Intelligent Drilling Technology Research Status and Development Trends

-

摘要:

随着油气勘探开发逐渐向非常规、低渗透、深层、深水等复杂油气领域发展,钻井工程在安全、经济和效率等方面面临一系列难题和挑战。基于大数据和人工智能等前沿技术的智能钻井技术,有望实现钻井过程的超前探测、智能导向、闭环控制和智能决策,从而大幅提高油气井产量和采收率,降低钻井成本,近年来已成为国内外研究热点。详细介绍了国内外智能钻井关键技术的发展现状,包括井眼轨道智能优化、钻速智能优化、智能导向钻井、井下闭环调控、智能监测与决策等技术,并分析了国内外智能钻机、智能钻杆、智能钻头、智能控压钻井系统和智能导向钻井系统等装备的主要进展,指出基于我国人工智能技术的高速发展,需要加强钻井工程与前沿理论、技术的跨界融合,强化协同创新,建立完善的智能钻井理论与技术体系,为实现我国复杂油气资源高效勘探开发和油气发展战略提供技术支撑。

Abstract:As oil and gas exploration and development shift to unconventional, low permeability, deep formations, deepwater and other complex hydrocarbon resources, drilling engineering is facing a series of difficulties and challenges in terms of safety, economics and efficiency. Centering around cutting-edge technologies such as big data and artificial intelligence, intelligent drilling technology is expected to be able to incorporate advanced detection, intelligent steering, closed-loop control and intelligent decision-making in the drilling process, thereby greatly increasing the productivity and oil and gas recovery ratio and reducing drilling costs. In recent years, intelligent drilling technology is absolutely cutting edge, as both the frontier and the key hotspot of research worldwide. In this paper, we introduced in detail the development status of key engineering technologies in intelligent drilling, including the intelligent optimization of borehole trajectory and drilling speed, intelligent steering, downhole closed-loop control, intelligent monitoring and decision-making, etc. The principle breakthroughsin intelligent drilling equipment such as smart drilling rig, drill pipe, drill bit, intelligent pressure management drilling system and intelligent steering drilling system were analyzed. Due to the rapid development of artificial intelligence technology in China, it is necessary to strengthen the cross-border integration of drilling engineering and cutting-edge theory/technology, to enhance collaborative inno-vation and to establish a comprehensive intelligent drilling technology system, so as to provide technical supports in the efficient exploration and development of complex oil and gas resources as well as in the strategies of oil and gas development in China.

-

Keywords:

- intelligent drilling /

- drilling equipment /

- technical status /

- development trends

-

-

-

[1] 胡文瑞. 地质工程一体化是实现复杂油气藏效益勘探开发的必由之路[J]. 中国石油勘探, 2017, 22(1): 1–5. doi: 10.3969/j.issn.1672-7703.2017.01.001 HU Wenrui. Geology-engineering integration: a necessary way to realize profitable exploration and development of complex reservoirs[J]. China Petroleum Exploration, 2017, 22(1): 1–5. doi: 10.3969/j.issn.1672-7703.2017.01.001

[2] LEE J, PARK C, KANG J M, et al. Horizontal well design incorporated with interwell interference, drilling location, and trajectory for the recovery optimization[R]. SPE 125539, 2009.

[3] VLEMMIX S, JOOSTEN G J P, BROUWER R, et al. Adjoint-based well trajectory optimization[R]. SPE 121891, 2009.

[4] MORALES A N, NASRABADI H, ZHU D. A modified genetic algorithm for horizontal well placement optimization in gas condensate reservoirs[R]. SPE 135182, 2010.

[5] LYU Z, SONG X, GENG L, et. al Optimization of multilateral well configuration in fractured reservoirs[J]. Journal of Petroleum Science and Engineering, 2019, 172: 1153–1164. doi: 10.1016/j.petrol.2018.09.024

[6] HEGDE C, GRAY K. Evaluation of coupled machine learning models for drilling optimization[J]. Journal of Natural Gas Science and Engineering, 2018, 56: 397–407. doi: 10.1016/j.jngse.2018.06.006

[7] ARABJAMALOEI R, SHADIZADEH S. Modeling and optimizing rate of penetration using intelligent systems in an Iranian southern oil field (Ahwaz Oil Field)[J]. Petroleum Science and Technology, 2011, 29(16): 1637–1648. doi: 10.1080/10916460902882818

[8] BATAEE M, MOHSENI S. Application of artificial intelligent systems in ROP optimization: a case study[R]. SPE 140029, 2011

[9] LIAO X, KHANDELWAL M, YANG H, et al. Effects of a proper feature selection on prediction and optimization of drilling rate using intelligent techniques[J/OL]. Engineering with Computers, 2019:1–12[2019–08–15]. https://doi.org/10.1007/s00366-019-00711-6.

[10] GAN C, CAO W, WU M, et al. Two-level intelligent modeling method for the rate of penetration in complex geological drilling process[J]. Applied Soft Computing, 2019, 80: 592–602. doi: 10.1016/j.asoc.2019.04.020

[11] CUI M, WANG G H, GE H Y, et al. Maximizing drilling performance with real-time drilling vibration mitigation in the deep wells[R]. SPE 181003, 2016.

[12] ZHAO F, WANG H, CUI M. Optimizating drilling operating parameters with real-time surveillance and mitigation system of downhole vibration in deep wells[R]. SPE 180661, 2016.

[13] SUGIURA J, BOWLER A, HAWKINS R, et al. Downhole steering automation and new survey measurement method significantly improves high-dogleg rotary-steerable system performance[R]. SPE 166165, 2013.

[14] ZHANG C, ZOU W, CHENG N, et al. Trajectory tracking control for rotary steerable systems using interval type-2 fuzzy logic and reinforcement learning[J]. Journal of the Franklin Institute, 2018, 355(2): 803–826. doi: 10.1016/j.jfranklin.2017.12.001

[15] SONG X, VADALI M, XUE Y, et al. Tracking control of rotary steerable toolface in directional drilling: IEEE International Conference on Advanced Intelligent Mechatronics (AIM)[R/OL]. [2019–08–15]. https://doi.org/10.1109/AIM.2016.7576935.

[16] KULLAWAN K, BRATVOLD R B, NIETO C M. Decision-oriented geosteering and the value of look-ahead information: a case-based study[J]. SPE Journal, 2017, 22(3): 767–782. doi: 10.2118/184392-PA

[17] KAMEL M A, ELKATATNY S, MYSOREWALA M F, et al. Adaptive and real-time optimal control of stick-slip and bit wear in autonomous rotary steerable drilling[J]. Journal of Energy Resources Technology, Transactions of the ASME, 2018, 140(3): 1–12.

[18] ABDULGALIL F, SIGUERDIDJANE H. PID based on sliding mode control for rotary drilling system[C/OL]//EUROCON 2005—The International Conference on “Computer as a Tool”. [2019–08–15]. https://doi.org/10.1109/EURCON.2005.1629911

[19] HUO A, HE Y, WANG Y, et al. Research of disc valve friction torque modeling and integral sliding mode adaptive control for rotary steering drilling tool: 2010 2nd International Conference on Computer Engineering and Technology[C/OL]. [2019–08–15]. https://doi.org/10.1109/ICCET.2010.5485370.

[20] MATHEUS J, IGNOVA M, HORNBLOWER P. A hybrid approach to closed-loop directional drilling control using rotary steerable systems[J]. IFAC Proceedings Volumes, 2012, 45(8): 84–89. doi: 10.3182/20120531-2-NO-4020.00008

[21] 牛海峰, 蒋世全, 李汉兴, 等.旋转导向钻井工具井下闭环控制技术研究[C]//2011年度钻井技术研讨会暨第十一届石油钻井院所长会议论文集.北京: 石油工业出版社, 2011. NIU Haifeng, JIANG Shiquan, LI Hanxing, et al. Study on downhole closed-loop control technology of rotary steerable drilling tool[C]//Drilling Technology Seminar and Conference of Petroleum Drilling Institute. Beijing: Petroleum Industry Press, 2011.

[22] 李远志.新型静态偏置指向式旋转导向执行机构导向控制研究[D].天津: 天津大学, 2013. LI Yuanzhi. Steering control research on a new steering mechanism for static point-the-bit rotary steerable system[D]. Tianjin: Tianjin University, 2013.

[23] GARNER L, VACIK L, LIVESCU S, et al. Operational improvements with the expansion of an intelligent coiled tubing system to include real-time tension, compression, and torque data moni-toring[R]. SPE 179101, 2016.

[24] CORSER G P, HARMSE J E, CORSER B A, et al. Field test results for a real-time intelligent drilling monitor[R]. SPE 59227, 2000.

[25] 廖明燕.钻井过程实时状态监测与诊断技术研究[D].东营: 中国石油大学(华东), 2010. LIAO Mingyan. Real-time drilling process state monitoring and diagnosis[D]. Dongying: China University of Petroleum, 2010.

[26] 李浩.面向钻井现场监测的无线传感器网络传输信道建模与分析[D].武汉: 湖北工业大学, 2015. LI Hao. Transmission channel modeling and analysis of wireless sensor network for drilling site monitoring[D]. Wuhan: Hubei University of Technology, 2015.

[27] SVENSSON I, SAEVERHAGEN E, BOUILLOUTA F M. Driving rig performance through real-time data analysis, benchmarking, dashboards and developed key performance indicators[R]. SPE 173413, 2015.

[28] BAAZIZ A, QUONIAM L. How to use big data technologies to optimize operations in upstream petroleum industry[J]. International Journal of Innovation, 2014, 1(1): 19–25.

[29] 李琪,徐英卓. 基于数据仓库的钻井工程智能决策支持系统研究[J]. 石油学报, 2003, 24(4): 77–80. doi: 10.3321/j.issn:0253-2697.2003.04.018 LI Qi, XU Yingzhuo. Intelligent decision support system based on data warehouse for drilling engineering[J]. Acta Petrolei Sinica, 2003, 24(4): 77–80. doi: 10.3321/j.issn:0253-2697.2003.04.018

[30] 高晓荣,徐英卓,李琪. 基于CBR的井下复杂情况与事故智能诊断和处理系统[J]. 计算机应用研究, 2008, 25(5): 1446–1449. doi: 10.3969/j.issn.1001-3695.2008.05.049 GAO Xiaorong, XU Yingzhuo, LI Qi. Intelligent diagnosis and process system case-based reasoning for drilling complex circs and accident[J]. Application Research of Computers, 2008, 25(5): 1446–1449. doi: 10.3969/j.issn.1001-3695.2008.05.049

[31] 杨红满,卢世浩,徐高军,等. 西北油田智能监测溢流预警系统建立与应用效果评价[J]. 化工设计通讯, 2017, 43(7): 90–92. doi: 10.3969/j.issn.1003-6490.2017.07.085 YANG Hongman, LU Shihao, XU Gaojun, et al. Establishment and application of intelligent monitoring overflow warning system in northwest oilfield[J]. Chemical Engineering Design Communications, 2017, 43(7): 90–92. doi: 10.3969/j.issn.1003-6490.2017.07.085

[32] 王以法. 人工智能钻井系统展望[J]. 石油钻探技术, 2000, 28(2): 36–38. doi: 10.3969/j.issn.1001-0890.2000.02.014 WANG Yifa. Prospect of artificial intelligence on drilling system[J]. Petroleum Drilling Techniques, 2000, 28(2): 36–38. doi: 10.3969/j.issn.1001-0890.2000.02.014

[33] 唐丽华,王洪英. 国外几种典型的新型自动化钻机[J]. 石油机械, 2005, 33(11): 78–80. doi: 10.3969/j.issn.1001-4578.2005.11.026 TANG Lihua, WANG Hongying. Several typical new types of foreign automated drilling rigs[J]. China Petroleum Machinery, 2005, 33(11): 78–80. doi: 10.3969/j.issn.1001-4578.2005.11.026

[34] REID D. The development of automated drilling rigs[R]. SPE 39373, 1998.

[35] DUNN M D, ARCHEY P J, OPSTAD E A, et al. Design, specification, and construction of a light, automated drilling system (LADS)[R]. SPE 74451, 2002.

[36] 张鹏飞,朱永庆,张青锋,等. 石油钻机自动化、智能化技术研究和发展建议[J]. 石油机械, 2015, 43(10): 13–17. ZHANG Pengfei, ZHU Yongqing, ZHANG Qingfeng, et al. Research and development of automatic and intelligent technologies for drilling rig[J]. China Petroleum Machinery, 2015, 43(10): 13–17.

[37] SMITH N, TONNESSEN L, BAUMANN U, et al. Novel machinery[M]// KLAUS B, RAINER K. Compression machinery for oil and gas. Cambridge MA: Gulf Professional Publishing, 2019: 543–567.

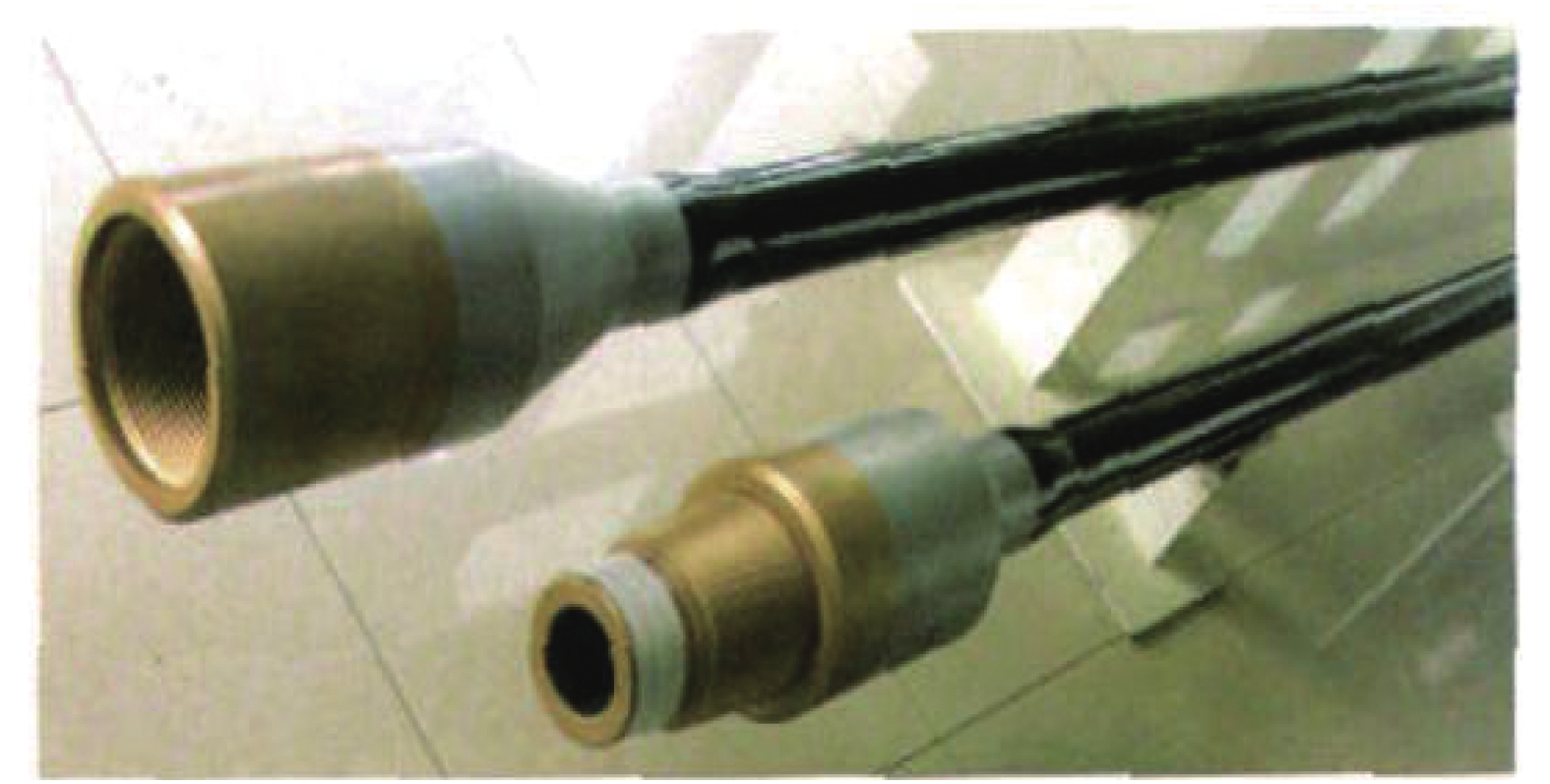

[38] 袁鹏斌,欧阳志英,余荣华. 智能钻杆研究现状及海隆电导通钻杆的试制[J]. 焊管, 2010, 33(6): 36–39. doi: 10.3969/j.issn.1001-3938.2010.06.008 YUAN Pengbin, OUYANG Zhiying, YU Ronghua. The current research status of intelligent drill pipe and trial-production of hailong's electrical conductance pass drill pipe[J]. Welded Pipe and Tube, 2010, 33(6): 36–39. doi: 10.3969/j.issn.1001-3938.2010.06.008

[39] 杨金华,朱桂清,张焕芝,等. 值得关注的国际石油工程前沿技术(Ⅰ)[J]. 石油科技论坛, 2012, 31(4): 43–50. doi: 10.3969/j.issn.1002-302x.2012.04.013 YANG Jinhua, ZHU Guiqing, ZHANG Huanzhi, et al. Noteworthy advanced international petroleum engineering technology(Ⅰ)[J]. Oil Forum, 2012, 31(4): 43–50. doi: 10.3969/j.issn.1002-302x.2012.04.013

[40] JELLISON M J, HALL D R, HOWARD D C, et al. Telemetry drill pipe: enabling technology for the downhole internet[R]. SPE 79885, 2003.

[41] JELLISON M J, HALL D R. Intelligent drill pipe creates the drilling network[R]. SPE 80454, 2003.

[42] 石崇东,张绍槐. 智能钻柱设计方案及其应用[J]. 石油钻探技术, 2004, 32(6): 7–10. doi: 10.3969/j.issn.1001-0890.2004.06.003 SHI Chongdong, ZHANG Shaohuai. Scheme design and application of intelligent drill string[J]. Petroleum Drilling Techniques, 2004, 32(6): 7–10. doi: 10.3969/j.issn.1001-0890.2004.06.003

[43] 刘选朝,张绍槐. 智能钻柱信息及电力传输系统的研究[J]. 石油钻探技术, 2006, 34(5): 10–13. doi: 10.3969/j.issn.1001-0890.2006.05.003 LIU Xuanchao, ZHANG Shaohuai. Study on information and power transmission based on an intelligent drill string[J]. Petroleum Drilling Techniques, 2006, 34(5): 10–13. doi: 10.3969/j.issn.1001-0890.2006.05.003

[44] 郭永峰.挪威公司推出自动优选层位的智能钻杆井下取芯工具[J].中国石油企业, 2019(增刊1): 86. GUO Yongfeng. Norwegian company launches intelligent drill pipe downhole coring tool with automatic preferred horizon [J]. China Petroleum Enterprise, 2019(supplement1): 86.

[45] 胡永建,王岚. 基于线性仿真的高频磁耦合有缆钻杆信道建模[J]. 石油钻探技术, 2019, 47(2): 120–126. doi: 10.11911/syztjs.2019050 HU Yongjian, WANG Lan. Modeling high-frequency magnetic coupling wired drill pipe channel based on linear simulation[J]. Petroleum Drilling Techniques, 2019, 47(2): 120–126. doi: 10.11911/syztjs.2019050

[46] 王以法. 新型智能钻头的设计[J]. 石油学报, 2003, 24(1): 92–95. doi: 10.3321/j.issn:0253-2697.2003.01.019 WANG Yifa. A new intelligent bit design[J]. Acta Petrolei Sinica, 2003, 24(1): 92–95. doi: 10.3321/j.issn:0253-2697.2003.01.019

[47] LESEULTRE A, LAMINE E, JONSSON A. An instrumented bit: a necessary step to the intelligent BHA[R]. SPE 39341, 1998.

[48] SINOR L A, HANSEN W R, DYKSTRA M W, et al. Drill bits with controlled cutter loading and depth of cut: US6298930[P]. 2001-10-09.

[49] 兰雪梅. 贝克休斯公司发布第一款自适应钻头[J]. 天然气勘探与开发, 2017, 40(3): 127. LAN Xuemei. Baker Hughes releases its first adaptive drill bit[J]. Natural Gas Exploration and Development, 2017, 40(3): 127.

[50] 朱丽华. 哈里伯顿推出新一代CruzerTM深切削滚珠元件钻头技术[J]. 钻采工艺, 2017, 40(4): 118–118. doi: 10.3969/j.issn.1006-768X.2017.04.040 ZHU Lihua. Halliburton introduces a new generation of CruzerTM deep-cutting ball drill bit technology[J]. Drilling & Production Technology, 2017, 40(4): 118–118. doi: 10.3969/j.issn.1006-768X.2017.04.040

[51] 吴红建,郗凤亮,柯晓华. 智能控压钻井控制技术试验研究[J]. 石油天然气学报, 2013, 35(11): 150–154. doi: 10.3969/j.issn.1000-9752.2013.11.034 WU Hongjian, XI Fengliang, KE Xiaohua. Experimental study on intelligent managed pressure drilling[J]. Journal of Oil and Gas Technology, 2013, 35(11): 150–154. doi: 10.3969/j.issn.1000-9752.2013.11.034

[52] 周英操,刘伟. PCDS精细控压钻井技术新进展[J]. 石油钻探技, 2019, 47(3): 68–74. ZHOU Yingcao, LIU Wei. New progress on PCDS precise pressure management drilling technology[J]. Petroleum Drilling Techniques, 2019, 47(3): 68–74.

[53] HERNANDEZ J, PEREZ T C, GALLO Z J F, et al. Successful application of automated choke MPD system to prevent salt water kicks while drilling in a high pressure tertiary salt diapir with OBM in southern Mexico[C]. SPE 122211, 2009.

[54] 石林,杨雄文,周英操,等. 国产精细控压钻井装备在塔里木盆地的应用[J]. 天然气工业, 2012, 32(8): 6–10. doi: 10.3787/j.issn.1000-0976.2012.08.002 SHI Lin, YANG Xiongwen, ZHOU Yingcao, et al. Application of China-made precise managed pressure drilling equipment in the Tarim Basin[J]. Natural Gas Industry, 2012, 32(8): 6–10. doi: 10.3787/j.issn.1000-0976.2012.08.002

[55] 周英操,杨雄文,方世良,等. 精细控压钻井系统研制与现场试验[J]. 石油钻探技术, 2011, 39(4): 7–12. doi: 10.3969/j.issn.1001-0890.2011.04.002 ZHOU Yingcao, YANG Xiongwen, FANG Shiliang, et al. Development and field test of PCDS-I precise managed pressure drilling system[J]. Petroleum Drilling Techniques, 2011, 39(4): 7–12. doi: 10.3969/j.issn.1001-0890.2011.04.002

[56] 大安, Tom. 一款具有高度的智能控压钻井系统[EB/OL].(2019–08–02)[2019–09–10]http://www.oilsns.com/article/413800. Daan, Tom. An intelligent managed pressure drilling system with high performance [EB/OL]. (2019–08–02)[2019–09–10]. http://www.oilsns.com/article/413800.

[57] 王植锐,王俊良. 国外旋转导向技术的发展及国内现状[J]. 钻采工艺, 2018, 41(2): 37–41. doi: 10.3969/J.ISSN.1006-768X.2018.02.11 WANG Zhirui, WANG Junliang. Development of rotary steerable technology in foreign countries and China[J]. Drilling & Production Technology, 2018, 41(2): 37–41. doi: 10.3969/J.ISSN.1006-768X.2018.02.11

[58] GRINI M, RICE B, STROMBERG S. Field development utilizing rotary steering technology[R]. SPE 71398, 2001.

[59] ZALLUHOGLU U, DEMIRER N, MARCK J, et al. Steering advisory system for rotary steerable systems[R]. SPE 194090, 2019.

[60] 陈虎,和鹏飞,万圣良. 国产旋转导向及随钻测井系统在渤海某油田的应用[J]. 探矿工程(岩土钻掘工程), 2017, 44(3): 35–38. CHEN Hu, HE Pengfei, WAN Shengliang. Application of China-made rotary steering and logging while drilling systems in adjustment well of Bohai[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 2017, 44(3): 35–38.

-

期刊类型引用(5)

1. 任向海,李楠,李晶辉,杨志,彭振华,丁雯. 大排量深抽减载抽油泵研制. 重庆科技学院学报(自然科学版). 2024(02): 116-120 .  百度学术

百度学术

2. 秦飞,王禧文,丁保东,曹畅,高晨豪,郭继香. 塔河油田稠油开发经济效益评价. 天然气与石油. 2023(04): 144-150 .  百度学术

百度学术

3. 刘玉国,杨利萍,彭振华,曹畅,丁保东. 塔河油田抽油机效能提升技术研究与应用. 石油石化节能与计量. 2023(10): 1-5 .  百度学术

百度学术

4. 尹丹,罗日蕾. 空心抽油杆杆式电加热技术在高含蜡井的应用. 石油石化节能. 2022(07): 33-36 .  百度学术

百度学术

5. 杜坤,王鹏,李杨,蒋海岩,白玉. 塔河油田典型深抽工艺研究. 辽宁石油化工大学学报. 2019(05): 45-52 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: