Precise Managed Pressure Drilling Technology for Ultra-High Pressure Brine Layer in the Kuqa Piedmont of the Tarim Oilfield

-

摘要:

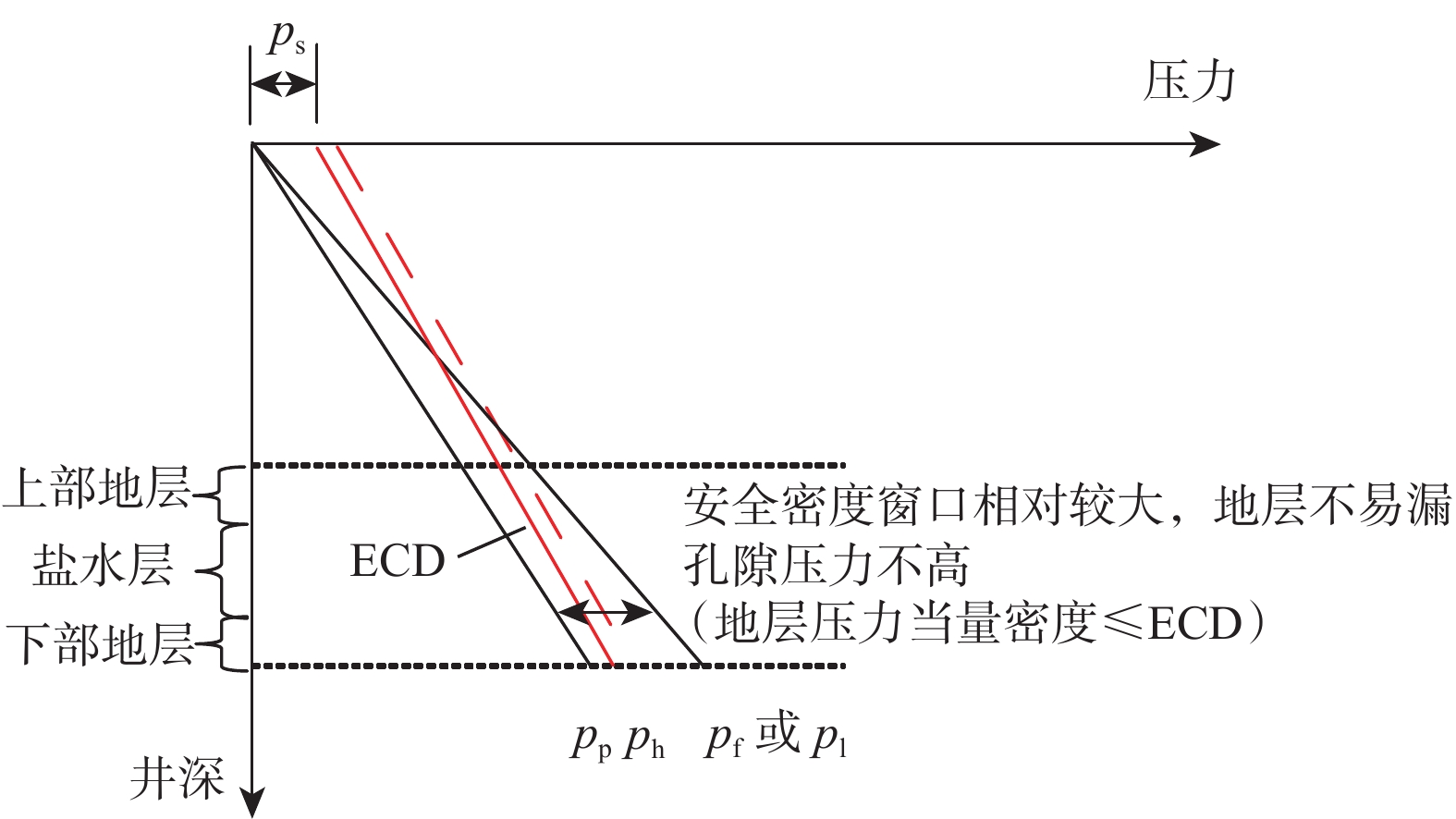

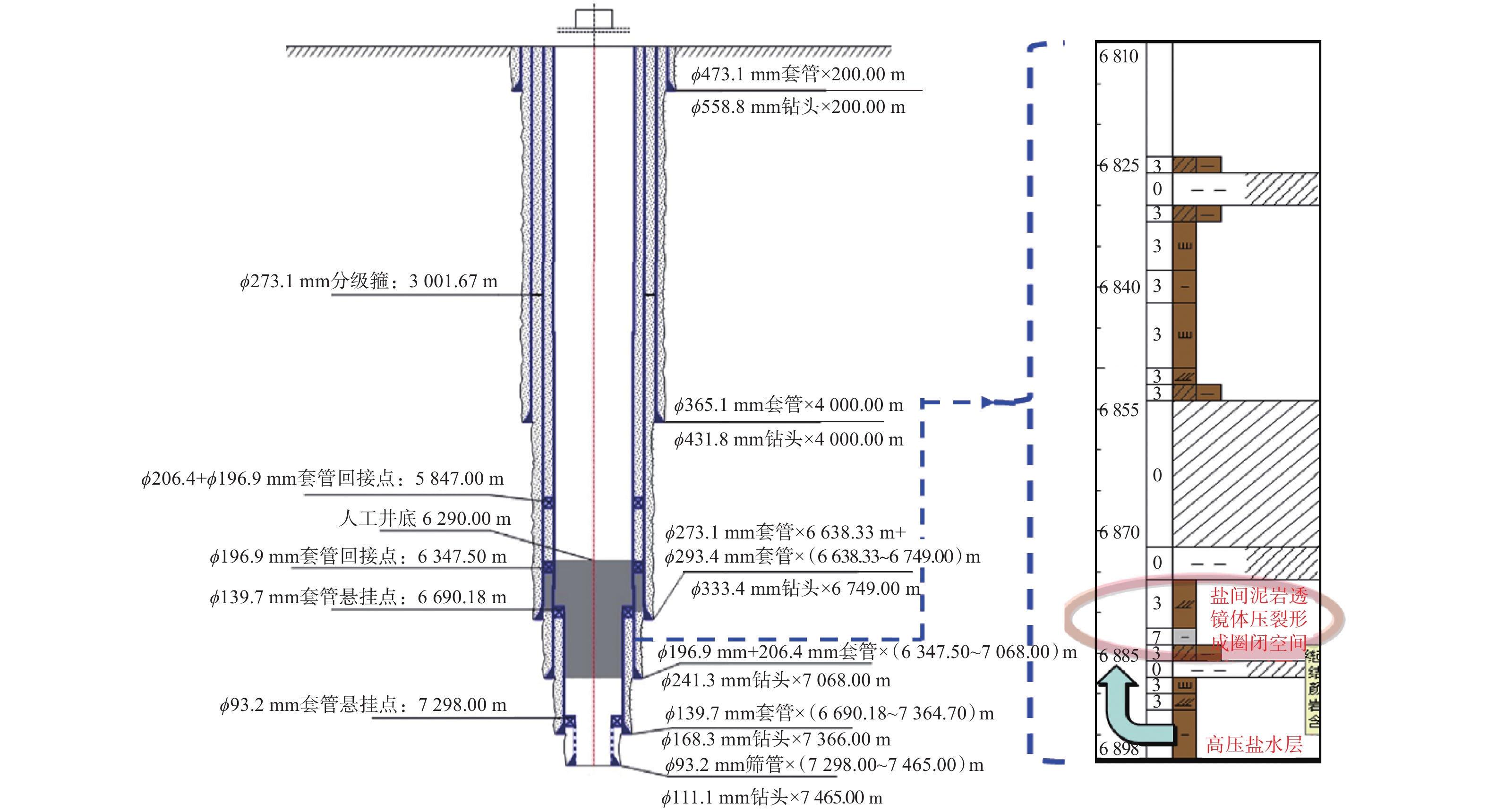

塔里木油田库车山前巨厚盐膏层普遍发育超高压盐水,且盐膏层中夹杂破裂压力低的泥岩层,导致安全钻井密度窗口窄, 易发生井涌、井漏、井塌和卡钻等井下故障。通过精细描述钻井液循环系统流量变化特征,定量化钻井液出入口流量差与溢流量、漏失量及高密度钻井液弹性变形量间的相互关系,可以实时快速判断溢流和漏失,计算求取地层压力,并将自动控压排水与控压压回相结合,精确控制地层与井底的压力差,有效控制合适的盐水返出量,大幅降低溢流、井漏等井下风险,形成了超高压盐水层微流量精细控压钻井技术。该技术在克深A井和克深B井进行了现场试验,均安全快速钻穿超高压盐水层,大幅提高了机械钻速,缩短了钻井周期,降低了钻井成本。研究与应用表明,超高压盐水层微流量精细控压钻井技术可快速发现溢流和漏失,精确控制地层盐水返出或者钻井液漏入地层,实现可控微溢流或漏失,大幅减少了盐水排放时间,确保了井眼稳定,实现了安全快速钻穿超高压盐水层的目的,为超深井复杂地层高效钻进提供了新的技术手段。

Abstract:Ultra-high pressure brine development (pressure co-efficient of up to 2.65) is common in the thick salt formation of the Kuqa Piedmont in the Tarim Oilfield, and the salt formation contains a mudstone layer with a low fracture pressure gradient, which leads to a narrow drilling safety density window, prone to downhole problems such as spill, lost circulation, collapse, stuck pipe, etc. By precisely describing the flowrate change characteristics of drilling fluid circulation system, and quantifying the correlation among the inlet/outlet flowrate difference of the drilling fluid, the spill volume, leakage volume and the elastic deformation volume of high-density drilling fluid, it is possible to realize the rapid and real-time identification of spill and leakage and calculate the formation pressure. By combining the automatic pressure-controlled drainage and pressure-controlled bull-heading, it is possible to accurately control the difference between the formation pressure and bottomhole pressure, and effectively control the appropriate amount of brine return. In this way, it is possible to significantly reduce the downhole risks of both spill and leakage, forming the managed pressure drilling technology by a fine controllable micro-flowrate in an ultra-high pressure brine layer. The technology has been tested in Well Keshen A and B, and drilled through the ultra-high pressure brine layers safely and quickly, which greatly increases the ROP, shortens the drilling cycle and saves the drilling cost. Research and application showed that the managed pressure drilling technology by fine micro-flowrate control in ultra-high pressure brine layer could quickly detect spill and leakage, accurately control formation brine return or lost circulation of drilling fluid, and achieve a controllable micro-spill or leakage, which can reduce the brine discharge time greatly, ensure the borehole stability, and achieve the purpose of drilling through ultra-high pressure brine layer safely and quickly. The technology has provided a technical means for the efficient drilling of ultra deep wells in complex formations.

-

页岩油储集层岩石矿物成分复杂,具有低孔隙度、低渗透率等特点,目前页岩油开发主要采用“水平井+密切割体积压裂”技术[1]。但是,页岩油水平井受多种因素影响,时有套管变形发生[2-4],如随着吉木萨尔凹陷页岩油逐步扩大开发与规模建产,套变井的数量和比例逐年递增,2019 年套变井比例已经超过 50%[5];沧东凹陷新钻页岩油水平井均采用大规模体积压裂方式开发[6-7],开发初期也有套变问题发生,变形严重时造成压裂施工丢段,无法发挥整井产能,造成资源浪费。

目前,套管整形工艺主要有机械整形和液压整形2类。机械整形是利用顿击式胀管器的冲击力或偏心辊子胀管器转动产生的挤压力修复变形套管[8],存在易损伤套管及易发生钻杆折断、工具胀裂或辊子中心轴断裂落井等问题,故目前已经很少使用;液压滚珠整形技术是将增压后的液压力转换成轴向机械推力,推动滚珠扩径胀头挤压套管内壁实现整形[9-10],但常规液压整形技术存在大量滚珠落井、有效期短等问题,在直井上使用较多,不适合于页岩油水平井。因此,有必要研究页岩油水平井套管液压整形技术。大港油田研究团队针对页岩油水平井套管整形开展了技术调研,改进并研发了系列整形工具,结合室内试验结果完善了施工工艺,并在沧东凹陷页岩油水平井GD1701H井现场试验取得了成功,为下一步连续管扫塞、恢复全井段产能提供了通道。

1. 页岩油水平井套变现状

页岩油藏具有低孔低渗特征,直井开发无法获得稳定的工业产量,只有通过水平井精准钻遇“甜点”并进行压裂改造才能获得产能突破[11]。如果套变点在A靶点附近,体积压裂时无法实施分段下桥塞封堵,发生套管变形后不能改造的井段一般就放弃了施工,投产时井筒不能满足连续管扫塞,造成页岩油井产量低、开发时间短,井控资源量得不到有效利用。

为了降低体积压裂造成的套管变形概率,除了优化压裂工艺外,还采用提高套管钢级、增加壁厚来增强套管抗变形能力[12],如采用TP125V级特种钢材,壁厚从9.17,10.54 mm提高至12.70 mm,沧东凹陷页岩油水平井的套变数量得到了有效控制。但是,页岩油水平井压裂套损机理复杂、影响因素多,套损种类也较多,如丝扣渗漏、套管本体穿孔和套变缩径等,尤以套变缩径占比最大,前2种套损井采用补贴管或膨胀管工艺可以恢复生产,套变缩径处理难度大,行业内尚未有成熟的案例可供借鉴。

2. 常规液压整形技术及其不足

常规液压胀套工艺的工具串组合(自下而上)为:滚珠胀管器+动力杆+多级液压加力器(增力液缸)+水力锚组+油管。套管整形时,地面泵车打压,管柱内高压流体使多级增力液缸产生向下的推力,推动胀管器,使胀管器锥体外围的滚珠滚压扩张管壁,对套管缩径井段进行修复[13-14]。常规液压整形技术在页岩油套变井应用存在以下不足:

1)滚珠碎裂变形落井。滚珠胀管器胀头锥形面上排列一定数量的钢质滚珠,胀套时滚珠在锥面槽内自下而上滚压套管,为了提升胀套修复能力,滚珠设计硬度都比较高,受挤压时易碎裂落井;同时,滚珠槽受到滚珠挤压变形,造成滚珠挤出落井。滚珠大量碎裂、脱落现象在常规直井施工中比较普遍,如果脱落滚珠及碎片堆积在页岩油水平井下部封堵桥塞上,将会导致投产时连续管磨铣底部桥塞受阻。

2)工具串受力不均蹩断。页岩油水平井套管变形段一般在A靶点或断层附近,井斜角大,井眼轨迹复杂,套管变形不规则。胀套工具串总长度达到10~15 m,工具之间为丝扣刚性连接,在液缸下推力作用下,胀管器胀头无法准确找正井眼,工具串轴向和径向受力不均匀,存在蹩断落井的风险。

3)套管回弹有效期短。目前页岩油水平井所用套管壁厚均大于常规套管,TP125V钢级或更高钢级的钢材强度大、弹性应变能力强,胀管器挤压力卸载后回弹量大于常规材料[15]。锥形胀头最大外径段通过变形点后,变形套管回弹卡住胀管器;更为严重的是,套管经过常规液压整形修复后,短期内回弹恢复原先变形状态,造成生产管柱卡钻,现场已经发生多起类似案例。

页岩油井普遍采用水平井钻井完井方式,井壁摩阻大,常规修井机额定提升负荷小,解卡能力弱,整形工具串卡钻风险高;且页岩油井开发投资巨大,修复有效期直接关系着页岩油井的全生命周期和投资回报,所以有效的套变修复方法在页岩油开发过程中显得非常重要和迫切。

3. 页岩油水平井液压整形工具

针对页岩油水平井特殊的井身结构和条件,克服常规液压整形技术的不足,改进并研发了系列整形工具。

3.1 扩张式胀管器

扩张式胀管器如图1所示,胀头由芯轴和扩张牙片组成,芯轴外部和分瓣式扩张牙片内侧设计成6°~8°锥度斜坡。套管整形时,多级液压加力器的动力杆推动扩张头芯轴下行,推动扩张牙片径向挤胀缩径套管进行修复,将常规滚珠胀头的滚珠点接触转变成分瓣式牙片面接触,扩张牙片强度大、受力均匀,多级液缸可以施加更大的下推力,有助于缩径套管恢复。胀头通过变形点后,复位弹簧带动扩张牙片回缩,开始下一个胀套行程。

3.2 保径短节

保径短节如图2所示,连接在扩张式胀管器后部,外径和胀管器胀头最大直径保持一致。胀管器通过变形点后,带动保径短节继续下行,短节上的钢珠对扩张过的套管进行滚压,增大套管的塑性形变,消除套管的回弹应力,滚压作用还能提升变形段套管表面硬度,防止修复后套管短期内回弹,延长修复有效期。变形套管的修复主要靠扩张头的挤压作用,降低了对滚珠强度的要求,同时滚珠在原位转动滚压,避免了因滚珠槽受力变形造成滚珠落井。

3.3 柔性短节

柔性短节如图3所示,由柔性钻杆单根丝扣连接而成,单根长度0.15 m,活动关节角度0°~4.5°可调,额定扭矩25 kN·m,抗拉强度1 200 kN。套管整形时,每个活动关节在液压加力器缓慢下压力的作用下角度发生变换,引导扩张式胀管器找正井眼,柔性短节提高了工具串的挠度,避免工具串受压时由于刚性高导致蹩断。

3.4 减阻接箍和减阻短节

为了降低工具串和管串与套管之间的摩擦阻力,从而有助于扶正工具串,提升管串的脱困能力,设计了减阻接箍(见图4)和减阻短节(见图5),分别安装在工具串中和大斜度井段处的管串中。

3.5 工具组合

基于变形套管的塑性回弹和井下大直径工具较多等原因,液压胀套施工过程中不可避免地会发生卡工具现象。因此,为了顺利进行液压胀套,除了加装减阻工具降低井壁的摩擦阻力外,还在工具串顶部加装震击器和加速器,在井口四通上安装液压辅助解卡装置。其中,应用辅助解卡装置的目的是提高管柱在整形过程中的安全性,降低对修井机提升负荷的依赖。

综上所述,页岩油水平井液压整形井下工具串组合自下而上为:扩张式胀管器+保径短节+(螺旋刮削器)+柔性短节+动力杆+多级液压加力器(增力液缸)+水力锚组+泄压阀+水力锚组+震击器+加速器+18°斜坡钻杆。

从理论上讲,采用上述工具组合后,胀头的抗外挤能力得到加强,工具串挠度大,胀头可以自动找正防止劈裂,消除变形套管塑性回弹,辅助工具可以提升管串的解卡能力,提升液压胀套技术的工艺适应性,延长整形修复的有效期。页岩油水平井液压整形技术与常规技术的对比情况如表1所示。

表 1 页岩油水平井液压整形技术与常规技术对比Table 1. Comparison of hydraulic shaping technology and conventional technology in horizontal shale oil wells技术 工艺可靠性 卡钻风险 修复效果 常规液压整形技术 滚珠及碎裂残片落井;工具串刚性大,易蹩断 风险高 变形套管短期内回弹 页岩油水平井液压整形技术 扩张牙片强度高、受力均匀;工具串挠度大,胀头自动找正 风险低 塑性大硬度高,有效期长 4. 室内试验

现场试验前,开展了室内模拟试验,以验证页岩油水平井套管液压整形工具的可靠性、工艺的可行性,并根据发现的问题进行改进和完善。

4.1 试验器材

试验平台,ϕ139.7 mm ×12.7 mm TP125V级套管,压力机,系列套管液压整形工具。

4.2 试验步骤

1)将套管固定在试验台上,用压力机加压,折算外挤力为870 kN,套管内径从118.6 mm变形至47.0 mm,模拟井下变形套管。

2)将套管固定在试验台上,试验台推送机顶杆连接扩张式胀管器,模拟井下套管修复过程。

a.第一次加压。投放ϕ98.0 mm扩张式胀管器,液压站压力为15 MPa,胀头折算外挤力600 kN,变形段套管有少量恢复,从套管底部发现胀管器不居中(见图6(a)),胀头牙片劈裂(见图6(b))。分析认为,选择的胀头偏大,套管内圆周变形不一致,扩张头没有找正,导致分瓣式牙片受力不均劈裂损坏,无法完成理想修复。根据以上情况,决定减小扩张器尺寸,增加柔性短节协助找正。

b.第二次加压。投放ϕ54.0 mm扩张式胀管器+柔性短节,液压站压力为25 MPa,折算外挤力1 000 kN,变形段套管部分恢复。

c.第三次加压。分别投放ϕ98.0,ϕ100.0和ϕ102.0 mm扩张式胀管器(见图7(a)),分段加压至15,25和28 MPa,变形段套管恢复明显,胀管器顺利通过(见图7(b)),由于室内整形安全风险高,ϕ102.0 mm整形头通过后未做进一步试验。

4.3 试验结果

室内试验结果表明,页岩油水平井变形套管液压整形技术可行,液压产生的下推力使整形胀管器不断扩径,将套管内壁胀压恢复圆形状态,从而达到修复变形套管的目的。试验结果也表明,施工时需要考虑胀头找正,胀头由小到大分步实施。

5. 现场试验

页岩油水平井变形套管液压整形技术先在庄 6-12-10井和西 36-4井等2口直井进行了现场试验,套管钢级分别为N80和J55。其中,西36-4井油层套管为大直径(ϕ177.8 mm)套管,井下工具串长度11.44 m,采用ϕ73.0 mm油管和400 kN修井机施工,扩张式胀管器级差初定4.0 mm。胀套施工过程中,地面泵压高、施工效率低并发生了卡钻现象,由于修井机提升负荷不足,采用井口液压辅助解卡装置顺利解卡;后期将胀管器级差降为2.0 mm,降低了施工泵压,施工效率得到了提升,最终一级胀管器顺利通过变形段,不阻不卡,2口井套管修复均取得了成功。此后,该技术在页岩油水平井GD1701H井进行了现场试验。

5.1 GD1701H井试验概况

GD1701H井是沧东凹陷页岩油先导试验水平井,完钻井深5 465 m,最大井斜90.12°,采用壁厚10.54 mm、钢级TP125V的ϕ139.7 mm油层套管完井。该井压裂后四十臂测井显示套管局部内凹(见图8(a)),井深4 081~4 083和4 084~4 087 m处套管变形(见图8(b)),具体变形参数见表2。

表 2 GD1701H井测40臂解释结果Table 2. 40-arm logging interpretation results of Well GD1701H序号 起始深度/m 终止深度/m 长度/m 正常半径/mm 最小半径/mm 最大半径/mm 测井解释 1 4 081 4 083 2 59.31 39.09 65.98 变形 2 4 084 4 087 3 59.31 43.71 63.60 变形 ϕ94.75 mm×1.20 m通径规通过连续油管带时有明显遇阻显示。地质开发方案要求修复套管内径,满足ϕ108.0 mm磨鞋通过变形井段磨铣压裂段桥塞,恢复下部井段产能。针对该井深度大,钻具自身负荷高,TP125V套管钢级硬度大、回弹形变大等不利因素,设计采用1 200 kN修井机(带转盘)和S135钢级18°斜坡钻杆,施工遵循 “降低级差、胀滚结合、柔性找正、震击防卡”的修复思路,工具串胀头包含柔性短节及相应的减阻接箍和减阻短节,初期工具串长度达到15.70 m,为了降低对套管的刻蚀损伤,设计了6组水力锚。

5.2 GD1701H井试验效果

5.2.1 降低胀头尺寸级差

GD1701H井套变井段井斜角80°,狗腿度4.69°/30m。井斜角大、井眼复杂导致井下管柱与套管摩阻大,如果单次胀套尺寸过大,变形套管易回弹造成工具串卡钻,解卡难度大。因此,设计胀管器级差从常规施工的4.0 mm降至2.0 mm,逐级采用ϕ110.0,ϕ112.0,ϕ114.0和ϕ115.6 mm 系列扩张式胀管器逐步修复,避免了卡钻的发生。

5.2.2 合理配置水力锚数量

采用多级液缸串联,增大动力杆的下推力和胀管器分瓣牙片的外推力,为确保管柱具有足够的锚定力,必须配备多组水力锚[16],开始2趟胀套工具串在泄压阀上下各安装3组(共计6组)水力锚。胀套施工过程中,水力锚锚牙在多次打压后没有完全回缩,锚牙在套管上刻蚀出毛刺,导致工具串无法下行,水力锚锚牙被不正常磨损(见图9(a)),本体也被套管毛刺刻蚀出深槽(见图9(b)),第3趟胀套失败。在充分计算水力锚锚定力和套管强度后,泄压阀下水力锚设定为2组,泄压阀上部水力锚设定为1组,降低了锚牙回缩的不一致性,刮削完套管毛刺后,胀管器带着工具串顺利下行。

5.2.3 工具串模拟通井

ϕ115.6 mm胀套工具串顺利通过后,为保证胀套修复效果,将多级ϕ114.0 mm保径短节连接,长度超过1.20 m,工具串保径短节后接螺旋槽刮削器铲除毛刺,在套管变形井段反复胀套、滚压和刮削,以消除套管回弹应力,不仅保证了套变修复效果,也起到了模拟通井效果。

5.2.4 辅助液压解卡

GD1701H井胀套工具串上配置井下震击器和加速器,在井口四通上安装辅助液压解卡器,解卡器举升负荷1 200 kN,下压负荷800 kN,即使管串卡钻也能顺利脱困。

5.2.5 总体试验效果

通过胀套工具的合理配置和精心施工,经过7趟修复,GD1701H井套管通径从94.75 mm恢复至115.60 mm,恢复率97.45 %,并消除了变形套管的回弹应力。ϕ112.0 mm ×1.20 m通井规顺利通过变形井段至井底桥塞,下ϕ50.8 mm连续油管带+ϕ79.0 mm×4.90 m螺杆钻具+ϕ108.0 mm磨鞋顺利扫塞至井底,半年后停喷带压下泵投产,产液量由修复前的9.6 m3/d增加至23.2 m3/d,后期2次检泵维护施工均未发现套变现象,套管修复施工效果较好,满足了地质开发需求。

6. 结论与建议

1)针对页岩油水平井压裂后变形套管的液压整形技术需求,基于提高整形工具的可靠性,消除变形套管的塑性回弹应力,避免施工时损伤套管和卡钻等风险的研究思路,改进并研发了系列井下工具,完善了现场施工工艺,形成了胀头自动找正、套管滚压加固和辅助解卡等技术系列。

2)室内试验表明,页岩油井高钢级套管需要的整形力大,对工具要求高,相对而言更适合使用扩张式胀管器,施工时要保证胀头能自动找正。

3)现场试验表明,页岩油水平井变形套管液压整形技术能够恢复套管内径,避免压裂丢段,满足投产时连续管扫塞恢复底层井段能量的需要,该技术对页岩气开发中类似套变的治理也有借鉴意义。

4)页岩油水平井变形套管液压整形技术要遵循“降低级差、胀滚结合、柔性找正、震击防卡”的技术思路选配井下工具,并根据井下显示和起出工具的磨损程度及时做出调整。

5)建议进一步建立理论模型,准确计算不同钢级变形套管需要的外推力,优化工具数量,缩短工具串长度,进一步提高页岩油水平井变形套管液压整形技术的工艺适应性。

-

-

[1] 尹达,叶艳,李磊,等. 塔里木山前构造克深7井盐间高压盐水处理技术[J]. 钻井液与完井液, 2012, 29(5): 6–8. doi: 10.3969/j.issn.1001-5620.2012.05.002 YIN Da, YE Yan, LI Lei, et al. High pressure salt water treatment technology of Well Keshen7 in foothill structural zone of Tarim[J]. Drilling Fluid & Completion Fluid, 2012, 29(5): 6–8. doi: 10.3969/j.issn.1001-5620.2012.05.002

[2] 田径.钻遇盐膏层高压盐水的井控技术[D].成都: 西南石油大学, 2012. TIAN Jing. Well control technology of high pressure brine drilling in salt gypsum layer[D]. Chengdu: Southwest Petroleum University, 2012.

[3] 卢俊安,王春生,冯少波,等. 超高压盐水溢流处置技术[J]. 钻采工艺, 2017, 40(5): 5–7. doi: 10.3969/J.ISSN.1006-768X.2017.05.02 LU Jun'an, WANG Chunsheng, FENG Shaobo, et al. Disposal measures for ultra-high-pressure brine overflow[J]. Drilling & Production Technology, 2017, 40(5): 5–7. doi: 10.3969/J.ISSN.1006-768X.2017.05.02

[4] 汪蓬勃. 基于巨厚盐膏层以及碳酸盐储层的钻井技术研究[D].成都: 西南石油大学, 2015. WANG Pengbo. Research on the drilling technique based on the layer of thick salt paste and carbonate reservoir[D]. Chengdu: Southwest Petroleum University, 2015.

[5] 周健,贾红军,刘永旺,等. 库车山前超深超高压盐水层安全钻井技术探索[J]. 钻井液与完井液, 2017, 34(1): 54–59. doi: 10.3969/j.issn.1001-5620.2017.01.010 ZHOU Jian, JIA Hongjun, LIU Yongwang, et al. Research on safe drilling technology for ultra deep ultrahigh pressure saltwater zones in Piedmont Area, Kuche[J]. Drilling Fluid & Completion Fluid, 2017, 34(1): 54–59. doi: 10.3969/j.issn.1001-5620.2017.01.010

[6] 周健.塔里木油田KS9区块含盐地层钻井关键技术研究[D].青岛: 中国石油大学(华东), 2017. ZHOU Jian. Study on key techniques of salt formation drilling on KS9 Block of Tarim Oilfield[D]. Qingdao: China University of Petroleum (East China), 2017.

[7] 梁红军,李军,李卫东,等. 高压盐水层控压放水室内实验研究[J]. 钻采工艺, 2019, 42(2): 21–23. LIANG Hongjun, LI Jun, LI Weidong, et al. Experimental study on controlled pressure discharge of high pressure brine out of formations[J]. Drilling & Production Technology, 2019, 42(2): 21–23.

[8] 董萌.克拉苏构造盐膏层钻井提速措施研究与应用[D].成都: 西南石油大学, 2017. DONG Meng. The research and application of the high quality and high speed drilling of salt layer in Kelasu[D]. Chengdu: Southwest Petroleum University, 2017.

[9] 任保友,刘锋报,徐兴梁,等. 塔里木山前构造克深某区块盐膏层井漏技术处理[J]. 西部探矿工程, 2018, 30(2): 75–78. doi: 10.3969/j.issn.1004-5716.2018.02.027 REN Baoyou, LIU Fengbao, XU Xingliang, et al. Treatment of lost circulation in salt gypsum layer in Keshen Block of Tarim Piedmont Structure[J]. West-China Exploration Engineering, 2018, 30(2): 75–78. doi: 10.3969/j.issn.1004-5716.2018.02.027

[10] 周英操,崔猛,查永进. 控压钻井技术探讨与展望[J]. 石油钻探技术, 2008, 36(4): 1–4. doi: 10.3969/j.issn.1001-0890.2008.04.001 ZHOU Yingcao, CUI Meng, ZHA Yongjin. Discussion and prospect of managed pressure drilling technology[J]. Petroleum Drilling Techniques, 2008, 36(4): 1–4. doi: 10.3969/j.issn.1001-0890.2008.04.001

[11] CHATAR C, IMLER M D. Overcoming a difficult salt drilling environment in the Gulf of Mexico: a case study[R]. SPE 128192, 2010.

[12] 张桂林. 土库曼斯坦亚苏尔哲别油田控压钻井技术[J]. 石油钻探技术, 2010, 38(6): 37–41. doi: 10.3969/j.issn.1001-0890.2010.06.009 ZHANG Guilin. Application of managed pressure drilling technology in Azores Area, Turkmenistan[J]. Petroleum Drilling Techniques, 2010, 38(6): 37–41. doi: 10.3969/j.issn.1001-0890.2010.06.009

[13] CURRY D A, LOURENCO A M, LEDGERWOOD L W, et al. The effect of borehole pressure on the drilling process in salt[R]. SPE 173023, 2015.

[14] 韩烈祥. CQMPD精细控压钻井技术应用与思考[J]. 石油钻采工艺, 2018, 40(5): 559–562. HAN Liexiang. Application and thinking of CQMPD fine pressure controlling drilling technology[J]. Oil Drilling & Production Technology, 2018, 40(5): 559–562.

[15] QASIM Ashraf, ALI Khalid, KHURRAM Luqman, et al. Managed pressure drilling saves multimillion dollar well from abandonment; enabled operator to drill and isolate section to target depth in a challenging plastic salt formation[R]. IPTC 19438, 2019.

[16] 苏勤,邢树宾. 缅甸D区块Yagyi-1x井控压钻井技术[J]. 石油钻探技术, 2011, 39(4): 25–28. doi: 10.3969/j.issn.1001-0890.2011.04.005 SU Qin, XING Shubin. Managed pressure drilling for Well Yagyi-1x in Block D of Myanmar[J]. Petroleum Drilling Techniques, 2011, 39(4): 25–28. doi: 10.3969/j.issn.1001-0890.2011.04.005

[17] 史肖燕,周英操,赵莉萍,等. 精细控压钻井过程中溢流的模拟和控制[J]. 石油机械, 2019, 47(5): 24–30. SHI Xiaoyan, ZHOU Yingcao, ZHAO Liping, et al. Influx simulation and control during managed pressure drilling[J]. China Petroleum Machinery, 2019, 47(5): 24–30.

[18] 周英操,杨雄文,方世良,等. PCDS-Ⅰ精细控压钻井系统研制与现场试验[J]. 石油钻探技术, 2011, 39(4): 7–12. doi: 10.3969/j.issn.1001-0890.2011.04.002 ZHOU Yingcao, YANG Xiongwen, FANG Shiliang, et al. Development and field test of PCDS-Ⅰ precise managed pressure drilling system[J]. Petroleum Drilling Techniques, 2011, 39(4): 7–12. doi: 10.3969/j.issn.1001-0890.2011.04.002

[19] 王江帅,李军,任美鹏,等. 控压钻井环空多相流控压响应时间研究[J]. 石油机械, 2019, 47(5): 61–65. WANG Jiangshuai, LI Jun, REN Meipeng, et al. Study on response time of multi-phase annular flow in MPD[J]. China Petroleum Machinery, 2019, 47(5): 61–65.

[20] 周英操,刘伟. PCDS精细控压钻井技术新进展[J]. 石油钻探技术, 2019, 47(3): 68–74. ZHOU Yingcao, LIU Wei. New progress on PCDS precise pressure management drilling technology[J]. Petroleum Drilling Techniques, 2019, 47(3): 68–74.

[21] 周英操,杨雄文,方世良,等. 国产精细控压钻井系统在蓬莱9井试验与效果分析[J]. 石油钻采工艺, 2011, 33(6): 19–22. doi: 10.3969/j.issn.1000-7393.2011.06.005 ZHOU Yingcao, YANG Xiongwen, FANG Shiliang, et al. Field test and analysis on effect of auto-controlled pressure drilling system in the Well Penglai 9[J]. Oil Drilling & Production Technology, 2011, 33(6): 19–22. doi: 10.3969/j.issn.1000-7393.2011.06.005

[22] 刘伟,周英操,段永贤,等. 国产精细控压钻井技术与装备的研发及应用效果评价[J]. 石油钻采工艺, 2014, 36(4): 34–37. LIU Wei, ZHOU Yingcao, DUAN Yongxian, et al. Development of domestic fine controlled pressure drilling technology and equipment and evaluation on their application effect[J]. Oil Drilling & Production Technology, 2014, 36(4): 34–37.

[23] 周英操.精细控压钻井技术及其应用[M].北京: 石油工业出版社, 2018. ZHOU Yingcao. Precise pressure management drilling technology and its application[M]. Beijing: Petroleum Industry Press, 2018.

-

期刊类型引用(3)

1. 何英伟,吴景春,李红军,石芳,周文秀,赵曼永,王陈英,李明昊,孙馨. Z89区块全缝长压裂模拟及储层改造研究. 中国煤炭地质. 2024(01): 18-24 .  百度学术

百度学术

2. 夏熙,牟建业,张士诚,李月丽. 大牛地气田复杂岩性储层酸蚀裂缝导流能力规律研究. 断块油气田. 2024(06): 1083-1089 .  百度学术

百度学术

3. 戴一凡,侯冰. 碳酸盐岩酸蚀裂缝面粗糙度与导流能力相关性分析. 断块油气田. 2023(04): 672-677 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: