Progress, Outlook, and the Development Directions at Sinopec in Cementing Technology Progress

-

摘要:

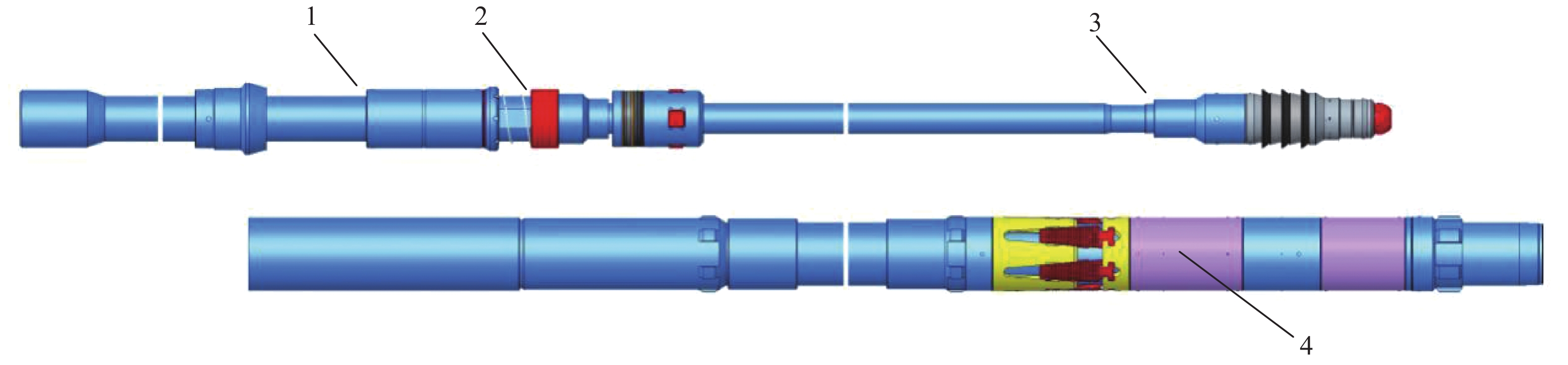

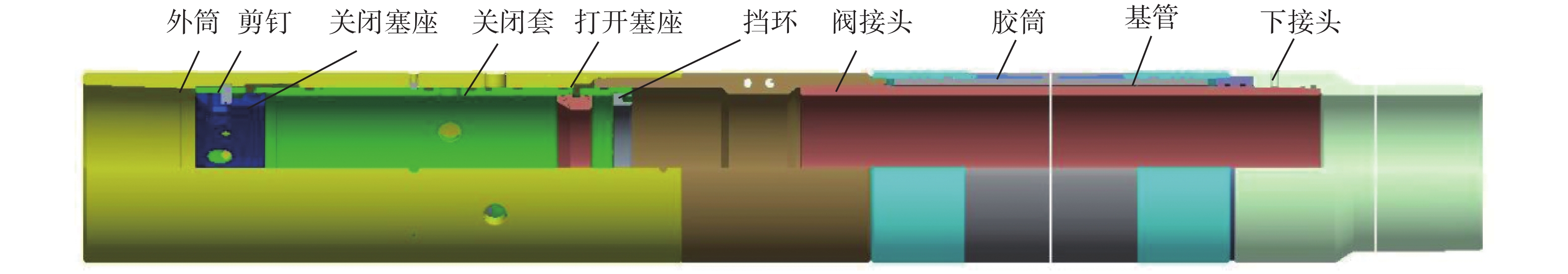

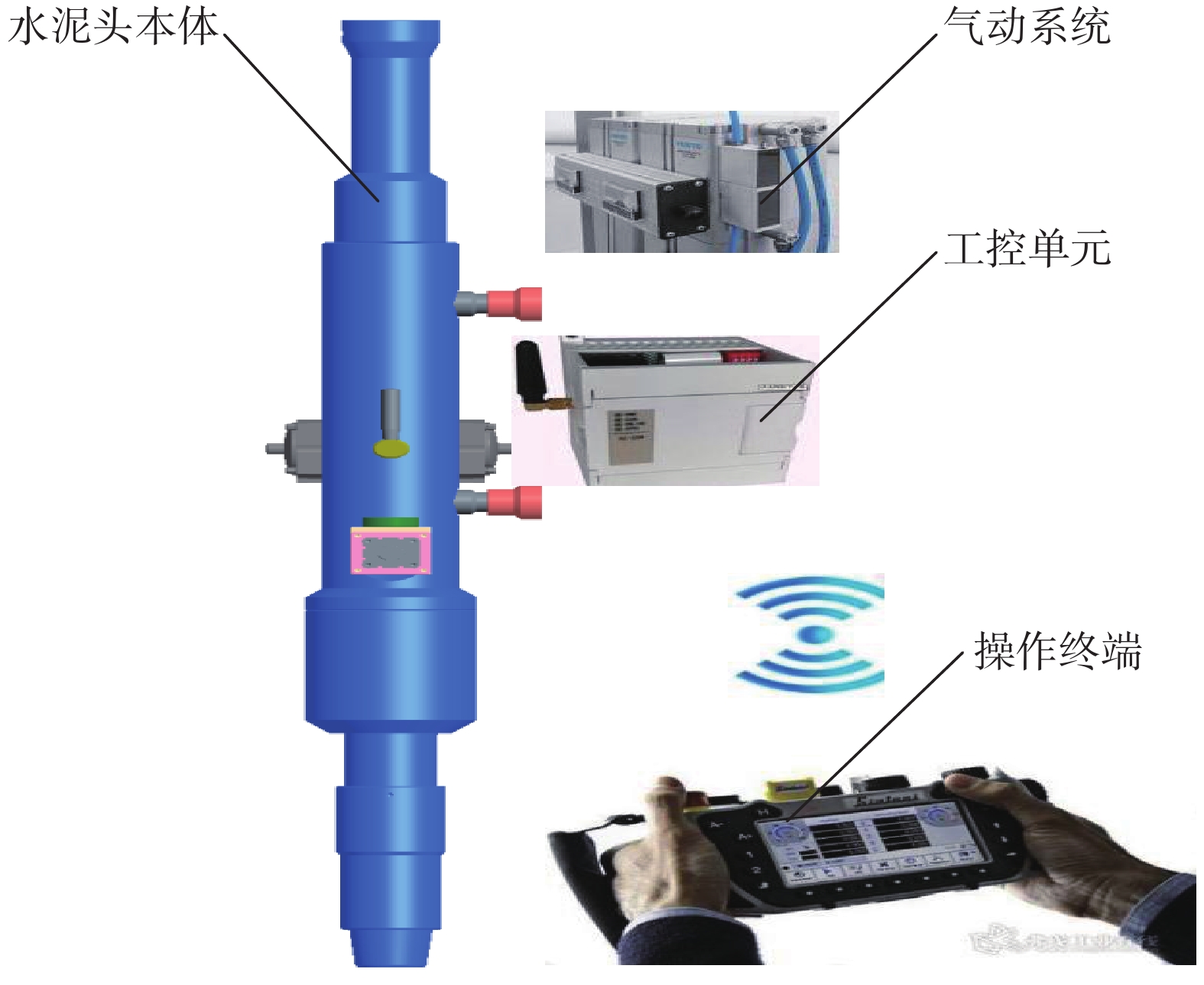

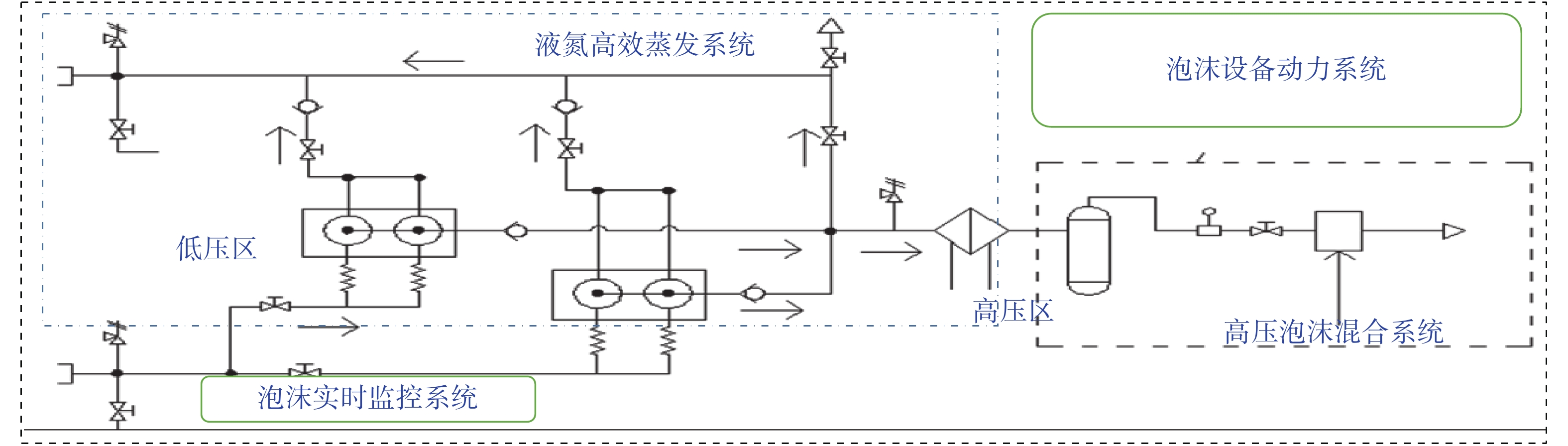

近年来,中国石化持续加大了深层超深层油气、页岩气和致密油气的勘探开发,为满足油气勘探开发需求,研制开发了自愈合、纳米液硅、温度广谱性等高性能新型油井水泥外加剂,开发了具有自身特色的抗高温、高密度和低密度(两高一低)以及弹塑性水泥浆,形成了超深井高温高压固井技术、页岩油气固井技术以及超长封固段大温差固井配套技术,基本满足了复杂地质条件下的 固井技术需求,推动了中国石化油气勘探开发进程。成功开发了系列高性能尾管悬挂器、分级注水泥等系列化固井工具、新型自动化控制的水泥车和一体化注氮泡沫水泥浆系统等固井装备、具有自主知识产权的固井优化设计软件,提高了我国固井技术水平和核心竞争力。展望未来,中国石化固井技术发展要坚持以需求为导向,重点发展复杂深井超深井固井技术、低渗透与页岩油气固井技术、老油田调整井复杂压力体系固井技术,更好地服务于复杂油气藏高效勘探开发。同时,加强跨界融合,研发新型多功能、广谱化、智能化、一体化新型固井材料以及大功率、自动化、智能化、设计监控一体化固井设备是未来固井技术发展的方向。

Abstract:In recent years, Sinopec has maintained a commitment to intensivying the exploration & development of deep, ultra-deep strata, shale gas and tight oil and gas. In order to meet the needs of complex oil and gas exploration & development, Sinopec has developed a series of new oil well additives with high performance qualities. The additives include self-healing, nano-liquid silicon, and cover a wide temperature spectrum, are resistant to high temperatures. In addition, Sinopec has developed, high density and low density as well as elastoplastic cement slurry, and has formed the matching technology of ultra-deep well HTHP cementing, shale oil/gas cementing, as well as the ultra-long interval cementing with significant temperature difference. These new additives can also meet the cementing requirement under complex geological conditions, and promote the company’s oil and gas exploration & development process. Many new tools, equipment and products have been developed, including high-performance liner hangers, multiple stage cementers, automatic control cementing truck and integrated nitrogen foam cement slurry system, etc. Optimized cementing design software with independent intellectual property rights has been developed, so as to improve the level of domestic cementing technologies and core competitiveness. Going forward, the cementing technology development of Sinopec plans to adhere to the principle of demand-oriented product development, while maintaining a focus on the development trends of cementing for complex deep/ultra-deep wells, low-permeability and shale oil/gas, and complex pressure system technology for adjustment wells in old oilfields. Thus, the new technologies will better serve high-efficiency exploration & development of complex oil and gas reservoirs. At the same time, more effort will be directed to strengthen cross-disciplinary technology integration. In addition, Sinopec will research and develop new multi-functional, broad-spectrum, intelligent and integrated cementing materials, as well as cementing equipment to integrate with high-power, automation, intelligence, designing and monitoring.

-

Keywords:

- cementing technology /

- cement additive /

- cement slurry /

- cementing tool /

- cementing equipment /

- Sinopec

-

-

表 1 1000型固井泵性能参数(容积效率100%)

Table 1 Performance parameters of 1000 type cement pump (volume efficiency 100%)

输入转速/

(r·min–1)泵冲/

min–1工作排量/

(L·min–1)工作压力/

MPa231 50 236 70.0 548 119 562 70.0 922 200 946 42.6 1 383 300 1 419 28.4 2 075 450 2 128 18.9 -

[1] 路保平,丁士东,何龙,等. 低渗透油气藏高效开发钻完井技术研究主要进展[J]. 石油钻探技术, 2019, 47(1): 1–6. LU Baoping, DING Shidong, HE Long, et al. Key achievement of drilling & completion technologies for the efficient development of low permeability oil and gas reservoirs[J]. Petroleum Drilling Techniques, 2019, 47(1): 1–6.

[2] 杜金虎,何海清,杨涛,等. 中国致密油勘探进展及面临的挑战[J]. 中国石油勘探, 2014, 19(1): 1–9. doi: 10.3969/j.issn.1672-7703.2014.01.001 DU Jinhu, HE Haiqing, YANG Tao, et al. Progress in China′s tight oil exploration and challenges[J]. China Petroleum Exploration, 2014, 19(1): 1–9. doi: 10.3969/j.issn.1672-7703.2014.01.001

[3] 路保平,丁士东. 中国石化页岩气工程技术新进展与发展展望[J]. 石油钻探技术, 2018, 46(1): 1–13. LU Baoping, DING Shidong. New progress and development prospect in shale gas engineering technologies of Sinopec[J]. Petroleum Drilling Techniques, 2018, 46(1): 1–13.

[4] 刘洋,严海兵,余鑫,等. 井内压力变化对水泥环密封完整性的影响及对策[J]. 天然气工业, 2014, 34(4): 95–98. doi: 10.3787/j.issn.1000-0976.2014.04.015 LIU Yang, YAN Haibing, YU Xin, et al. Negative impacts of borehole pressure change on cement sheath sealing integrity and countermeasures[J]. Natural Gas Industry, 2014, 34(4): 95–98. doi: 10.3787/j.issn.1000-0976.2014.04.015

[5] 谭春勤,刘伟,丁士东,等. SFP弹韧性水泥浆体系在页岩气井中的应用[J]. 石油钻探技术, 2011, 39(3): 53–56. doi: 10.3969/j.issn.1001-0890.2011.03.009 TAN Chunqin, LIU Wei, DING Shidong, et al. Application of SFP elasto-toughness slurry in shale gas well[J]. Petroleum Drilling Techniques, 2011, 39(3): 53–56. doi: 10.3969/j.issn.1001-0890.2011.03.009

[6] 齐奉忠,杨成颉,刘子帅. 提高复杂油气井固井质量技术研究:保证水泥环长期密封性的技术措施[J]. 石油科技论坛, 2013, 32(1): 66–67. doi: 10.3969/j.issn.1002-302x.2013.01.004 QI Fengzhong, YANG Chengjie, LIU Zishuai. Improve cementing quality of complicated oil and gas wells-ensure long-term sealing performance of cement sheath[J]. Oil Forum, 2013, 32(1): 66–67. doi: 10.3969/j.issn.1002-302x.2013.01.004

[7] 陶谦. 气井水泥环长期密封失效机理及预防措施[J]. 钻采工艺, 2018, 41(3): 25–29. doi: 10.3969/J.ISSN.1006-768X.2018.03.08 TAO QIAN. Long-term sealing failure mechanism of cement sheath in gas wells and preventive measures[J]. Drilling & Production Technology, 2018, 41(3): 25–29. doi: 10.3969/J.ISSN.1006-768X.2018.03.08

[8] 陶谦,陈星星. 四川盆地页岩气水平井B环空带压原因分析与对策[J]. 石油钻采工艺, 2017, 39(5): 588–593. TAO Qian, CHEN Xingxing. Causal analysis and countermeasures on B sustained casing pressure of shale-gas horizontal wells in the Sichuan Basin[J]. Oil Drilling & Production Technology, 2017, 39(5): 588–593.

[9] 卢子臣,孔祥明,岳蕾,等. 水泥石单一裂隙的渗流规律及其遇水自愈合性能[J]. 硅酸盐学报, 2014, 41(8): 960–965. LU Zichen, KONG Xiangming, YUE Lei, et al. Water flow through single cracpaste and self-healing property of crack[J]. Journal of the Chinese Ceramic Society, 2014, 41(8): 960–965.

[10] 刘仍光,周仕明,陶谦,等. 掺橡胶乳液和弹性粒子柔性油井水泥石的微结构[J]. 硅酸盐学报, 2015, 43(10): 1475–1482. LIU Rengguang, ZHOU Shiming, TAO Qian, et al. Micro-structure of flexible oilwell cement stone mixed with latex and elastic particle[J]. Journal of the Chinese Ceramic Society, 2015, 43(10): 1475–1482.

[11] 高元,桑来玉,杨广国,等. 胶乳纳米液硅高温防气窜水泥浆体系[J]. 钻井液与完井液, 2016, 33(3): 67–72. doi: 10.3969/j.issn.1001-5620.2016.03.014 GAO Yuan, SANG Laiyu, YANG Guangguo, et al. Cement slurry treated with latex Nano liquid silica anti-gas-migration agent[J]. Drilling Fluid & Completion Fluid, 2016, 33(3): 67–72. doi: 10.3969/j.issn.1001-5620.2016.03.014

[12] 魏浩光,张鑫,丁士东,等. PEG对纳米硅水泥浆触变性改善的研究[J]. 钻井液与完井液, 2018, 35(4): 82–86. doi: 10.3969/j.issn.1001-5620.2018.04.015 WEI Haoguang, ZHANG Xin, DING Shidong, et al. Rheological improvement of nano-phase silicon cement slurry with polyglycol[J]. Drilling Fluid & Completion Fluid, 2018, 35(4): 82–86. doi: 10.3969/j.issn.1001-5620.2018.04.015

[13] 刘学鹏,刘仍光. 油井水泥降失水剂的作用机理研究[J]. 化学研究与应用, 2017, 29(12): 1298–1302. LIU Xuepeng, LIU Rengguang. Mechanisms involved influid loss control of oilwell cement slurries by water-soluble polyme[J]. Chemical Research and Application, 2017, 29(12): 1298–1302.

[14] 刘学鹏,张明昌,方春飞. 耐高温油井水泥降失水剂的合成和性能[J]. 钻井液与完井液, 2015, 32(6): 61–64, 107. LIU Xuepeng, ZHANG Mingchang, FANG Chunfei. Synthesis and properties of a high temperature filter loss reducer for oil well cementing[J]. Drilling Fluid & Completion Fluid, 2015, 32(6): 61–64, 107.

[15] 方春飞,刘学鹏,张明昌. 耐高温油井水泥缓凝剂SCR180L的合成及评价[J]. 石油钻采工艺, 2016, 38(2): 171–175. FANG Chunfei, LIU Xuepeng, ZHANG Mingchang. Synthesis and assessment of heat-resistant cement retardant SCR180L for oil producers[J]. Oil Drilling & Production Technology, 2016, 38(2): 171–175.

[16] 王敏生,光新军,孔令军. 形状记忆聚合物在石油工程中的应用前景[J]. 石油钻探技术, 2018, 46(5): 14–20. WANG Minsheng, GUANG Xinjun, KONG Lingjun. The prospects of applying shape memory polymers in petroleum engineering[J]. Petroleum Drilling Techniques, 2018, 46(5): 14–20.

[17] 陈雷,周仕明,赵艳,等. 固井用热固性树脂–镁氧水泥复合材料研究[J]. 石油钻探技术, 2019, 47(2): 74–80. CHEN Lei, ZHOU Shiming, ZHAO Yan, et al. Study on thermosetting resin-magnesia composites for cementing[J]. Petroleum Drilling Techniques, 2019, 47(2): 74–80.

[18] 刘伟,刘学鹏,陶谦. 适合页岩气固井的洗油隔离液的研究与应用[J]. 特种油气藏, 2014, 21(6): 119–122, 147. doi: 10.3969/j.issn.1006-6535.2014.06.029 LIU Wei, LIU Xuepeng, TAO Qian. Development and application of flushing spacer for cementing in shale gas reservoirs[J]. Special Oil & Gas Reservoirs, 2014, 21(6): 119–122, 147. doi: 10.3969/j.issn.1006-6535.2014.06.029

[19] 马兰荣,达伟,韩峰,等. 高性能尾管悬挂器关键技术[J]. 断块油气田, 2017, 24(6): 859–862. MA Lanrong, DA Wei, HAN Feng, et al. Key techniques for high-performance liner hanger[J]. Fault-Block Oil & Gas Field, 2017, 24(6): 859–862.

[20] 肖京男,刘建,桑来玉,等. 充气泡沫水泥浆固井技术在焦页9井的应用[J]. 断块油气田, 2016, 23(6): 835–837. XIAO Jingnan, LIU Jian, SANG Laiyu, et al. Application of foamed cement slurry to Jiaoye-9 Well[J]. Fault-Block Oil & Gas Field, 2016, 23(6): 835–837.

[21] 陶谦,周仕明,张晋凯,等. 水泥浆流变性对水平井固井顶替界面的影响:基于天河一号大规模集群计算平台的数值模拟[J]. 石油钻采工艺, 2017, 39(2): 185–191. TAO Qian, ZHOU Shiming, ZHANG Jinkai, et al. Effect of rheological property of slurry on cementing displacement interface of horizontal well: the numerical simulation based on large-scale cluster computing platform Tianhe-1[J]. Oil Drilling & Production Technology, 2017, 39(2): 185–191.

[22] 齐奉忠,杜建平,魏群宝. 固井材料技术新进展及研究方向[J]. 石油科技论坛, 2015, 34(4): 45–48. doi: 10.3969/j.issn.1002-302x.2015.04.009 QI Fengzhong, DU Jianping, WEI Qunbao. New development and research area of cementing material and technology[J]. Oil Forum, 2015, 34(4): 45–48. doi: 10.3969/j.issn.1002-302x.2015.04.009

[23] 刘硕琼,齐奉忠. 中国石油固井面临的挑战及攻关方向[J]. 石油钻探技术, 2013, 41(6): 6–11. doi: 10.3969/j.issn.1001-0890.2013.06.002 LIU Shuoqiong, QI Fengzhong. Challenges and development trends of cementing technology in CNPC[J]. Petroleum Drilling Tech-niques, 2013, 41(6): 6–11. doi: 10.3969/j.issn.1001-0890.2013.06.002

[24] 齐奉忠,刘硕琼,沈吉云,等. 中国石油固井技术进展及面临的问题[J]. 石油科技论坛, 2013, 32(4): 5–8, 69. doi: 10.3969/j.issn.1002-302x.2013.04.002 QI Fengzhong, LIU Shuoqiong, SHEN Jiyun, et al. Problem facing CNPC well cementing technological development[J]. Oil Forum, 2013, 32(4): 5–8, 69. doi: 10.3969/j.issn.1002-302x.2013.04.002

-

期刊类型引用(7)

1. 张光伟,尹福来,程礼林,侯朋朋. 全旋转指向式导向钻井工具结构设计与仿真. 机械设计与制造. 2024(05): 136-140 .  百度学术

百度学术

2. 刘永旺,郭福贵,管志川,秦晓兵. 协同钻头推靠与指向作用控制井眼轨迹的旋转导向系统. 中国石油大学学报(自然科学版). 2022(05): 73-80 .  百度学术

百度学术

3. 滕学清,刘洪涛,李宁,王天博,汝大军,董仁. 塔里木博孜区块超深井自动垂直钻井难点与技术对策. 石油钻探技术. 2021(01): 11-15 .  本站查看

本站查看

4. 宋红喜,崔谦,曾义金,张卫,米金泰,黄中伟. 旋转导向单总线传输机制研究. 石油机械. 2021(05): 35-41 .  百度学术

百度学术

5. 狄勤丰,芮子翔,周星,冯大军,王文昌,陈锋. 带旋转导向工具的底部钻具组合横向振动特性研究. 石油钻探技术. 2021(06): 8-16 .  本站查看

本站查看

6. 张光伟,乔阳,高嗣土,田帆. 全旋转内置式可控弯接头运动特性. 石油钻采工艺. 2020(01): 45-51 .  百度学术

百度学术

7. 张光伟,高嗣土,乔阳,田帆. 指向式旋转导向系统内外环转速对PDC钻头破岩效率的影响. 石油钻探技术. 2019(06): 27-33 .  本站查看

本站查看

其他类型引用(8)

下载:

下载: