Research and Application of Key Technologies for Slim Hole Sidetracking Wells in the Subei Basin

-

摘要:

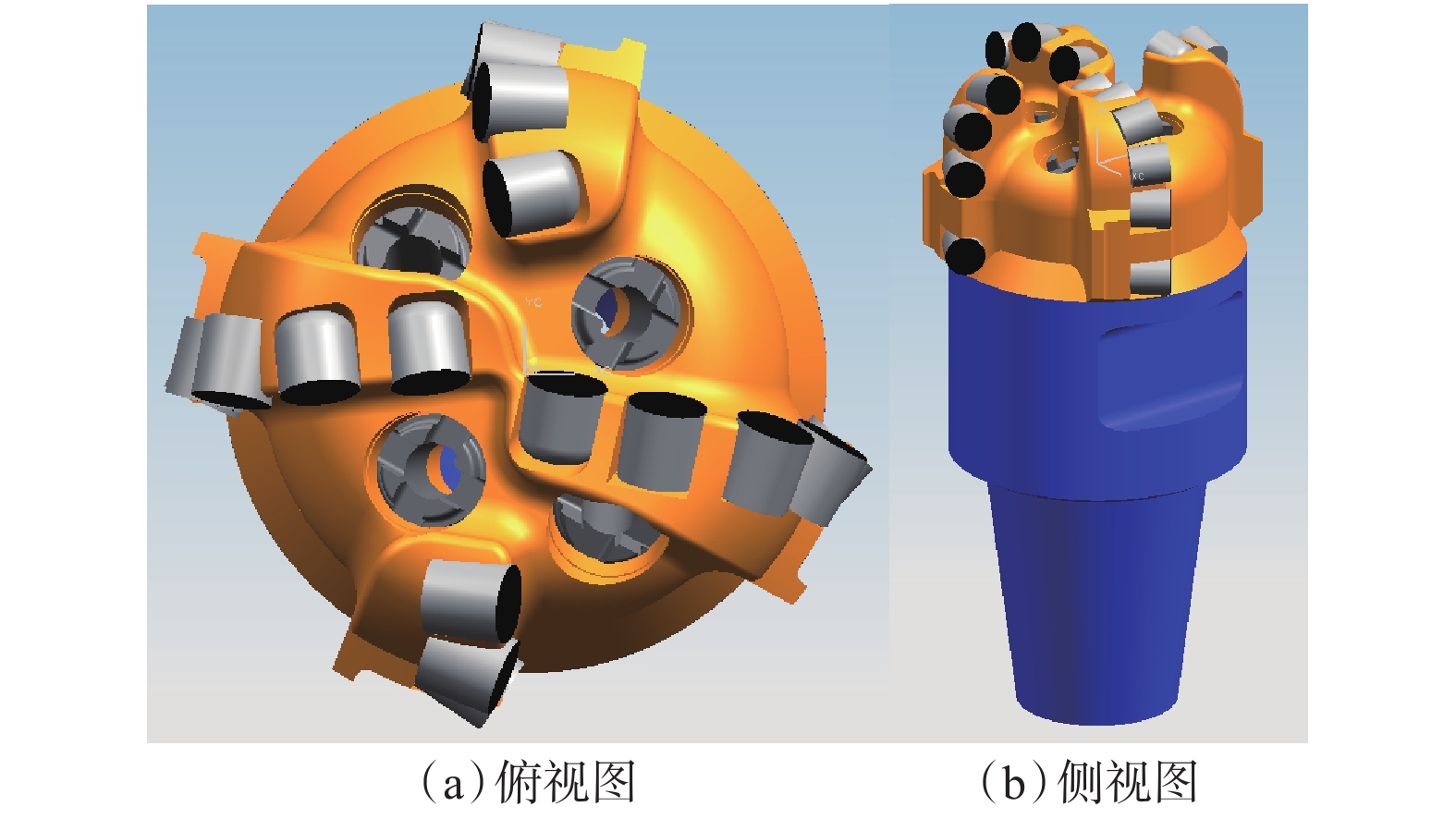

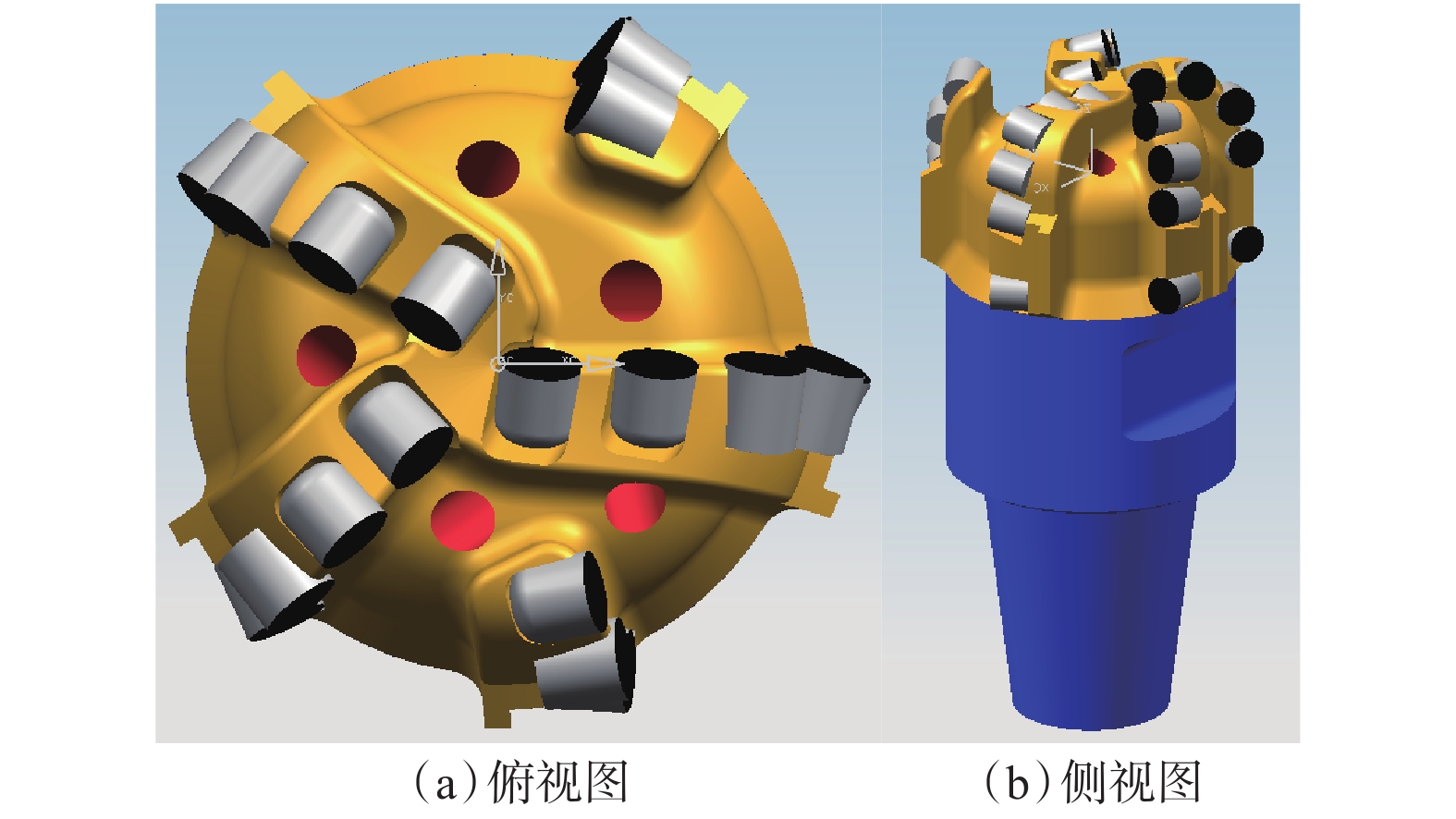

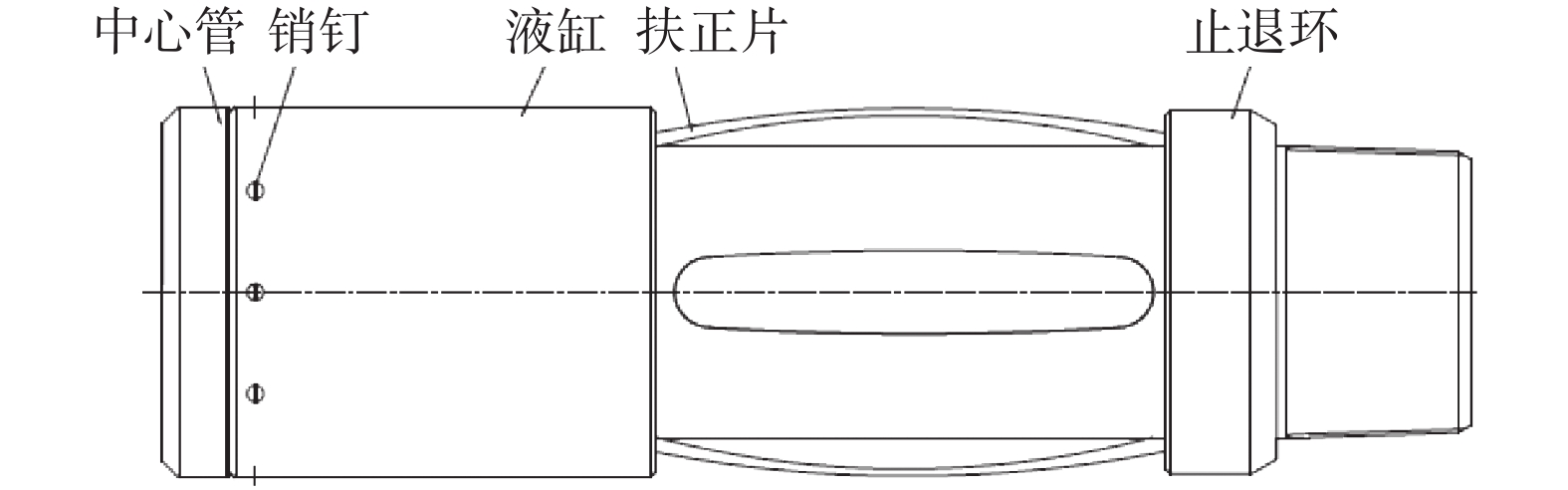

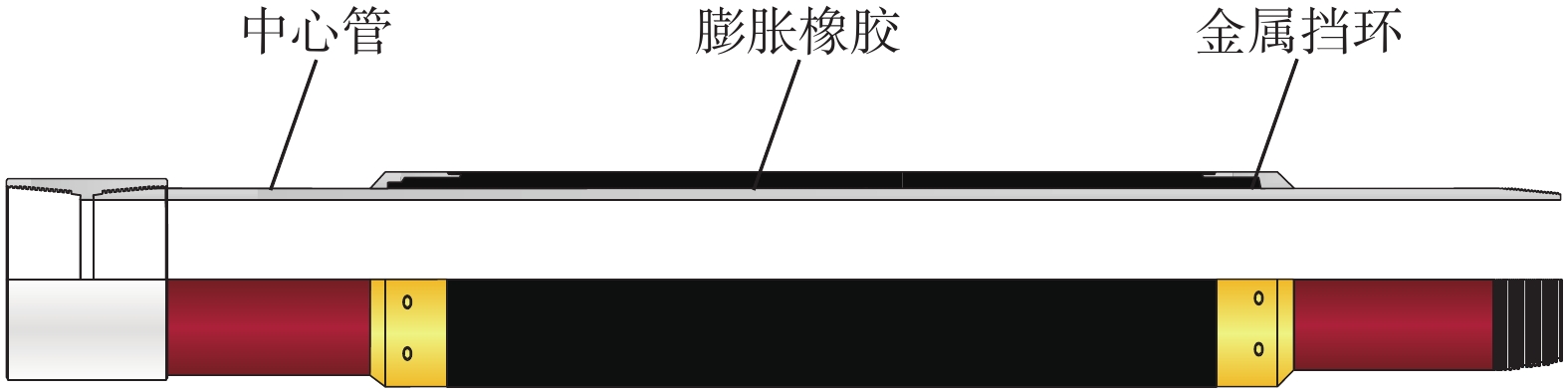

针对苏北盆地小井眼套管开窗侧钻井窗口不规则、机械钻速低、井眼易失稳、摩阻扭矩大及固井质量难以保证等问题,进行了套管开窗方案设计、开窗工具优选、井眼轨迹调整及控制、岩屑床清除、个性化钻头设计、钻井液体系优选及固井技术优化等方面的研究。根据侧钻点不同,优选了开窗工具,优化了井眼轨道,制定了井眼轨迹调整与控制措施,采用了螺旋清砂钻杆,以降低施工摩阻和扭矩;针对不同地层岩性特点及工况,设计了2种PDC钻头,以增加单趟钻进尺,并提高机械钻速;优选了胺基聚合物钻井液体系,配合使用高效极压减摩剂,以满足井壁稳定、井眼净化及润滑防塌要求;采用了防窜增韧水泥浆,配合使用小尺寸液压变径套管扶正器和遇水自膨胀封隔器,以提高固井质量。小井眼侧钻井关键技术在苏北盆地9口井进行了应用,与前期施工井相比,机械钻速提高了125.3%,钻井周期缩短了45.8%,复杂时效下降了87.0%。研究结果表明,苏北盆地小井眼侧钻井关键技术能提高小井眼侧钻井机械钻速、缩短钻井周期和降低复杂时效,提速提效效果显著,具有推广应用价值。

Abstract:Irregular windows, low ROP, wellbore instability, large drag and torque make it difficult to ensure the cementing quality in the windowing/sidetracking of slim hole wells in the Subei Basin. Therefore studies were carried out including windowing schemes and tools, wellbore trajectory adjustment and control, special bit design, drilling fluid system selection and cementing technology optimization. According to the different sidetracking points, the proper windowing tools and wellbore trajectory design scheme were optimized, and adopted the spiral sand removal drill pipe to reduce the drag and torque. For the lithological characteristics and different working conditions of the Subei Basin, two kinds of PDC bits were selected, which achieve high single bit footage and increase the ROP. Further, the amine polymer drilling fluid system was optimized, and combined with a high-efficiency extreme pressure friction reducing agent, it can meet the requirements of wellbore stability, cuttings carrying, lubrication and collapse prevention. By adopting the anti-channeling and toughening cement slurry system, combined with the small-sized hydraulic variable diameter casing centralizer and water-swelling packer, the cementing quality can be improved. The above-mentioned key technologies developed in this study have been successfully applied in 9 slim hole in Subei Basin, the ROP was increased by 125.3%, the drilling cycle shortened by 45.8%, and the complex time efficiency reduced by 87.0%, compared with the previously completed wells. Research results showed that the application of those key technologies could effectively improve the ROP, shorten the drilling cycle and reduce the complex time efficiency of slim hole in the Subei Basin, with excellent rapid drilling effect and remarkable promotion value, making it a good potential candidate for adoption.

-

Keywords:

- slim hole /

- sidetracking /

- hole trajectory /

- penetration rate /

- drilling fluid /

- cementing quality /

- Subei Basin

-

随着对清洁能源需求的日益增长和水力压裂技术的不断发展,页岩气在许多国家蓬勃发展,但绝大多数页岩气井均表现出初期递减率高、采收率较低的特征。B. Kurtoglu等人[1-2]较先提出利用水力压裂提高页岩气采收率的手段。端祥刚等人[3]总结了提高页岩气井采收率面临的技术与科学问题。其中,立体开发调整是目前可行性最强的一种提高采收率手段[4-6]。但立体调整过程中,压裂干扰现象不可避免[7-8],当井距较小时可能对老井生产造成负面影响[9-10]。专家学者已在井间干扰现象方面做了很多研究,J. P. Detring等人[11-12]认为当老井附近出现明显压降时裂缝易连通,老井复产后加密井井口压力会下降;郭旭洋等人[13]介绍了国内外页岩油气藏的井间、层间干扰现象及诊断方法的研究进展;A. Ataei等人[14]利用解析模型,采用RTA、PTA双对数曲线分析法判断干扰情况;Fang Sidong等人[15]采用EDFM技术,模拟了3种缝网干扰下裂缝属性对生产特征的影响;王军磊等人[16]利用地质工程一体化技术,模拟研究了页岩气立体开发缝网延伸特征及生产规律。

以上调研可以看出,前人在页岩气立体开发方面的研究以机理研究和数值模拟为主[17-18]。基于这一局限,笔者以南川常压页岩气藏为研究对象,开展了页岩气立体开发井施工压力对比分析,明确了各开发层系施工特点,以指导立体开发方案部署顺序和压裂施工设计;对比分析了同开发层系加密、不同开发层系调整时压裂施工对老井的干扰现象,剖析缝网沟通机理,并结合干扰前后老井产能变化,完善了页岩气立体开发井压裂缝网干扰评价体系,以根据压裂期间老井套压变化或干扰后老井生产特征预测井间压裂改造效果,从而指导立体开发井动态优化调整。

1. 常压页岩气立体开发特征研究

南川地区一次井网水平井钻遇层位以五峰组—龙马溪组①~③小层为主,生产5年,2020年开始出现递减,现处于低压低产阶段,单井平均累计产气量0.7×108 m3,综合递减率24.6%。为保障老区的高效稳产,纵向上细分开发层系,不断探索立体开发的可行性。目前该区块已经按照“下部气层加密+中、上部气层调整”的模式实施了三层立体开发试验,3套层系评价井均取得较好的试采效果,预测可大幅提高老区剩余储量的均衡动用。

1.1 压裂施工参数分布特征

1.1.1 纵向上与静态指标变化规律一致

根据测井解释、试验分析结果,南川地区五峰组—龙马溪组从上到下9个小层的孔渗、含气性逐渐变好[19-21]。综合地应力、静态指标,可以将五峰组—龙马溪组分为下部气层、中部气层和上部气层3套开发层系[22]。其中,下部气层埋深3 100 m,压力系数1.32,总有机碳含量2.8%~7.0%,孔隙度2.8%~4.8%,含气量4.2~7.2 m3/t;中部气层埋深2 920 m,压力系数1.25,总有机碳含量1.5%~2.6%,孔隙度2.4%~4.5%,含气量1.8~4.6 m3/t;上部气层埋深2650 m,压力系数1.15,总有机碳含量0.9%~1.3%,孔隙度2.9%~4.4%,含气量1.6~2.1 m3/t。

由五峰组—龙马溪组应力剖面可知,下部气层最大水平主应力67.3~76.4 MPa、中部气层最大水平主应力73.1~82.7 MPa、上部气层最大水平主应力76.8~82.9 MPa,局部存在⑤、⑦小层2个应力高峰。据调研,压裂液难以突破高应力层实现裂缝纵向延伸[23-25]。统计已实施的50余口立体开发井压裂施工情况可知,在埋深、地应力等因素作用下,从上至下各层系开发井的施工压力逐渐升高[26-27]。下部气层破裂压力梯度2.5 MPa/100m,停泵压力32.3~57.4 MPa;中部气层破裂压力梯度2.4 MPa/100m,停泵压力30.1~56.0 MPa;上部气层破裂压力梯度2.3 MPa/100m,停泵压力25.5~41.2 MPa。

1.1.2 平面上与井距、采出程度相关性明显

平面上,井间加密施工难易程度受埋深、井间距离、老井采出程度、局部应力等多重因素综合影响。对比不同井距、采出程度时加密井施工压力可以看出,当井距大于450 m或老井动态控制储量的采出程度低于60%时,加密井施工压力受老井的影响相对较小,此时破裂压力比老井略低5~10 MPa;当老井井距小于450 m时,加密井破裂压力比老井低9~20 MPa(见表1)。

表 1 不同加密类型下的施工压力对比Table 1. Fracturing pressure comparison of different infill types加密类型 老井间距/m 加密前老井累计

产气量/108m3井间采出程度,% 破裂压力/MPa 破裂压力梯度/

(MPa∙(100 m)−1)下部气层老井 350~550 57.1~86.4 1.9~3.0 大井距加密 450~550 0.9 58.0 56.8~85.1 2.0~3.0 大井距加密 450~550 1.0 64.5 54.2~81.3 1.8~2.9 小井距加密 350~450 0.7 54.7 51.8~76.6 1.8~2.8 小井距加密 350~450 0.8 62.5 46.3~65.5 1.6~2.5 对比加密井与老井破裂压力梯度差值散点图也可以看出,随着井距增加或老井采出程度降低,新老井破裂压力梯度差值减小(见图1和图2)。这一规律符合现场实践,随着新老井距离减小、井间储量动用程度提高,加密时的地层压力较原始地层压力小很多,加密井施工相对更容易,表现为破裂压力低、停泵压力低。如果地层亏空严重时,加密井在钻井、连续油管钻塞过程中还会发生漏失。

1.2 产能对比分析

非稳态产能分析方法以气藏不稳定渗流与井筒流动耦合为理论基础,利用气井生产数据,实现对气井产量、压力、无阻流量及采出程度等随时间变化的预测,并可拟合气井的地层参数,求取页岩气动态储量[28-29]。国内外研究表明,对于低渗气藏的大型加砂压裂气井,会出现较长时间的地层线性流动,在忽略表皮效应的理想状态下,压裂井不稳定产能方程为:

pR2−pwf2q=A√t+C (1) 其中A=μZT78.489Kh√3.6KϕμCtxf2 (2) C=G(Fcd)−lnxfrw (3) 式中:pR为原始地层压力,MPa;pwf为井底流压,MPa;q为产气量,104m3/d;t为时间,d;A为产能系数;C为与人工缝导流性相关的附加值;μ为黏度,mPa∙s;Z为气体偏差系数;T为地层热力学温度,K;K为渗透率,mD;h为气层有效厚度,m;ϕ为孔隙度;Ct为综合压缩系数,MPa−1;rw为井筒半径,m;xf为裂缝半长,m;G(Fcd)为裂缝导流能力G函数。

A值越大,表明储层流动系数越大,产能越高;C值越大,表明人工裂缝越短,流体渗流阻力越大。

不稳态产能拟合结果表明:1)下部气层老井与下部气层加密井的A值均为12.3,中部气层井A值为11.6,上部气层井A值为5.2;2)C值关系为:上部气层井>>下部气层老井>中部气层井>下部气层加密井(见图3)。因此,下部气层井产能优于中部气层井,上部气层井产能最差;就改造效果而言,下部气层加密井受井间动用影响,改造难度小,相同压裂规模下改造效果最佳。

2. 立体开发缝网干扰分析

立体开发缝网干扰主要包括平面和纵向缝网干扰。平面缝网干扰,即同一开发层系新井或加密井与相邻老井的缝网沟通、干扰;纵向缝网干扰,即某一开发层系新井压裂时,与上、下开发层系老井之间的干扰。

2.1 平面干扰特征

2.1.1 压裂干扰现象

为防止加密井压裂时与老井形成主缝窜通,影响加密井正常施工,现场在加密井压裂施工期间一般采取老井关井处理。据统计,老井关井期间套压变化可归为3种类型,可以通过对比压力变化,粗略预测老井改造效果。

1)平稳上升型。伴随加密井压裂施工,老井套压逐步增大,增大幅度平稳,且套压增大到一定数值后基本稳定。此现象通常发生在老井各段改造均衡情况下,当加密井与老井空间距离大于280 m时,老井套压增大2.0~6.5 MPa;当加密井与老井空间距离在240~280 m时,老井套压增大5.1~13.2 MPa。这种类型的老井,往往在加密井压裂结束后开井复产时日产气量、套压高于关井前生产水平,随着关井期间压力增幅的不同,压裂受效时间(即恢复原日产油量时间)有所不同。

2)迅速上升型。加密井压裂施工一开始,老井套压先迅速升高,然后呈小幅度增长趋势,并伴有上、下波动。此情况多发生在中小井距加密方式下,或老井改造效果好、缝网复杂时。由于老井压后形成的缝网渗透性好,加密井在进行压裂时压力传播速度加快,所以老井的套压会迅速达到一定高值(压力增幅一般不低于4.0 MPa),后续套压的波动主要是压差作用下SRV内的水流入井底造成液面波动。这种类型的老井,开井复产后产液量有小幅增大。

3)升降型。加密井压裂施工周期内,老井套压一直增长且增幅较大,后续下降至平稳。此种类型的老井主缝相对较长,且套压波动现象越早,表明老井主缝越长,施工压力波及时间越短,积液越快。重新开井后,产液量由0~10 m3/d明显增加至50~65 m3/d。

2.1.2 缝网干扰机理及数值模拟研究

加密井与老井产生压裂干扰形式多样,如加密井压裂缝与老井天然缝、改造缝沟通等,具体是哪种缝网沟通起主要干扰作用,取决于气藏天然缝网发育程度及页岩气井压裂改造水平,大致可以总结归纳为以下4种干扰机理:

1)干扰机理1。老井与加密井压裂缝直接沟通,即新老井的高导流缝沟通,干扰形式为加密井压裂期间施工压力异常低,老井套压变化类型为升降型。

2)干扰机理2。老井压裂缝与加密井微裂缝沟通,即老井高导流缝与加密井低导流缝沟通,加密井压裂期间老井套压类型为平稳增大型,增幅较大。

3)干扰机理3。老井天然缝或改造微裂缝与加密井压裂缝沟通,即老井低导流缝与加密井高导流缝沟通,加密井压裂期间老井套压类型为迅速上升型。

4)干扰机理4。老井微裂缝与加密井微裂缝沟通,即新老井低导流缝进行沟通,加密井压裂期间老井套压类型为平稳增大型,增幅较小。

选取南川页岩气藏实际地质参数,利用Compass数值模拟软件建立双重介质水平井分段压裂模型,包括同层系开发的2口老井和1口加密井。模型尺寸2 500 m×1 000 m×110 m,网格数量250×100×27,平面I/J方向网格步长10 m,纵向K方向网格步长4 m。模型基础参数为:埋深3 200 m,孔隙度2.9%~4.4%,渗透率0.18 μD,含气饱和度0.6%~0.7%,形状因子1.0×10−5,井距500 m,水平段长度2 000 m,裂缝半长120~180 m,定产量6.5×104 m3/d,生产时长15年。数值模型中,缝网沟通机理可简化为FRAC-FRAC、FRAC–SRV、SRV-FRAC、SRV-SRV和无沟通等5种形式,模拟结果见图4—图5。

从图4可以看出,无论是老井与加密井低导流缝间(SRV-SRV)的沟通,还是老井高导流缝与加密井低导流缝沟通(FRAC-SRV),受压降漏斗影响,老井都会抢夺加密井的井控储量,累计产气量从大到小依次为:SRV-SRV>FRAC-SRV>FRAC-FRAC>SRV-FRAC>井间无沟通。

根据加密井累计产气量曲线(见图5)可知,与老井不同的是,当加密井高导流缝与老井低导流缝沟通(SRV-FRAC)时,可以适当抵消老井压降影响进而抢气。对于井组而言,低导流缝间的沟通(SRV-SRV)为最佳方案,此时储量动用最充分,井组累计产气量最高。

2.1.3 缝网干扰对老井生产的影响

综合缝网干扰类型,利用现代试井解释成果和递减规律,可将不同干扰机理对老井生产水平的影响分为以下4类情况。

1)老井最终可采储量(estimated ultimate recovery,EUR)增加。可能存在裂缝沟通或压裂改造体积重叠(干扰机理1或2),既补充驱动能量,又改善了老井渗流条件,典型曲线平行上移。若老井复产后日产气量大幅上升,老井液量很快恢复至压裂干扰前水平,则为机理2;若复产初期产液量大幅上升,则为机理1。

2)老井EUR、典型曲线均不变。井间连通性弱(干扰机理4),老井复产后日产气量和套压有一定增大,但典型曲线仍在原趋势线上。

3)老井EUR不变、典型曲线先增后降至原水平。仅增大驱动压差(无沟通),典型曲线为先增大、后以较大斜率回落至原趋势线。

4)老井EUR有减小趋势。老井低导流缝与加密井高导流缝沟通(干扰机理3),老井日产气量增幅大、递减快,典型曲线逐渐低于原趋势。老井复产初期受加密井压裂后地层能量的补充,日产气量也会增大,但最终预测的EUR降低。

以上分析可以得出,对于同开发层系,大井距加密时,可以适当提高老井EUR或采气速度;而小井距加密时需严格论证施工参数,控制压裂规模,既要满足井间剩余储量的充分动用,又要防止主缝过长,影响气井采收率。

2.2 纵向干扰特征

立体开发纵向干扰,主要指不同开发层系井压裂时与邻近层系井的缝网沟通现象。

2.2.1 压裂干扰现象

微地震监测结果显示,人工改造裂缝主要在平面上扩展,纵向上扩展有限,有效裂缝高约15~25 m。区块上部气层井压裂时,下部气层老井(空间距离180~340 m)套压增幅低于3.0 MPa;中部气层井压裂时,下部气层老井(空间距离160~190 m)套压明显波动,套压增大2.5~6.0 MPa。据统计,不同开发层系井压裂对老井生产无明显影响,老井复产后短期内出现日产气量、套压上升现象,但很快回落至压裂关井前的生产水平。

2.2.2 2套层系立体开发井拉链压裂

研究表明,页岩气井压裂对正钻井施工有显著影响[30],但对压裂施工相互影响的研究相对较少,且层间干扰无法忽略[31]。近期,南川地区实施了中部气层井焦页206-Z1HF和下部气层加密井焦页195-M2HF拉链式压裂。2口井空间距离150~190 m,压裂段对应关系与最小水平主应力方向基本平齐,压裂过程中2口井的施工压力均高于同开发层系邻井水平。其中,焦页195-M2HF井平均破裂压力82.0 MPa,破裂压力梯度2.8 MPa/100m,比下部气层老井高0.1~0.6 MPa/100m;同期施工的焦页206-Z1HF井平均破裂压力80.9 MPa,比同开发层系井高10.0~12.0 MPa,破裂压力梯度2.9 MPa/100m,比同开发层系井高0.8~1.0 MPa/100m。不同层系井拉链压裂对缝网复杂程度的影响,还有待进一步验证。

3. 结论与建议

1)不同层系立体开发井施工压力纵向上与储层孔渗、压力系数等参数规律具有良好的一致性,下部气层井破裂压力梯度高于中部气层井,上部气层井破裂压力梯度最低。同开发层系加密井施工压力一般低于相邻老井,且随井距增加或井间采出程度减小,加密井与老井破裂压力梯度差值减小。

2)立体开发井产能主要受地层能量、储量丰度影响,下部气层井产能优于中部气层井,上部气层井产能最差。综合立体调整井压裂改造难易程度,建议优先动用下部气层,其次实施下部气层加密井和中部气层井,最后实施上部气层井。

3)同层系加密施工时,当老井套压平稳上升,若复产后EUR增加,表明老井高导流缝和加密井低导流缝沟通;若EUR不变,则新老井之间为低导流缝间的沟通。当老井套压迅速上升并伴随波动,复产后老井EUR减小,干扰机理为老井低导流缝与加密井高导流缝沟通。当老井套压表现为升降型,复产后EUR增加,则新老井之间为高导流缝间的沟通。数值模拟研究表明,老井和加密井低导流缝沟通时的采出程度最高,储量动用最充分。

4)建议在实施立体调整前利用建模数模一体化落实区块三层立体开发潜力,根据一次井网井距和改造效果优化调整加密井压裂规模,深化立体开发技术适应性分析,为方案整体部署提供依据。

-

表 1 应用井情况及效果

Table 1 Conditions of application wells and the effect

井号 侧钻点井深/m 完钻井深/m 进尺/m 机械钻速/(m·h−1) 钻井周期/d 复杂时效,% CM24–10 857.00 1 636.00 779.00 9.05 7.85 0 CA29A 1 524.00 2 328.00 804.00 6.39 9.33 0 CD2–8 1 444.50 2 225.00 780.50 4.14 15.94 0 CZ48 1 952.00 3 140.00 1 188.00 4.13 26.30 4.4 CT83–7 1 956.00 2 644.00 688.00 7.69 7.00 0 CF83–7 2 275.00 3 100.00 825.00 9.36 6.65 0 CF83–7A 2 252.00 2 980.00 728.00 1.95 17.42 2.9 CH24平1 2 522.79 3 150.00 627.21 3.21 26.58 0 CY7–15 1 164.50 1 955.00 790.50 7.96 9.21 0 -

[1] 胡博仲, 董福洲, 李子丰.小井眼钻采技术[M].北京: 石油工业出版社, 1997: 3–4. HU Bozhong, DONG Fuzhou, LI Zifeng. Slim hole drilling and production technology[M]. Beijing: Petroleum Industry Press, 1997:3–4.

[2] 李广,韩强,赵海艳,等. 胜利油田小井眼定向套管开窗侧钻技术[J]. 石油钻探技术, 2008, 36(4): 75–78. doi: 10.3969/j.issn.1001-0890.2008.04.020 LI Guang, HAN Qiang, ZHAO Haiyan, et al. Casing sidetrack in slim wellbore in Shengli Oilfield[J]. Petroleum Drilling Techniques, 2008, 36(4): 75–78. doi: 10.3969/j.issn.1001-0890.2008.04.020

[3] 李文魁,陈建军,王云,等. 国内外小井眼井钻采技术的发展现状[J]. 天然气工业, 2009, 29(9): 54–56, 63. doi: 10.3787/j.issn.1000-0976.2009.09.014 LI Wenkui, CHEN Jianjun, WANG Yun, et al. Development of slim hole drilling and production technology at home and abroad[J]. Natural Gas Industry, 2009, 29(9): 54–56, 63. doi: 10.3787/j.issn.1000-0976.2009.09.014

[4] 张凯,李明,刘小利,等. 国内外小井眼固井技术研究现状[J]. 钻采工艺, 2015, 38(2): 23–26. doi: 10.3969/J.ISSN.1006-768X.2015.02.07 ZHANG Kai, LI Ming, LIU Xiaoli, et al. Research status of slim hole cementing technology at home and abroad[J]. Drilling & Production Technology, 2015, 38(2): 23–26. doi: 10.3969/J.ISSN.1006-768X.2015.02.07

[5] 杨伟平,张东海,张伟. ϕ139.7 mm套管开窗侧钻技术现状及其展望[J]. 石油钻采工艺, 2006, 28(3): 19–22. doi: 10.3969/j.issn.1000-7393.2006.03.007 YANG Weiping, ZHANG Donghai, ZHANG Wei. Status quo and expectation of the ϕ139.7 mm casing side tracking technology[J]. Oil Drilling & Production Technology, 2006, 28(3): 19–22. doi: 10.3969/j.issn.1000-7393.2006.03.007

[6] 金晶,王建,任飞. 侧钻井技术在江苏油田的应用[J]. 石油天然气学报, 2012, 34(11): 211–212. JIN Jing, WANG Jian, REN Fei. Application of side drilling technology in Jiangsu Oilfield[J]. Journal of Oil and Gas Technology, 2012, 34(11): 211–212.

[7] 蒋海涛,王益山,韩振强,等. 小井眼开窗侧钻井固井工艺技术[J]. 石油钻采工艺, 2003, 25(2): 29–31. doi: 10.3969/j.issn.1000-7393.2003.02.008 JIANG Haitao, WANG Yishan, HAN Zhenqiang, et al. Slim hole sidetracking cementing technology[J]. Oil Drilling & Production Technology, 2003, 25(2): 29–31. doi: 10.3969/j.issn.1000-7393.2003.02.008

[8] 许杰, 刘小刚, 崔治军, 等. 复杂条件下小井眼固井技术在科探井中的应用[J].石油钻采工艺, 2012,34(增刊1):23–25. XU Jie, LIU Xiaogang, CUI Zhijun, et al. Cementing technology of slim hole under complicated conditions in the scientific exploration well[J]. Oil Drilling & Production Technology, 2012, 34 (supplement 1): 23–25.

[9] 何生辉,高俊奎,牛庆华. 小井眼固井技术[J]. 钻采工艺, 2006, 29(4): 12–13. HE Shenghui, GAO Junkui, NIU Qinghua. Slim hole cementing technology[J]. Drilling & Production Technology, 2006, 29(4): 12–13.

[10] 周大志,刘加杰,吴英. 自膨胀封隔器的技术现状和发展趋势[J]. 机械研究与应用, 2018, 31(3): 214–216. ZHOU Dazhi, LIU Jiajie, WU Ying. Technology status and development trend of self-swelling packer[J]. Mechanical Research & Application, 2018, 31(3): 214–216.

[11] 马兰荣,王德国,韩峰,等. 遇水膨胀封隔器关键技术研究[J]. 石油钻探技术, 2014, 42(4): 27–31. MA Lanrong, WANG Deguo, HAN Feng, et al. Research on key technology of water-swellable packer[J]. Petroleum Drilling Techniques, 2014, 42(4): 27–31.

[12] 许婵婵,余金陵,徐鑫. 遇水自膨胀封隔器专用橡胶的合成与性能分析[J]. 石油钻探技术, 2012, 40(3): 38–42. doi: 10.3969/j.issn.1001-0890.2012.03.008 XU Chanchan, YU Jinling, XU Xin. Manufacture and properties analysis of rubber for water swelling packer[J]. Petroleum Drilling Techniques, 2012, 40(3): 38–42. doi: 10.3969/j.issn.1001-0890.2012.03.008

-

期刊类型引用(19)

1. 林魂,宋西翔,杨兵,袁勇,张健强,孙新毅. 温-压耦合作用下断层滑移对套管应力的影响. 石油机械. 2023(06): 136-142+158 .  百度学术

百度学术

2. 刘奎,丁士东,初永涛,刘仍光. 页岩气井压裂交变载荷水泥环密封能力研究. 石油机械. 2023(11): 79-86 .  百度学术

百度学术

3. 丁士东,刘奎,刘小刚,周仕明,陶谦,李鹏程. 环空加压固井对双层套管水泥环界面径向应力的影响. 石油钻探技术. 2022(01): 30-37 .  本站查看

本站查看

4. 郝海洋,刘俊君,何吉标,王建斌,彭博,张家瑞. 页岩气超长水平井预控水泥环封固失效水泥浆技术. 天然气勘探与开发. 2022(03): 108-115 .  百度学术

百度学术

5. 高德利,刘奎,王宴滨,刘金海,李轩. 页岩气井井筒完整性失效力学机理与设计控制技术若干研究进展. 石油学报. 2022(12): 1798-1812 .  百度学术

百度学术

6. 郑双进,杜冬楠,李足平,刘涛,刘裕,潘祎. 固井水泥环封隔压力预测方法. 中国科技论文. 2021(01): 7-11 .  百度学术

百度学术

7. 刘奎,丁士东,周仕明,陶谦,杨广国,刘仍光,高元. 套管内压周期变化水泥环应力计算与失效分析. 石油机械. 2021(05): 1-8 .  百度学术

百度学术

8. 席岩,李方园,王松,刘明杰,夏铭莉,曾夏茂,钟文力. 利用预应力固井方法预防水泥环微环隙研究. 特种油气藏. 2021(06): 144-150 .  百度学术

百度学术

9. 何吉标,彭小平,刘俊君,屈勇,袁欢,彭博. 抗高交变载荷水泥浆的研制及其在涪陵页岩气井的应用. 石油钻探技术. 2020(03): 35-40 .  本站查看

本站查看

10. 毛新军,曹植纲,陈超峰,胡广文,封猛,咸玉席. 高产井地层特征的热流耦合温度反演新方法. 石油钻探技术. 2020(04): 118-123 .  本站查看

本站查看

11. 丁嘉迪,沈吉云,张硕,纪宏飞,王琳琳. 基于多孔介质理论的油井水泥石破坏准则. 钻井液与完井液. 2020(06): 763-770 .  百度学术

百度学术

12. 席岩,李军,柳贡慧,陶谦,连威. 页岩气水平井压裂过程中水泥环完整性分析. 石油科学通报. 2019(01): 57-68 .  百度学术

百度学术

13. 高德利,刘奎. 页岩气井井筒完整性若干研究进展. 石油与天然气地质. 2019(03): 602-615 .  百度学术

百度学术

14. 罗攀登,李涵宇,翟立军,李春月,吕欣润,牟建业. 塔河油田超临界CO_2压裂井筒与裂缝温度场. 断块油气田. 2019(02): 225-230 .  百度学术

百度学术

15. 吴怡,谢仁军,刘书杰,蒋凯,邓金根,蔚宝华. 考虑温度效应的高温高压直井井壁稳定性规律. 断块油气田. 2019(02): 253-256 .  百度学术

百度学术

16. 曾静,高德利,王宴滨,房军. 体积压裂井筒水泥环拉伸失效机理研究. 钻采工艺. 2019(03): 1-4+6 .  百度学术

百度学术

17. 张智,丁剑,赵苑瑾,邓虎,卢齐. 页岩气井环空带压临界控制值计算方法. 西南石油大学学报(自然科学版). 2019(06): 155-164 .  百度学术

百度学术

18. 曾德智,喻智明,何奇垚,刘乔平,施太和. 页岩气井环空带压安全风险定量评价方法研究. 西南石油大学学报(自然科学版). 2019(06): 146-154 .  百度学术

百度学术

19. 章娅菲,祁珊珊,窦益华. 基于纳米流控系统的超弹套管保护套结构原理与性能试验. 石油钻探技术. 2018(06): 54-58 .  本站查看

本站查看

其他类型引用(13)

下载:

下载: