Development of Dispersed Copolymer Particle System for Profile Control in Offshore Oilfield

-

摘要:

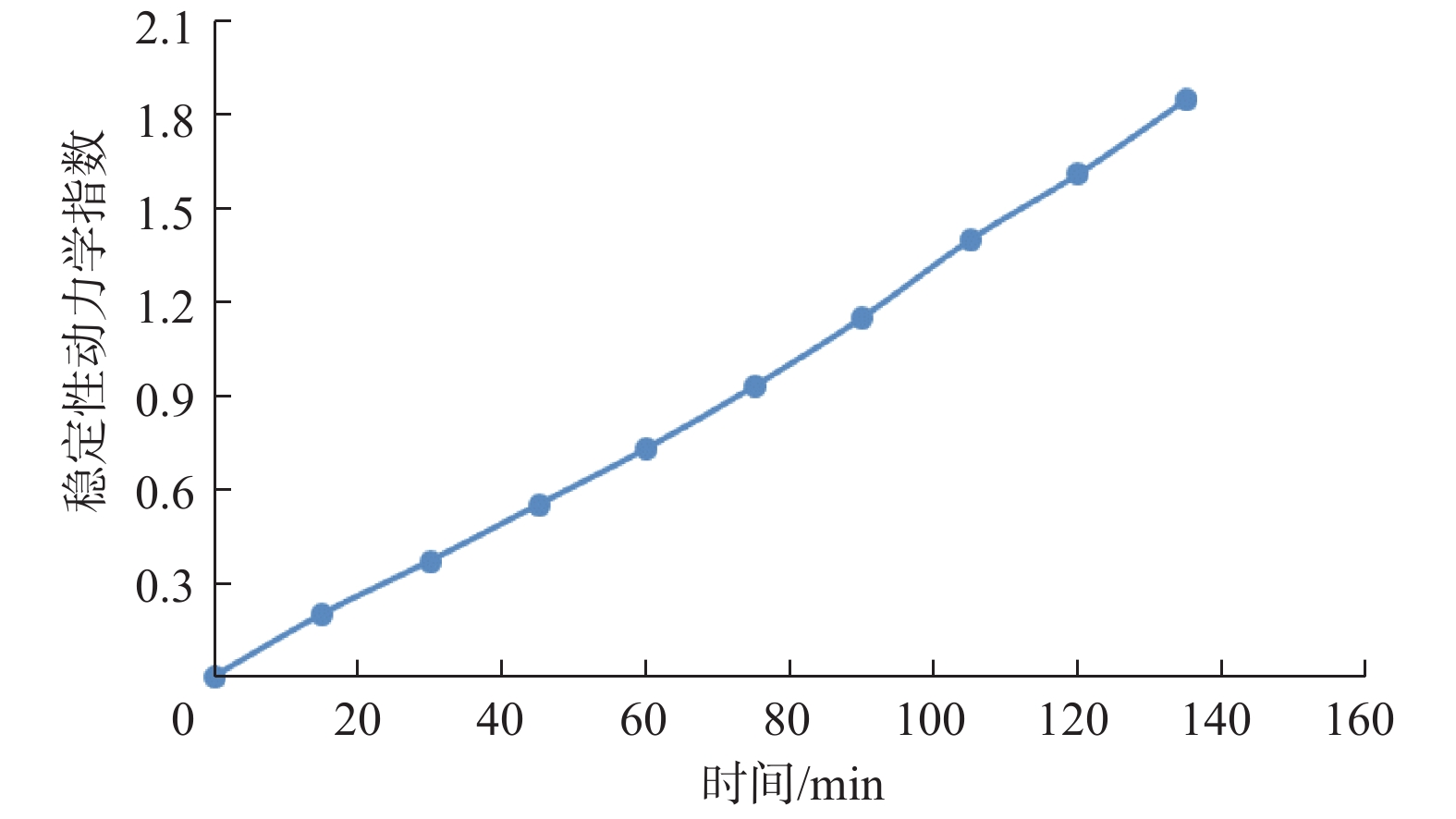

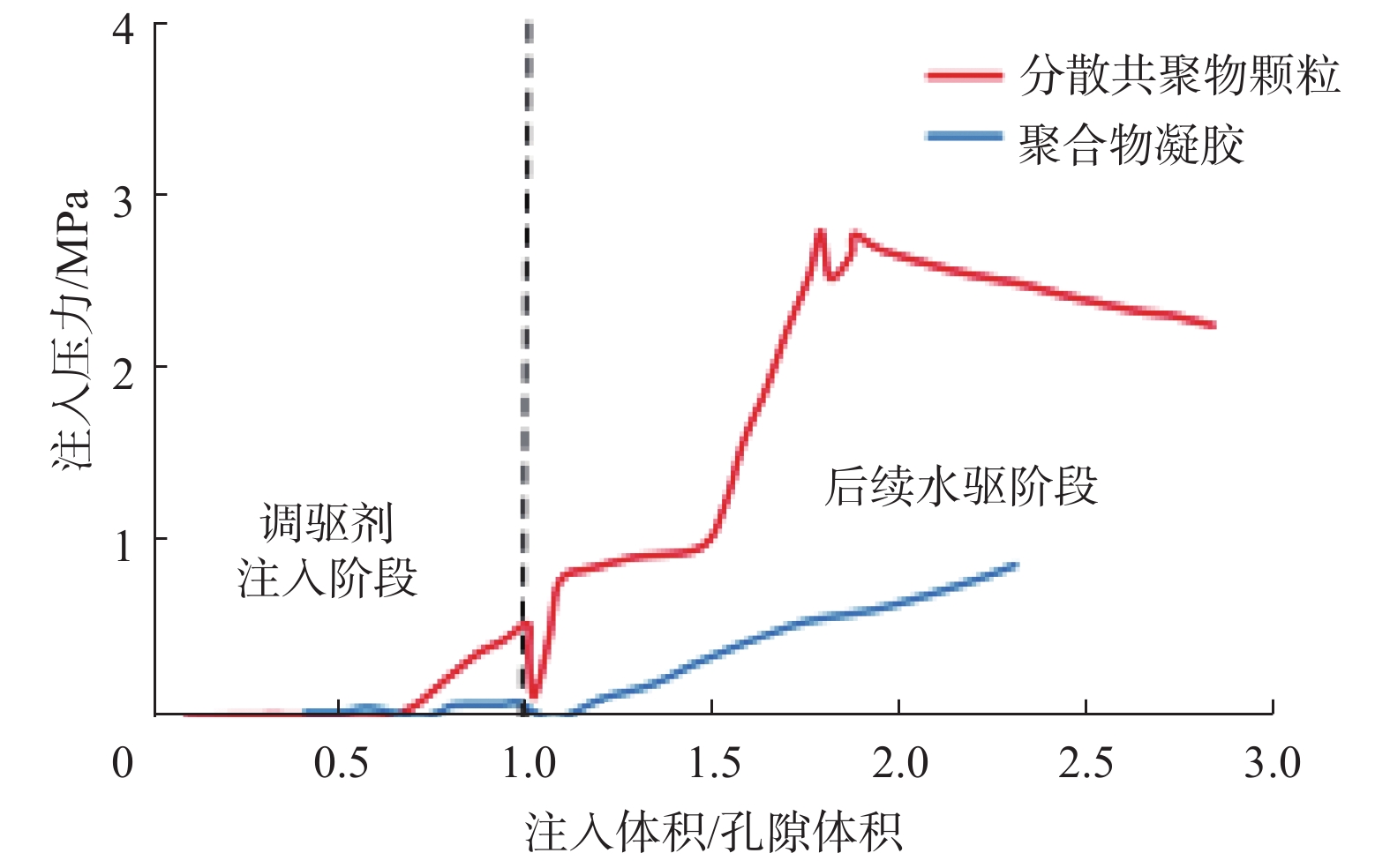

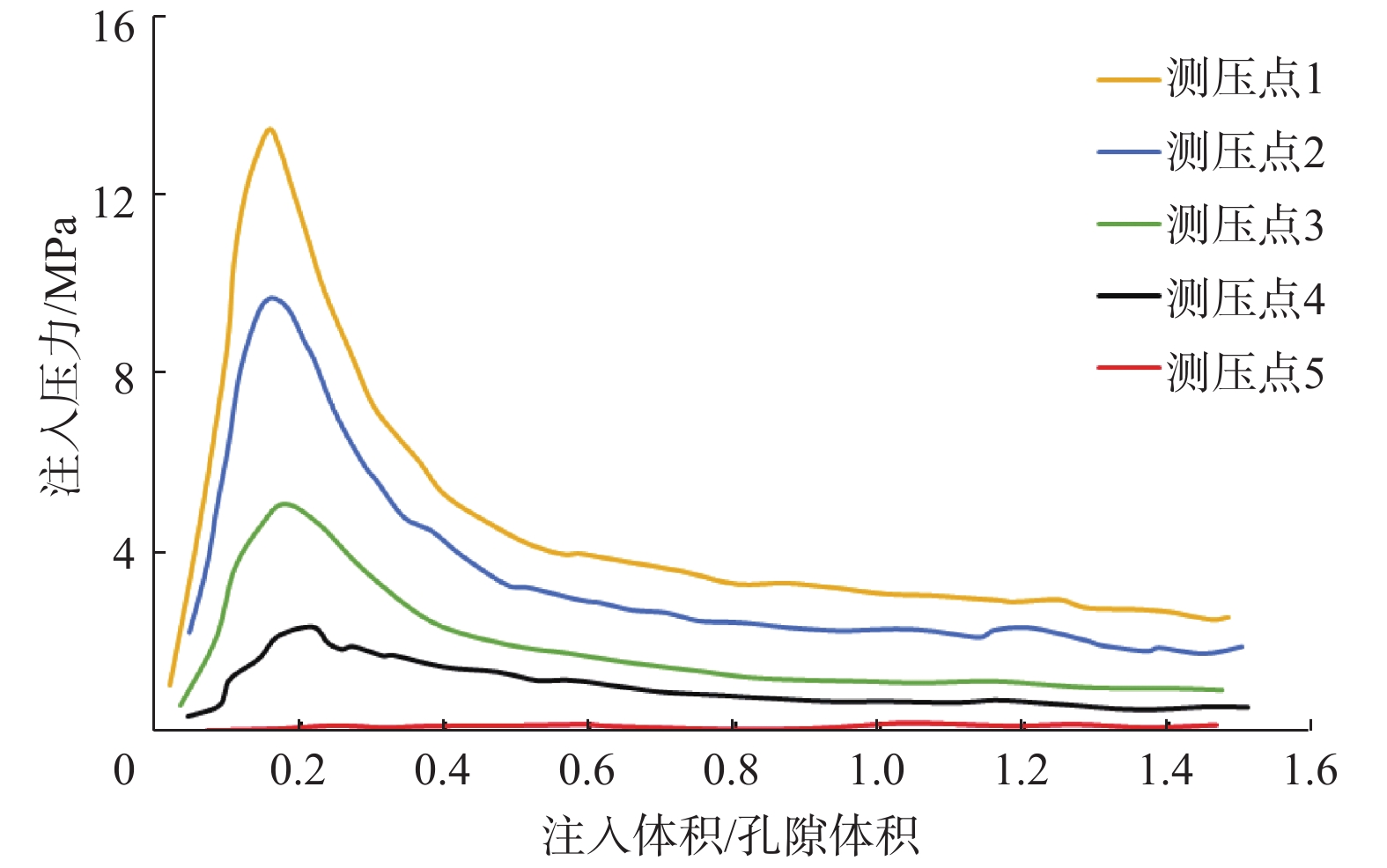

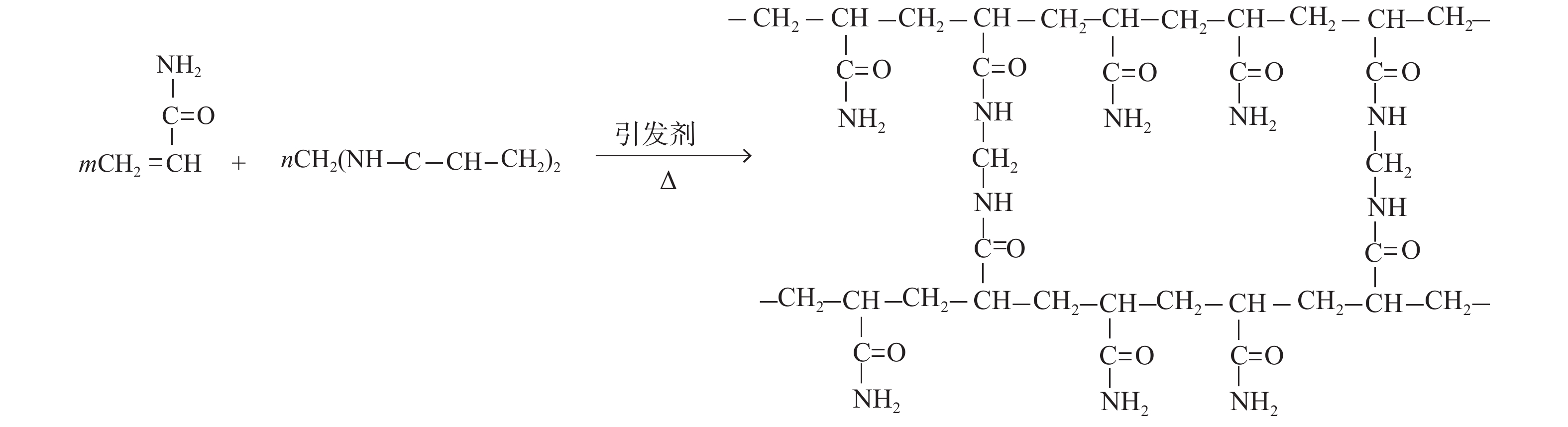

为了对海上油田中高含水期非均质油层进行剖面调整,以丙烯酰胺(AM)为主剂,N, N亚甲基双丙烯酰胺(MBA)为交联剂,合成了网状结构的高黏聚合物,经研磨控制技术处理后,制得分散共聚物颗粒体系。试验结果表明,在AM质量分数(5%)和AM/MBA质量比(250∶1)一定的条件下,研磨速率和研磨时间对粒径分布影响较大。封堵运移性能评价试验结果表明,分散共聚物颗粒体系具有良好注入性、深部运移能力及封堵性能,在等用量条件下,分散共聚物颗粒的封堵能力显著优于聚合物凝胶。研究表明,研制的分散共聚物颗粒粒径分布宽,纳米至微米级别可控,且可实现在线注入,具有制备工艺简单、成本低、抗高温和环保等特点,对海上中高含水期油田剖面调整具有较好的适用性,可在现场推广应用。

Abstract:A high-viscosity polymer was developed in order to adjust the profile of heterogeneous offshore oilfields in the middle-high water cut period. Performance advantages were achieved by taking acrylamide (AM) as the main agent and N, N methylenebisacrylamide (MBA) as the crosslinker. This polymer can be processed by the grinding control technology to obtain a dispersed copolymer particle system. The experimental results showed that the grinding rate and grinding time had a large impact on the particle size distribution for the given monomer mass fraction (5%) and the AM/MBA mass ratio of 250 to 1. The results of plugging and migration experiment under simulated formation conditions indicated that the dispersed copolymer particle system had good injectability, deep migration ability and plugging performance. For the given dosage, the plugging ability of dispersed copolymer particles was significantly better than that of the polymer gel. The research suggested that the particle size distribution of this system was wide and controllable in the nanometer to micrometer level, making online injection possible. The system has the advantages of simple formulating process, low cost, temperature resistance and environmental protection, etc. It possesses good applicability in offshore oilfields for the profile control in the middle-high water cut period, and can be promoted and applied in oilfields.

-

Keywords:

- dispersed copolymer particle /

- preparation /

- performance test /

- profile control /

- offshore oilfield

-

-

表 1 共聚物的制备参数

Table 1 Preparation parameters of the copolymer

AM质量分数,

%AM/MBA

质量比合成时间/

h共聚物黏度/

(mPa·s)5 167∶1 2.0 16 460 5 250∶1 2.5 15 320 表 2 分散共聚物颗粒粒径随研磨时间的变化

Table 2 Viscosity change of dispersed copolymer particles in grinding process

剪切时间/min 平均粒径/μm 最大粒径/μm 最小粒径/μm 1 1 520.0 3 080.0 31.1 5 135.0 352.0 4.6 -

[1] 刘春林,肖伟. 油田水驱开发指标系统及其结构分析[J]. 石油勘探与开发, 2010, 37(3): 344–348. doi: 10.1016/S1876-3804(10)60037-7 LIU Chunlin, XIAO Wei. Index system of the water flooding development of oil fields and its structural analysis[J]. Petroleum Exploration and Development, 2010, 37(3): 344–348. doi: 10.1016/S1876-3804(10)60037-7

[2] 由庆,于海洋,王业飞,等. 国内油田深部调剖技术的研究进展[J]. 断块油气田, 2009, 16(4): 68–71. YOU Qing, YU Haiyang, WANG Yefei, et al. Technologies of in-depth profile control in China[J]. Fault-Block Oil & Gas Field, 2009, 16(4): 68–71.

[3] 张吉磊,龙明,何逸凡,等. 渤海Q油田隔夹层发育底水稠油油藏精细注采技术[J]. 石油钻探技术, 2018, 46(2): 75–80. ZHANG Jilei, LONG Ming, HE Yifan, et al. Fine injection-production technology for bottom-water viscous oil reservoirs with interlayers in Bohai Q Oilfield[J]. Petroleum Drilling Techniques, 2018, 46(2): 75–80.

[4] 宫红茹, 唐顺卿,胡志成. 胡状集油田特高含水油藏剩余油水驱技术[J]. 石油钻探技术, 2018, 46(5): 95–101. GONG Hongru, TANG Shunqing, HU Zhicheng. Water flooding technology for the residual oil in the ultra-high water cut oil reservoirs of the Huzhuangji Oilfield[J]. Petroleum Drilling Techniques, 2018, 46(5): 95–101.

[5] 苑光宇,罗焕. 宽分子量聚合物/表面活性剂复合驱油体系性能评价[J]. 石油钻采工艺, 2018, 40(6): 805–810. YUAN Guangyu, LUO Huan. Evaluation on the properties of broad-molecular-weight polymer/surfactant flooding system[J]. Oil Drilling & Production Technology, 2018, 40(6): 805–810.

[6] 刘义刚,丁名臣,韩玉贵,等. 支化预交联凝胶颗粒在油藏中的运移与调剖特性[J]. 石油钻采工艺, 2018, 40(3): 393–399. LIU Yigang, DING Mingchen, HAN Yugui, et al. Migration and profile control properties of B-PPG in oil reservoirs[J]. Oil Drilling & Production Technology, 2018, 40(3): 393–399.

[7] 刘光普,刘述忍,李翔,等. 淀粉胶体系调剖性能的影响因素[J]. 石油钻采工艺, 2018, 40(1): 118–122. LIU Guangpu, LIU Shuren, LI Xiang, et al. Factors influencing the profile control performance of starch gel[J]. Oil Drilling & Production Technology, 2018, 40(1): 118–122.

[8] 贾玉琴,郑明科,杨海恩,等. 长庆油田低渗透油藏聚合物微球深部调驱工艺参数优化[J]. 石油钻探技术, 2018, 46(1): 75–82. JIA Yuqin, ZHENG Mingke, YANG Haien, et al. Optimization of operational parameters for deep displacement involving polymer microspheres in low permeability reservoirs of the Changqing Oilfield[J]. Petroleum drilling technology, 2018, 46(1): 75–82.

[9] 刘玉章,熊春明,罗健辉,等. 高含水油田深部液流转向技术研究[J]. 油田化学, 2006, 23(3): 248–251. doi: 10.3969/j.issn.1000-4092.2006.03.014 LIU Yuzhang, XIONG Chunming, LUO Jianhui, et al. Studies on indepth fluid diverting in oil reservoirs at high water cut stages[J]. Oilfield Chemistry, 2006, 23(3): 248–251. doi: 10.3969/j.issn.1000-4092.2006.03.014

[10] 吴春新,崔名喆,杨东东,等. 海上多层合采油藏乳状液调剖性能定量表征[J]. 特种油气藏, 2018, 25(1): 146–149. WU Chunxin, CUI Mingzhe, YANG Dongdong, et al. Quantitative characterization of effshore multi-layer production reservoir[J]. Special Oil & Gas Reservoirs, 2018, 25(1): 146–149.

[11] 张建国. 低矿化度水/表面活性剂复合驱提高采收率技术[J]. 断块油气田, 2019, 26(5): 609–612. ZHANG Jianguo. Alternative injection of low salinity water/surfactant to improve recovery[J]. Fault-Block Oil & Gas Field, 2019, 26(5): 609–612.

[12] 孙志刚,杨海博,杨勇,等. 注采交替提高采收率物理模拟实验[J]. 断块油气田, 2019, 26(1): 88–92. SUN Zhigang, YANG Haibo, YANG Yong, et al. Physical simulation experiment by alternation of injection and production to improve oil recovery[J]. Fault-Block Oil & Gas Field, 2019, 26(1): 88–92.

[13] 陈宗淇, 王光信, 徐桂英.胶体与界面化学[M].北京: 高等教育出版社, 2001: 152–164. CHEN Zongqi, WANG Guangxin, XU Guiying. Colloid and interface chemistry[M]. Beijing: Higher Education Press, 2001: 152–164.

[14] ZHANG Hao, CHALLA R S, BAI Baojun, et al. Using screening test results to predict the effective viscosity of swollen superabsorbent polymer particles extrusion through an open fracture[J]. Industrial & Engineering Chemistry Research, 2010, 49(23): 12284–12293.

[15] YOU Qing, TANG Yongchun, DAI Caili, et al. A study on the morphology of a dispersed particle gel used as a profile control agent for improved oil recovery[J]. Journal of Chemistry, 2014, 2014: 150256.

[16] LAKATOS I J, LAKATOS-SZABÓ J, KOSZTIN, B, et al. Application of silicate/polymer water shut-off treatment in faulted reservoirs with extreme high permeability[R]. SPE 144112, 2011.

-

期刊类型引用(10)

1. 戴文潮,刘奔. 高性能底封拖动分段压裂工具研制及试验. 钻采工艺. 2023(01): 120-125 .  百度学术

百度学术

2. 谢斌,陈超峰,马都都,练章华,史君林. 超深高温高压井尾管悬挂器安全性评价新方法. 天然气工业. 2022(09): 93-101 .  百度学术

百度学术

3. 郭朝辉,李振,罗恒荣. Φ273.1mm无限极循环尾管悬挂器在元坝气田的应用研究. 石油钻探技术. 2021(05): 64-69 .  本站查看

本站查看

4. 古青,宋剑鸣,曹博,马淼,蒋立坤,杨旭,冯治锋. 高温高压尾管悬挂器研制与应用. 石油矿场机械. 2021(06): 51-57 .  百度学术

百度学术

5. 高果成. 内嵌卡瓦尾管悬挂器在老井侧钻中的优势综合分析. 钻采工艺. 2020(01): 77-80+12 .  百度学术

百度学术

6. 马开华,谷磊,叶海超. 深层油气勘探开发需求与尾管悬挂器技术进步. 石油钻探技术. 2019(03): 34-40 .  本站查看

本站查看

7. 朱晓丽,张金法,魏书雷. 尾管用内嵌式卡瓦坐挂机构承载能力分析. 石油矿场机械. 2018(05): 84-87 .  百度学术

百度学术

8. 马兰荣,达伟,韩峰,张瑞. 高性能尾管悬挂器关键技术. 断块油气田. 2017(06): 859-862 .  百度学术

百度学术

9. 刘珂兵,贾彪,王庆,黄煜鹏. 关于内嵌卡瓦尾管悬挂器的应用探讨. 中国石油和化工标准与质量. 2016(22): 74-75 .  百度学术

百度学术

10. 韩峰,崔晓杰,薛占峰,邓同军. 悬挂器坐挂引起的套管二维屈曲失效形式研究. 中国科技论文. 2016(23): 2696-2699+2710 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: