11.003 CHEN Zhixue, FENG Xiaowei, FAN Honghai, et al. Research on the application of torsional impactor in Xinjiang’s volcanic strata[J]. China Petroleum Machinery, 2013, 41(11): 11–13. doi: 10.3969/j.issn.1001-4578.2013.11.003

[5] 周燕,金有海,董怀荣,等. SLTIDT型钻井提速工具研制[J]. 石油矿场机械, 2013, 42(1): 67–70. doi: 10.3969/j.issn.1001-3482.2013.01.016 ZHOU Yan, JIN Youhai, DONG Huairong, et al. Development of SLTIDT type torsion impact fast drilling tool[J]. Oil Field Equipment, 2013, 42(1): 67–70. doi: 10.3969/j.issn.1001-3482.2013.01.016

[6] 查春青,柳贡慧,李军,等. 复合冲击钻具的研制及现场试验[J]. 石油钻探技术, 2017, 45(1): 57–61. ZHA Chunqing, LIU Gonghui, LI Jun, et al. Development and field application of a compound percussive jet[J]. Petroleum Drilling Techniques, 2017, 45(1): 57–61.

[7] 贾红军,王攀,冯伟雄,等. 深井硬岩地层钻井高频低幅扭转振荡耦合冲击器研制与应用[J]. 特种油气藏, 2018, 25(4): 158–163. doi: 10.3969/j.issn.1006-6535.2018.04.032 JIA Hongjun, WANG Pan, FENG Weixiong, et al. Development and application of high-frequency low-torque impactor with torsion-oscillation coupling for drilling of deep and hard formations[J]. Special Oil & Gas Reservoirs, 2018, 25(4): 158–163. doi: 10.3969/j.issn.1006-6535.2018.04.032

[8] 罗恒荣,索忠伟,谭勇,等. 防托压冲击器在盘40斜501井的应用[J]. 石油钻探技术, 2015, 43(5): 112–115. LUO Hengrong, SUO Zhongwei, TAN Yong, et al. Application of reducing WOB stack impactor in Well Pan 40-Xie 501[J]. Petroleum Drilling Techniques, 2015, 43(5): 112–115.

[9] 查春青,柳贡慧,李军,等. PDC钻头扭转振动减振工具设计及现场应用[J]. 特种油气藏, 2019, 26(2): 170–174. doi: 10.3969/j.issn.1006-6535.2019.02.031 ZHA Chunqing, LIU Gonghui, LI Jun, et al. PDC bit torsional vibration damper design and field application[J]. Special Oil & Gas Reservoirs, 2019, 26(2): 170–174. doi: 10.3969/j.issn.1006-6535.2019.02.031

[10] 索忠伟. ϕ228.6 mm射流冲击器研制及硬地层提速试验[J]. 石油钻探技术, 2019, 47(4): 54–58. doi: 10.11911/syztjs.2019085 SUO Zhongwei. The development of ϕ228.6 mm hydro-efflux hammer and ROP increase test in hard formations[J]. Petroleum Drilling Techniques, 2019, 47(4): 54–58. doi: 10.11911/syztjs.2019085

[11] 孙起昱,张雨生,李少海,等. 钻头扭转冲击器在元坝10井的试验[J]. 石油钻探技术, 2010, 38(6): 84–87. doi: 10.3969/j.issn.1001-0890.2010.06.018 SUN Qiyu, ZHANG Yusheng, LI Shaohai, et al. Application of bit torsional impact generator in Well Yuanba 10[J]. Petroleum Drilling Techniques, 2010, 38(6): 84–87. doi: 10.3969/j.issn.1001-0890.2010.06.018

[12] 侯子旭,李双贵,贾晓斌,等. 深部泥岩地层扭力冲击器钻井钻头优选研究[J]. 钻采工艺, 2014, 37(3): 36–38. doi: 10.3969/J.ISSN.1006-768X.2014.03.11 HOU Zixu, LI Shuanggui, JIA Xiaobin, et al. Optimization of the PDC bit for torque impactor drilling in the deep mudstone formation[J]. Drilling & Production Technology, 2014, 37(3): 36–38. doi: 10.3969/J.ISSN.1006-768X.2014.03.11

[13] 周祥林,张金成,张东清. TorkBuster扭力冲击器在元坝地区的试验应用[J]. 钻采工艺, 2012, 35(2): 15–17. doi: 10.3969/J.ISSN.1006-768X.2012.02.05 ZHOU Xianglin, ZHANG Jincheng, ZHANG Dongqing. Experimental application of TorkBuster torsional impactor in Yuanba region[J]. Drilling & Production Technology, 2012, 35(2): 15–17. doi: 10.3969/J.ISSN.1006-768X.2012.02.05

[14] 郑瑞强. 液动旋冲工具的研制[J]. 石油机械, 2017, 45(1): 30–33. ZHENG Ruiqiang. Development of hydraulic rotary impact tool[J]. China Petroleum Machinery, 2017, 45(1): 30–33.

[15] 祝效华,汤历平,童华. 高频扭转冲击钻进的减振与提速机理研究[J]. 振动与冲击, 2012, 31(20): 75–78. ZHU Xiaohua, TANG Liping, TONG Hua. Rock breaking mechanism of a high frequency torsional impact drilling[J]. Journal of Vibration and Shock, 2012, 31(20): 75–78.

[16] 汤历平. 深部硬地层钻头粘滑振动特性及减振方法研究[D]. 成都: 西南石油大学, 2012. TANG Liping. Research of property of bit stick-slip vibration and method of vibration absorption in deep hard formation[D]. Chengdu: Southwest Petroleum University, 2012.

[17] 李美求,李嘉文,李宁,等. 周向冲击扭矩作用下PDC钻头的黏滑振动分析[J]. 石油钻采工艺, 2018, 40(3): 287–292. LI Meiqiu, LI Jiawen, LI Ning, et al. Analysis on the stick-slip vibration of PDC bit under the effect of circumferential torque impact[J]. Oil Drilling & Production Technology, 2018, 40(3): 287–292.

[18] 刘勤志,李兴杰,张国田,等. 水力加压器的研制与现场应用[J]. 石油机械, 2013, 41(1): 20–23. doi: 10.3969/j.issn.1001-4578.2013.01.006 LIU Qinzhi, LI Xingjie, ZHANG Guotian, et al. Development and field application of hydraulic thruster[J]. China Petroleum Machinery, 2013, 41(1): 20–23. doi: 10.3969/j.issn.1001-4578.2013.01.006

[19] 唐玉渤,秦利民,赵希江. 长伸缩距液力加压器的研制[J]. 石油矿场机械, 2010, 39(3): 85–86. doi: 10.3969/j.issn.1001-3482.2010.03.025 TANG Yubo, QIN Limin, ZHAO Xijiang. Development of hydraulic thruster with long expand and contract distance[J]. Oil Field Equipment, 2010, 39(3): 85–86. doi: 10.3969/j.issn.1001-3482.2010.03.025

[20] 林元华,黄万志,施太和,等. 水力加压器研制及应用[J]. 石油钻采工艺, 2003, 25(3): 1–3. doi: 10.3969/j.issn.1000-7393.2003.03.001 LIN Yuanhua, HUANG Wanzhi, SHI Taihe, et al. Development and application of the thruster[J]. Oil Drilling & Production Technology, 2003, 25(3): 1–3. doi: 10.3969/j.issn.1000-7393.2003.03.001

-

期刊类型引用(1)

1. 肖功勋. 复杂层状地层的随钻核磁共振测井响应模拟分析. 中国石油和化工标准与质量. 2021(05): 103-105 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: