Clay-Free Drilling Fluid with Anti-Water Locking and Low Damage Performance Used in the Changbei Block

-

摘要:

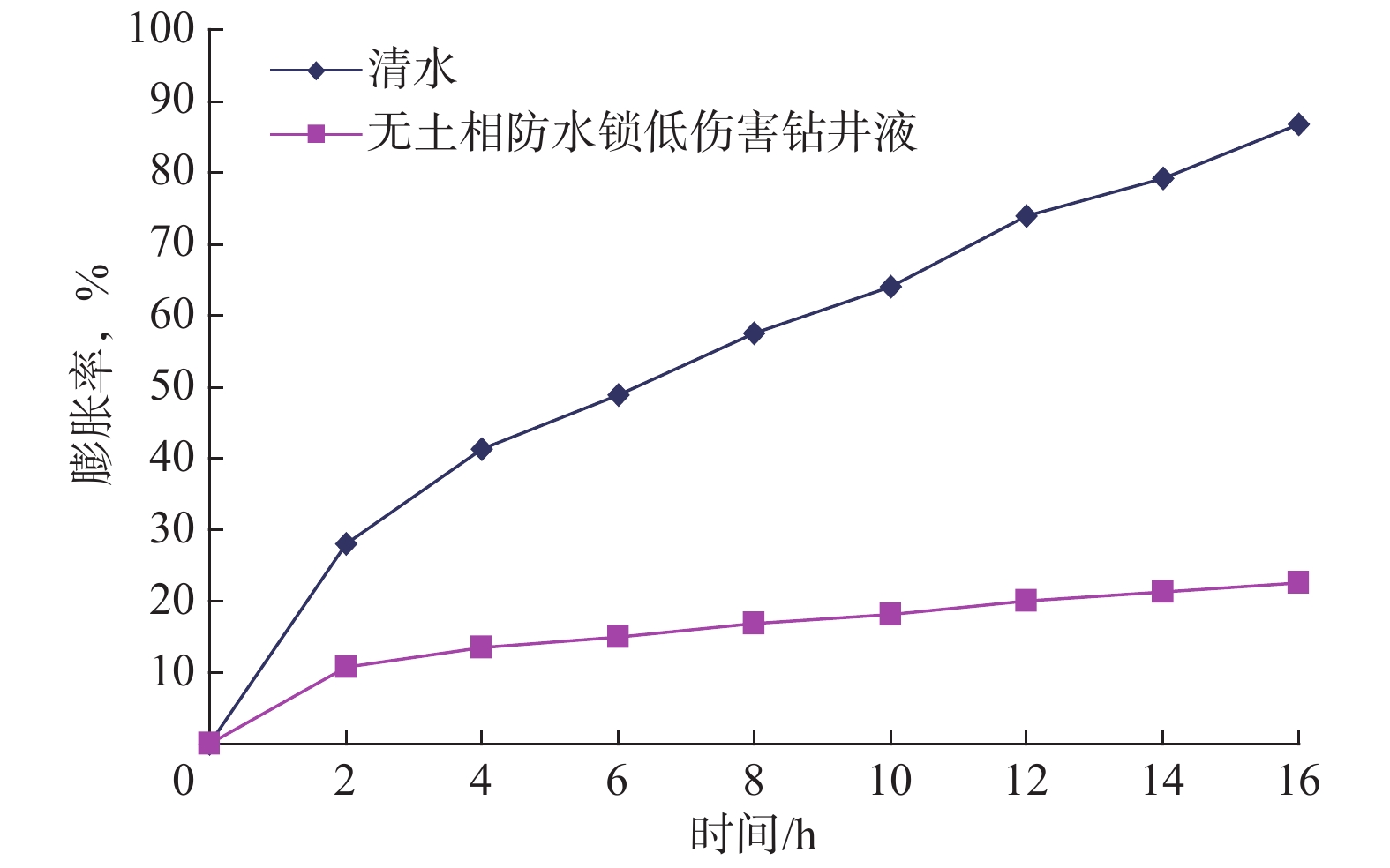

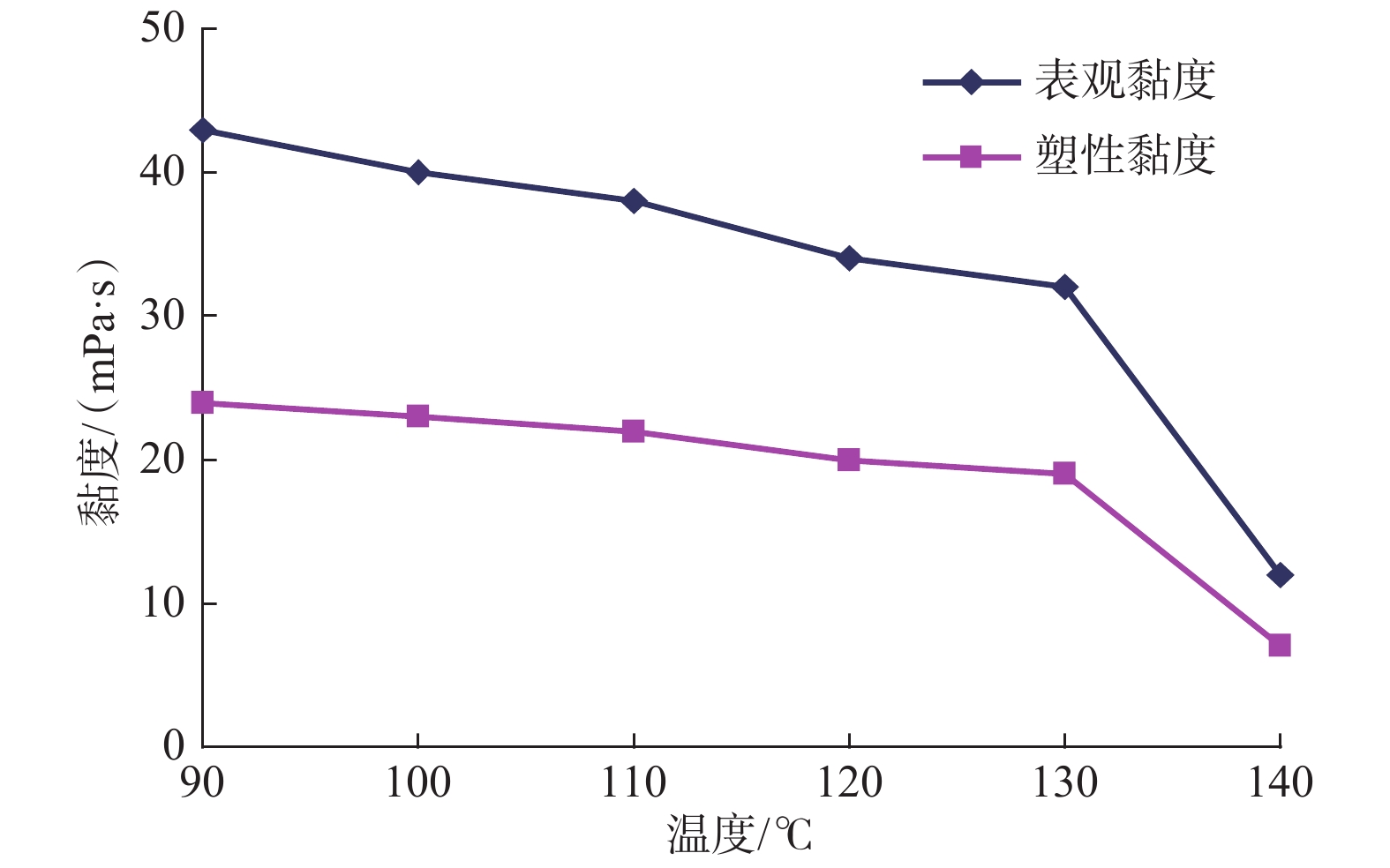

针对长北区块生产井持续生产致使地层压力衰减、压差增大,导致钻井液对储层伤害加剧的问题,在分析长北区块储层伤害机理的基础上,研制了解水锁剂G311,优选了润滑剂G316,并对其加量进行了优化,形成了适用于长北区块压力衰减储层的无土相防水锁低伤害钻井液。该钻井液与无土相低伤害钻井液相比,钻井液滤液表面张力降低率达77.8%,线性膨胀率达22.6%,岩心伤害率低于15.0%,具有解除水锁、抑制水敏及储层保护效果显著等优点。无土相防水锁低伤害钻井液在长北区块2口气井进行了现场试验,钻井过程中没有发生井下故障,起下钻顺畅,井眼始终处于良好净化状态。其中,CX–5井平均机械钻速提高12.1%,裸眼完井并直接气举投产,产气量达70×104m3/d,高于预期产气量。研究结果表明,无土相防水锁低伤害钻井液能够满足长北区块压力衰减地层长水平段水平井钻井安全及储层保护要求。

Abstract:Continuous mass production of wells in Changbei Block has led to formation pressure attenuation, differential pressure increase and formation damage by drilling fluids. Therefore, the damage mechanism of reservoir has been studied. After doing so, the G311 water-locking removal agent and other agents were implemented, so as to form a clay-free drilling fluid with anti-water locking and lower damage performance, and it is suitable for the Changbei Block depleted reservoir. Compared with the clay-free low damage drilling fluid, its filtrate has a surface tension reduction rate of 77.8%, a linear expansion rate of 22.6%, and a core damage rate of lower than 15.0%. It has the advantage of water-locking removal, water sensitivity inhibition and remarkable reservoir protection effect. The new drilling fluid has been tested in 2 wells of the Changbei Phase II project, and no downhole failure occurred during the drilling process. The trip operation was smooth, and the wellbore maintained a well cleaned state. Among them, the average ROP of Well CX-5 increased by 12.1%, the open hole completion and direct gas lifting production were used in this well, and the production reached 70×104 m3/d, higher than the expected gas production. The research results showed that the clay-free drilling fluid with anti-water locking and lower damage performance could meet the requirement of drilling safety and reservoir protection, suitable for long horizontal section drilling in pressure attenuated formation of Changbei Phase II.

-

Keywords:

- horizontal well /

- reservoir protection /

- water lock /

- clay-free drilling fluid /

- Changbei Block

-

-

表 1 岩心自吸含水饱和度随吸水时间的变化

Table 1 Self-absorbed water saturation of cores with time

岩心

编号不同时间下岩心自吸含水饱和度,% 0.5 min 1.0 min 5.0 min 10.0 min 20.0 min 50.0 min 100.0 min 1 6.8 12.6 34.8 53.9 68.7 72.3 73.3 2 14.3 21.7 41.4 50.9 55.2 61.9 62.9 3 21.2 32.4 58.6 61.5 74.3 87.8 88.6 表 2 山西组2段岩心水锁伤害实验结果

Table 2 Results of water-locking damage experiment with cores in the second member of Shanxi Formation

岩心

编号原始含水

饱和度,%原始含水饱

和度下的

渗透率/

mD束缚水饱和度,% 束缚水饱和度下的渗透率/

mD水锁伤

害率,%评价

结果4 28.1 1.439 67.2 0.435 69.8 中 5 15.9 1.417 61.0 0.332 76.6 强 6 10.0 2.743 50.6 0.417 84.8 强 7 30.9 3.936 81.7 0.252 93.6 强 平均 21.2 65.1 81.2 强 表 3 不同压差下的岩心伤害试验结果

Table 3 Experimental results of core damage under different pressure differences

压差/MPa 岩心数量 伤害率,% 平均伤害率,% 14 6 25.3~28.3 26.8 17 5 23.8~46.0 33.8 19 6 69.8~70.1 70.0 21 4 78.6~91.6 85.4 表 4 渗透率与含水饱和度关系

Table 4 Relationship between permeability and water saturation

序号 岩心抽真空饱

和标准盐水岩心自吸标准盐水 岩心自吸解水锁剂 含水饱和度,% 渗透率/

mD含水饱和度,% 渗透率/

mD含水饱和度,% 渗透率/

mD1 93.6 0.111 80.2 0.095 70.2 0.104 2 82.8 0.117 74.1 0.101 60.3 0.111 3 80.5 0.130 70.8 0.127 55.1 0.141 4 78.4 0.139 67.6 0.136 51.9 0.199 5 71.6 0.145 62.4 0.143 45.9 0.392 6 62.1 0.199 60.3 0.165 38.8 0.483 7 59.8 0.390 57.9 0.374 33.9 0.581 8 58.2 0.499 57.6 0.509 32.6 0.713 9 38.3 0.729 33.5 0.941 24.4 0.903 10 31.2 1.067 27.6 1.316 14.6 1.215 11 20.6 1.477 21.2 1.537 12.8 1.798 表 5 润滑剂G316加量对钻井液性能的影响

Table 5 Effect of G316 dosage on drilling fluid performance

G316加

量,%实验条件 表观黏度/

(mPa·s)塑性黏度/

(mPa·s)滤失量/

mL润滑系数 0 老化前 46.0 24 5.6 0.304 100 ℃/16 h 43.0 22 5.8 0.304 0.5 老化前 45.0 23 5.4 0.131 100 ℃/16 h 41.5 21 5.8 0.137 1.0 老化前 44.0 20 5.6 0.097 100 ℃/16 h 42.0 19 5.4 0.094 1.5 老化前 43.5 22 5.4 0.070 100 ℃/16 h 45.0 23 5.8 0.063 2.0 老化前 44.0 21 5.6 0.041 100 ℃/16 h 40.0 18 5.6 0.041 2.5 老化前 42.0 19 5.4 0.030 100 ℃/16 h 41.0 19 5.6 0.034 3.0 老化前 39.0 17 5.4 0.029 100 ℃/16 h 38.0 18 5.2 0.027 表 6 岩心伤害试验结果

Table 6 Results of core damage experiment

岩心

编号长度/

cm直径/

cm孔隙

度,%渗透率/mD 伤害

率,%钻井液 伤害前 伤害后 1 4.88 2.53 6.03 0.764 0.570 39.8 NDW无土相低

伤害钻井液2 4.14 2.54 8.10 0.954 0.575 25.4 3 3.63 2.54 8.20 0.707 0.433 38.9 4 3.43 2.54 9.31 1.120 0.915 18.3 NWP无土相防水

锁低伤害钻井液5 4.53 2.53 8.78 0.856 0.751 12.3 6 4.48 2.53 7.63 0.795 0.703 11.6 -

[1] 赵向阳,张小平,陈磊,等. 甲酸盐钻井液在长北区块的应用[J]. 石油钻探技术, 2013, 41(1): 40–44. doi: 10.3969/j.issn.1001-0890.2013.01.008 ZHAO Xiangyang, ZHANG Xiaoping, CHEN Lei, et al. Application of formate drilling fluid in Changbei Block[J]. Petroleum Drilling Techniques, 2013, 41(1): 40–44. doi: 10.3969/j.issn.1001-0890.2013.01.008

[2] 崔贵涛,林海,董海东,等. NDW无土相低伤害储层钻井液在CB8-3井的应用[J]. 石油钻采工艺, 2012, 34(5): 39–41. CUI Guitao, LIN Hai, DONG Haidong, et al. Application of NDW clay-free low damage drilling fluid on Well CB8-3[J]. Oil Drilling & Production Technology, 2012, 34(5): 39–41.

[3] 贾俊,赵向阳,刘伟. 长庆油田水基环保成膜钻井液研究与现场试验[J]. 石油钻探技术, 2017, 45(5): 36–42. JIA Jun, ZHAO Xiangyang, LIU Wei. Research and field test of water-based environmental- friendly membrane forming drilling fluid technology in Changqing Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(5): 36–42.

[4] 黎金明,杨斌,陈在君,等. 鄂尔多斯盆地长北气田储层保护技术[J]. 天然气工业, 2009, 29(3): 68–70. doi: 10.3787/j.issn.1000-0976.2009.03.019 LI Jinming, YANG Bin, CHEN Zaijun, et al. Reservoir protection technology in the Changbei Gas Field, Ordos Basin[J]. Natural Gas Industry, 2009, 29(3): 68–70. doi: 10.3787/j.issn.1000-0976.2009.03.019

[5] 金祥哲,王长宁,杨斌. 长北气田水平井钻井液润滑剂的优选与应用[J]. 天然气工业, 2009, 29(4): 61–63. JIN Xiangzhe, WANG Changning, YANG Bin. Selection and application of drilling fluid lubricant for horizontal wells in the Changbei Gas Field[J]. Natural Gas Industry, 2009, 29(4): 61–63.

[6] 向雄,杨洪烈,刘喜亮,等. 南海西部超浅层气田水平井EZFLOW无固相弱凝胶钻井液研究与应用[J]. 石油钻探技术, 2018, 46(2): 38–43. XIANG Xiong, YANG Honglie, LIU Xiliang, et al. Research and application of EZFLOW solid-free weak gel drilling fluid in horizontal wells in shallow gas fields in the Western South China Sea[J]. Petroleum Drilling Techniques, 2018, 46(2): 38–43.

[7] 陈在君,黎金明,杨斌,等. 长北气田长水平井段裸眼钻井(完井)液技术[J]. 天然气工业, 2007, 27(11): 49–51. doi: 10.3321/j.issn:1000-0976.2007.11.014 CHEN Zaijun, LI Jinming, YANG Bin, et al. Drilling and completion fluid technology for long horizontal openhole completion in Changbei Gas Field[J]. Natural Gas Industry, 2007, 27(11): 49–51. doi: 10.3321/j.issn:1000-0976.2007.11.014

[8] 郭永宾,管申,刘智勤,等. 涠洲12-1油田水平井无固相有机盐钻井液技术[J]. 石油钻探技术, 2017, 45(6): 31–36. GUO Yongbin, GUAN Shen, LIU Zhiqin, et al. Solid-free organic salt drilling fluid for horizontal wells in the Weizhou 12-1 Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(6): 31–36.

[9] 蒋官澄,王晓军,关键,等. 低渗特低渗储层水锁损害定量预测方法[J]. 石油钻探技术, 2012, 40(1): 69–73. doi: 10.3969/j.issn.1001-0890.2012.01.014 JIANG Guancheng, WANG Xiaojun, GUAN Jian, et al. The quantitative prediction method of water blocking damage in low and extra-low permeability reservoir[J]. Petroleum Drilling Techniques, 2012, 40(1): 69–73. doi: 10.3969/j.issn.1001-0890.2012.01.014

[10] 李洪,李治平,王香增,等. 表面活性剂对低渗透油藏渗吸敏感因素的影响[J]. 石油钻探技术, 2016, 44(5): 100–103. LI Hong, LI Zhiping, WANG Xiangzeng, et al. The effect of surfactants on imbibition-sensitive factors of low-permeability reservoirs[J]. Petroleum Drilling Techniques, 2016, 44(5): 100–103.

[11] 董宏伟,贾俊,凡帆,等. 解除低渗砂岩气层钻井液伤害的洗井液研究与应用[J]. 钻井液与完井液, 2015, 32(4): 40–44. doi: 10.3969/j.issn.1001-5620.2015.04.011 DONG Hongwei, JIA Jun, FAN Fan, et al. Flushing fluid eliminating damage to low permeability sandstone gas reservoir by drilling fluid[J]. Drilling Fluid & Completion Fluid, 2015, 32(4): 40–44. doi: 10.3969/j.issn.1001-5620.2015.04.011

[12] 董兵强,邱正松,陆朝晖,等. 临兴区块致密砂岩气储层损害机理及钻井液优化[J]. 钻井液与完井液, 2018, 35(6): 65–70. doi: 10.3969/j.issn.1001-5620.2018.06.012 DONG Bingqiang, QIU Zhengsong, LU Zhaohui, et al. Damage mechanisms determination for tight sands gas reservoir in Block Linxing and drill-in fluid optimization for protection of the reservoir[J]. Drilling Fluid & Completion Fluid, 2018, 35(6): 65–70. doi: 10.3969/j.issn.1001-5620.2018.06.012

[13] 蒋官澄,张志行,张弘. KCl聚合物钻井液防水锁性能优化研究[J]. 石油钻探技术, 2013, 41(4): 59–63. doi: 10.3969/j.issn.1001-0890.2013.04.013 JIANG Guancheng, ZHANG Zhihang, ZHANG Hong. Anti-water lock optimization of KCl polymer drilling fluid[J]. Petroleum Drilling Techniques, 2013, 41(4): 59–63. doi: 10.3969/j.issn.1001-0890.2013.04.013

[14] 韩成,黄凯文,韦龙贵,等. 海上低渗储层防水锁强封堵钻井液技术[J]. 钻井液与完井液, 2018, 35(5): 67–71. doi: 10.3969/j.issn.1001-5620.2018.05.013 HAN Cheng, HUANG Kaiwen, WEI Longgui, et al. A drilling fluid with water block preventive capacity and strong plugging capacity for offshore low permeability reservoir drilling[J]. Drilling Fluid & Completion Fluid, 2018, 35(5): 67–71. doi: 10.3969/j.issn.1001-5620.2018.05.013

[15] 耿学礼,吴智文,黄毓祥,等. 低渗储层新型防水锁剂的研究及应用[J]. 断块油气田, 2019, 26(4): 537–540. GENG Xueli, WU Zhiwen, HUANG Yuxiang, et al. Research and application of new waterproof locking agent for low permeability reservoir[J]. Fault-Block Oil & Gas Field, 2019, 26(4): 537–540.

[16] 陈二丁,赵洪涛,李秀灵,等. 用于滩坝砂低渗透油藏的复合盐低伤害钻井液技术[J]. 钻井液与完井液, 2018, 35(4): 66–72. doi: 10.3969/j.issn.1001-5620.2018.04.012 CHEN Erding, ZHAO Hongtao, LI Xiuling, et al. Low damage compound salt drilling fluid for low permeability beach bar sand reservoirs[J]. Drilling Fluid & Completion Fluid, 2018, 35(4): 66–72. doi: 10.3969/j.issn.1001-5620.2018.04.012

[17] 黄维安,雷明,滕学清,等. 致密砂岩气藏损害机理及低损害钻井液优化[J]. 钻井液与完井液, 2018, 35(4): 33–38. doi: 10.3969/j.issn.1001-5620.2018.04.006 HUANG Weian, LEI Ming, TENG Xueqing, et al. Damaging mechanism of tight sandstone gas reservoirs and optimization of drilling fluids for reservoir protection[J]. Drilling Fluid & Completion Fluid, 2018, 35(4): 33–38. doi: 10.3969/j.issn.1001-5620.2018.04.006

[18] 唐洪明,徐诗雨,王茜,等. 克拉苏气田超致密砂岩气储层水锁损害[J]. 断块油气田, 2017, 24(4): 541–545. TANG Hongming, XU Shiyu, WANG Xi, et al. Water blocking damage of hyper-tight sandstone gas reservoir in Kelasu Gas Field[J]. Fault-Block Oil & Gas Field, 2017, 24(4): 541–545.

-

期刊类型引用(14)

1. 赵楠,李万渠,冯金钰,王奕儒,李丽. 多裂纹对裂纹搭接规律影响数值模拟及机理研究. 钻采工艺. 2022(02): 160-164 .  百度学术

百度学术

2. 张瑞萍,祝云,窦益华,杨晓儒,李明飞. 基于FLAC~(3D)的压裂工况下地应力重新分布规律研究. 石油机械. 2021(08): 91-99 .  百度学术

百度学术

3. 何其胜,王贵君. 砂砾岩水压致裂机理及数值仿真研究. 三峡大学学报(自然科学版). 2020(06): 45-49 .  百度学术

百度学术

4. 尉雪梅,吴飞鹏,刘恒超,徐尔斯,张艳玉,蒲春生. 燃爆压裂井井周诱导应力分布规律. 中国石油大学学报(自然科学版). 2018(01): 105-112 .  百度学术

百度学术

5. 王坤,葛腾泽,曾雯婷. 低产油气井强制裂缝转向重复压裂技术. 石油钻探技术. 2018(02): 81-86 .  本站查看

本站查看

6. 吴飞鹏,徐尔斯,尉雪梅,刘恒超,李德,丁乾申. 燃爆诱导水力压裂多裂缝耦合起裂规律. 天然气工业. 2018(11): 65-72 .  百度学术

百度学术

7. 苏超,李士斌,刘照义,徐晶,薛东阳,张维薇. 体积压裂裂缝对地应力场干扰规律的研究. 北京石油化工学院学报. 2017(04): 16-23 .  百度学术

百度学术

8. 彭瑀,李勇明,赵金洲. 考虑任意压力分布的裂缝诱导应力场计算模型及其应用. 中国石油大学学报(自然科学版). 2017(03): 92-97 .  百度学术

百度学术

9. 李玮,纪照生. 暂堵转向压裂机理有限元分析. 断块油气田. 2016(04): 514-517 .  百度学术

百度学术

10. 胡海洋,金军,田树烜. 分段压裂技术在贵州松河煤层气开发中的应用. 煤矿安全. 2016(09): 137-140 .  百度学术

百度学术

11. 李玉梅,吕炜,宋杰,李军,杨宏伟,于丽维. 层理性页岩气储层复杂网络裂缝数值模拟研究. 石油钻探技术. 2016(04): 108-113 .  本站查看

本站查看

12. 陈作,周健,张旭,吴春方,张啸宇. 致密砂岩水平井组同步压裂过程中诱导应力场变化规律. 石油钻探技术. 2016(06): 78-83 .  本站查看

本站查看

13. 李士斌,官兵,张立刚,陈双庆,王业强. 水平井压裂裂缝局部应力场扰动规律. 油气地质与采收率. 2016(06): 112-119 .  百度学术

百度学术

14. 林飞,盛萍,李春颖. 煤层气藏水平井分段压裂裂缝参数优化. 中州煤炭. 2016(02): 126-128 .  百度学术

百度学术

其他类型引用(7)

下载:

下载: