The Ascending Law of Gas Bubbles in a Wellbore Considering the Phase Change of Natural Gas Hydrates during Deepwater Well Shut-in

-

摘要:

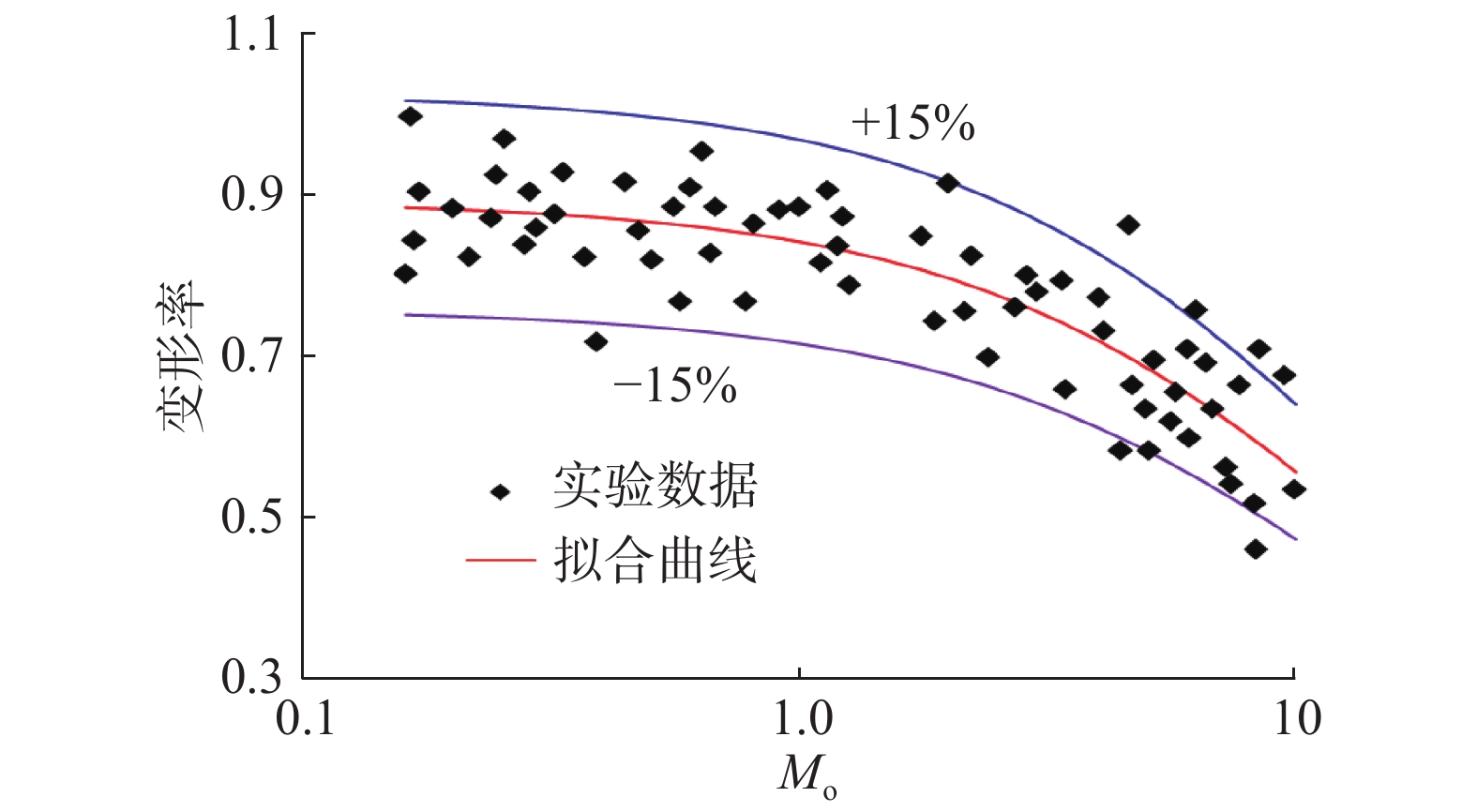

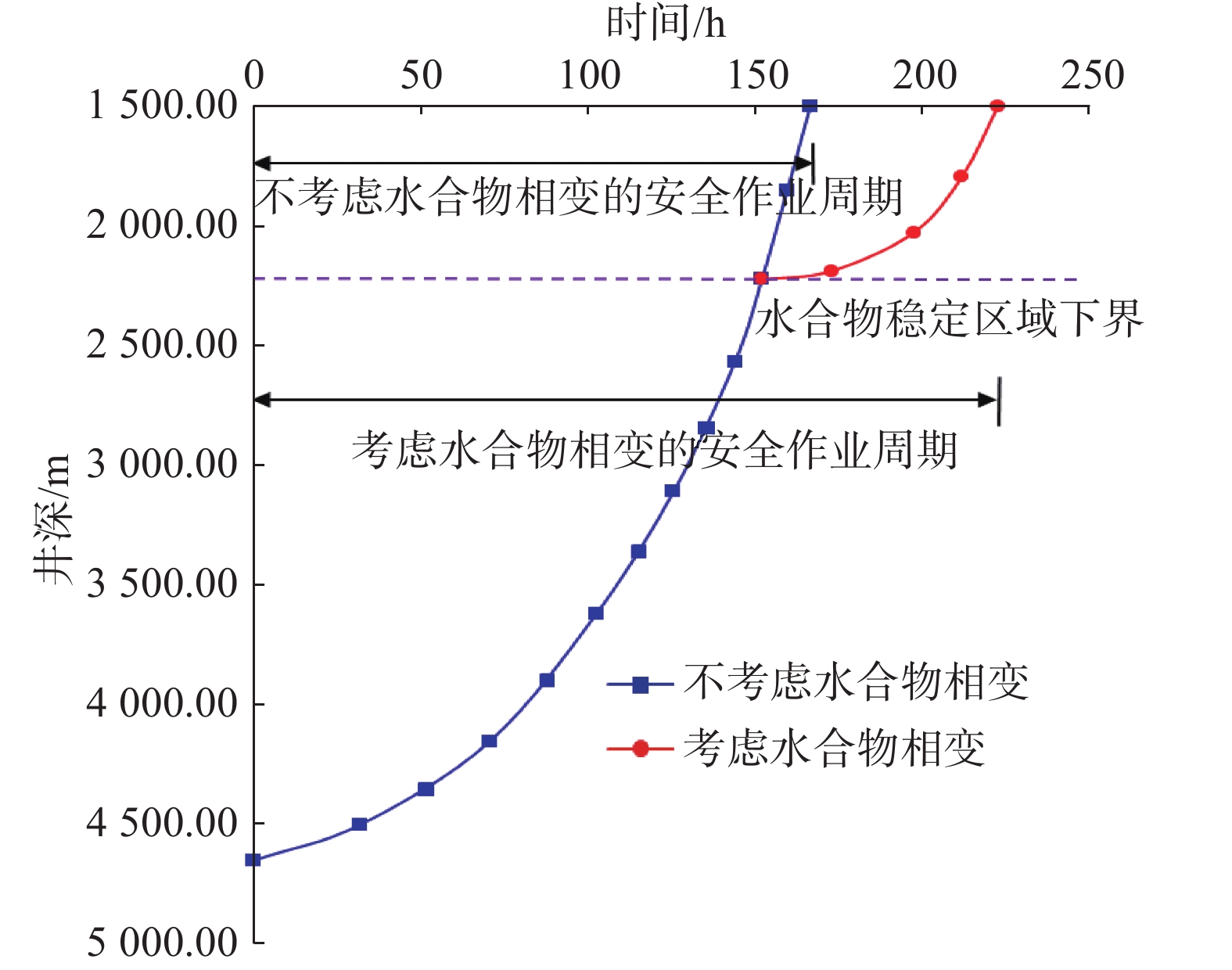

深水油气井关井期间天然气水合物的生成会导致气泡迁移滞后,影响钻井安全作业周期,为此利用室内垂直圆筒模拟深水井筒环境,实验研究了甲烷气泡表面水合物膜生长特性,提出了考虑自然对流传热的水合物横向生长模型及水合物膜厚度预测方法;分析了水合物气泡变形率与莫顿数、拖曳力系数及雷诺数之间的相关性,据此建立了关井条件下井筒中含水合物相变的气泡上升速度综合预测模型,并对南海某井的安全作业周期进行了预测和分析。通过实验和模拟分析发现,建立的自然对流传热模型对水合物膜横向生长速率和厚度具有较高的预测精度;水合物气泡的变形率随莫顿数增大而减小,拖曳力系数随雷诺数增大先减小然后逐渐增大,并拟合得到了气泡变形率、拖曳力系数计算公式。研究表明,气泡表面水合物的生成显著降低了气泡的上升速度,延长了安全作业周期,但气体到达海底井口后水合物堵塞风险增加,现场应根据关井时间采取针对性的井控措施。

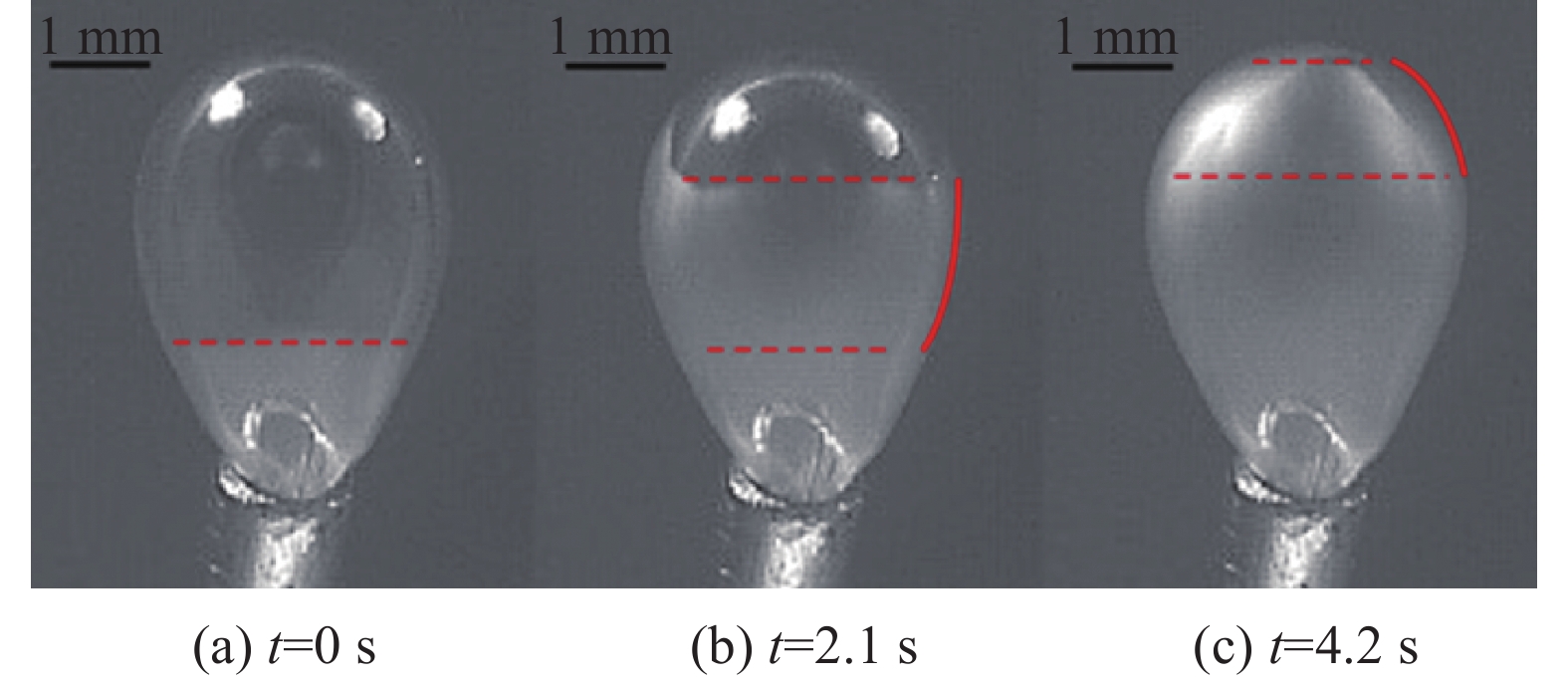

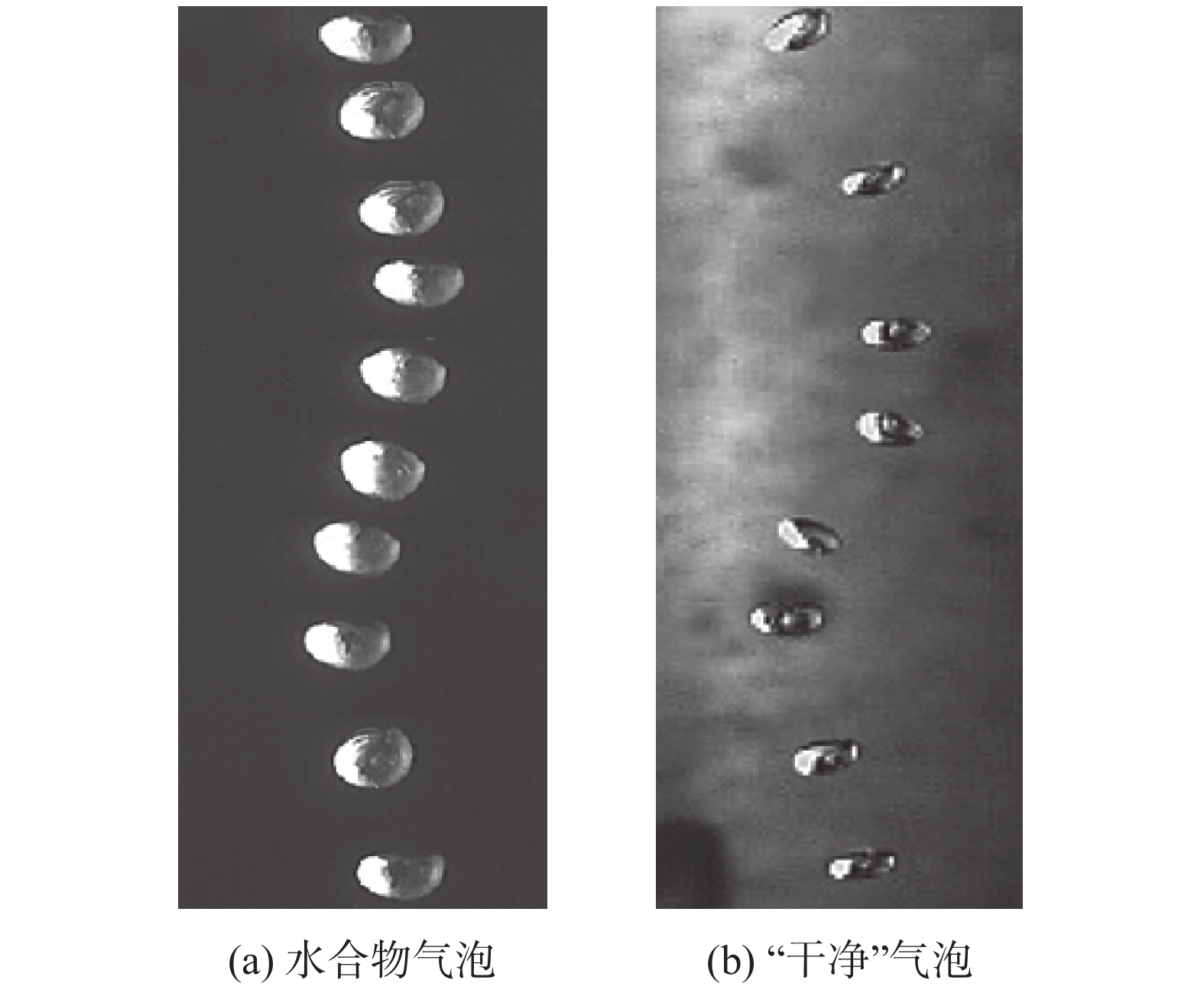

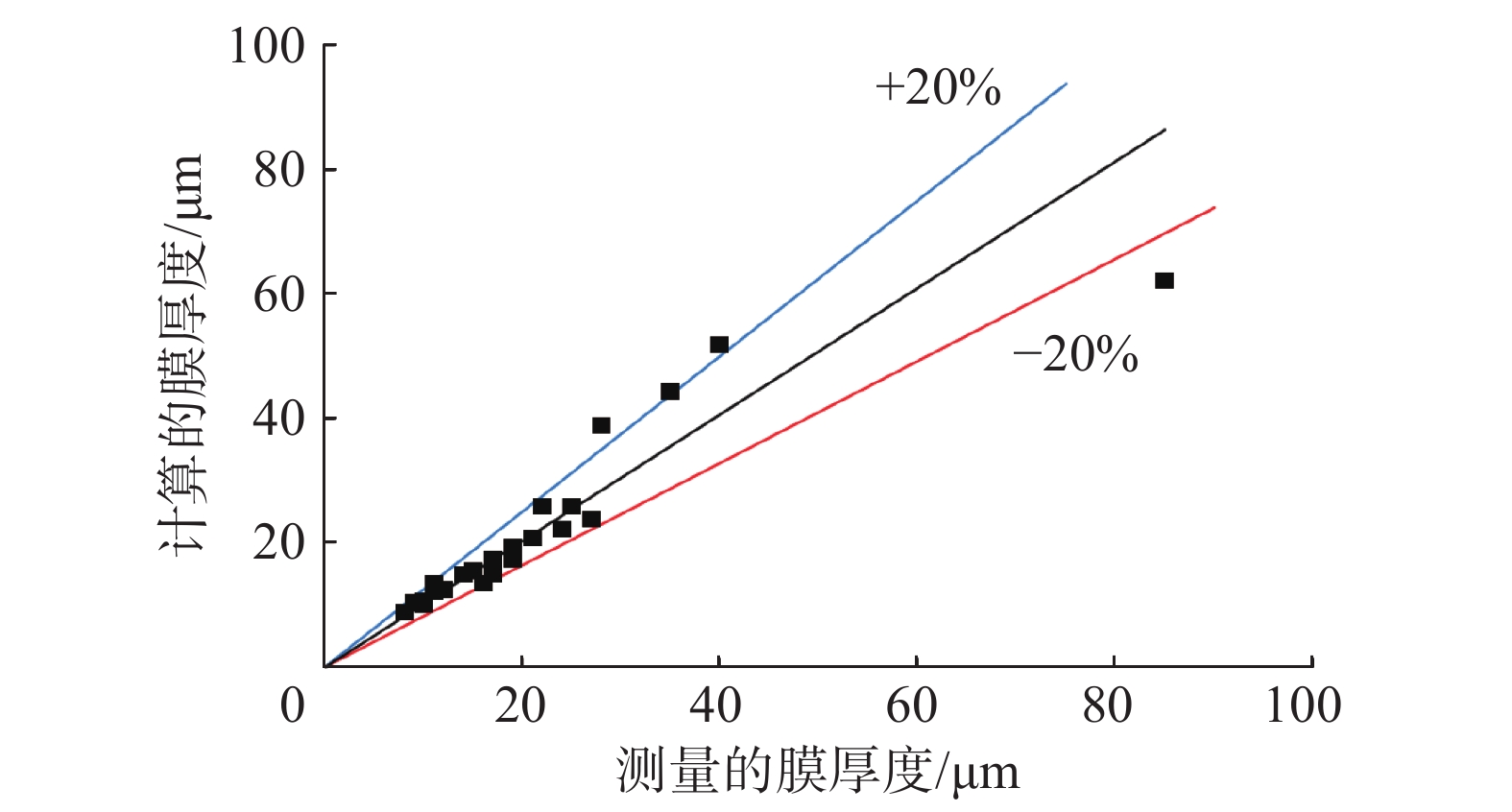

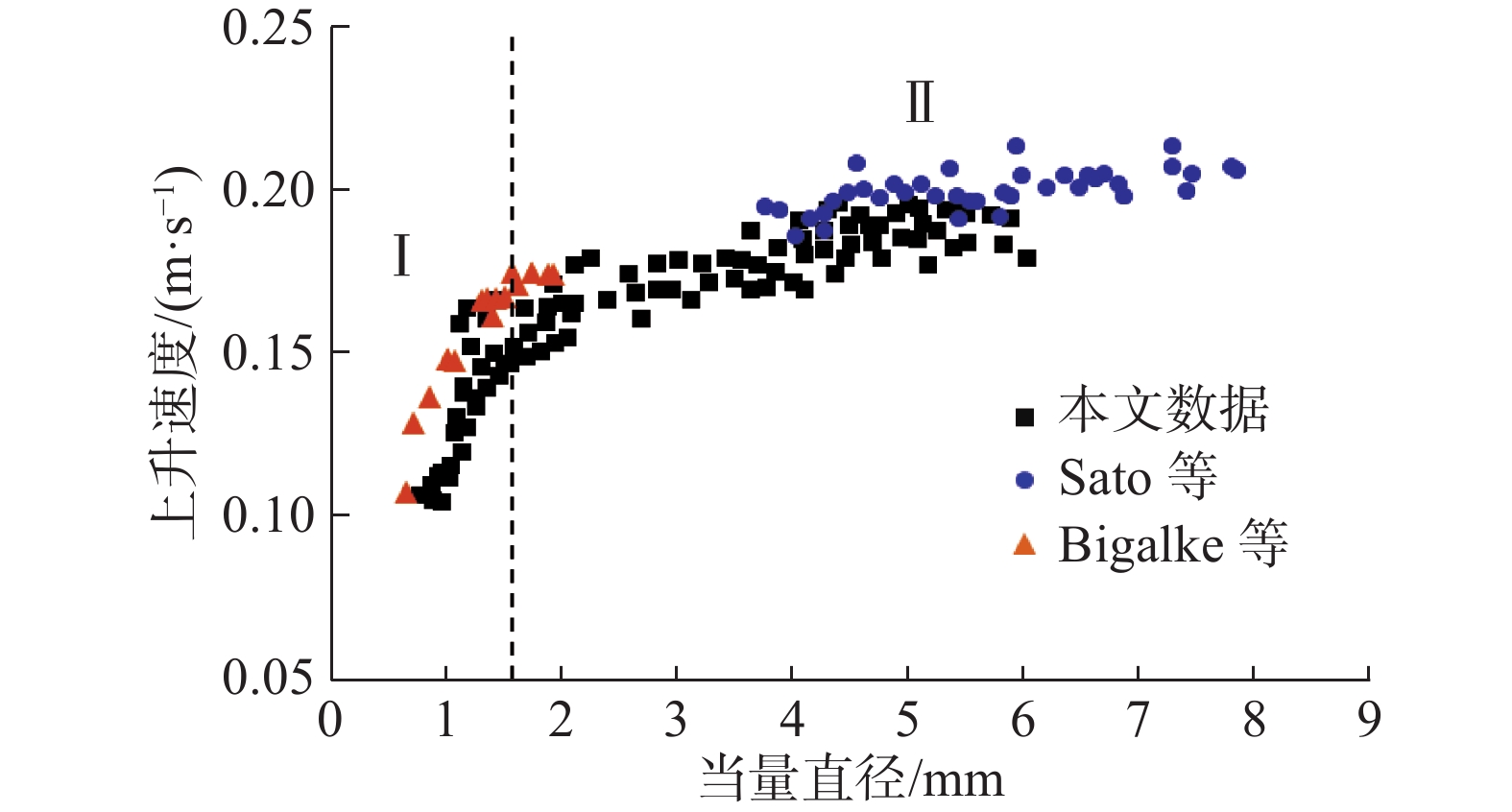

Abstract:During the shut-in of deepwater wells, the formation of natural gas hydrate will significantly delay the migration of bubbles and affect the safe operation cycle of drilling. The bubble ascending dynamics considering the phase change of hydrate was studied. In the study, an indoor vertical cylinder was used to simulate the deepwater wellbore and to investigate the growth characteristics of hydrate film on the surface of methane bubbles.. A model was proposed which incorporated the hydrate lateral growth model and the hydrate film thickness prediction method considering natural convection heat transfer. The correlations between hydrate bubble deformation rate and Morton number, drag coefficient and Reynolds number were explored. A comprehensive prediction model of bubble ascending velocity in wellbore considering hydrate phase change under shut-in conditions was established based on the study, and the safe operation cycle of a well in the South China Sea was predicted and analyzed. The experimental and simulation results show that the newly established natural convection heat transfer model has higher prediction accuracy for the lateral growth rate and thickness of the hydrate film and that the deformation rate of hydrate bubble decreases with the Morton number. The drag coefficient decreases first and then increases gradually with the Reynolds number and the corresponding calculation formula was obtained through fitting. Studies suggest that the formation of hydrate on the surface of the bubbles can significantly reduce the ascending velocity of bubbles and prolong the safe operation cycle. However, the risk of hydrate blockage will increase as gas reaches the subsea wellhead, and pertinent well control measures should be taken according to the shut-in time.

-

Keywords:

- deepwater well /

- gas hydrate /

- phase transition /

- gas bubble /

- rising velocity /

- safe operation cycle /

- drag coefficient

-

塔河油田碳酸盐岩缝洞型油藏与普通砂岩油藏不同,储集空间类型多样、形态差异较大,非均质性极强[1]。该油田开发初期主要依靠天然能量开采,随着开发不断进行,天然能量出现不足,采出能力开始下降,注水开发是初期解决该问题的最有效方法,但进入注水开发后期,储层经过长时间注水后,油水界面升高,驱油效果逐渐变差[2-6]。为此,进行了碳酸盐岩缝洞型油藏气水复合驱技术研究。该技术是在长时间注水后,改为注入氮气,注入的氮气会聚集在储集体高部位的阁楼体内[5-8],将阁楼体内的剩余油油置换出来,但是由于缺乏横向驱动力,剩余油可能会大量富集在注采井网的井间;于是,在当前注气井网条件下,需再次注水增加横向水驱动力,提高井间剩余油的动用程度,从而改善碳酸盐岩缝洞型油藏的开发效果。该技术在塔河油田 4 区 7 个注采井组进行了现场应用,并获得良好的增产效果。

1. 碳酸盐岩缝洞型油藏特征

塔河油田奥陶系碳酸盐岩缝洞型油藏发育于新疆塔里木盆地沙雅隆起阿克库勒凸起的西南部,油藏埋深5 400.00~7 600.00 m,储集空间主要为溶蚀孔洞、大型洞穴和溶蚀裂缝,储集体主要为裂缝–溶洞型和裂缝–孔洞型,部分区域奥陶系一间房组地层发育微裂缝[9]。其中洞穴和孔洞的储集性能最好,裂缝既是储集空间,又是流体流动的主要通道,流体流动以管流为主[10-11]。各类岩溶体储层空间展布具有极强的非均质性,油气水运移规律复杂。

2. 气水复合驱油开发模式研究

2.1 气水复合驱油机理

在利用多属性地震资料描述储集体形态特征的基础上,通过刻蚀玻璃的方法建立了一套20 mm×30 mm的缝洞储集体物理模拟模型,该模型设计为裂缝–溶洞型储集体,孔隙度为18%。利用该模型进行气水复合驱油物理模拟试验,先注入试验用油,待模型空腔充满试验用油,再注水进行水驱,待出口已经完全出水后再注入氮气,注入一定量氮气后再次注水。试验过程中观察不同阶段模型内流体的运移情况,结果见图1。从图1可以看出,该模型在充满试验用油经水驱后,顶部的7、8号储集体内仍存在大量剩余油(见图1(a));对其进行气驱,7、8号储集体内的剩余油被驱替到水驱通道上(见图1(b)),再次进行水驱,注入水将水驱通道上的剩余油从出口端驱替出(见图1(c))。由此可知缝洞型油藏气水复合驱油机理:氮气作为纵向驱动力,向下驱替缝洞体顶部剩余油,将剩余油驱替至水驱通道上,注入水作为横向驱动力,形成二次水驱。

2.2 气水复合驱开发方式

在认识气水复合驱油机理的基础上,利用地震资料刻画井洞关系,根据生产动态识别注采井之间的连通通道,明确剩余油分布,针对不同剩余油分布特征构建了4种井组模式(见图2):对于水驱通道在含油高度内的“阁楼油”,构建了注入井先注气、后注水的常规协同模式,为单方向一注一采的模式;对于水驱失效的多井区域的“阁楼油”,构建了注入井注气、周边邻井注水的栅状协同模式;对于出现气窜的井组,构建了换向协同模式;对于失效或未见效并且水驱通道在含油高度外的“阁楼油”,构建了注入井注气后先调流封堵水通道、再注水的调剖协同模式。

2.3 气水复合驱井网设计

主要依托岩溶背景及储层展布特征,根据基础井组模式有针对性地构建气水复合立体井网,如图3所示。对于风化壳岩溶,其展布面积广,多向连通条件好,构建面状注采井网;对于断溶体、古河道储层展布方向性强,连通特征表现为带状连通或线性连通,分别建立带状井网和线状井网[5]。

纵向上,根据井间通道路径长短、构造高低、规模大小等因素配置井网。对于有利驱替路径为陡构造、短路径、规模较小的山梁、断溶体或暗河等,如果采用低注高采井网很容易发生气窜,而采用高注低采井网则可以发挥作用集中、见效快和控制气窜的优势;有利驱替路径为缓构造、长路径,阁楼储集体靠近注入井,可以采用低注高采井网以提高驱替效率。

总体而言,需要根据通道的规模确定采用高注低采井网还是低注高采井网:短路径、小通道采用高注低采井网,以气驱为主,水驱为辅,以预防水窜;长路径、大通道采用低注高采井网,以水驱为主,气驱为辅,以提高气驱效率。实践中,2种纵向井网模式对不同规模的通道均有其优势。

2.4 气水复合驱参数设计

根据历史注水水驱效果确定水驱可动用空间,对比累计注气体积与水驱可动用空间判断通道内剩余油的再次充满程度,根据充满程度确定水驱历史等效阶段,用等效阶段的历史注水强度指导气水复合驱参数设计。

气水复合驱的作用过程分为2部分:1)垂向上,注入气将“阁楼油”驱至水驱可动用空间;2)横向上,注入水进入水驱可动用空间将油驱至受效井。注入气不断垂向驱油,关键是如何形成有效的横向水驱。根据历史注水水驱效果确定水驱可动用空间,通过对比累计注气体积与水驱可动用空间判断通道内剩余油的再次充满程度,根据剩余油充满程度确定水驱历史等效阶段,再根据等效阶段历史注水强度设计气水复合驱参数。理想驱替模型中,注采比应为1∶1,注入水前缘突破前的注水量等于增油量,注水过程中纵向上大量分水,少部分水形成了有效横向驱替。水驱结束时生产井总增油量即为有效横向水量,即水驱可驱扫空间总量。具体计算步骤(见图4)如下:

1)确定水驱可动用空间体积。对于具有完整的水驱见效至失效阶段的注采井组,认为井间水驱可动用空间体积即水驱采油量的地下体积。

2)确定水驱可动用空间的充满程度。首先根据累计注入气量的地下体积与气驱采油量的地下体积的差,求出水驱通道中剩余油的体积;然后计算水驱可动空间的充满程度,即水驱通道剩余油体积与水驱可动用空间体积之比。

3)对应注水水驱等效阶段。利用等效原理,把任意气驱阶段对应的充满程度在水驱阶段找到对应相等充满程度的时间节点。

4)类比当时注水强度。通道充满程度相同时,注水受效日注水量为Qt。

5)确定目前的注水强度。设计目前的注水量QM≥Qt,即气水复合阶段要提供足够的横向驱动力驱动注入气顶替至水驱可动用空间内的剩余油,此时不需要考虑注水强度过大再次发生水窜的风险,因为单元注气阶段不同于注水水驱阶段,“阁楼油”可反复进入水驱通道。

3. 现场应用

气水复合驱技术在塔河油田4区7个注采井组进行了现场应用,均获得良好的增产效果,井组产油量平均提高86.0 t,累计增产油量1.3×104 t,且增油效果不断改善。下面以TK428CH–TK408井组为例,介绍气水复合驱技术的应用情况。

3.1 TK428CH–TK408井组概况

TK428CH井是注水兼注气井,TK408井是采油井,井组平面特征是沿山梁发育的风化壳岩溶,纵向特征为平缓山梁,注气路径长,“阁楼油”靠近注入井,采用低注高采井网(如图5所示)。

3.2 注入参数设计

1)确定水驱可动用空间。水驱可动用空间等于前期受效增油量,该井组经历了完整的水驱阶段,水驱通道内的原油被驱替得较为彻底,因此该井组水驱增油量的地下体积等于水驱可动用空间的体积,通过计算该井组水驱可动用空间体积为5.47×104 m3。

2)判断水驱通道剩余油富集程度。该井累计注气5.70×104 m3,累计增油3.81×104 m3,通道内剩余油1.89×104 m3,水驱可动用空间充满程度为34.0%。

3)类比相同充满程度的水驱强度。当水驱阶段通道内剩余油充满程度为34.0%时,水驱处于效果变差阶段,此阶段注水量为300 m3/d,因此目前该井组合理注水量至少需要达到300 m3/d,连续注水。

4)现场注采调整及效果。调整前TK428CH井累计注气2.8×104 m3见效,后期效果出现变差趋势,计算水驱通道剩余油充满程度34.0%,水驱通道内仍富集大量剩余油,需要加强水驱动用水驱通道内的剩余油,于是TK428CH井恢复注水,并且将注水量提高至300 m3/d,TK408井生产效果改善,日增油量稳定在30 t。

4. 结论与建议

1)针对水驱和气驱无法有效动用塔河油田缝洞型碳酸盐岩油藏高部位剩余油的问题,根据其储层特征及剩余油分布特征,研究形成了气驱替油、水驱提供横向驱动力的气水复合驱技术。

2)现场应用表明,气水复合驱技术可以实现塔河油田缝洞型碳酸盐岩油藏高部位剩余油的有效动用,改善开发效果。

3)目前气水复合驱参数的设计是基于历史水驱效果进行的,还处于半定量阶段,建议进一步研究,通过地质建模和数值模拟实现定量计算。

-

-

[1] 谢仁军, 刘书杰, 文敏, 等. 深水钻井溢流井控期间水合物生成主控因素[J]. 石油钻采工艺, 2015, 37(1): 64–67. XIE Renjun, LIU Shujie, WEN Min, et al. Main control factor of hydrate generation during overflow well control period of deepwater drilling[J]. Oil Drilling & Production Technology, 2015, 37(1): 64–67.

[2] 王金波, 王志远, 张伟国, 等. 南海深水海域避台风期间井控安全作业周期研究[J]. 石油钻探技术, 2013, 41(3): 51–55. doi: 10.3969/j.issn.1001-0890.2013.03.010 WANG Jinbo, WANG Zhiyuan, ZHANG Weiguo, et al. Well control safety operation cycle during typhoon at deep waters of South China Sea[J]. Petroleum Drilling Techniques, 2013, 41(3): 51–55. doi: 10.3969/j.issn.1001-0890.2013.03.010

[3] 叶鹏, 刘道平, 张健. 悬浮气泡表面天然气水合物形成的特性研究[J]. 石油与天然气化工, 2013, 42(5): 468–472. doi: 10.3969/j.issn.1007-3426.2013.05.006 YE Peng, LIU Daoping, ZHANG Jian. Characteristics researches of natural gas hydrate growth on the suspended bubble surface[J]. Chemical Engineering of Oil & Gas, 2013, 42(5): 468–472. doi: 10.3969/j.issn.1007-3426.2013.05.006

[4] 张健, 刘道平, 苏星, 等. 水滴和气泡表面气体水合物的生长特性对比[J]. 石油与天然气化工, 2013, 42(1): 37–41. doi: 10.3969/j.issn.1007-3426.2013.01.008 ZHANG Jian, LIU Daoping, SU Xing, et al. Comparative analysis of growth characteristics of hydrate formation on the surface of suspended water droplet and bubble[J]. Chemical Engineering of Oil & Gas, 2013, 42(1): 37–41. doi: 10.3969/j.issn.1007-3426.2013.01.008

[5] 蔡婷. 天然气水合物在管道中沉积与崩塌的预测模型研究[J]. 钻采工艺, 2018, 41(6): 46–49. doi: 10.3969/J.ISSN.1006-768X.2018.06.14 CAI Ting. Model for predicting deposition and collapse of natural gas hydrate in pipeline[J]. Drilling & Production Technology, 2018, 41(6): 46–49. doi: 10.3969/J.ISSN.1006-768X.2018.06.14

[6] LIU Zheng, LI Hao, CHEN Litao, et al. A new model of and insight into hydrate film lateral growth along the gas-liquid interface considering natural convection heat transfer[J]. Energy & Fuels, 2018, 32(2): 2053–2063.

[7] BATCHELOR G K. An introduction to fluid dynamics[M]. Cambridge: Cambridge University Press, 2000: 211-219.

[8] DAVIES R M, TAYLOR G I. The mechanics of large bubbles rising through extended liquids and through liquids in tubes[J]. Proceedings of the Royal Society A, 1950, 200(1062): 375–390.

[9] WALLIS G B. The terminal speed of single drops or bubbles in an infinite medium[J]. International Journal of Multiphase Flow, 1974, 1(4): 491–511. doi: 10.1016/0301-9322(74)90003-2

[10] 闫红杰, 赵国建, 刘柳, 等. 静止水中单气泡形状及上升规律的实验研究[J]. 中南大学学报(自然科学版), 2016, 47(7): 2513–2520. YAN Hongjie, ZHAO Guojian, LIU Liu, et al. Experimental study on shape and rising behavior of single bubble in stagnant water[J]. Journal of Central South University (Science and Technology), 2016, 47(7): 2513–2520.

[11] BIGALKE N K, ENSTAD L I, REHDER G, et al. Terminal velocities of pure and hydrate coated CO2 droplets and CH4 bubbles rising in a simulated oceanic environment[J]. Deep Sea Research Part Ⅰ: Oceanographic Research Papers, 2010, 57(9): 1102–1110. doi: 10.1016/j.dsr.2010.05.008

[12] SATO Y, KIYONO F, OGASAWARA K, et al. An experimental study on the dynamics of a rising methane bubble covered with hydrates[J]. Journal of the Mining and Materials Processing Institute of Japan, 2013, 129(4): 124–131. doi: 10.2473/journalofmmij.129.124

[13] FISHENDEN M W, SAUNDERS O A. An introduction to heat transfer[M]. Oxford : Clarendon Press, 1950: 136-138.

[14] LEWANDOWSKI W M, RADZIEMSKA E, BUZUK M, et al. Free convection heat transfer and fluid flow above horizontal rectangular plates[J]. Applied Energy, 2000, 66(2): 177–197. doi: 10.1016/S0306-2619(99)00024-0

[15] SAVILLE D A, CHURCHILL S W. Laminar free convection in boundary layers near horizontal cylinders and vertical axisymmetric bodies[J]. Journal of Fluid Mechanics, 1967, 29(2): 391–399. doi: 10.1017/S0022112067000904

[16] PENG B Z, DANDEKAR A, SUN Changyu, et al. Hydrate film growth on the surface of a gas bubble suspended in water[J]. The Journal of Physical Chemistry B, 2007, 111(43): 12485–12493.

[17] WILKINSON P M, HARINGA H, VAN DIERENDONCK L L. Mass transfer and bubble size in a bubble column under pressure[J]. Chemical Engineering Science, 1994, 49(9): 1417–1427. doi: 10.1016/0009-2509(93)E0022-5

[18] UCHIDA T, EBINUMA T, KAWABATA J, et al. Microscopic observations of formation processes of clathrate-hydrate films at an interface between water and carbon dioxide[J]. Journal of Crystal Growth, 1999, 204(3): 348–356. doi: 10.1016/S0022-0248(99)00178-5

[19] MORI Y H. Estimating the thickness of hydrate films from their lateral growth rates: application of a simplified heat transfer model[J]. Journal of Crystal Growth, 2001, 223(1/2): 206–212.

[20] FREER E M, SELIM M S, SLOAN E D Jr. Methane hydrate film growth kinetics[J]. Fluid Phase Equilibria, 2001, 185(1/2): 65–75.

[21] MOCHIZUKI T, MORI Y H. Clathrate-hydrate film growth along water/hydrate-former phase boundaries-numerical heat-transfer study[J]. Journal of Crystal Growth, 2006, 290(2): 642–652.

[22] LI Shengli, SUN Changyu, LIU Bei, et al. Initial thickness measurements and insights into crystal growth of methane hydrate film[J]. AIChE Journal, 2013, 59(6): 2145–2154. doi: 10.1002/aic.13987

下载:

下载: