The Setting Depth of the Testing Safety Valve in Deepwater Oil and Gas Wells for Gas Hydrate Blockage Prevention

-

摘要:

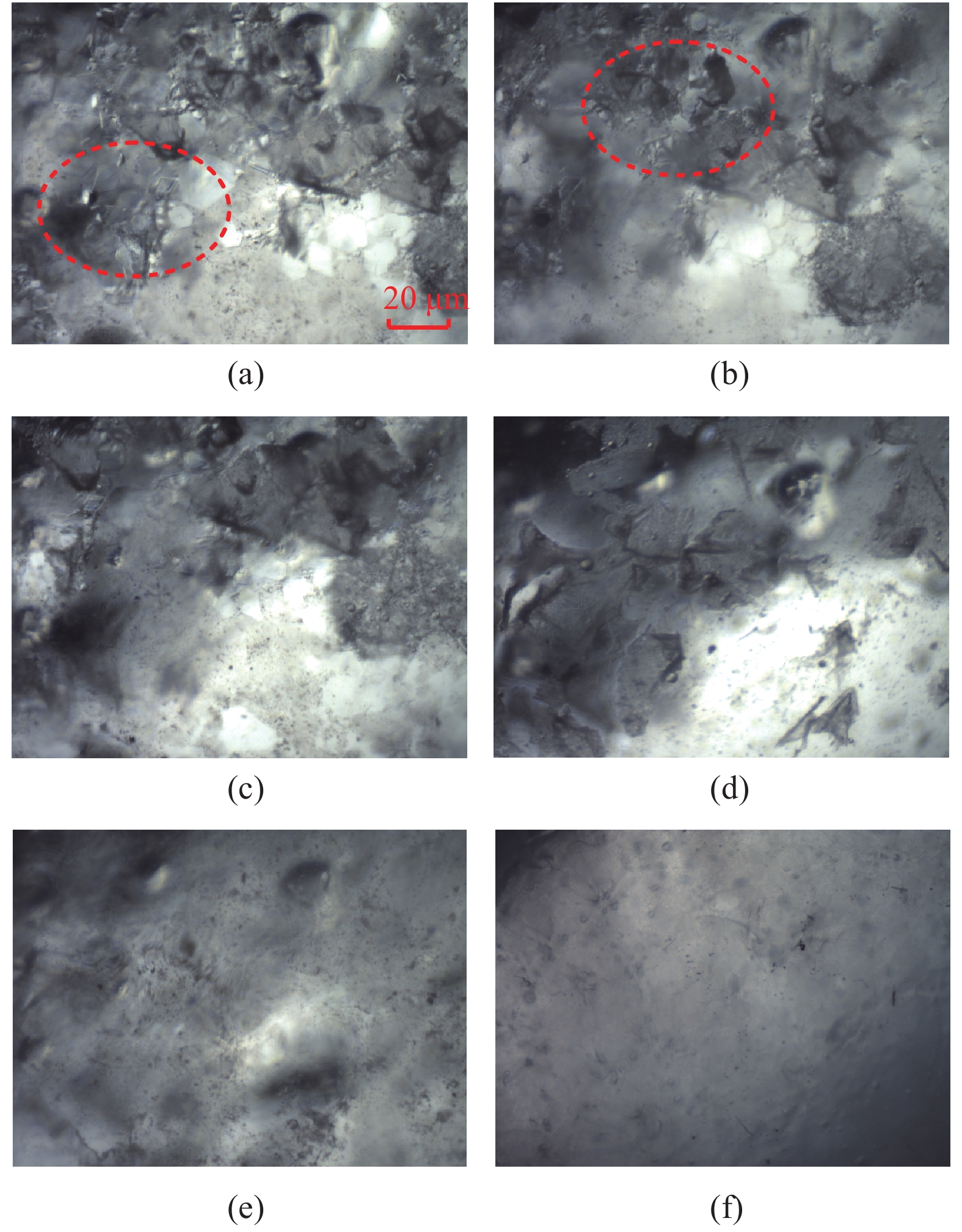

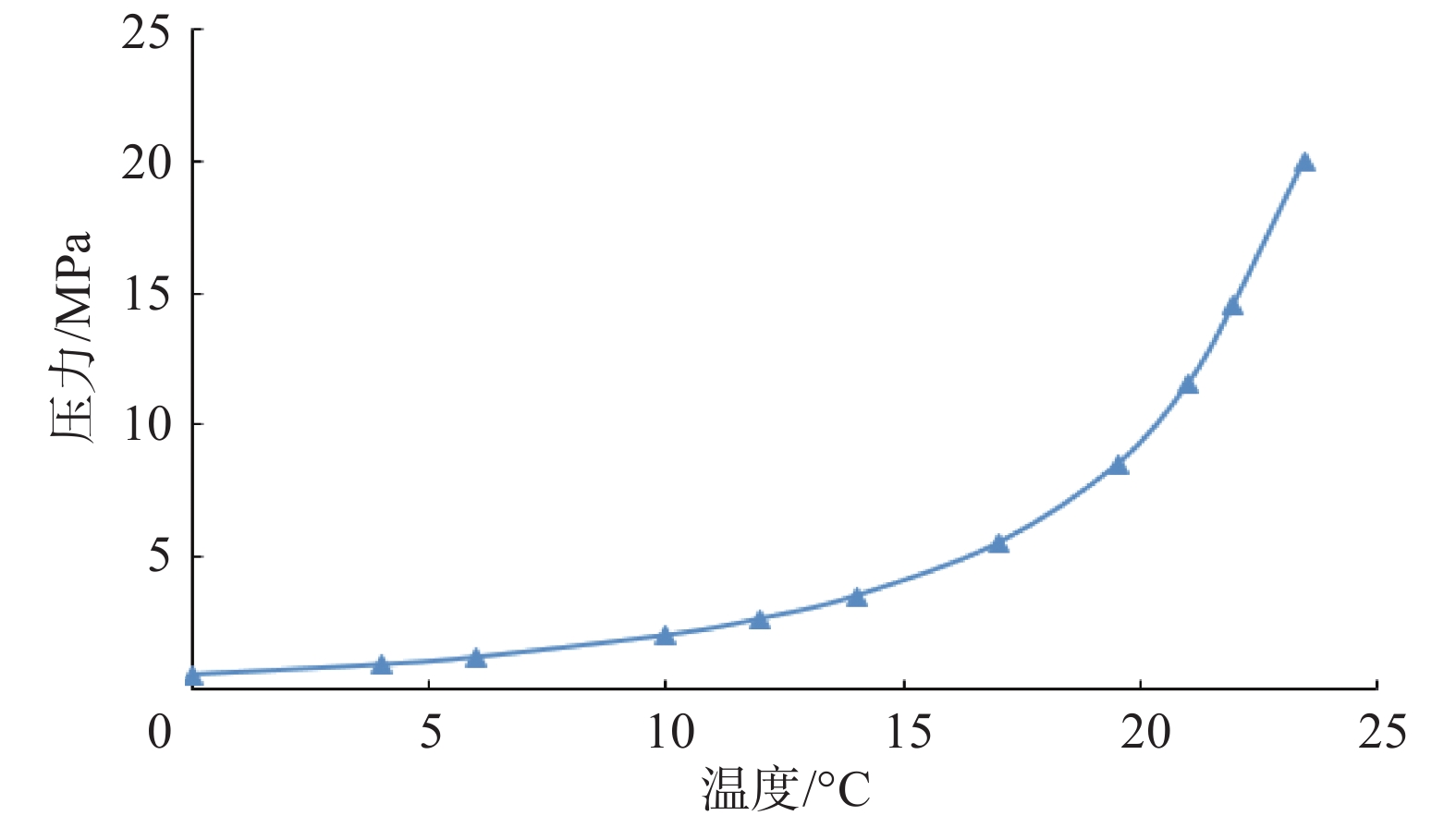

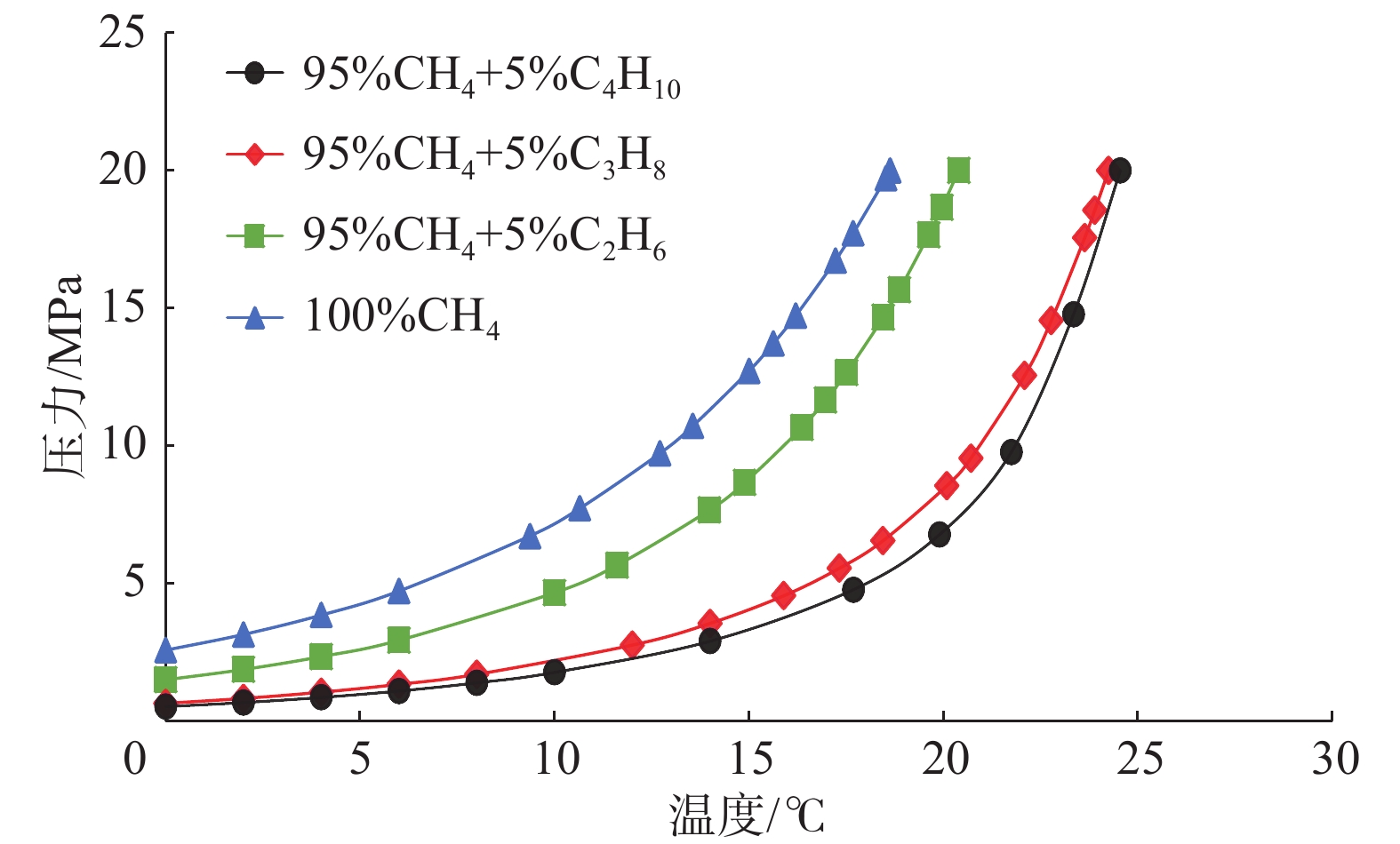

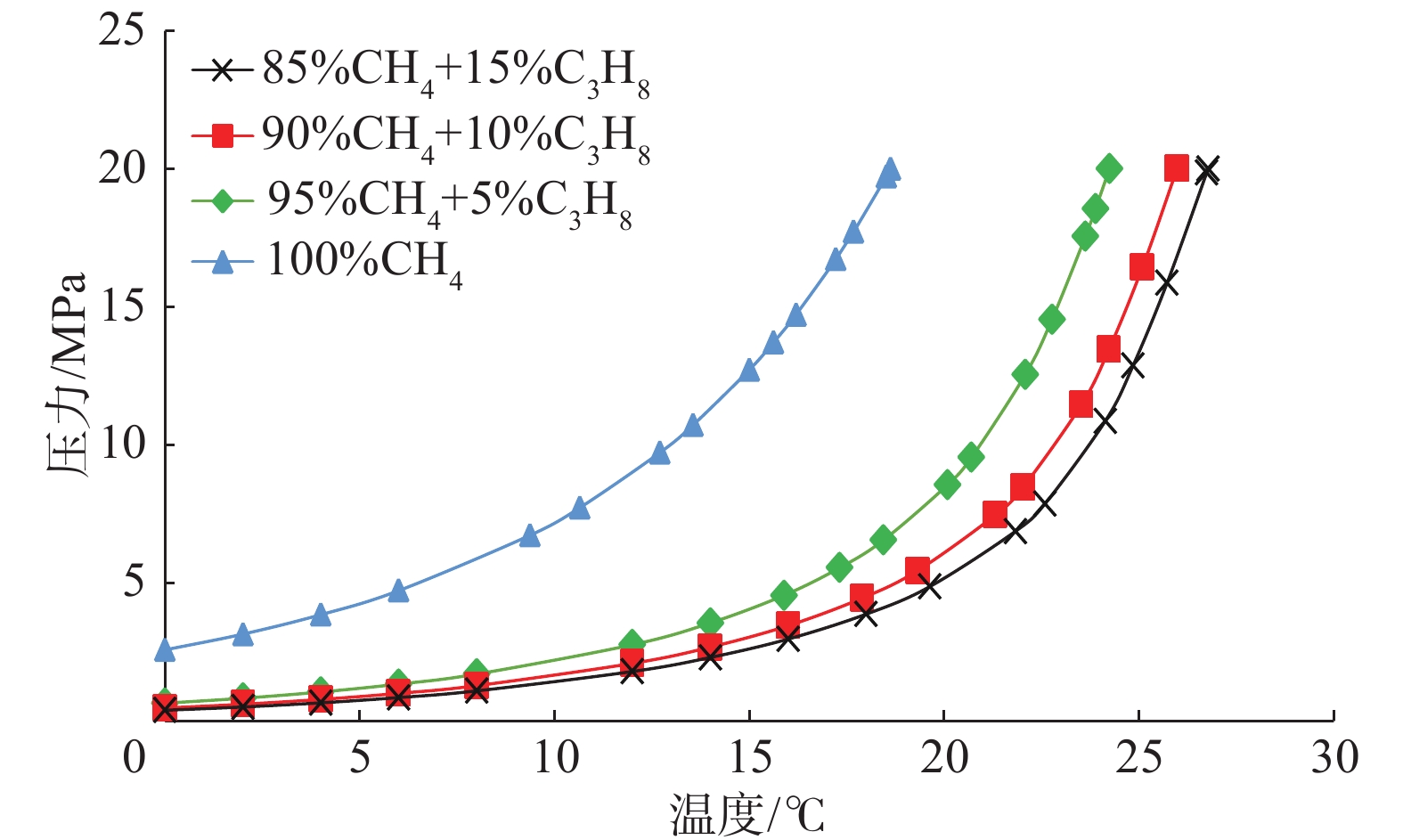

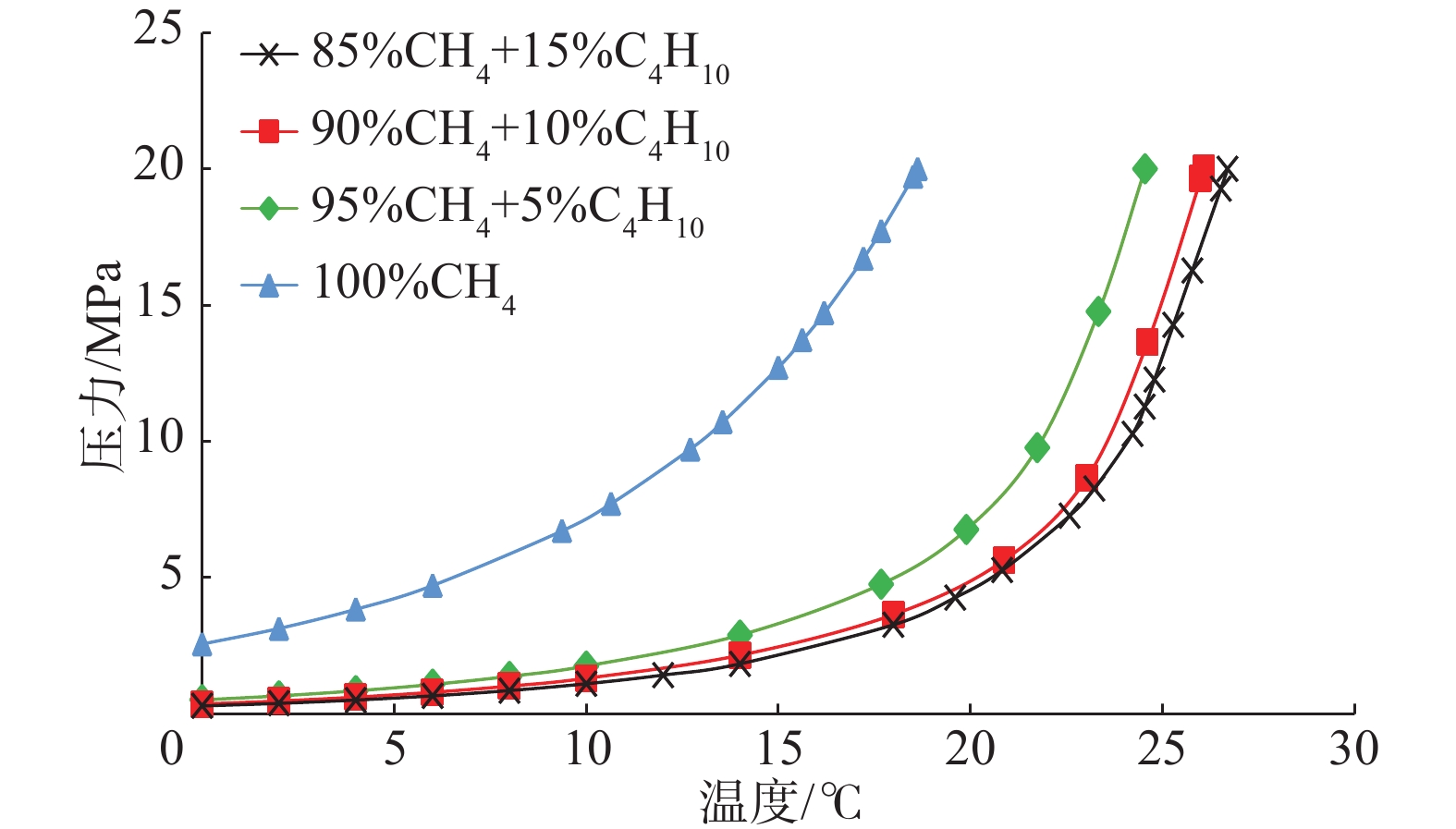

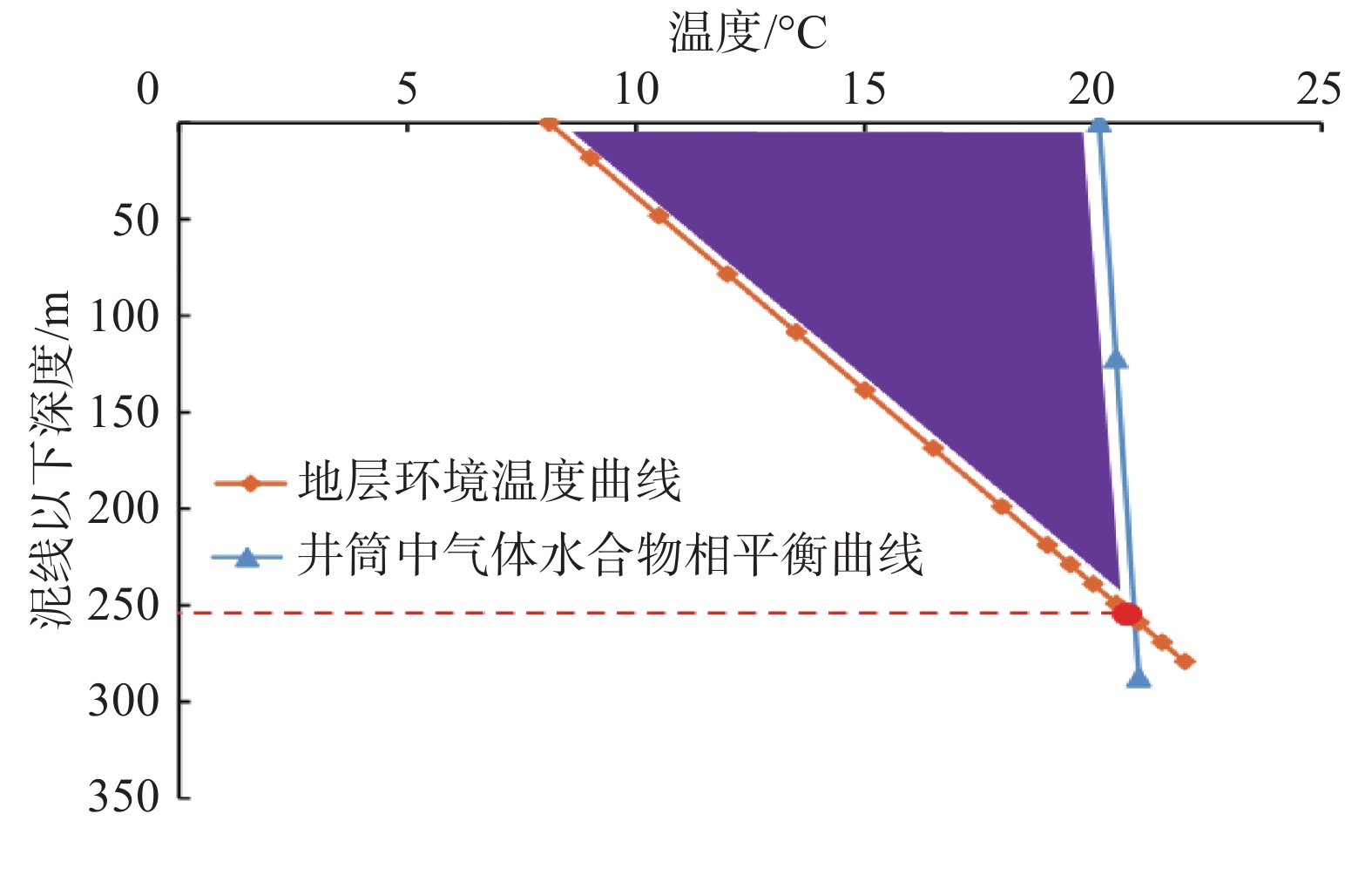

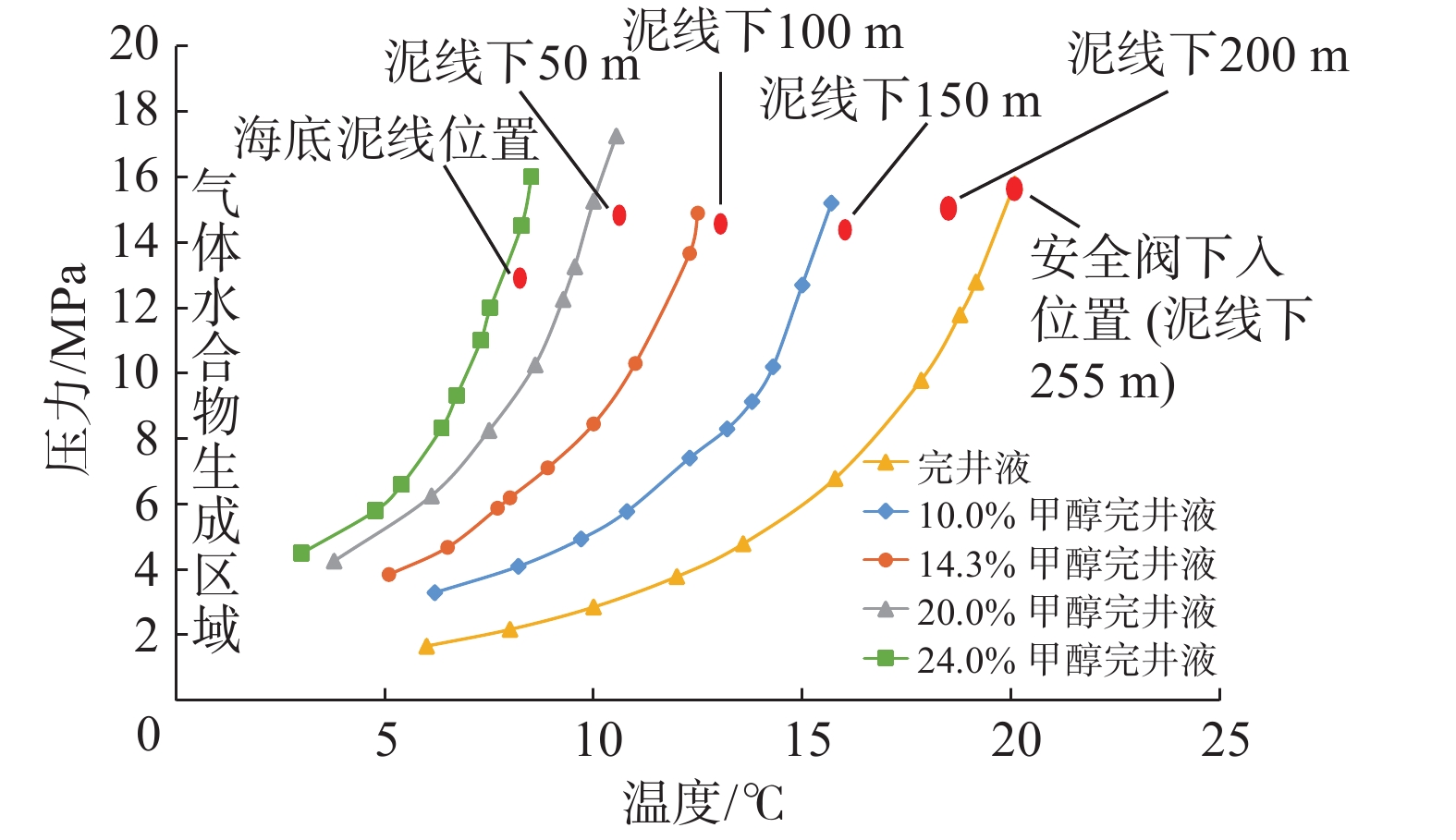

深水油气井测试过程中,容易发生气体水合物堵塞井下安全阀的问题,为避免出现该问题,研究了安全阀合理下入位置的确定方法。利用气体水合物相平衡微观试验装置,在室内模拟了地层水矿化度下多组分气体水合物在水中的相变过程,得到了温度和压力对气体水合物相平衡的影响规律;分析了气体组分、水深、地温梯度和井口压力对生成气体水合物的影响,预测了气体水合物的生成区域,从安全和成本2方面考虑给出了安全阀最小下入深度的确定方法。研究发现,气体组分、水深、地温梯度、井口压力均会影响安全阀的下入位置,产出气中乙烷、丙烷和丁烷含量增加更易生成气体水合物;同时,水深越深,地温梯度越小,井口压力越大,生成气体水合物的区域越大,安全阀需要下入到更深的位置。研究认为,上述研究成果可为深水油气井测试中安全阀下入位置的确定提供参考。

Abstract:During the testing of deep water oil and gas wells, gas hydrate is prone to block downhole safety valves. To prevent it from happening, a method for determining the reasonable setting depth of safety valve was studied. The gas hydrate phase of equilibrium micro-test device was used to simulate the phase transition process of multi-component gas hydrates under various formation water salinities in the laboratory and to obtain the influencing law of temperature and pressure on the phase equilibrium of gas hydrate. The effects of gas composition, water depth, the geothermal gradient and wellhead pressure on the formation of gas hydrate were analyzed to predict the formation area of gas hydrate, and the method in determining the minimum setting depth of safety valve was obtained from the aspects of safety and cost. Studies suggest that all the factors including gas composition, water depth, geothermal gradient, and wellhead pressure could affect the setting depth of safety valve, and the increased contents of ethane, propane and butane in the produced gas are more likely to form gas hydrates. In addition, the setting depth of the safety valve will be further lower as deeper water depth, smaller geothermal gradient, higher wellhead pressure, and larger gas hydrate formation area. The results of this study could provide a reference for determining the setting depth of test safety valve in deep water oil and gas wells.

-

Keywords:

- gas hydrate /

- deepwater oil and gas /

- safety valve /

- gas hydrate blockage /

- phase equilibrium

-

-

-

[1] SLOAN E D, KOH C A. Clathrate hydrates of natural gas[M]. 3rd ed. Boca Raton: CRC Press, 2007: 1-11.

[2] 关利军,任金山,孙宝江,等. 深水气井测试水合物抑制剂优选及注入方法[J]. 中国海上油气, 2014, 26(2): 55–60. GUAN Lijun, REN Jinshan, SUN Baojiang, et al. An optimization and of hydrate inhibitors and its injection method for the testing of deep water gas wells[J]. China Offshore Oil and Gas, 2014, 26(2): 55–60.

[3] SY/T 10024—1998 井下安全阀系统的设计、安装、修理和操作的推荐作法[S]. SY/T 10024—1998 Recommended practice for design, installation, repair and operation of subsurface safety valve system[S].

[4] 谢梅波,岳江河,王海东. 各类井下安全阀系统的特点及安装设计概述[J]. 中国海上油气(工程), 1995, 7(4): 31–42. XIE Meibo, YUE Jianghe, WANG Haidong. The feature of various downhole safety valve system and overview of installation design[J]. China Offshore Oil and Gas (Engineer), 1995, 7(4): 31–42.

[5] GARY B, HOSLI C, LUVIANO A, et al. Tubing retrievable surface controlled subsurface safety valve floating flapper remediation[R]. SPE 168271, 2014.

[6] 李林涛,万小勇,李渭亮,等. 高压井下安全阀的研制及性能评价[J]. 重型机械, 2018(6): 12–14. doi: 10.3969/j.issn.1001-196X.2018.06.003 LI Lintao, WAN Xiaoyong, LI Weiliang, et al. Development and performance evaluation of high pressure subsurface safety valve[J]. Heavy Machinery, 2018(6): 12–14. doi: 10.3969/j.issn.1001-196X.2018.06.003

[7] 张俊良,邵勇,贾长青,等. 高含硫气井井下安全阀失效的对策及现场实践[J]. 天然气技术与经济, 2018, 12(1): 32–34. doi: 10.3969/j.issn.2095-1132.2018.01.009 ZHANG Junliang, SHAO Yong, JIA Changqing, et al. Counter-measures against failure of subsurface safety valve used for a highsour gas well and their application[J]. Natural Gas Technology & Economy, 2018, 12(1): 32–34. doi: 10.3969/j.issn.2095-1132.2018.01.009

[8] 孙天礼,张广东,张文洪,等. 大牛地气田水合物堵塞预测与防治[J]. 中国科技成果, 2008(18): 42–45. doi: 10.3772/j.issn.1009-5659.2008.18.013 SUN Tianli, ZHANG Guangdong, ZHANG Wenhong, et al. Prediction and control of hydrate blockage in Daniudi Gas Field[J]. China Achievement of Science and Technology, 2008(18): 42–45. doi: 10.3772/j.issn.1009-5659.2008.18.013

[9] 孙志高,石磊,樊栓狮,等. 气体水合物相平衡测定方法研究[J]. 石油与天然气化工, 2001, 30(4): 164–166. doi: 10.3969/j.issn.1007-3426.2001.04.002 SUN Zhigao, SHI Lei, FAN Shuanshi, et al. Study of the measuring methods of gas hydrate phase equilibrium[J]. Chemical Engineering of Oil and Gas, 2001, 30(4): 164–166. doi: 10.3969/j.issn.1007-3426.2001.04.002

[10] 陈光进, 孙长宇, 马庆兰.气体水合物科学与技术[M].北京: 化学工业出版社, 2008: 9-11. CHEN Guangjin, SUN Changyu, MA Qinglan. Gas hydrate science and technology[M]. Beijing: Chemical Industry Press, 2008: 9-11.

[11] 邓柯,李颖川,李群生. 天然气水合物生成的影响因素及敏感性分析[J]. 钻井液与完井液, 2006, 23(6): 64–67. doi: 10.3969/j.issn.1001-5620.2006.06.021 DENG Ke, LI Yingchuan, LI Qunsheng. The generation of natural gas hydrates: contributing factors and sensitivity analysis[J]. Drilling Fluid & Completion Fluid, 2006, 23(6): 64–67. doi: 10.3969/j.issn.1001-5620.2006.06.021

[12] 许威,邱楠生,孙长宇,等. 不同因素对天然气水合物稳定带厚度的影响[J]. 天然气地球科学, 2010, 21(3): 528–534. XU Wei, QIU Nansheng, SUN Changyu, et al. Effects of different factors on the thickness of gas hydrate stability zone[J]. Natural Gas Geoscience, 2010, 21(3): 528–534.

[13] 张振楠,孙宝江,王志远,等. 深水气井测试天然气水合物生成区域预测及分析[J]. 水动力学研究与进展(A辑), 2015, 30(2): 167–172. ZHANG Zhennan, SUN Baojiang, WANG Zhiyuan, et al. Predic-tion and analysis of natural gas hydrate formation region during deep water gas well testing[J]. Chinese Journal of Hydrodynamics, 2015, 30(2): 167–172.

-

期刊类型引用(25)

1. 柳洁,沈德来,严锐锋,邓伟,屈文涛. 卡瓦下座用表面改性可溶性镁合金耐腐蚀性能研究. 石油钻探技术. 2024(03): 118-126 .  本站查看

本站查看

2. 张毅,任勇强,李瑞祺,郭云鹏,李宁,杨东. 油气井富含CO_2酸性环境下Ca~(2+)对可降解铝镁合金的影响. 天然气勘探与开发. 2022(03): 75-81 .  百度学术

百度学术

3. 赵金洲,任岚,蒋廷学,胡东风,吴雷泽,吴建发,尹丛彬,李勇明,胡永全,林然,李小刚,彭瑀,沈骋,陈曦宇,尹庆,贾长贵,宋毅,王海涛,李远照,吴建军,曾斌,杜林麟. 中国页岩气压裂十年:回顾与展望. 天然气工业. 2021(08): 121-142 .  百度学术

百度学术

4. 王明凯,文星星,段纪青,陈振宇,周爱军. PBS/HNBR共混可降解橡胶的制备与性能. 武汉工程大学学报. 2021(05): 529-533 .  百度学术

百度学术

5. 刘超群. 大庆油田不动管柱6~8层压裂工艺. 油气井测试. 2021(05): 44-49 .  百度学术

百度学术

6. 张毅,杨继现,张伟,聂伟,刘昌泰,周萌. 可降解压裂封隔器材料优选及设计. 西部探矿工程. 2020(04): 75-78 .  百度学术

百度学术

7. 王红丽. 不动管柱压裂工艺封隔器及配套工具优化. 油气井测试. 2020(02): 32-36 .  百度学术

百度学术

8. 廖勇. 一种桥塞坐封试验测试装置的研制. 江汉石油职工大学学报. 2019(01): 34-37 .  百度学术

百度学术

9. 张毅,李景卫,杨小涛,张伟,刘晓林,王荫刚. 新型可降解压裂封隔器胶筒. 油气井测试. 2019(02): 51-55 .  百度学术

百度学术

10. 王乐顶,王怀婧,陈新海,槐巧双,李晓勇. 井下圆球运动分析与新型试压体设计. 探矿工程(岩土钻掘工程). 2019(05): 44-47 .  百度学术

百度学术

11. 杨同玉,魏辽,李强,朱和明,吴晋霞. 全自溶分段压裂滑套的研制与应用. 特种油气藏. 2019(03): 153-157 .  百度学术

百度学术

12. 张锦宏. 中国石化石油工程技术现状及发展建议. 石油钻探技术. 2019(03): 9-17 .  本站查看

本站查看

13. 王鹏. 电缆输送式电动液压坐封桥塞技术. 油气井测试. 2019(05): 39-43 .  百度学术

百度学术

14. 纪志康,于思荣,刘丽,姜倩,刘迪. Al含量对漂珠/镁合金可溶复合材料组织与性能的影响. 复合材料学报. 2018(05): 1211-1218 .  百度学术

百度学术

15. 周歆,杨小城. 可降解压裂球试验研究及现场应用. 石油矿场机械. 2018(01): 62-66 .  百度学术

百度学术

16. 路保平,丁士东. 中国石化页岩气工程技术新进展与发展展望. 石油钻探技术. 2018(01): 1-9 .  本站查看

本站查看

17. 张毅,于丽敏,任勇强,杨东,张宇,冯丹. 一种新型可降解压裂封隔器坐封球. 油气井测试. 2018(02): 53-58 .  百度学术

百度学术

18. 周小林,高志华,张冲. 龙凤山气田大通径免钻桥塞分段压裂先导试验. 油气井测试. 2018(01): 62-67 .  百度学术

百度学术

19. 仇炜谏,李纯金,吉浩,周宏根. 一种新型电动式液压增力桥塞坐封工具的研制. 机械工程师. 2018(10): 13-15 .  百度学术

百度学术

20. 钟诗宇,关馨,王小红. 水平井分段压裂用桥塞研究现状及发展趋势. 新疆石油科技. 2018(03): 35-38 .  百度学术

百度学术

21. 王林,张世林,平恩顺,邹鹏,李楠,黄其,徐庆祥. 分段压裂用可降解桥塞研制及其性能评价. 科学技术与工程. 2017(24): 228-232 .  百度学术

百度学术

22. 张芬娜,张晧,綦耀光,朱洪迎,张健,张兵,郭晖. 基于煤系气双管柱分压合采技术的适用性分析. 煤炭学报. 2017(10): 2657-2661 .  百度学术

百度学术

23. 平恩顺,王林,邹鹏,张建华,李楠,黄其,徐庆祥,汪强,邓立泽. 分段压裂工具用可降解金属材料降解性能研究. 石油化工应用. 2017(02): 133-136 .  百度学术

百度学术

24. 何汉平. 一种新的油气井射孔丢枪管柱设计. 石油矿场机械. 2017(04): 52-56 .  百度学术

百度学术

25. 李鹏飞,刘旭辉,王杰. 免钻型大通径桥塞研制与应用现状. 石油矿场机械. 2016(11): 93-97 .  百度学术

百度学术

其他类型引用(17)

下载:

下载: