Numerical Calculation Method of the Wellbore Temperature Field for Electric Heating Heavy Oil Thermal Recovery

-

摘要:

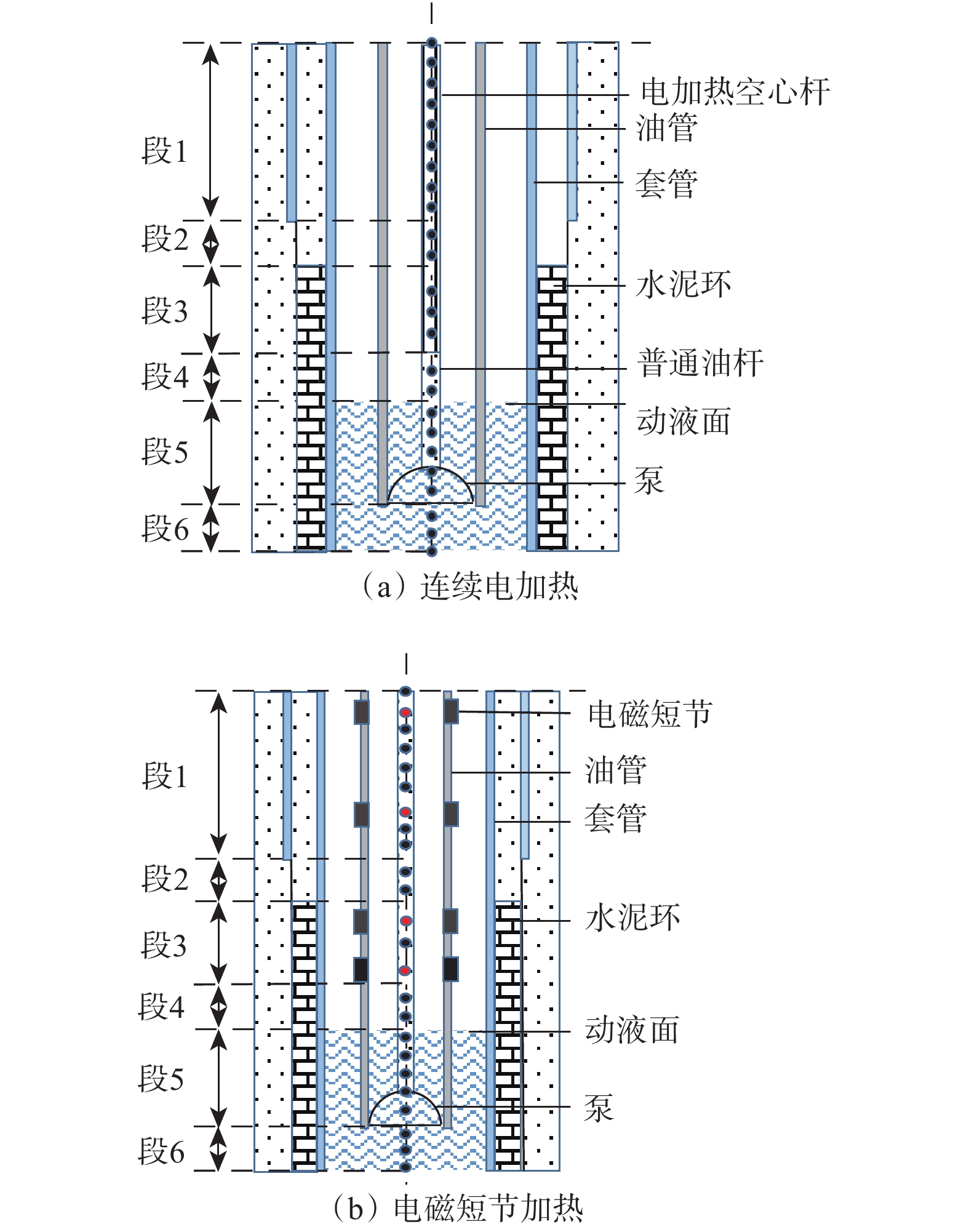

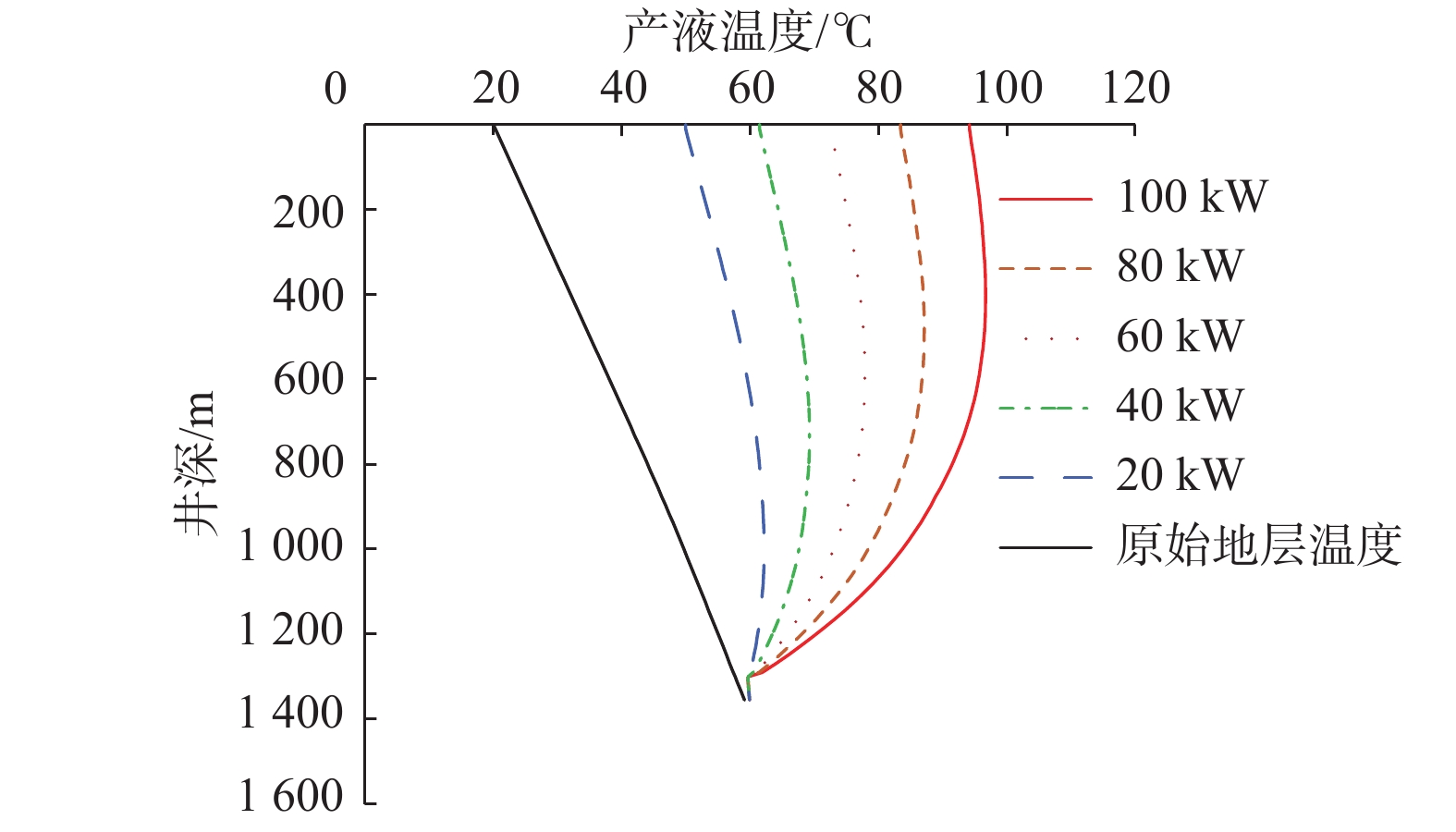

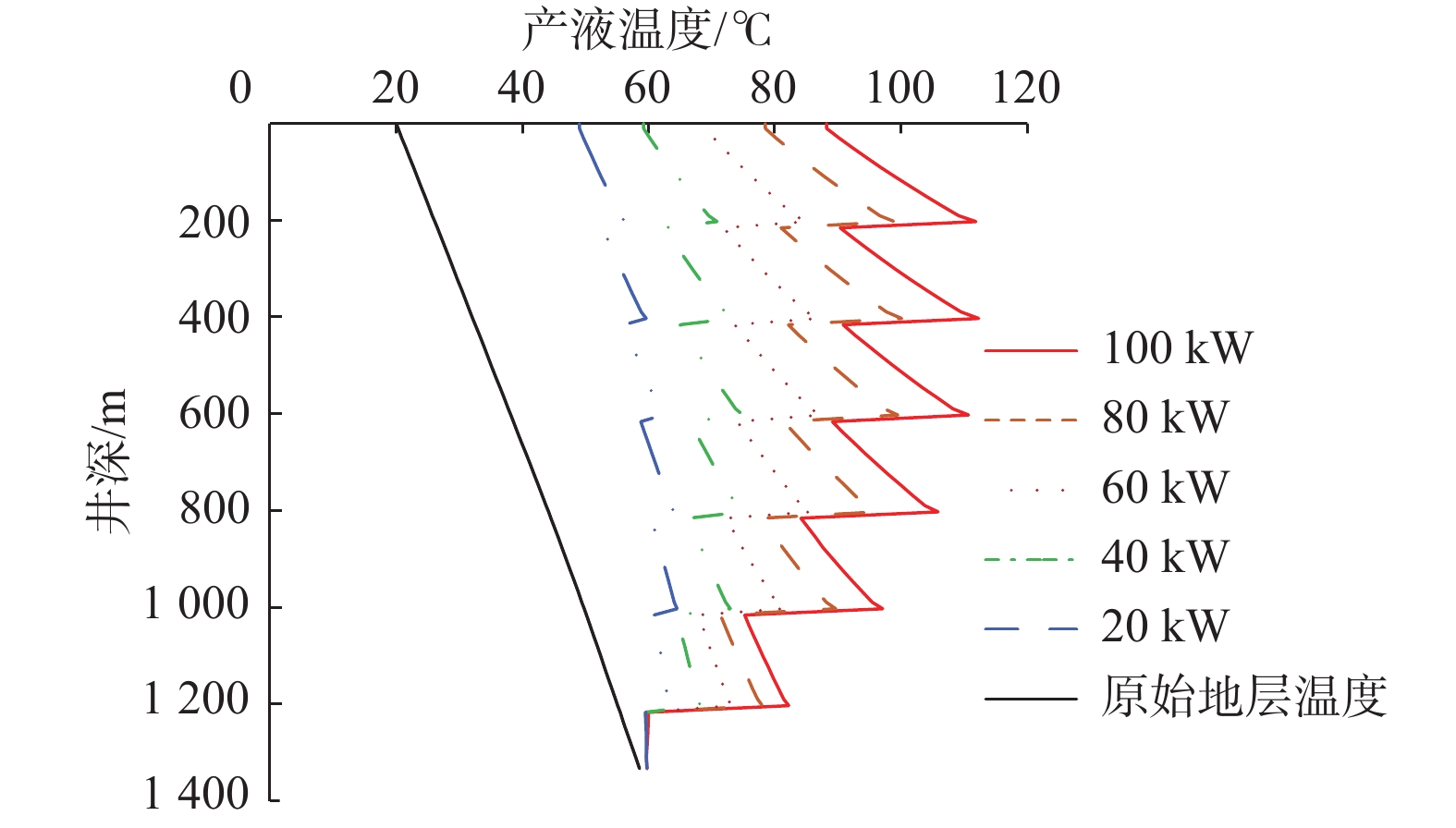

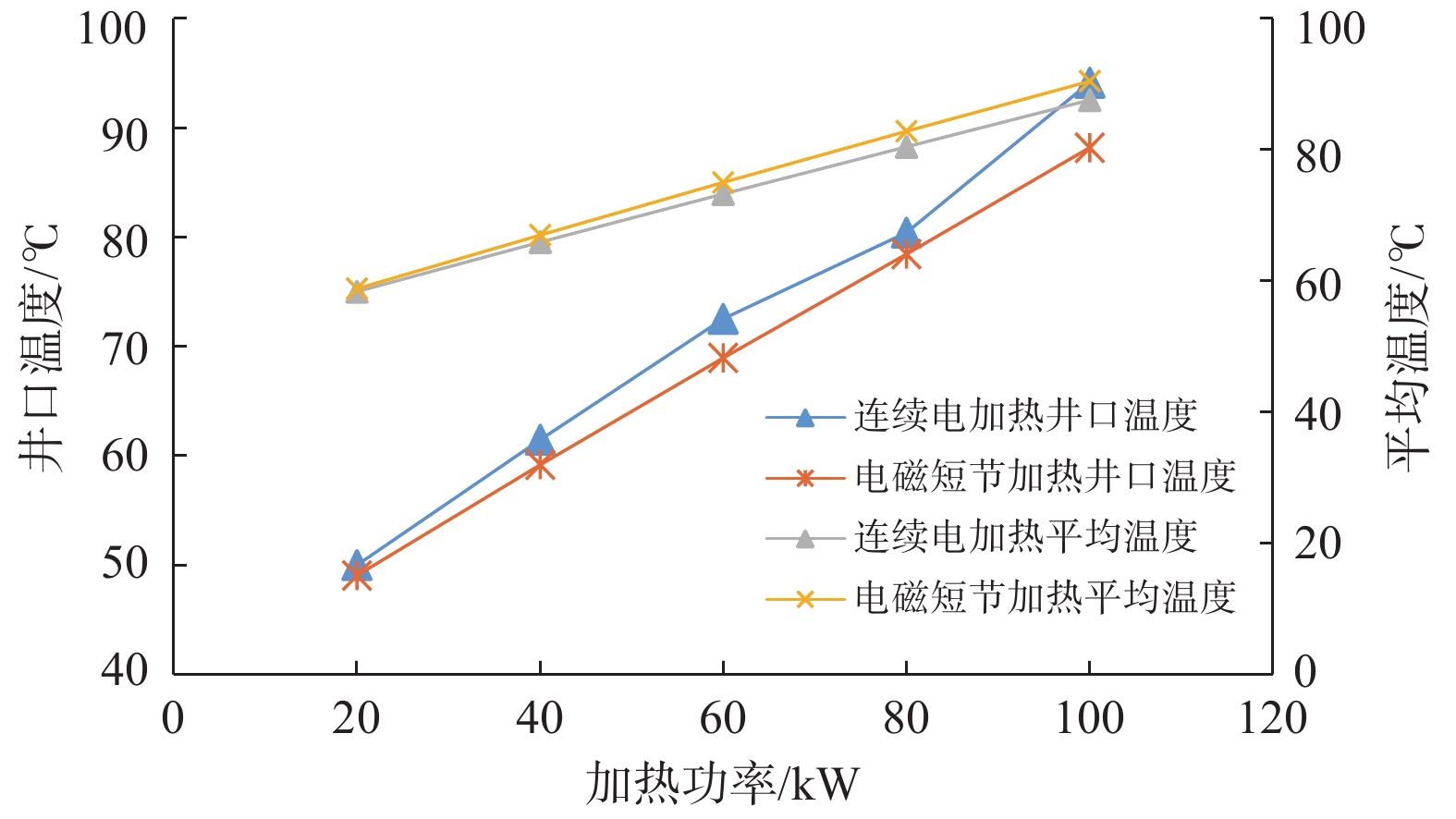

电加热稠油热采井筒温度场是热采作业参数设计的核心依据,基于传热学理论和气液两相流井筒温压场计算方法,考虑温度对稠油热物性影响,建立了连续电加热和电磁短节加热工艺井筒温度场的数值计算方法,并以大港油田X井为例,计算了不同加热功率下连续电加热和电磁短节加热工艺的井筒温度场。计算结果表明:井口温度的模型计算结果与实测值相对误差仅为3.10%,满足工程设计精度要求,也验证了计算方法的有效性和准确性;连续电加热工艺的井筒温度剖面平滑连续,而电磁短节加热工艺的井筒温度剖面呈锯齿形,且温度波动更大;连续电加热工艺的井口温度高于电磁短节加热,而连续电加热工艺的平均温度则低于电磁短节加热工艺。该研究结果可为电加热稠油热采工艺选择、作业参数设计提供指导和借鉴。

Abstract:The wellbore temperature field of electric heating-based heavy oil thermal recovery forms the basis of the thermal recovery operation parameters design. Based on the heat transfer theory and the calculation method of wellbore temperature/pressure fields for gas-liquid two-phase flow, the wellbore temperature field numerical calculation method for continuous electric heating and electromagnetic nipple heating processes that considers the influence of temperature on the thermal properties of heavy oil was established. By taking the Well X in Dagang Oilfield as an example, the wellbore temperature fields of continuous electric heating and electromagnetic nipple heating processes under different heating powers were calculated. The calculation results showed that the relative error between the wellhead temperature calculated with this model and the measured one was only 3.10%. This met the requirements of engineering design accuracy, and verified the validity and accuracy of this calculation method. The wellbore temperature profile formed by continuous electric heating was smooth and continuous, whereas the profile formed by electromagnetic nipple heating process was zigzag and had dramatic fluctuations. The wellhead temperature formed by the continuous electric heating process was higher than that of the electromagnetic nipple heating, and the average temperature of the continuous electric heating process was lower than that of the electromagnetic nipple heating process. The research results could provide guidance and reference for the selection of electric heating heavy oil thermal recovery processes and operation parameters design.

-

随着勘探开发技术的不断进步,页岩油已成为世界各国油气勘探的重点。由于页岩储层孔喉细小,渗透率极低,导致页岩油藏一次衰竭采收率极低,主要通过加密钻井技术和多级水力压裂技术实现一次采油的短期增产[1-3]。对于大多数地层能量不足的页岩储层,注气是一种常用的方法,与其他气体相比,CO2与页岩油的最小混相压力最低,不但易溶解在页岩油中增大原油体积系数,降低原油黏度,还能在压力大于7.38 MPa、温度高于31.2 ℃时达到超临界状态。CO2注入分为驱替和吞吐2种方式[4-5],其中CO2吞吐具有用量少、规模小和见效快的优势,学者们也针对CO2吞吐技术开展了深入研究。F. Torabi等人[6-7]通过室内CO2吞吐试验,研究了渗透率、CO2注入压力、闷井时间和吞吐次数等参数对低渗透油藏采收率的影响。杨正明等人[8]进行了岩心吞吐试验,认为第一轮吞吐是CO2吞吐的关键,最佳吞吐次数为3次,CO2波及体积随着闷井时间的增长而增大;但注入过量的CO2,会导致CO2利用率和排油率降低。钱坤等人[9-10]引入核磁共振方法,从微观尺度研究了CO2注入压力、注气速度和闷井时间对微观孔隙的动用程度,评价了微观剩余油的分布特征。

然而,页岩储层开发过程中必然伴随着水力压裂增产技术,压裂后的地层中形成和分布了大量裂缝,目前大部分研究主要集中在CO2吞吐提高采收率和注采参数优化等方面[11-13],对于压裂后裂缝的渗流特征及裂缝与基质之间的流体交换特征,以及不同渗透率条件下裂缝对CO2吞吐效果的影响研究很少。因此,笔者选取江汉油田潜3段储层不同渗透率级别页岩,开展了CO2吞吐试验,研究了裂缝对不同渗透率储层CO2吞吐效果的影响,并结合低场核磁共振技术,从微观孔隙尺度揭示了吞吐过程中裂缝–基质之间的流体交换特征,定量评价了小孔隙、大孔隙的动用程度,为评价裂缝性页岩储层产油特征、改善生产动态提供了依据和参考。

1. CO2吞吐试验

1.1 试验岩心

试验用页岩取自江汉油田王场地区潜3段,从所有钻取的短岩心中选孔隙度和渗透率相近的2块岩心作为一组,共选取3组6块岩心进行试验,其基本参数见表1。由表1可知,1#和2#页岩的平均孔隙半径最小,5#和6#页岩渗透率最大(平均孔隙半径也最大),3#和4#页岩储层物性居中。此外,为了模拟CO2–原油在裂缝与基质间的渗流特征,避免CO2注入后直接沿裂缝窜流,将1#、3#和5#岩心按照总体积的1/3横向切割(见图1),模拟人造裂缝。

表 1 试验岩心基本参数Table 1. Basic parameters of experimental cores岩心编号 长度/mm 直径/mm 孔隙度, % 渗透率/mD 有机碳含量,% 平均孔隙半径/nm 裂缝横向长度/mm 裂缝纵向长度/mm 1# 80.3 25.1 9.45 0.007 5 3.77 11.72 80.3 21.6 2# 81.3 25.2 8.76 0.005 2 3.59 8.13 无裂缝 无裂缝 3# 78.4 25.1 8.95 0.027 0 3.08 16.81 78.4 22.4 4# 79.2 25.2 9.57 0.044 0 2.74 19.24 无裂缝 无裂缝 5# 81.1 25.1 10.22 0.086 0 1.66 27.43 81.1 22.1 6# 80.6 25.1 11.38 0.094 0 2.14 24.86 无裂缝 无裂缝 1.2 试验流体

试验原油取自生产层位为潜3段的地面分离器原油。储层温度(73 ℃)下原油密度为0.862 kg/L,黏度为4.74 mPa·s。原油组分色谱分析结果表明,目标储层原油中C5—C25的摩尔分数为61.3%,而C32+的摩尔分数为11.2%,说明目标储层原油组分整体偏轻,但仍然含有一定量的重质组分。长细管(细管直径4.52 mm,长度150 mm)试验结果表明,在目标储层条件(18.7 MPa、73 ℃)下,原油与CO2的最小混相压力为20.4 MPa,说明在目前储层条件CO2与原油无法达到混相。测得不同压力下不同CO2溶解比例下的原油膨胀系数如图2所示,可以看出随着平衡压力增大,即随着CO2溶解量增大,原油膨胀系数呈线性增大;当平衡压力达到18.7 MPa时,原油膨胀率达到43.8%,说明目标储层原油具有较高的CO2溶解性和膨胀性。

1.3 试验装置

CO2吞吐试验装置包括多尺寸可调节无磁岩心夹持器、高压活塞驱替泵、恒温箱、压力传感器、回压阀、油气分离器(精度0.1 mL)、气体流量计和SPEC-RC2型低场核磁共振扫描仪等(见图3)。其中,岩心夹持器可夹持的岩心最大直径45 mm,长度120 mm;驱替泵的流量精度小于0.2 μL/min,压力精度小于0.5%;低场核磁共振扫描仪的磁场强度为0.23 T±0.03 T,脉冲发生器最小间隔50 ns,数字采集器脉冲精度100 ns,频率合成器范围1~40 MHz。

1.4 试验步骤

1)将所有岩心用甲苯和石油醚反复清洗后,放入200 ℃烘箱中加热24 h,充分排出岩心中的水蒸气,再将岩心放入高压密闭釜中抽真空48 h。

2)将试验原油在恒压50 MPa下注入放有页岩的高压密闭釜,充分饱和至注入泵体积不再变化时,恒压老化7 d;降压后取出页岩,将切割好的岩心放入热缩套管中,将岩心密封于套管中,确保试验过程中岩心裂缝尺寸不变;对饱和油后的岩心进行T2谱扫描。

3)将岩心放入夹持器中,加围压后关闭岩心出口端,从另一端以0.5 mL/min速度向岩心中恒速注入CO2,当注入体积达到0.2倍孔隙体积时,停止注入CO2,关闭注入端阀门,闷井12 h。

4)打开夹持器注入端,以同一压降梯度衰竭开发,直至压力降至大气压力,记录产出油和气量,并对吞吐后的岩心进行T2谱扫描,第一轮吞吐完成,然后再重复步骤3)—4),开始下一轮吞吐,累计吞吐3次。

1.5 试验结果

6块试验岩心经过3轮CO2吞吐,每轮吞吐采收率及累计吞吐采收率见表2。

表 2 试验岩心CO2吞吐采收率Table 2. CO2 huff and puff recovery of experimental cores岩心编号 吞吐采收率,% 累计吞吐

采收率,%第一轮 第二轮 第三轮 1# 20.6 8.8 2.4 31.8 2# 11.4 2.8 1.4 15.6 3# 22.4 11.6 4.3 38.3 4# 16.2 6.7 2.2 25.1 5# 25.8 14.1 4.7 44.6 6# 19.6 8.4 3.2 31.2 2. 裂缝对CO2吞吐效果的影响

2.1 裂缝对相同渗透率岩心采收率的影响

对比1#和2#岩心每轮吞吐采收率(见表2)可知,当无裂缝作用时,2#岩心第一轮吞吐采收率为11.4%,虽然后续2轮吞吐采收率分别为2.8%和1.4%,但从提高采收率幅度看,后续2次吞吐的采收率很低,可以认为有效吞吐次数为1次[14];当有裂缝作用时,相比于2#岩心,1#岩心第一轮吞吐采收率提高幅度80.7%,第二轮吞吐采收率提高幅度214.3%,有效吞吐次数增至2次。以上研究表明,岩心渗透率相当时,裂缝不但能够提高有效吞吐次数,还能提高每轮吞吐采收率;裂缝能够有效提高吞吐初期(前2轮)采收率,但对后期(第三轮)吞吐采收率影响较小。

2.2 裂缝对不同渗透率岩心采收率的影响

为了评价裂缝对不同渗透率岩心吞吐效果的影响,分别对比了不同渗透率条件下裂缝对CO2吞吐采收率的影响及有/无裂缝作用下不同渗透率岩心的吞吐采收率。由表2可知,有裂缝作用的1#、3#、5#岩心的累计吞吐采收率比无裂缝作用的2#、4#、6#岩心的累计吞吐采收率分别提高了103.4%、52.6%和42.9%。以上研究表明,随着渗透率增大,累计吞吐采收率不断升高。这说明虽然裂缝能够提高每轮吞吐采收率及累计吞吐采收率,但随着岩心渗透率增大,裂缝对吞吐采收率的影响程度不断下降。

此外,渗透率对裂缝岩心的吞吐采收率影响较小,而对无裂缝岩心的吞吐采收率影响较大。特别是前2轮吞吐中,在无裂缝作用下,当渗透率由0.044 0 mD(4#岩心)降至0.005 2 mD(2#岩心)时,第一轮吞吐采收率的降低幅度为35.8%,第二轮吞吐采收率的降低幅度达58.2%;相反,在有裂缝作用下时,当渗透率由0.027 0 mD(3#岩心)降至0.007 5 mD(1#岩心)时,第一轮和第二轮吞吐采收率的下降幅度分别仅为8.0%和24.1%。说明裂缝能够减小渗透率降低对CO2吞吐采收率的影响,也就是说压裂能够有效改善页岩油储层CO2吞吐的开发效果。

2.3 裂缝对采油速度的影响

第一轮降压衰竭中1#、2#岩心采油速度及采出程度的关系曲线见图4。从图4可以看出,有裂缝的1#岩心在放喷初期采油速度快速上升,而后采油速度呈阶梯状下降,当衰竭时间接近15 min时,采出程度基本保持不变;无裂缝的2#岩心在放喷初期采油速度缓慢上升,且最大采油速度仅为有裂缝作用下采油速度的一半。这主要是因为无裂缝作用时,放喷泄油面仅在采出端面,随着出口端压力的降低,CO2携带原油从基质孔隙中排出,孔隙距离采出端面越远,原油排出需要克服的阻力越大,导致很多远端孔隙中的原油随CO2运移时“半途而止”;裂缝的存在大大增加了基质的泄油面积,降低了基质中原油进入出口端的阻力,提高了放喷初期和中期的采油速度。

3. 微观孔隙动用特征分析

在低磁场强度中,可以通过测量岩石孔隙中含氢流体的弛豫信号振幅和弛豫速率来建立T2谱分布,研究岩石的微观孔隙结构特征[15-16]。岩石孔隙中饱和流体的弛豫时间与孔隙半径成正比,而振幅强度则代表了某一孔径孔隙中流体的饱和量[17],因此,可以通过分析CO2吞吐前后的T2谱分布变化来定量评价不同孔径孔隙的原油动用特征。

3.1 裂缝作用下的基质动用特征

3.1.1 T2谱分布特征

根据不同孔径孔隙中原油产生的横向弛豫时间与孔隙半径成正比这一原理[16-17],结合T2谱曲线中波峰与波谷对应的弛豫时间,可以识别出岩心在饱和油状态下的基质与裂缝。1#、2#岩心饱和油及每轮吞吐后的T2谱分布结果如图5所示。1#岩心包含裂缝,0.1 ms<T2≤105 ms时对应的区间为基质,105 ms<T2≤1 100 ms时对应的区间为裂缝(见图5(a))。2#岩心中由于不存在裂缝,因此弛豫时间T2在105~1 100 ms之间既不存在信号振幅,也不存在波峰(见图5(b))。此外,为了便于后续研究不同孔径孔隙中原油的动用特征,进一步将基质孔隙大小划分为2类,即小孔隙(0.1 ms<T2≤10 ms)和大孔隙(10 ms<T2≤105 ms)。

由图5可知,1#和2#岩心饱和油状态下T2谱分布中小孔隙和大孔隙对应的T2谱形态基本相似。小孔隙对应波峰明显高于大孔隙对应波峰,说明2块岩心孔隙结构相似,小孔隙发育程度高,而大孔隙发育程度较差,且大孔隙、小孔隙之间连通性较差。随着CO2吞吐次数增多,2块岩心的小孔隙和大孔隙对应的振幅均下降,但下降幅度逐渐减小,且大孔隙对应振幅的下降幅度大于小孔隙,说明CO2吞吐过程中大、小孔隙均有动用,且大孔隙的动用程度高于小孔隙。而1#岩心的小孔隙和大孔隙对应振幅的下降幅度均明显大于2#岩心,说明裂缝不但提高了大孔隙中原油的动用程度,还提高了小孔隙中原油的动用程度。

3.1.2 不同孔径孔隙采出程度对比

为进一步定量评价小孔隙和大孔隙中原油的动用程度,根据岩心饱和油后某一弛豫时间范围内信号振幅之和与其对应孔径孔隙中的总饱和油量成正比的特征[18],计算出吞吐前后不同孔径孔隙中的原油采出程度:

ER=∑TmaxTminw0−∑TmaxTminwh∑TmaxTminw0×100% (1) 式中:ER为孔隙原油采出程度;Tmin,Tmax分别为T2谱分布中某一孔径孔隙对应的最小和最大驰豫时间,ms;w0为初始饱和油状态下T2谱的信号振幅;wh为某轮吞吐后T2谱的信号振幅。

1#和2#岩心每轮吞吐后不同孔隙的原油采出程度如图6所示。从图6可以看出,无论有无裂缝的影响,CO2吞吐过程中大孔隙原油采出程度一直大于小孔隙。而裂缝对大孔隙、小孔隙采出程度的影响会随着吞吐次数的增加而逐渐变化(见表3)。

表 3 不同吞吐轮次中裂缝对大、小孔隙采出程度提高幅度的影响Table 3. Influence on the increase rate in degree of reserve recovery from macropores and micropores contributed by fractures in each huff and puff cycle吞吐轮次 孔隙类型 采出程度,% 采出程度提高

幅度,%1#岩心 2#岩心 第一轮 小孔隙 6.8 4.4 54.5 大孔隙 37.5 24.6 52.4 第二轮 小孔隙 4.3 1.8 138.9 大孔隙 19.6 13.8 42.0 第三轮 小孔隙 1.8 0.6 200.0 大孔隙 10.5 8.7 20.7 从表3可知,第一轮吞吐中,有裂缝作用下大孔隙原油采出程度为37.5%,比无裂缝作用下大孔隙采出程度提高了近52.5%,虽然小孔隙采出程度较低,但相比于2#岩心,裂缝仍然能够将小孔隙采出程度提高近54.6%;第二轮吞吐中,裂缝提高大孔隙采出程度幅度下降至42.0%,而小孔隙采出程度提高幅度达到138.9%;第三轮吞吐中,裂缝提高大孔隙采出程度幅度下降至20.7%,而小孔隙采出程度提高幅度达到200.0%。说明随着CO2吞吐次数的增加,裂缝对大孔隙中原油采出程度的影响在减弱,而对小孔隙中原油采出程度的影响在增强。

3.2 不同渗透率岩心基质动用特征

3.2.1 T2谱分布特征

根据3.1节的识别方法,分别识别出3#和5#岩心的基质(小孔隙和大孔隙)及裂缝。2块岩心饱和油及每轮吞吐后的T2谱分布结果如图7所示。

从图7可以看出,3#和5#岩心在饱和油状态下的T2谱分布与1#岩心存在差异,3#岩心中小孔隙对应波峰的峰值与大孔隙对应波峰的峰值基本相当,说明该岩心物性较好,大孔隙、小孔隙发育程度较高且相当,大孔隙、小孔隙之间连通性较好。5#岩心中小孔隙对应波峰的峰值明显小于大孔隙对应波峰的峰值,说明该岩心大孔隙发育程度高,小孔隙发育程度较差,大、小孔隙之间连通性好,原油主要赋存于大孔隙之中[19-20]。结合图5(a)可知,随着岩心渗透率的增大,岩心孔隙结构参数变好,T2谱分布中大孔隙对应峰值及面积不断增大,小孔隙对应峰值及面积不断降低。在CO2吞吐过程中,随着吞吐次数增多,3#和5#岩心大孔隙、小孔隙对应振幅的变化规律与1#岩心相似,但由于3#和5#岩心大孔隙发育程度高,其对应振幅的下降幅度更大,可以看出采收率的提高主要来源于大孔隙。从T2谱分布的变化可知,对于储层物性较好的岩心,大孔隙仍然是后续挖潜的主要方向。

3.2.2 不同孔径孔隙采出程度对比

含有裂缝的3块岩心大孔隙、小孔隙采出程度关系曲线如图8所示。从图8可以看出,随着渗透率降低,小孔隙采出程度不断下降;但随着吞吐次数增加,3块岩心的小孔隙采出程度的差异减小。这说明高渗透率岩心由于大孔隙发育程度高,孔喉连通性好,CO2在进入大孔隙后,通过扩散和抽提作用能够动用与其连通的小孔隙,导致CO2波及体积大,小孔隙采出程度也相对较高。随着吞吐次数增加,由于小孔隙中原油的动用主要依靠缓慢的抽提和传质作用,导致小孔隙采出程度快速下降;而大孔隙采出程度随吞吐次数增多而快速下降,这主要是因为大孔隙原油的动用主要依靠原油体积膨胀和降压时的溶解气驱作用,这一过程快速且主要发生在吞吐初期,后续吞吐主要动用的是已波及区域内大孔隙中的剩余油,由于剩余油组分加重,导致后续吞吐中大孔隙的采出程度快速下降。

4. 结 论

1)裂缝能够显著提高CO2吞吐初期采油速度和采收率,但随着岩心渗透率升高和吞吐次数增多,裂缝对吞吐采收率的影响程度逐渐降低。另外,裂缝还能降低渗透率对CO2吞吐采收率的影响。

2)不管有无裂缝存在,CO2吞吐过程中大孔隙的动用程度高于小孔隙,但随着吞吐次数增多,裂缝对大孔隙原油采出程度的提高幅度不断减小,而对小孔隙原油采出程度的提高幅度不断增大。

3)大孔隙中原油主要靠CO2体积膨胀和溶解气驱方式动用,速度快且产量高;而小孔隙中原油主要靠抽提和传质方式动用,过程缓慢且产量低,导致后续轮次吞吐中CO2波及体积减小,动用效果变差,产量降低速度快。

-

表 1 大港油田X井实钻井身结构

Table 1 Actual casing program of Well X in Dagang Oilfield

套管 外径/mm 井眼直径/mm 套管下深/m 水泥返高/m 表层套管 244.50 311.1 290.00 地面 生产套管 139.70 215.9 1 388.00 865.00 表 2 连续电加热和电磁短节加热工艺的井筒温度场剖面均方差比较

Table 2 Comparison of the mean square errors of wellbore temperature field profiles formed by continuous electric heating and electromagnetic nipple heating processes

加热方法 不同加热功率的井筒温度场剖面均方差 20 kW 40 kW 60 kW 80 kW 100 kW 连续电加热 11.63 8.40 5.31 2.97 3.82 电磁短节加热 14.40 10.96 7.40 4.40 4.01 -

[1] 刘文章. 普通稠油油藏二次热采开发模式综述[J]. 特种油气藏, 1998, 5(2): 1–7. LIU Wenzhang. Summary of secondary thermal recovery for conventional heavy oil reservoir[J]. Special Oil & Gas Reservoirs, 1998, 5(2): 1–7.

[2] 梁丹,冯国智,曾祥林,等. 海上稠油两种热采方式开发效果评价[J]. 石油钻探技术, 2014, 42(1): 95–99. doi: 10.3969/j.issn.1001-0890.2014.01.019 LIANG Dan, FENG Guozhi, ZENG Xianglin, et al. Evaluation of two thermal methods in offshore heavy oilfields development[J]. Petroleum Drilling Techniques, 2014, 42(1): 95–99. doi: 10.3969/j.issn.1001-0890.2014.01.019

[3] 唐述凯,李明忠,刘陈伟,等. 闭式热流体循环井筒温度分布规律研究[J]. 石油钻探技术, 2014, 42(5): 104–108. TANG Shukai, LI Mingzhong, LIU Chenwei, et al. Temperature distribution in closed wellbore with hot fluid circulation[J]. Petroleum Drilling Techniques, 2014, 42(5): 104–108.

[4] 任瑛. 加热开采稠油工艺的探讨:井筒中的热流体循环[J]. 华东石油学院学报(自然科学版), 1982, 6(4): 53–66. REN Ying. Thermal production of viscous oil with recycling of hot fluid in well bore[J]. Journal of East China Petroleum Institute (Edition of Natural Science), 1982, 6(4): 53–66.

[5] 阚庆山,江永全,徐凌云,等. 大港油田火成岩油藏稠油热采工艺[J]. 石油钻采工艺, 2009, 31(2): 115–117. KAN Qingshan, JIANG Yongquan, XU Lingyun, et al. Technology of thermal recovery of volcanic high-viscosity reservoirs in Dagang Oilfield[J]. Oil Drilling & Production Technology, 2009, 31(2): 115–117.

[6] 李伟超,刘平,于继飞,等. 渤海稠油油田井筒电加热技术可行性分析[J]. 断块油气田, 2012, 19(4): 513–516. LI Weichao, LIU Ping, YU Jifei, et al. Feasibility analysis on electric heating of wellbore in heavy oilfield of Bohai[J]. Fault-Block Oil & Gas Field, 2012, 19(4): 513–516.

[7] 余五星, 潘建华, 林军, 等. 超稠油中频电加热采油技术[J]. 特种油气藏, 2000, 7(增刊1): 31–33. YU Wuxing, PAN Jianhua, LIN Jun, et al. Thermal producing of super heavy oil with frequency current[J]. Special Oil & Gas Reservoirs, 2000, 7(Supplement1): 31–33.

[8] 宋时权,张公社,李晶晶,等. 电加热杆抽油井温度分布计算[J]. 断块油气田, 2008, 15(3): 121–123. SONG Shiquan, ZHANG Gongshe, LI Jingjing, et al. Calculation of temperature distribution of electrical heating rod in pumping well[J]. Fault-Block Oil & Gas Field, 2008, 15(3): 121–123.

[9] 姚传进,雷光伦,吴川,等. 高凝原油井筒温度场影响因素研究[J]. 石油钻探技术, 2011, 39(5): 74–78. doi: 10.3969/j.issn.1001-0890.2011.05.016 YAO Chuanjin, LEI Guanglun, WU Chuan, et al. Study of the factors impacting on wellbore temperature in high pour point oil production[J]. Petroleum Drilling Techniques, 2011, 39(5): 74–78. doi: 10.3969/j.issn.1001-0890.2011.05.016

[10] 卢智慧,何雪芹,刘志恒,等. 考虑环境因素的井筒流动温度场计算[J]. 断块油气田, 2016, 23(5): 652–654. LU Zhihui, HE Xueqin, LIU Zhiheng, et al. Calculation of wellbore flowing temperature distribution considering environmental factors[J]. Fault-Block Oil & Gas Field, 2016, 23(5): 652–654.

[11] 李梦博,柳贡慧,李军,等. 考虑非牛顿流体螺旋流动的钻井井筒温度场研究[J]. 石油钻探技术, 2014, 42(5): 74–79. LI Mengbo, LIU Gonghui, LI Jun, et al. Research on wellbore temperature field with helical flow of non-Newtonian fluids in drilling operation[J]. Petroleum Drilling Techniques, 2014, 42(5): 74–79.

[12] 王江帅,李军,柳贡慧,等. 循环钻进过程中井筒温度场新模型[J]. 断块油气田, 2018, 25(2): 240–243. WANG Jiangshuai, LI Jun, LIU Gonghui, et al. New model of wellbore temperature field during drilling process[J]. Fault-Block Oil and Gas Field, 2018, 25(2): 240–243.

[13] RAMEY H J Jr. Wellbore heat transmission[J]. Journal of Petroleum Technology, 2013, 14(4): 427–435.

[14] 宋洵成,韦龙贵,何连,等. 气液两相流循环温度和压力预测耦合模型[J]. 石油钻采工艺, 2012, 34(6): 5–9. doi: 10.3969/j.issn.1000-7393.2012.06.004 SONG Xuncheng, WEI Longgui, HE Lian, et al. Acoupled model for wellbore temperature and pressure prediction of gas-liquid drilling fluid[J]. Oil Drilling & Production Technology, 2012, 34(6): 5–9. doi: 10.3969/j.issn.1000-7393.2012.06.004

[15] HASAN A R, KABIR C S, SAYARPOUR M. Simplified two-phase flow modeling in wellbores[J]. Journal of Petroleum Science and Engineering, 2010, 72(1/2): 42–49.

[16] BEGGS H D, BRILL J P. A study of two-phase flow in inclined pipes[J]. Journal of Petroleum Technology, 1973, 25(5): 607–617. doi: 10.2118/4007-PA

[17] ANSARI A M, SYLVESTER N D, SHOHAM O, et al. A comprehensive mechanistic model for upward two-phase flow in wellbores[R]. SPE 20630, 1990.

-

期刊类型引用(14)

1. 李斌会,邓森,张江,曹胜,郭天娇,徐全,霍迎冬. 古龙页岩油高温高压注CO_2驱动用效果. 大庆石油地质与开发. 2024(01): 42-51 .  百度学术

百度学术

2. 姚红生,高玉巧,郑永旺,邱伟生,龚月,钱洋慧. CO_2快速吞吐提高页岩油采收率现场试验. 天然气工业. 2024(03): 10-19 .  百度学术

百度学术

3. 李阳,曹小朋,赵清民,刘祖鹏,薛兆杰,蒋龙. 济阳坳陷陆相断陷盆地页岩油开发的几点思考. 石油钻探技术. 2024(04): 1-7 .  本站查看

本站查看

4. 吴壮坤,张宏录,池宇璇. 苏北页岩油二氧化碳强压质换技术. 石油钻探技术. 2024(04): 87-93 .  本站查看

本站查看

5. 李邦国,侯家鵾,雷兆丰,张博,王斌,陈江. 超临界CO_2萃取页岩油效果评价及影响因素分析. 石油钻探技术. 2024(04): 94-103 .  本站查看

本站查看

6. 陈洪才,王彪,李太伟,张鑫,朱杰,戴志鹏,孙敬,李思辰. 在线核磁监测法优化裂缝性页岩油藏赋能渗吸吞吐工艺. 石油钻采工艺. 2024(02): 228-237 .  百度学术

百度学术

7. 马先林,刘朕之,湛杰,潘晓甜,李成德. 基于物理信息神经网络的CO_2羽流分布预测方法. 石油钻探技术. 2024(05): 69-75 .  本站查看

本站查看

8. 黄千慧,李海波,杨正明,邢济麟,陈波,李杰,薛伟,姚兰兰,杜猛,孟焕. 页岩(致密)油藏注CO_2吞吐作用距离实验. 大庆石油地质与开发. 2024(06): 128-135 .  百度学术

百度学术

9. 张岩,冯海顺,翟勇,周晓梅,刘东青,王坤. 低渗透稠油油藏CO_2压驱提高采收率机理及规律研究. 石油钻探技术. 2024(06): 97-106 .  本站查看

本站查看

10. 张磊,于海洋,黄涛,唐慧婷,孙灵辉,曾华柯,汪洋. CO_2吞吐提高其埋存率及页岩油采收率的影响因素. 华南师范大学学报(自然科学版). 2024(05): 16-26 .  百度学术

百度学术

11. 刘雨奇,陈哲伟,雷启鸿,徐振华,罗二辉,雷征东,熊维亮,何右安. 庆城页岩油后期补能注伴生气吞吐注采参数优化. 科学技术与工程. 2023(12): 5033-5040 .  百度学术

百度学术

12. 饶志华,邓成辉,马倩芸,武广瑷,武治强,程小伟. CCUS井工况下不同引晶材料对水泥石裂缝自愈合过程的影响. 钻井液与完井液. 2023(04): 495-501 .  百度学术

百度学术

13. 张矿生,齐银,薛小佳,陶亮,陈文斌,武安安. 鄂尔多斯盆地页岩油水平井CO_2区域增能体积压裂技术. 石油钻探技术. 2023(05): 15-22 .  本站查看

本站查看

14. 杜书恒,沈文豪,赵亚溥. 页岩储层应力敏感性定量评价:思路及应用. 力学学报. 2022(08): 2235-2247 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: