Real-Time Intelligent Identification Method under Drilling Conditions Based on Support Vector Machine

-

摘要:

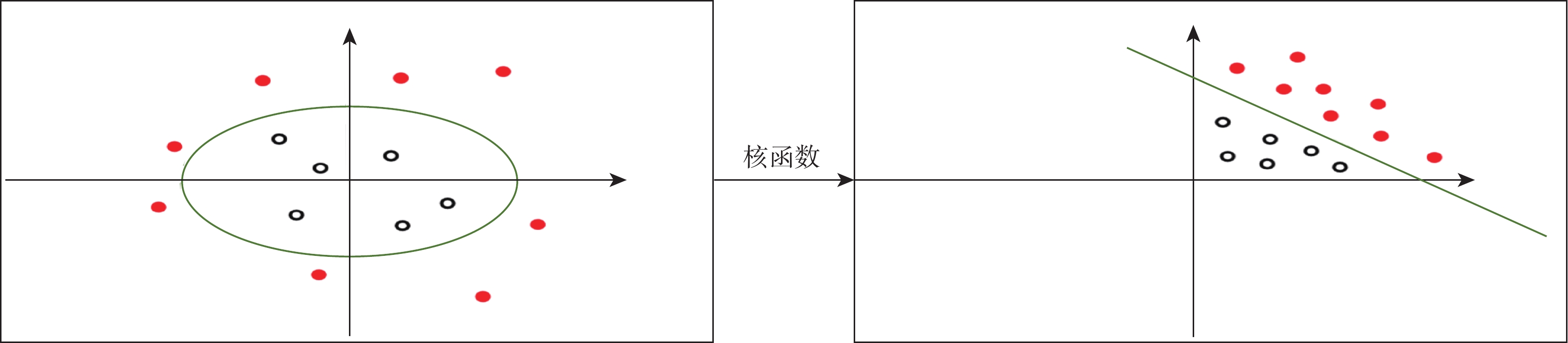

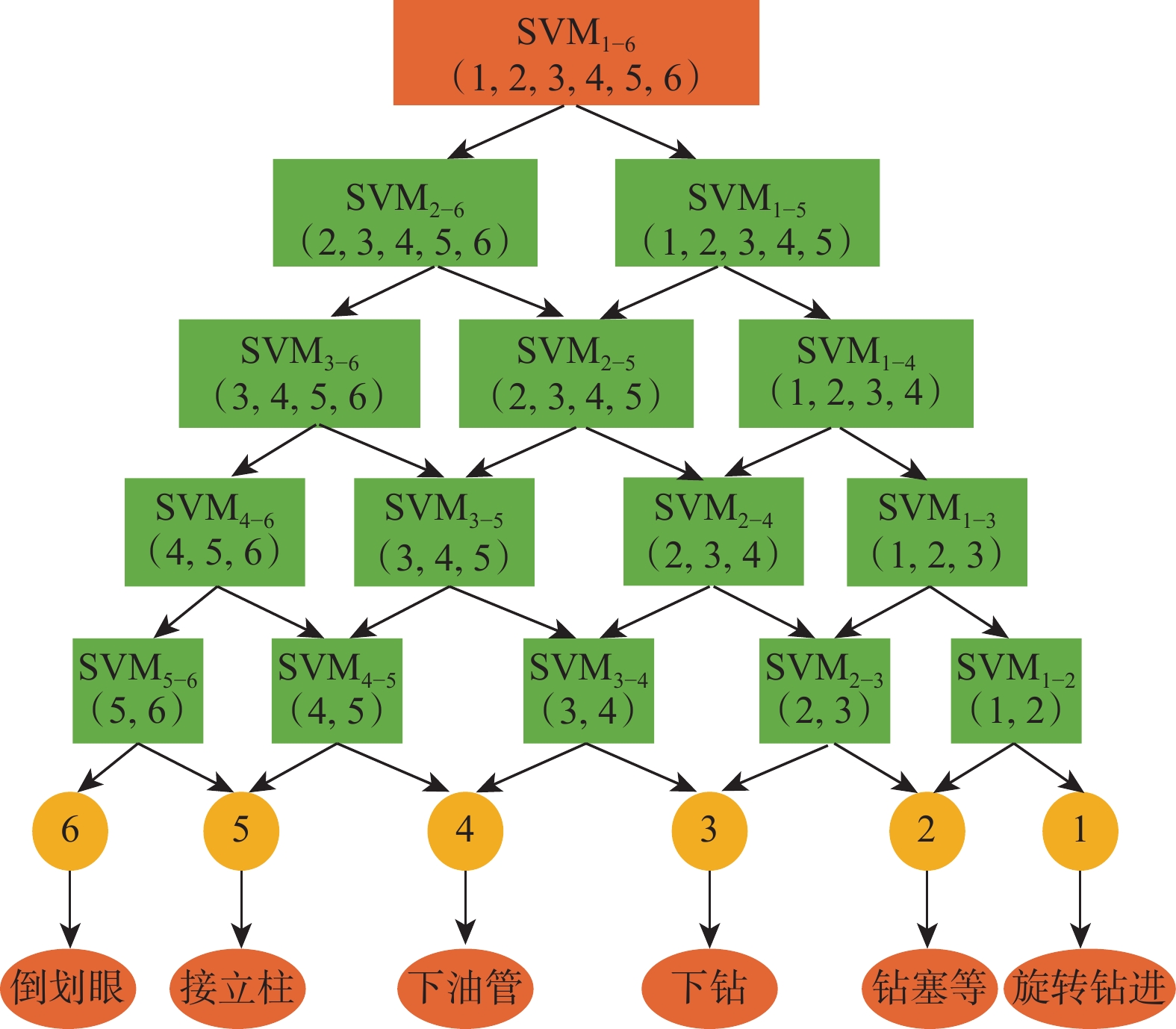

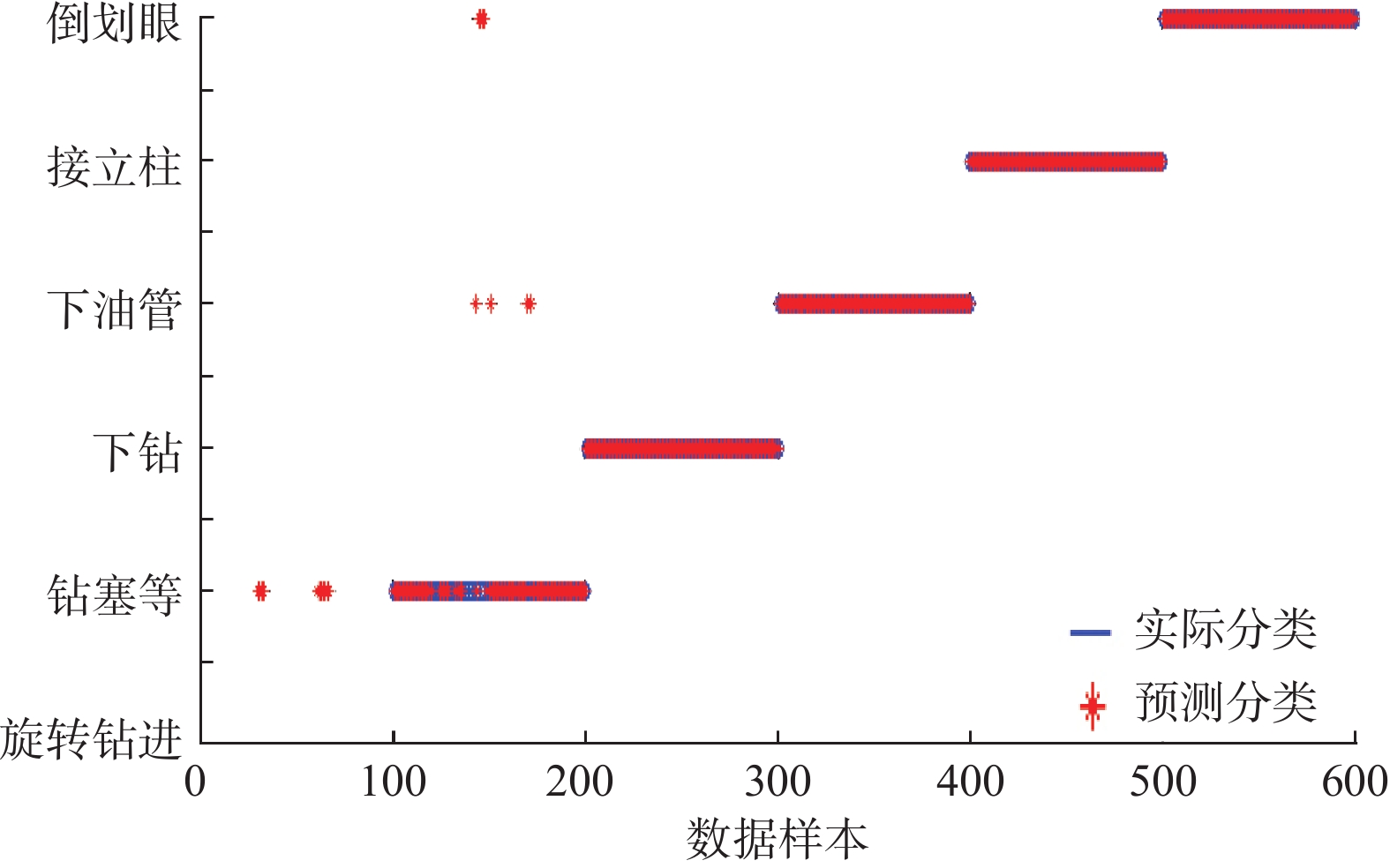

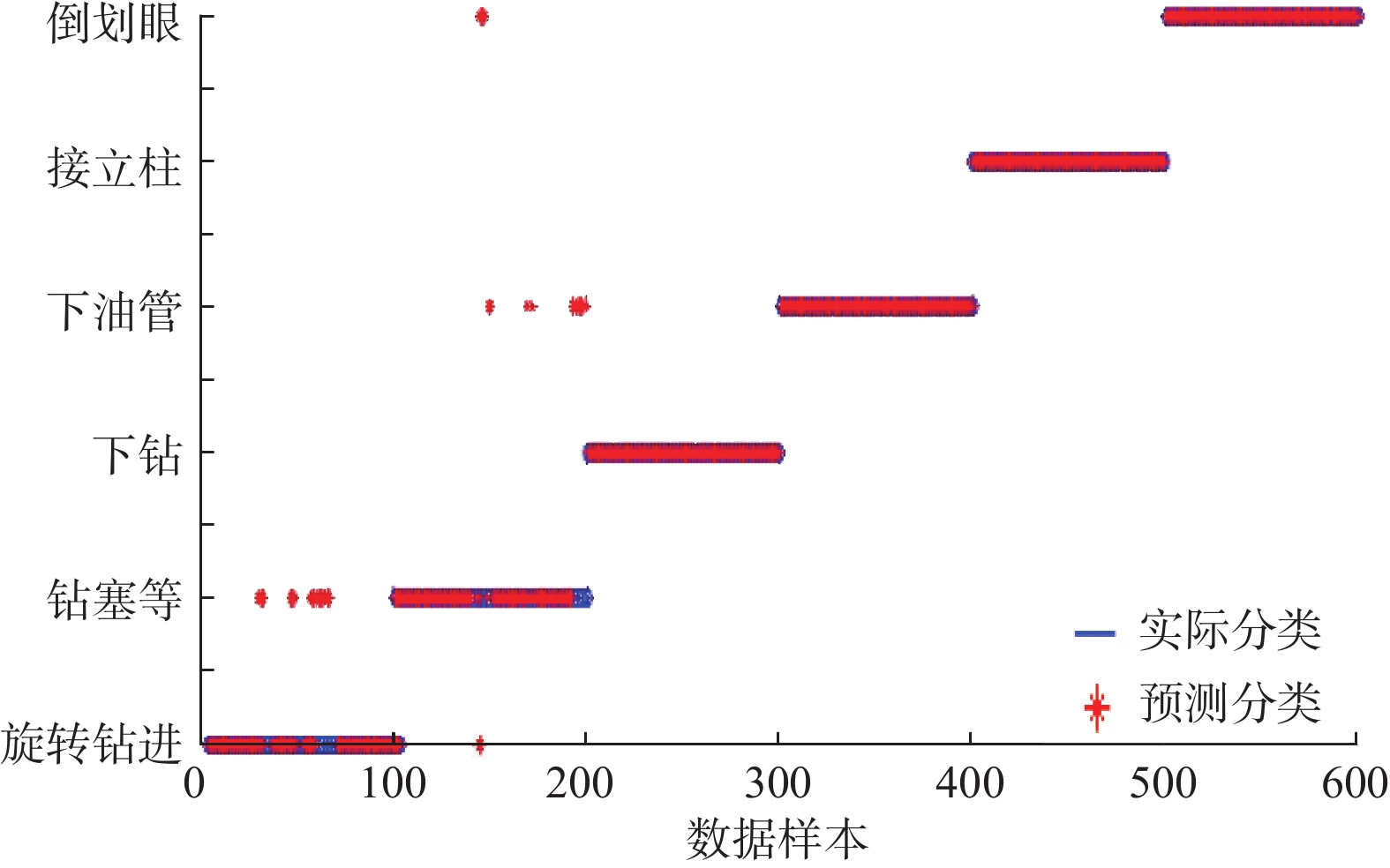

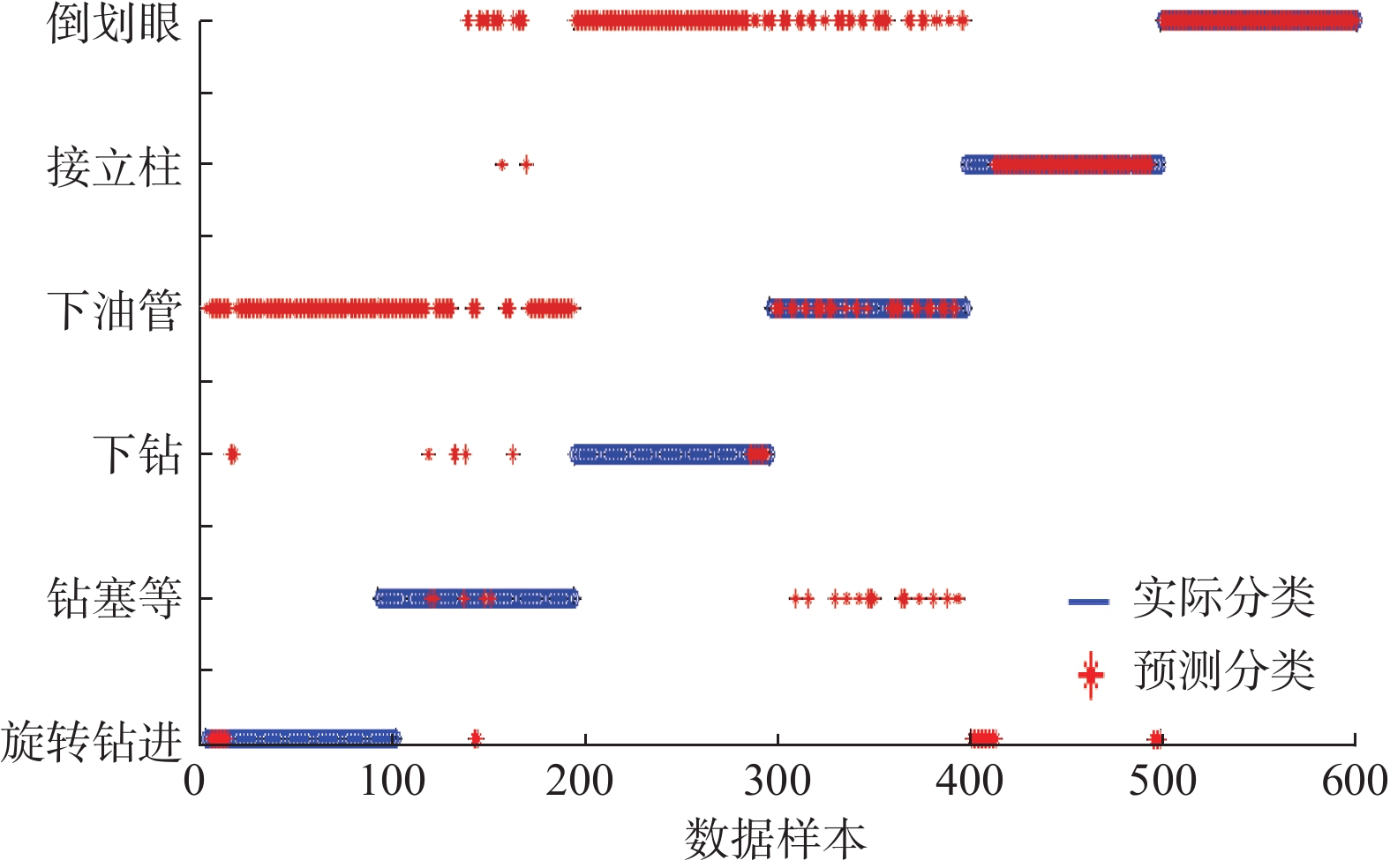

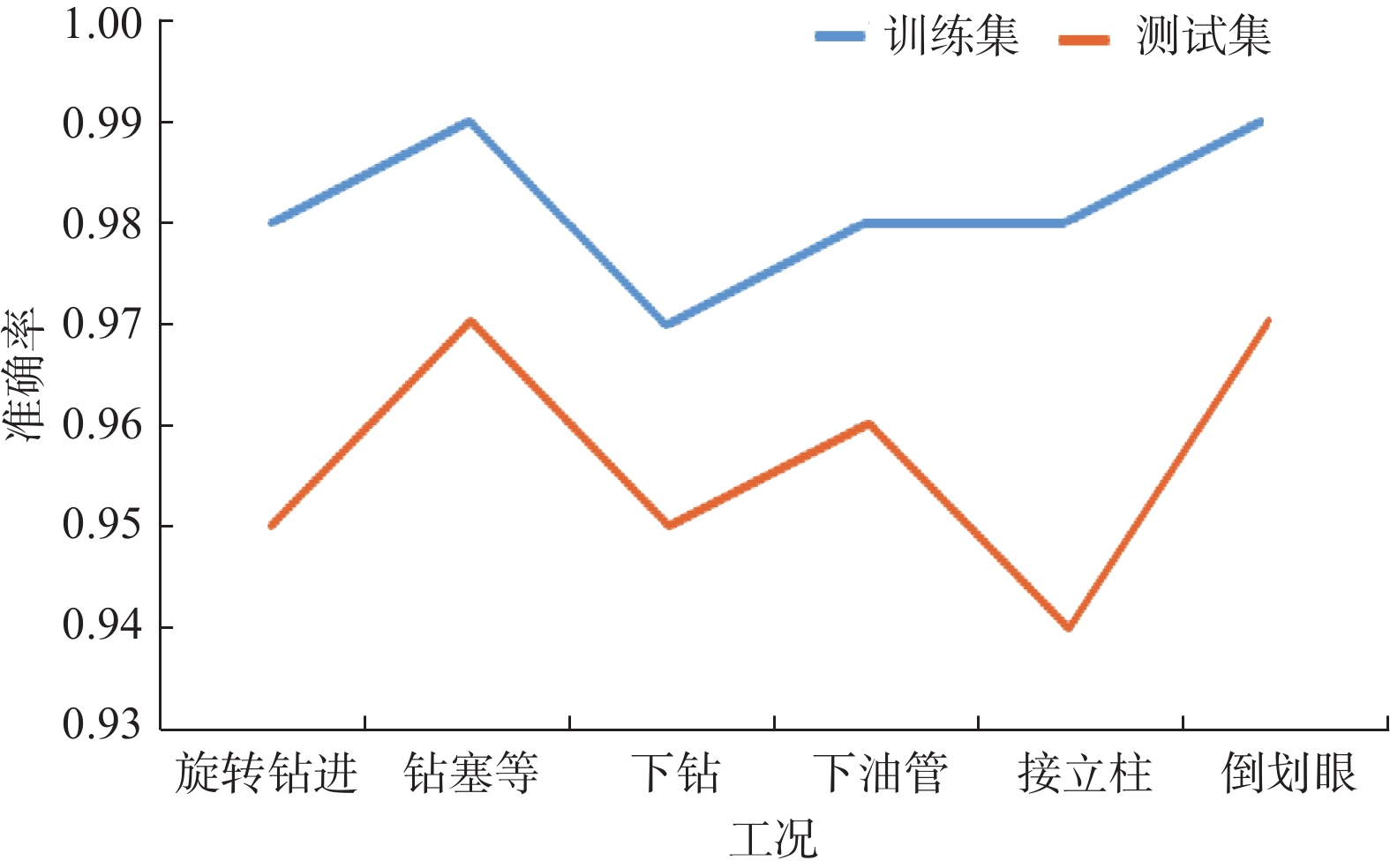

钻井时效分析通常是依靠人工进行事后分析,具有主观性和随意性,不能及时准确地反映真实的现场情况。为了实时准确地对钻井工况进行自动判别,提高钻井效率,提出了一种基于支持向量机(SVM)的用数据驱动的钻井工况实时识别方法,建立了多个智能识别模型,并对其中的核函数进行分析比较,得出了模型参数的最优值。采用4口井的录井数据验证了模型的准确性,识别结果与实际工况基本一致,6种工况的识别正确率均达到95%以上。钻井时效分析与应用表明,钻井过程中应用工况识别结果,减少了不可见非生产时间。支持向量机实现了钻井工况的实时智能识别,提高了钻井时效,符合油田数字化和智能化发展的要求。

Abstract:At present, the analysis of drilling time-efficiency usually relies on manual post-analysis, which is subjective and arbitrary, and not able to reflect the real field situation in time, with a lot of deviation. In order to identify drilling conditions automatically and accurately in real time and improve drilling efficiency, a data-driven real-time identification method of drilling conditions based on support vector machine (SVM) has been put forward, and established several intelligent identification models. By analyzing and comparing the kernel functions in the models, the optimal model parameters were obtained. Logging data from four wells were used to verify the correctness of the model, and the recognition results were basically consistent with the actual working conditions, and the recognition accuracy under six working conditions was higher than 95%. The analysis of drilling time-efficiency showed that the application of working condition identification result in drilling process shortened the invisible non-production time. Support vector machine has realized real-time intelligent identification of drilling conditions, and improved drilling time-efficiency, which could meet the requirements of digital and intelligent development of oilfields.

-

-

表 1 不同核函数计算结果对比

Table 1 Comparisons of calculation results with different kernel functions

核函数 样本

数量准确识别

数量准确

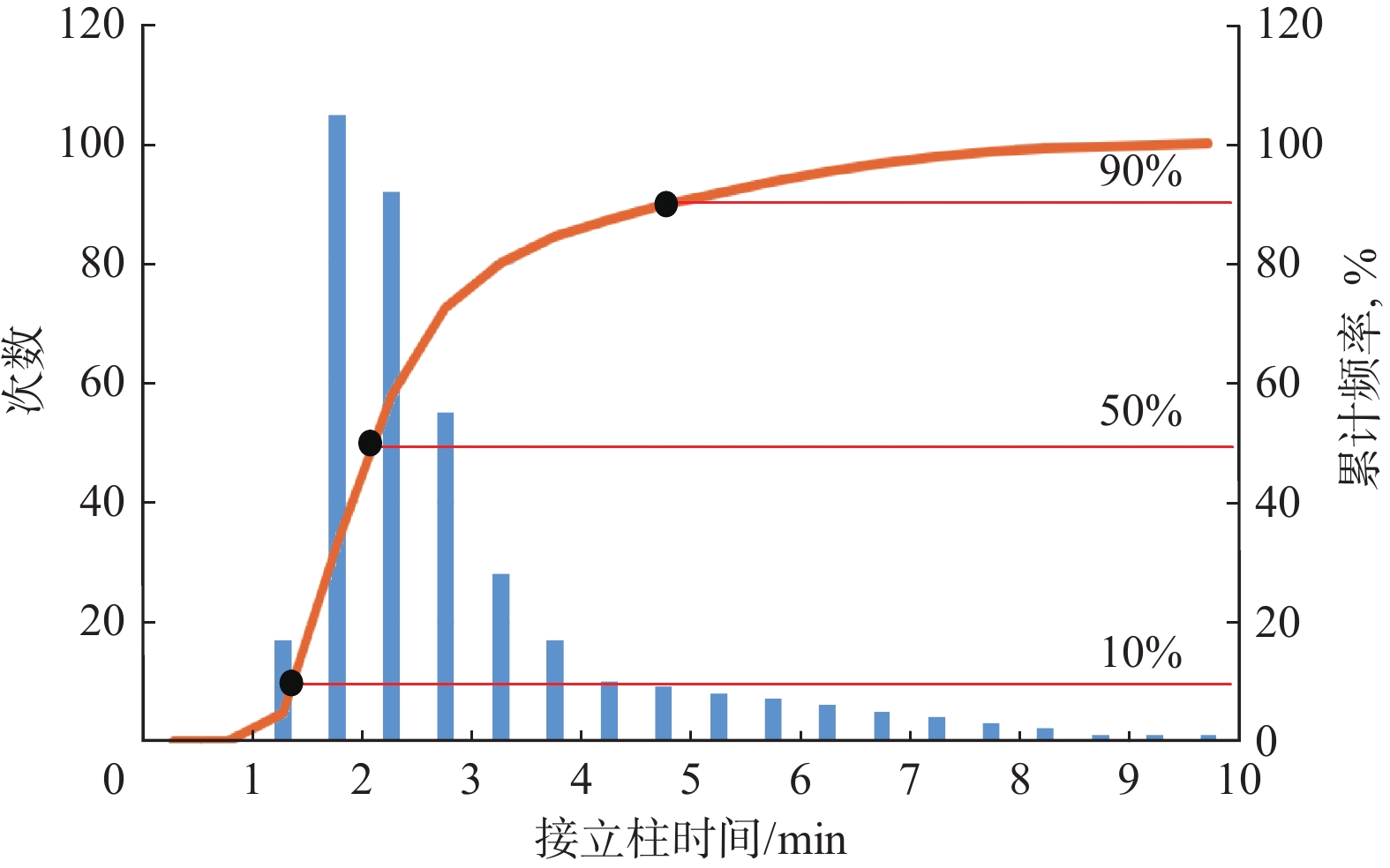

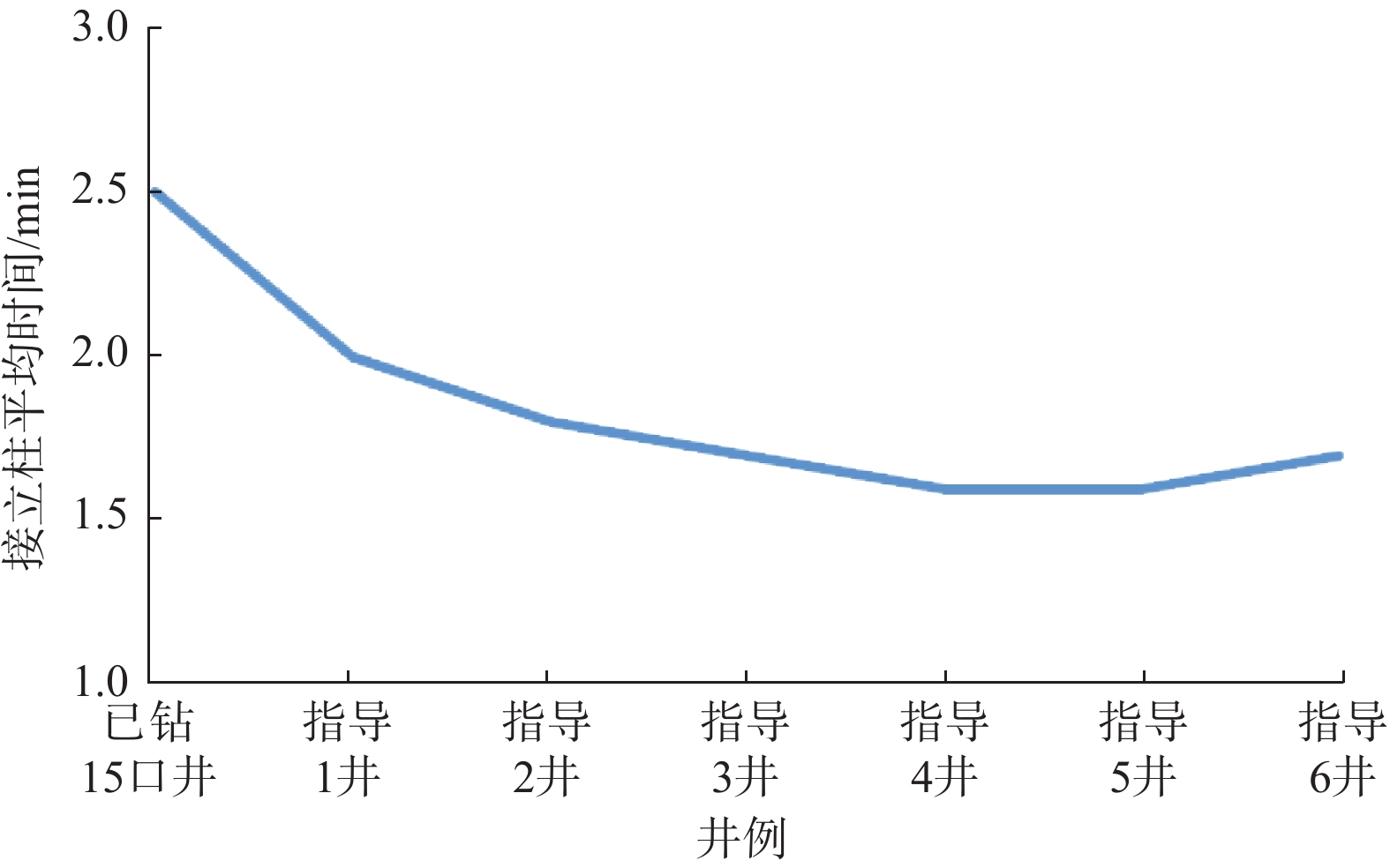

率,%计算用时/s 线性核函数 600 568 94.67 0.511 966 多项式核函数 600 564 94.00 0.670 709 径向基核函数 600 581 96.83 0.581 977 两层感知器核函数 600 242 40.33 2.917 935 表 2 不同层位接立柱时间统计

Table 2 Time statistics for making up a stand of drill pip

立柱序号 前期平均接

立柱时间/minSVM实时判断新井接

立柱时间/min现场决策 1—12 2.5 2.7 有待提高 13—24 2.6 有待提高 25—36 2.4 有所提高 37至最后 2.2 显著提高 -

[1] ALSALAMA A M, CANLAS J P, GHARBI S H. An integrated system for drilling real time data analytics[R]. SPE 181001, 2016.

[2] BALAJI K, RABIEI M, SUICMEZ V, et al. Status of data-driven methods and their applications in oil and gas industry[R]. SPE 190812, 2018.

[3] 刘刚.钻井复杂自适应智能预警模型及应用研究[D].西安: 西安石油大学, 2018. LIU Gang. Drilling complex adaptive intelligent early warning model[D]. Xi'an: Xi'an Shiyou University, 2018.

[4] 袁野.井眼轨迹预测及井眼轨迹三维可视化研究[D].大庆: 东北石油大学, 2017. YUAN Ye. Well trajectory prediction and 3D visualization study of well trajectory[D]. Daqing: Northeastern University of Petroleum, 2017.

[5] 孙万海.基于SVM和PSO的钻井事故智能预警系统研究[D].西安: 西安石油大学, 2014. SUN Wanhai. An intelligent early warning system for drilling accidents based on SVM and PSO[D]. Xi'an: Xi'an Shiyou University, 2014.

[6] 王江萍,孟祥芹,鲍泽富. 应用神经网络技术诊断钻井事故[J]. 西安石油大学学报(自然科学版), 2008, 23(2): 99–102. doi: 10.3969/j.issn.1673-064X.2008.02.024 WANG Jiangping, MENG Xiangqin, BAO Zefu. Diagnosis of drilling faults using neural network technology[J]. Xi'an University of Petroleum(Natural Science Edition), 2008, 23(2): 99–102. doi: 10.3969/j.issn.1673-064X.2008.02.024

[7] YIN Qishuai, YANG Jin, ZHOU Bo, et al. Improve the drilling operations efficiency by the big data mining of real-time logging[R]. SPE 189330, 2018.

[8] 王小川.MATLAB神经网络43个案例分析[M].北京: 北京航空航天大学出版社, 2013: 102-108. WANG Xiaochuan. 43 case analysis of MATLAB neural net-work[M]. Beijing: Beihang University Press, 2013:102-108.

[9] 狄勤丰,吴志浩,王文昌,等. 基于SVM的套管最大von Mises应力预测方法[J]. 石油钻探技术, 2019, 47(3): 62–67. DI Qinfeng, WU Zhihao, WANG Wenchang, et al. An prediction method for determining the maximum von Mises stress in casing based on SVM[J]. Petroleum Drilling Techniques, 2019, 47(3): 62–67.

[10] 彭成勇,吕欣润,马新仿,等. 海上低渗气田综合多因素压裂选井选层方法[J]. 断块油气田, 2015, 22(4): 508–513. PENG Chengyong, LYU Xinrun, MA Xinfang, et al. Fractured well and layer selection by multi-factor optimization for low permeability offshore gas field[J]. Fault-Block Oil & Gas Field, 2015, 22(4): 508–513.

[11] 徐生江,李杰,吴继伟,等. 基于支持向量机的钻井液高温高压静态密度预测模型[J]. 钻井液与完井液, 2014, 31(3): 28–31. XU Shengjiang, LI Jie, WU Jiwei, et al. HTHP static mud density prediction model based on support vector machine[J]. Drilling Fluid & Completion Fluid, 2014, 31(3): 28–31.

[12] 陈冲,张仕民,彭鹤,等. 基于支持向量机的钻柱黏滑振动等级评估方法[J]. 石油机械, 2019, 47(1): 20–26. CHEN Chong, ZHANG Shimin, PENG He, et al. Research on stick-slip vibration level estimation of drillstring based on SVM[J]. China Petroleum Machinery, 2019, 47(1): 20–26.

[13] 王杰祥,陈征,靖伟,等. 基于支持向量机的二氧化碳非混相驱效果预测[J]. 石油钻探技术, 2015, 43(2): 84–89. WANG Jiexiang, CHEN Zheng, JING Wei, et al. Prediction of the effect CO2 immiscible flooding based on support vector machine[J]. Petroleum Drilling Techniques, 2015, 43(2): 84–89.

[14] 陈民锋,白晓虎,郑伟,等. 基于支持向量机的早期聚合物驱动态预测研究[J]. 断块油气田, 2012, 19(2): 199–202. CHEN Minfeng, BAI Xiaohu, ZHENG Wei, et al. Development index prediction of early polymer flooding based on support vector machine[J]. Fault-Block Oil & Gas Field, 2012, 19(2): 199–202.

[15] 赵廷峰,赵春艳,何帆,等. 抽油杆柱磨损分析与安全性评价[J]. 石油机械, 2017, 45(8): 65–70. ZHAO Tingfeng, ZHAO Chunyan, HE Fan, et al. Wear analysis and safety assessment of sucker rod[J]. China Petroleum Machinery, 2017, 45(8): 65–70.

[16] BOSER B E, GUYON I M, VAPNIK V N. A training algorithm for optimal margin classifiers[C]// Proceedings of the 5th Annual Workshop on Computational Learning Theory (COLT'92). Pittsburgh: ACM Press, 1992: 144-152.

[17] JIN Chi, WANG Liwei. Dimensionality dependent PAC-Bayes margin bound[C]// NIPS′12 Proceedings of the 25th International Conference on Neural Information Processing Systems. Lake Tahoe: Curran Associates Inc, 2012(1): 1034-1042.

-

期刊类型引用(1)

1. 冷光耀. 空气和CO_2辅助蒸汽吞吐室内实验研究. 油田化学. 2018(03): 447-450+479 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: