An Experimental Study on the Heterometallic Corrosion Mechanism of 30CrMo Steel/625 Alloy for Underwater X-Trees

-

摘要:

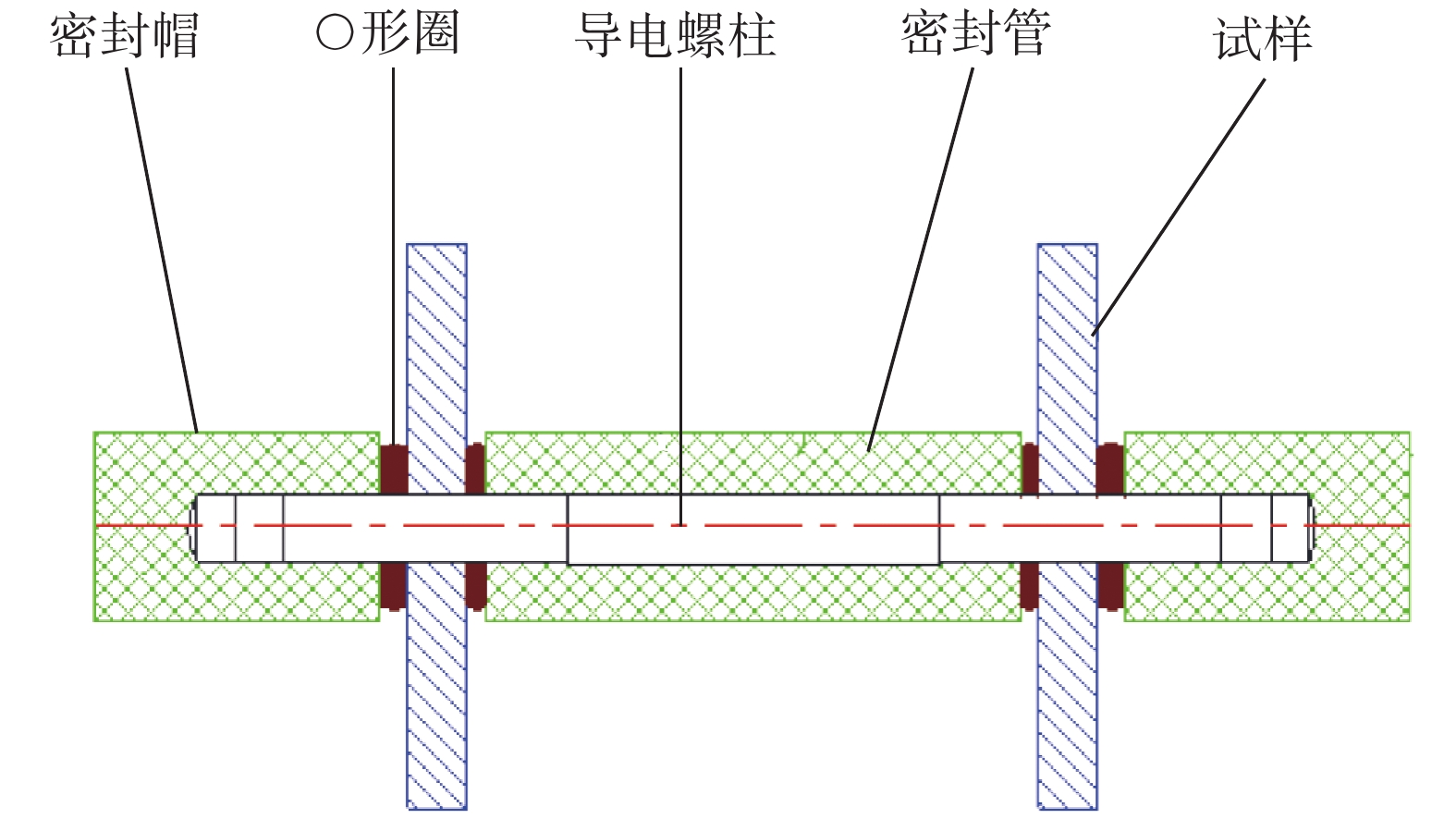

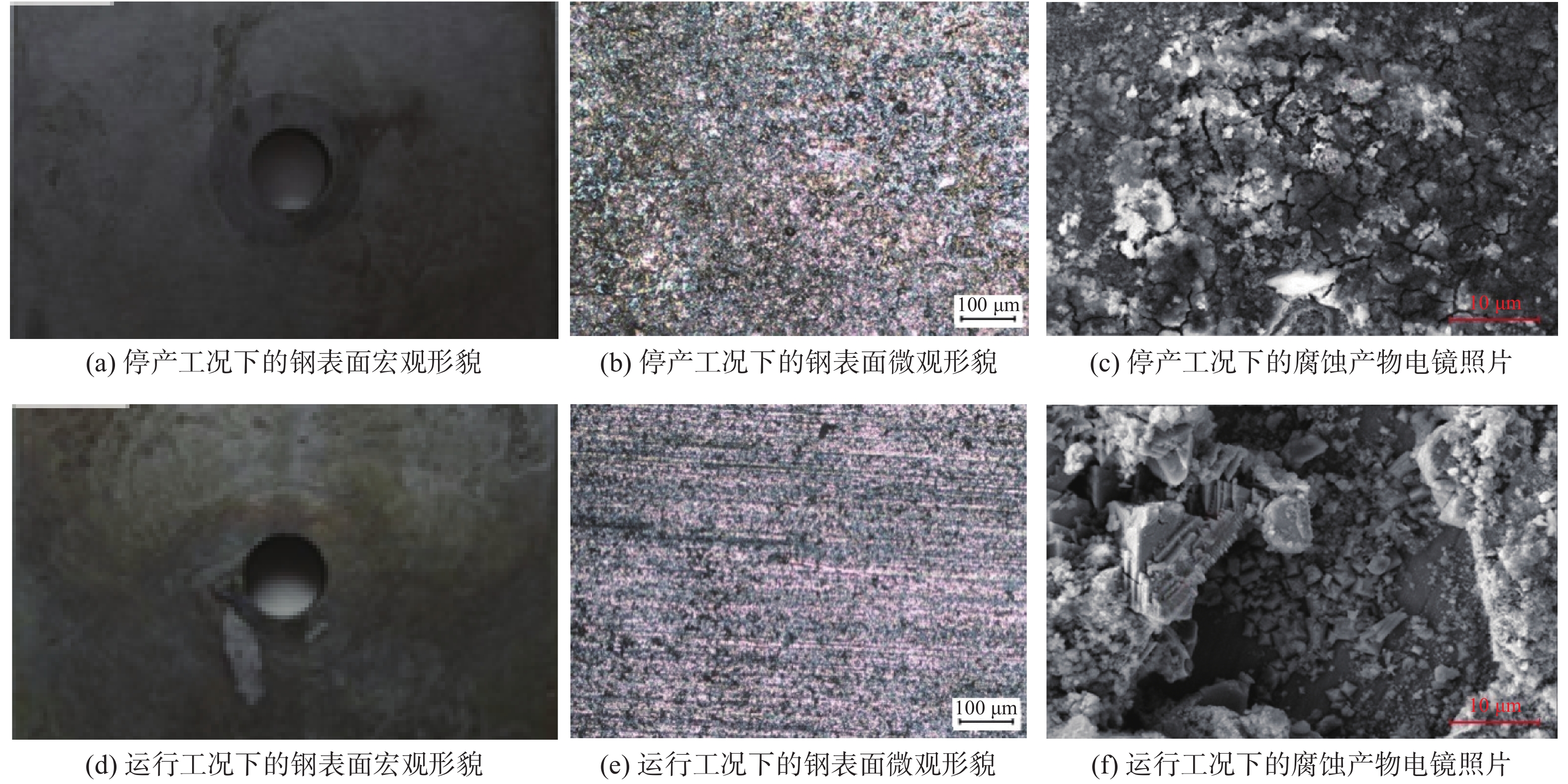

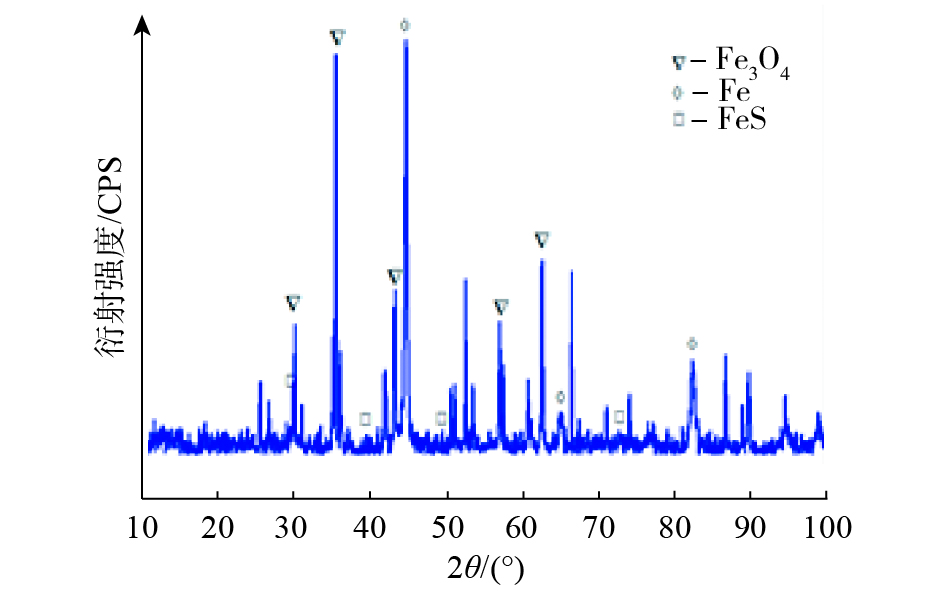

针对水下采油树在海水和内部流体长期作用下极易发生腐蚀的问题,借助高温高压反应釜,对流花11–1油田水下采油树的30CrMo钢/625合金的电偶腐蚀和堆焊金属腐蚀分别进行了腐蚀浸泡模拟试验,采用扫描电子显微镜和能谱分析仪分析了腐蚀产物膜的微观形貌和化学成分,并分析了30CrMo钢和625合金的异金属腐蚀机理。研究发现,水下采油树的30CrMo钢与625合金接触时,30CrMo钢易发生较严重的均匀腐蚀,且接触位置及堆焊焊缝处30CrMo钢存在较严重的沟槽腐蚀。水下采油树不同金属接触腐蚀的原因包括电偶腐蚀和缝隙腐蚀,堆焊修复后热影响区金相组织的不均匀性也会加剧缝隙腐蚀。研究结果表明,水下采油树应尽量避免不同金属接触形成异金属电偶腐蚀体系,修复已发生局部腐蚀失效的水下采油树时应合理选择堆焊材料并进行全覆盖堆焊,避免异金属腐蚀风险。

Abstract:Underwater X-trees are prone to ongoing corrosion under the action of seawater and internal fluids. To address the problem, simulation experiments for the galvanic corrosion and surfacing metal corrosion of 30CrMo steel/625 alloy for the underwater X (Christmas) tree of the Liuhua 11–1 Oilfield were conducted by means of high temperature high pressure reaction kettle; the micromorphology and chemical composition of corrosion product film were analyzed by scanning electron microscope and energy spectrum analyzer, respectively, and analyzed the heterometallic corrosion mechanism of 30CrMo steel/625 alloy. The studies suggested that 30CrMo steel side of the heterometallic contact surface of the underwater X-tree was more likely to suffer a more severe uniform corrosion, and the 30CrMo steel at the contact position and the surfacing weld had more serious groove corrosion. The causes of heterometallic corrosion in the X-tree include galvanic corrosion and crevice corrosion. After surfacing repair, the unevenness of the metallographic structure in the heat-affected zone also exacerbates the crevice corrosion. The research results showed that the underwater X-tree should try to avoid the heterometallic corrosion caused by the contact of different metals. Best practices now suggest that when repairing a underwater X-tree with local corrosion failure, the surfacing material should be properly selected and adopted fully covered surfacing to avoid the risk of heterometallic corrosion.

-

-

表 1 实际腐蚀环境与腐蚀试验模拟环境参数

Table 1 Environment parameters of actual corrosion and experimentally simulated corrosion

参数 实际范围 试验参数确定 H2S分压/MPa 0.106~0.124 随着H2S含量增加,钢腐蚀速率增加,呈现明显的局部腐蚀特征,故确定H2S分压为0.124 MPa CO2分压/MPa 0.190~0.240 在较低温度下(60 ℃以下),随着CO2分压增大,腐蚀速率增加,故确定CO2分压为0.240 MPa 总压/MPa 0.380 温度/℃ 65(油层)

50(井口)运行工况温度选用井口温度50 ℃;流花11–1油田水下300 m处水温约为12 ℃,确定停产工况温度为12 ℃ 流速/(m∙s–1) 1.7 偶接试样:运行工况及停产工况均为静止状态

堆焊试样:运行工况流速为1.7 m/s,停产工况流速为0 m/s氯离子含量/(mg∙L–1) 18 969 配制的试验溶液与之基本一致 -

[1] 王宇, 张俊斌, 陈斌, 等. 水下采油树应用技术发展现状[J]. 石油机械, 2016, 44(12): 59–64. WANG Yu, ZHANG Junbin, CHEN Bin, et al. Development status of subsea christmas tree[J]. China Petroleum Machinery, 2016, 44(12): 59–64.

[2] 袁晓兵, 欧宇钧, 卢沛伟, 等. 流花11–1油田水下采油树地面测试单元研制[J]. 石油矿场机械, 2015, 44(7): 64–69. doi: 10.3969/j.issn.1001-3482.2015.07.016 YUAN Xiaobing, OU Yujun, LU Peiwei, et al. Research of ground testing unit based on Liuhua 11-1 Oilfield subsea tree[J]. Oil Field Equipment, 2015, 44(7): 64–69. doi: 10.3969/j.issn.1001-3482.2015.07.016

[3] 于成龙, 李慧敏. 水下采油树在深海油气田开发中的应用[J]. 天然气与石油, 2014, 32(2): 53–56. doi: 10.3969/j.issn.1006-5539.2014.02.015 YU Chenglong, LI Huimin. Application of undersea Christmas tree in domestic deep sea oil and gas field development[J]. Natural Gas and Oil, 2014, 32(2): 53–56. doi: 10.3969/j.issn.1006-5539.2014.02.015

[4] 卢沛伟, 袁晓兵, 欧宇钧, 等. 水下采油树发展现状研究[J]. 石油矿场机械, 2015, 44(6): 6–13. LU Peiwei, YUAN Xiaobing, OU Yujun, et al. Research of development status of subsea tree[J]. Oil Field Equipment, 2015, 44(6): 6–13.

[5] 林秀娟, 肖文生. 基于灰色系统的深水采油树腐蚀可靠性设计[J]. 机床与液压, 2012, 40(5): 157–159. doi: 10.3969/j.issn.1001-3881.2012.05.049 LIN Xiujuan, XIAO Wensheng. Corrosion reliability design of subsea tree based on grey system theory[J]. Machine Tool & Hydraulics, 2012, 40(5): 157–159. doi: 10.3969/j.issn.1001-3881.2012.05.049

[6] 王旭东, 裴海涛, 王培勇, 等. 水下油气生产系统防腐蚀设计的探讨[J]. 腐蚀与防护, 2012, 33(5): 430–432, 455. WANG Xudong, PEI Haitao, WANG Peiyong, et al. Corrosion control design of subsea production system[J]. Corrosion & Protection, 2012, 33(5): 430–432, 455.

[7] 刘健, 朱元坤, 秦浩智, 等. 基于贝叶斯网络水下采油树系统泄露风险分析[J]. 润滑与密封, 2018, 43(1): 109–114,129. doi: 10.3969/j.issn.0254-0150.2018.01.021 LIU Jian, ZHU Yuankun, QIN Haozhi, et al. Risk analysis of subsea X-tree system leakage based on Bayesian networks[J]. Lubrication Engineering, 2018, 43(1): 109–114,129. doi: 10.3969/j.issn.0254-0150.2018.01.021

[8] 程姗姗,王金刚,王治国. 油气田金属设备硫化氢腐蚀行为研究[J]. 石油钻探技术, 2011, 39(1): 32–35. CHENG Shanshan, WANG Jingang, WANG Zhiguo. Hydrogen sulfide corrosion of metal equipment in oil and gas field[J]. Petroleum Drilling Techniques, 2011, 39(1): 32–35.

-

期刊类型引用(7)

1. 白财远,王虎,杨行蔚. 安全生产责任落实背景下石油钻探设备安全故障检测研究. 现代职业安全. 2024(02): 66-70 .  百度学术

百度学术

2. 方昕,沈澜,李飞,吕方兴. 基于压缩感知的井下振动高频测量方法研究. 电子测量技术. 2024(06): 20-27 .  百度学术

百度学术

3. 高德利,鲜保安,毕延森. 水平井尾管完井与钻井一体化设计控制技术. 石油勘探与开发. 2024(04): 878-888 .  百度学术

百度学术

4. GAO Deli,XIAN Baoan,BI Yansen. Integrated design and control technology of liner completion and drilling for horizontal wells. Petroleum Exploration and Development. 2024(04): 1009-1021 .  必应学术

必应学术

5. 肖新磊,席境阳,杜旭,王迎春. 胜利油田页岩油大井眼高效钻进技术研究与应用. 钻探工程. 2023(06): 122-128 .  百度学术

百度学术

6. 贾建伟. 钻具标准在生产检修中的作用. 现代制造技术与装备. 2022(03): 144-146 .  百度学术

百度学术

7. 蒲文学,范光第,朱建建,赵国山. 磁性随钻测斜仪所需无磁钻具长度及影响因素研究. 石油钻探技术. 2022(04): 129-134 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: