Cement Squeezing for Pressure-Bearing Plugging in Ultra-High Temperature and High Pressure Wells in the Yinggehai Basin

-

摘要:

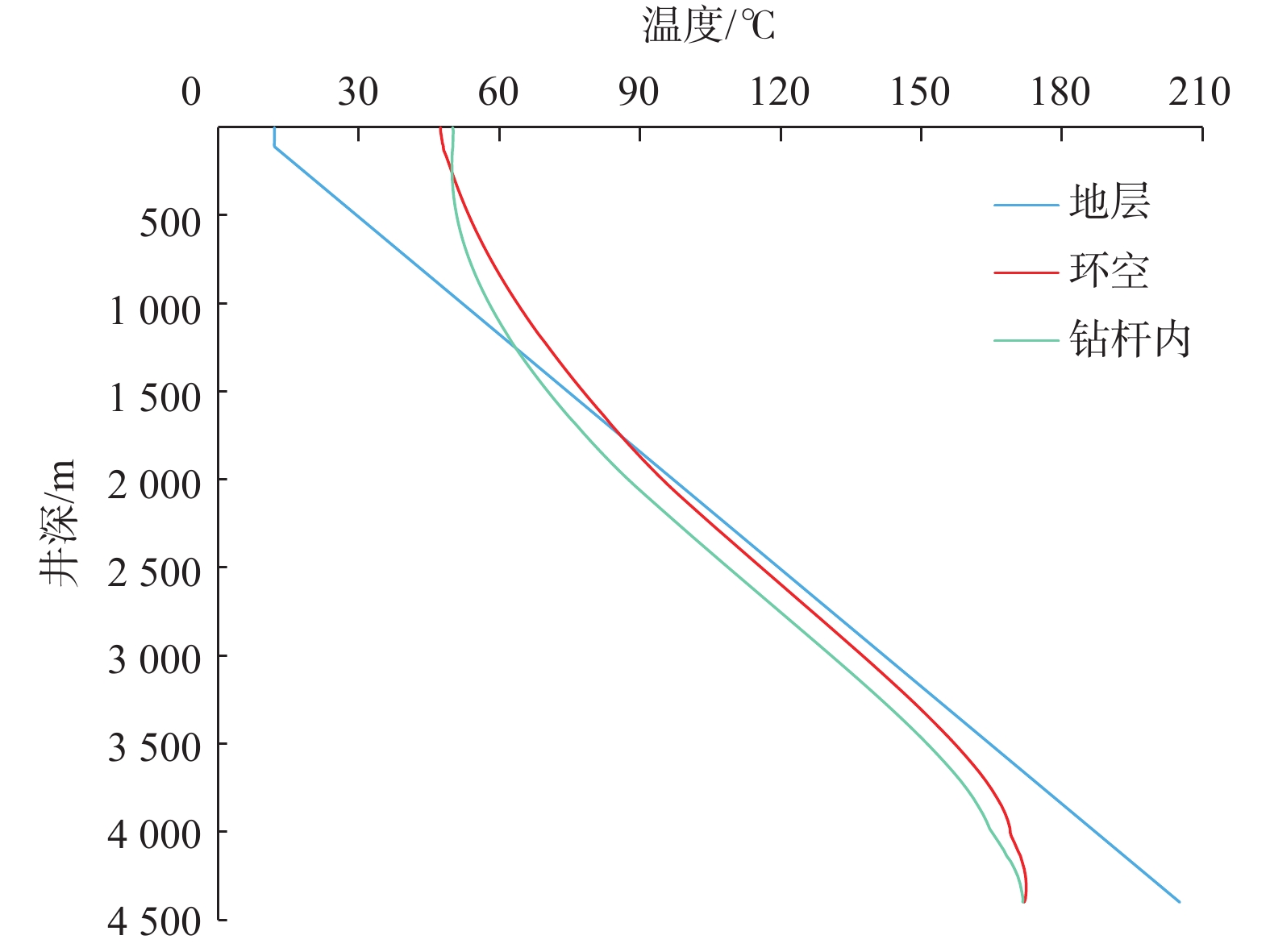

南海西部莺歌海盆地X构造具有超高温高压地质特征,最高地层温度204 ℃,最大地层压力系数2.19,但地层承压能力低,安全密度窗口窄,钻井过程中极易发生井漏等复杂情况,严重影响钻井安全。为提高地层承压能力,保证超高温高压井段钻井安全,设计了“前置液+抗高温水泥浆”注挤水泥浆体系,通过优化堵漏水泥浆配方,提高了堵漏水泥浆的耐温性能,增强了其封固性能;采用“试挤清洗液+注挤水泥浆”间歇式注挤水泥浆工艺,并利用Drillbench软件模拟分析了井筒温度场,根据井筒温度场精准控制注挤水泥时的水泥浆用量及胶凝时间,提高了堵漏效果。现场应用结果表明,X构造应用挤水泥承压堵漏技术,提高了地层承压能力,扩大了安全密度窗口,为后续超高温高压井段安全顺利钻进提供了重要条件。超高温高压井挤水泥承压堵漏技术可以满足莺歌海盆地X构造安全钻井的需求,并可为类似超高温高压井钻井提供借鉴。

Abstract:Cement squeezing in deep, hot, harsh environments presents special challenges The X structure of Yinggehai Basin in the western South China Sea oilfield is one such example. It has an ultra-high temperature and high pressure structure, with the formation temperature of up to 204 ℃ and formation pressure coefficient of up to 2.19. However, cement squeezing has been dangerously weak due to the low formation pressure-bearing capacity and narrow safety density window, and complications such as leakage could easily occur during drilling, which seriously affect the safety and integrity of operations. In order to improve the formation pressure-bearing capacity and ensure the safe and smooth drilling of ultra-high temperature and high pressure sections, a cement squeezing system “preflush + high temperature resistant cement slurry” was designed to improve the temperature resistance properties of leakage plugging slurry and enhance its sealing performance by optimizing the formulation of plugging cement slurry. The intermittent cement squeezing process of “cleaning pilot squeezing fluid + cement squeezing slurry” was adopted, and Drillbench software was used to simulate and analyze the wellbore temperature field, which accurately controls the slurry volume and gelation time based on the wellbore temperature field and effectively improves the plugging effect. Field application results showed that the technology could improve the pressure-bearing capacity of formation, and expand the safety density window in the X structure, as well as provide important conditions for the safe and smooth drilling in subsequent ultra-high temperature and high pressure sections. This technology can provide technical support for the successful drilling of the X structure in the Yinggehai Basin, which is worthy of reference for similar ultra-high temperature and high pressure wells.

-

-

表 1 堵漏剂PC-B62对0.5 mm宽裂缝的堵漏效果(180 ℃)

Table 1 Effect of PC-B62 plugging agent on 0.5 mm wide fracture (180 ℃)

裂缝宽度/mm PC-B62加量,% 试验压差/MPa 试验现象 0.5 0 1.00 全部漏失 0.5 0.5 2.02 漏失1/6堵住 0.5 0.5 3.00 无漏失 0.5 0.5 5.00 无漏失 0.5 1.0 1.60 漏失1/4堵住 0.5 1.0 2.00 无漏失 0.5 1.0 4.16 无漏失 0.5 1.0 5.17 无漏失 表 2 堵漏剂PC-B62对1.0 mm宽裂缝的堵漏效果(180 ℃)

Table 2 Effect of PC-B62 plugging agent on 1.0 mm wide fracture (180 ℃)

裂缝宽度/mm PC-B62加量,% 试验压差/MPa 试验现象 1.0 0.5 0.30 全部漏失 1.0 1.0 0.30 全部漏失 1.0 2.0 0.30 全部漏失 1.0 2.5 0.76 无漏失 1.0 2.5 1.50 无漏失 1.0 2.5 3.00 无漏失 1.0 2.5 4.00 无漏失 1.0 2.5 5.40 无漏失 表 3 X-10井挤水泥作业参数

Table 3 Operation parameters of cement squeezing in Well X-10

挤注

次序挤入体积/

m3挤入排量/

(m3·min–1)挤入压力/

MPa停泵压力/

MPa1 4.48 0.32 0.69~14.13 12.76 2 1.20 0.08 12.76~16.55 16.20 3 0.64 0.04 16.20~17.93 16.89 4 0.64 0.04 16.89~20.68 20.00 5 0.48 0.04 20.00~22.35 22.35 -

[1] 罗鸣,韩成,陈浩东,等. 南海西部高温高压井堵漏技术[J]. 石油钻采工艺, 2016, 38(6): 801–804. LUO Ming, HAN Cheng, CHEN Haodong, et al. Plugging technology for HTHP wells in western South China Sea[J]. Oil Drilling & Production Technology, 2016, 38(6): 801–804.

[2] 陈晓华,王翔,冯永超,等. 泾河油田裂缝性致密油藏防漏堵漏技术[J]. 断块油气田, 2017, 24(2): 297–300. CHEN Xiaohua, WANG Xiang, FENG Yongchao, et al. Loss prevention and control technology for fractured reservoirs in Jinghe Oilfield [J]. Fault-Block Oil & Gas Field, 2017, 24(2): 297–300.

[3] 柳伟荣,倪华峰,王学枫,等. 长庆油田陇东地区页岩油超长水平段水平井井技术[J]. 石油钻探技术, 2020, 48(1): 9–14. LIU Weirong, NI Huafeng, WANG Xuefeng, et al. Shale oil horizontal drilling technology with super-long horizontal laterals in the Longdong Region of the Changqing Oilfield[J]. Petroleum Drilling Techniques, 2020, 48(1): 9–14.

[4] 何选蓬,程天辉,周健,等. 秋里塔格构造带风险探井中秋1井安全钻井关键技术[J]. 石油钻采工艺, 2019, 41(1): 1–7. HE Xuanpeng, CHENG Tianhui, ZHOU Jian, et al. Key technologies of safe drilling in Zhongqiu 1 Well, a risk exploration well in Qiulitag tectonic belt[J]. Oil Drilling & Production Technology, 2019, 41(1): 1–7.

[5] 田军,刘文堂,李旭东,等. 快速滤失固结堵漏材料ZYSD的研制及应用[J]. 石油钻探技术, 2018, 46(1): 49–54. TIAN Jun, LIU Wentang, LI Xudong, et al. Development and application of rapid filtration and consolidation lost circulation material ZYSD[J]. Petroleum Drilling Techniques, 2018, 46(1): 49–54.

[6] 石秉忠,解超,李胜,等. 杭锦旗区块锦58井区钻井液技术实践与认识[J]. 石油钻探技术, 2017, 45(6): 37–41. SHI Bingzhong, XIE Chao, LI Sheng, et al. Development and application of drilling fluid in the Jin-58 Well Block of the Hangjinqi Block[J]. Petroleum Drilling Techniques, 2017, 45(6): 37–41.

[7] 马新中,张申申,方静,等. 塔河10 区碳酸盐岩裂缝型储层承压堵漏技术[J]. 钻井液与完井液, 2018, 35(5): 36–40. MA Xinzhong, ZHANG Shenshen, FANG Jing,et al. Study on mud loss control under pressure in drilling fractured carbonate reservoirs in Block Tahe 10[J]. Drilling Fluid & Completion Fluid, 2018, 35(5): 36–40.

[8] 罗宇维,陈良,罗东辉,等. 深水高压井负压力窗口固井关键技术[J]. 中国海上油气, 2016, 28(4): 83–87. LUO Yuwei, CHEN Liang, LUO Donghui, et al. Key technology for negative pressure-weindow cementing in high deep water well[J]. China Offshore Oil and Gas, 2016, 28(4): 83–87.

[9] 董强,窦宏恩,鄢爱民. 挤水泥技术在委内瑞拉Caracoles油田的应用[J]. 天然气工业, 2004, 24(10): 59–61. doi: 10.3321/j.issn:1000-0976.2004.10.019 DONG Qiang, DOU Hongen, YAN Aimin. Application of cement squeeze technology in Caracoles Oil Field, Venezuela[J]. Natural Gas Industry, 2004, 24(10): 59–61. doi: 10.3321/j.issn:1000-0976.2004.10.019

[10] 罗翰, 何世明, 罗德明. 川深1井超高温高压尾管固井技术[J]. 石油钻探技术, 2019, 47(4): 17–21. LUO Han, HE Shiming, LUO Deming. Ultra-high temperature and high pressure liner cementing technology in Well Chuanshen 1[J]. Petroleum Drilling Techniques, 2019, 47(4): 17–21.

[11] 姚晓, 葛荘, 汪晓静, 等. 加砂油井水泥石高温力学性能衰退机制研究进展[J]. 石油钻探技术, 2018, 46(1): 17–23. doi: 10.11911/syztjs.2018008 YAO Xiao, GE Zhuang, WANG Xiaojing, et al. Research progress of degradation of mechanical properties of sand-containing cement in high temperature regimes[J]. Petroleum Drilling Techniques, 2018, 46(1): 17–23. doi: 10.11911/syztjs.2018008

[12] 潘国臣,刘锋,徐伟,等. 塔河油田严重漏失井挤水泥堵水工艺研究[J]. 钻采工艺, 2013, 36(2): 12–14. doi: 10.3969/J.ISSN.1006-768X.2013.02.04 PAN Guochen, LIU Feng, XU Wei, et al. Study on cement squeeze water plugging technology of the serious absorption well in Tahe Oilfield[J]. Drilling & Production Technology, 2013, 36(2): 12–14. doi: 10.3969/J.ISSN.1006-768X.2013.02.04

[13] 王伟强,王义龙,张连进,等. 硅灰加入量对水泥结合铝硅浇注料性能的影响[J]. 工业炉, 2018, 40(2): 64–66. doi: 10.3969/j.issn.1001-6988.2018.02.017 WANG Weiqiang, WANG Yilong, ZHANG Lianjin, et al. Effect of the additions of Uf-SiO2 on properties of castables by combining alumina and silica with cement[J]. Industrial Furnace, 2018, 40(2): 64–66. doi: 10.3969/j.issn.1001-6988.2018.02.017

[14] 丹美涵,于斌,罗宇维,等. 超高温水泥浆在乐东A井中的应用[J]. 内蒙古石油化工, 2017(7): 21–24. doi: 10.3969/j.issn.1006-7981.2017.07.008 DAN Meihan, YU Bin, LUO Yuwei, et al. Ultra high temperature cement slurry applied in cementing Well Ledong-A[J]. Inner Mongolia Petrochemical Industry, 2017(7): 21–24. doi: 10.3969/j.issn.1006-7981.2017.07.008

[15] 苏勤,赵向阳. 一种精细控压钻井流动模型的研究与应用[J]. 石油钻探技术, 2013, 41(1): 8–13. doi: 10.3969/j.issn.1001-0890.2013.01.002 SU Qin, ZHAO Xiangyang. The research and application of a fine MPD flow model[J]. Petroleum Drilling Techniques, 2013, 41(1): 8–13. doi: 10.3969/j.issn.1001-0890.2013.01.002

-

期刊类型引用(6)

1. 李朋,张艳玉,孙晓飞,李冬冬,刘洋,陈会娟. SAGD循环预热割缝筛管参数影响规律研究. 工程热物理学报. 2020(04): 940-947 .  百度学术

百度学术

2. 薛衡,黄祖熹,王贺华,安永生,刘榧,成一,何冰,刘卡. Ahdeb油田水平井控水完井及一体化耦合模型. 石油与天然气地质. 2019(02): 423-429 .  百度学术

百度学术

3. 李朋,张艳玉,孙晓飞,陈会娟,刘洋. 稠油油藏双管水平井注汽井筒参数预测新模型. 特种油气藏. 2019(04): 85-90 .  百度学术

百度学术

4. 李朋,张艳玉,孙晓飞,刘洋,谢孟珂,王朝,陈会娟. SAGD循环预热注汽参数影响规律数值模拟. 中南大学学报(自然科学版). 2019(11): 2896-2905 .  百度学术

百度学术

5. 陈会娟,李明忠,狄勤丰,刘春苗. 多点注汽水平井井筒出流规律数值模拟. 石油学报. 2017(06): 696-704 .  百度学术

百度学术

6. 徐磊. 稠油热采井防砂筛管热稳定性优化仿真分析. 北京石油化工学院学报. 2016(02): 40-45 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: